Self-emulsifying type antifoaming agent and preparation method thereof

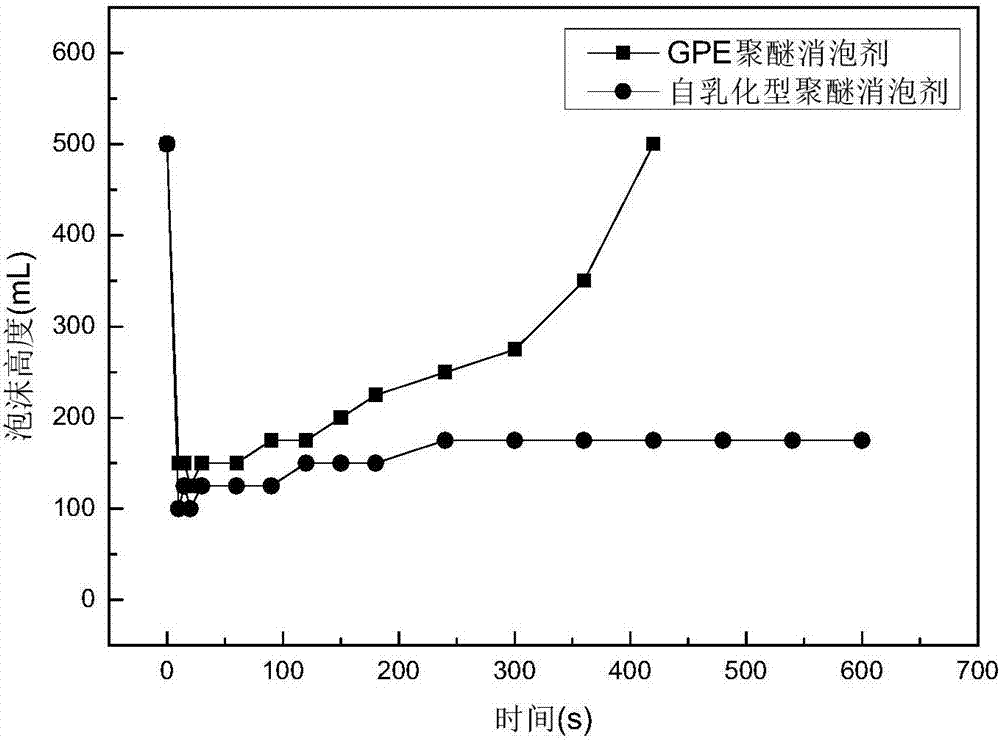

A self-emulsifying, defoaming agent technology, applied in the direction of foam dispersion/prevention, can solve the problems of slow and incomplete defoaming, low foam breaking rate of polyether defoaming agents, etc., achieve good foam suppression effect and promote dispersion The effect of good stability and good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The invention provides a kind of preparation method of self-emulsifying type defoamer, specifically comprises the following steps:

[0031] (1) Add 186g C in a 2.0L pressure reactor 12 Alcohol and 0.42g KOH, replace the air in the reaction kettle with nitrogen, heat up and dehydrate, when the temperature of the kettle rises to 100°C, start feeding 132g of ethylene oxide, keep the polymerization reaction temperature at 100°C, and keep the reaction pressure at 0.1Mpa, until the ethylene oxide is fully matured.

[0032] (2) After the aging reaction of ethylene oxide is complete, lower the temperature, add a small amount of water, phosphoric acid and 1.68g of magnesium silicate, then stir and mix, and filter the mixture after dehydration to obtain C 12 alcohol polyoxyethylene ether.

[0033] (3) Then in C 12 Add 0.2g of DMC catalyst (Zn-Co bimetallic catalyst) to the alcohol polyoxyethylene ether, raise the temperature to 120°C, start feeding 928g of propylene oxide, keep ...

Embodiment 2

[0035] The invention provides a kind of preparation method of self-emulsifying type defoamer, specifically comprises the following steps:

[0036] (1) Add 200g C in a 2.0L pressure reactor 12 ~C 14 Alcohol and 1.58g KOH, replace the air in the reaction kettle with nitrogen, heat up and dehydrate, when the temperature of the kettle rises to 110-120°C, start feeding 220g of ethylene oxide and 1160g of propylene oxide, and keep the polymerization reaction temperature at 130-140°C °C, the reaction pressure is kept at 0.1-0.4Mpa until the ethylene oxide and propylene oxide are fully matured.

[0037] (2) After the aging reaction of ethylene oxide and propylene oxide is complete, cool down, add a small amount of water, phosphoric acid, 2.1g magnesium silicate and 1.5g aluminum silicate, then stir and mix, filter the mixture after dehydration, and obtain C 12 ~C 14 Alcohol polyoxyethylene polyoxypropylene ether.

Embodiment 3

[0039] The invention provides a kind of preparation method of self-emulsifying type defoamer, specifically comprises the following steps:

[0040] (1) Add 200g iso-C to a 2.0L pressure reactor 13 Alcohol and 0.79g KOH, replace the air in the reaction kettle with nitrogen, heat up and dehydrate, when the temperature of the kettle rises to 110-120°C, start feeding 330g of ethylene oxide, keep the polymerization reaction temperature at 120-130°C, and keep the reaction pressure At 0.1 ~ 0.4Mpa, until the ethylene oxide is fully matured.

[0041] (2) After the ethylene oxide aging reaction is complete, lower the temperature, add a small amount of water, phosphoric acid and 2.65g of aluminum silicate, then stir and mix, dehydrate the mixture and filter to obtain iso-C 13 alcohol polyoxyethylene ether.

[0042] (3) Then in iso-C 13 Add 0.75g of DMC catalyst (Zn-Co bimetallic catalyst) to the alcohol polyoxyethylene ether, raise the temperature to 110-120°C, start feeding 1670g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com