Patents

Literature

31results about How to "Self-emulsifying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophilic block polyether amino silicone oil with amino branched chain, and preparation method and application thereof

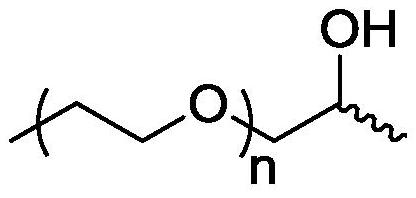

The invention discloses hydrophilic block polyether amino silicone oil with an amino branched chain and a preparation method thereof. The hydrophilic block polyether amino silicone oil with the amino branched chain has the following structure as shown in the specification, wherein R1 is represented by formulas shown in the specification. The preparation method comprises the following steps: carrying out mixing reaction of tetramethyl dihydro disiloxane, polysiloxane and concentrated sulfuric acid, neutralizing with anhydrous sodium carbonate, carrying out reduced pressure pumping to remove a low-boiling-point substance, and thus obtaining silicone oil with the end containing hydrogen; carrying out mixing reaction of the silicone oil with the end containing hydrogen, allyl epoxy polyether and a catalyst, and thus obtaining epoxy silicone oil; carrying out mixing reaction of the epoxy silicone oil, polyether amine and a solvent, and thus obtaining block polyether amino silicone oil; and carrying out mixing reaction of the block polyether amino silicone oil, a silane coupling agent hydrolysate and an alkali catalyst, neutralizing with glacial acetic acid, and thus obtaining the hydrophilic polyether amino silicone oil with the amino branched chain.

Owner:江阴市诺科科技有限公司

UV-curable elastic polyurethane acrylate emulsion and synthesis method thereof

InactiveCN104558499ASelf-emulsifyingGood flexibilityInksPolyurea/polyurethane coatingsPolyesterEndcapping

The invention discloses UV-curable elastic polyurethane acrylate emulsion and a synthesis method thereof. The synthesis method of the UV-curable elastic polyurethane acrylate emulsion comprises the following steps: carrying out reaction on polyester glycol or polyether glycol, carboxylic acid-containing glycol and diisocyanate to generate a prepolymer, adding an optimized micromolecular chain extender for carrying out chain extension, then adding hydroxy-containing acrylate for carrying out blocking reaction, diluting by virtue of an organic solvent, neutralizing and salifying by adopting organic amine, finally adding deionized water for carrying out hydration, and adding a photoinitiator to obtain the UV-curable elastic polyurethane acrylate emulsion. The UV-curable elastic polyurethane acrylate emulsion is polyurethane blocked by acrylate, and a molecular chain of the UV-curable elastic polyurethane acrylate emulsion is provided with hydrophilic negative ions and double bonds, so that the UV-curable elastic polyurethane acrylate emulsion has self-emulsifying property and photocuring activity; and a cured film formed by carrying out photocuring on the synthesized elastic polyurethane acrylate emulsion has excellent mechanical properties, tensile strength is 21MPa, and elongation is 350%, so that the elastic polyurethane acrylate emulsion can serve as matrix resin of water-based ink and waterborne UV-curable elastic paint.

Owner:HUNAN SUIFENG NEW MATERIAL & TECH DEV

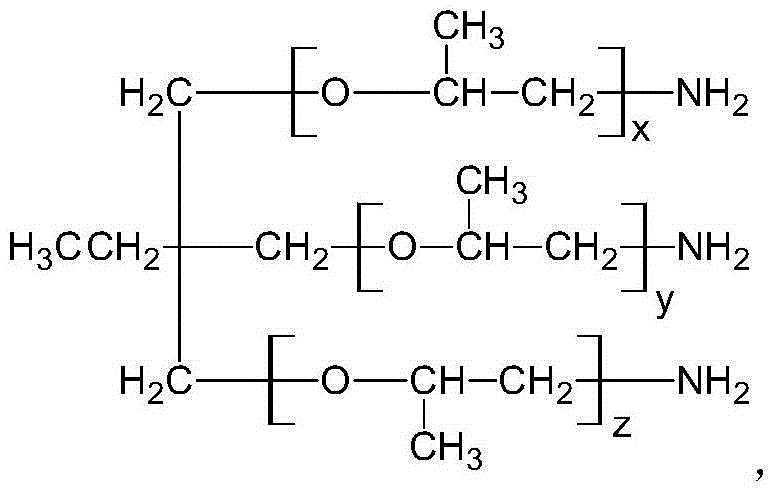

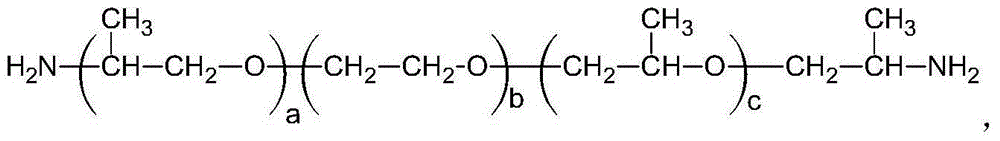

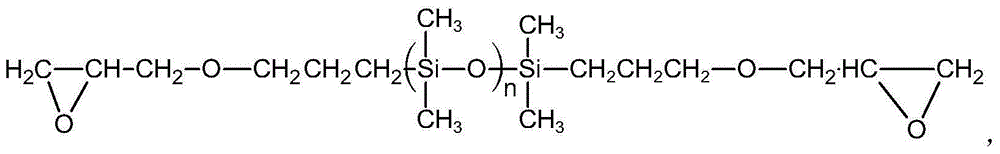

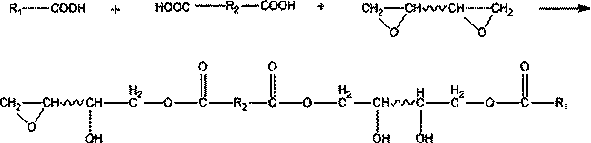

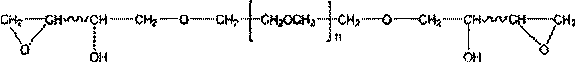

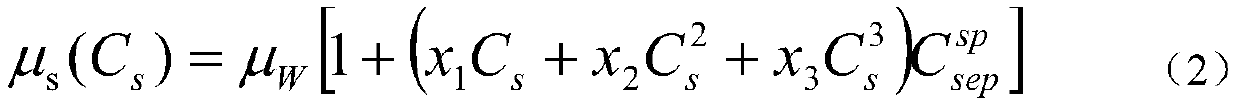

Block polyether elasticity organosilicone softener and preparation method and application thereof

The invention relates to a block polyether elasticity organosilicone softener and a preparation method and an application thereof. Fabric treated by adopting an existing organosilicone softener in a physical conformation has good softness and smoothness and excellent elasticity, but the softener requires addition of a lot of emulsifier for emulsification; and the product stability is poor, and therefore, the softener is not beneficial to wide application. The novel organosilicone softener with a net structure is prepared by epoxide addition reaction of three compounds in a general formula A, a general formula B and a general formula C; the structure of the softener is changed into (An1Bn2Cn3)p; n1 is 1-3; n2 is 1-3; n3 is 1-3; and p is 1-10. According to the block polyether elasticity organosilicone softener provided by the invention, the fabric can be endowed with comprehensive feel of softness, smoothness, fluffiness and elasticity; and particularly, the block polyether elasticity organosilicone softener has an excellent elastic handle style, and has the characteristics of self-emulsification and excellent chemical stability of acid resistance, alkali resistance, salt resistance and the like.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

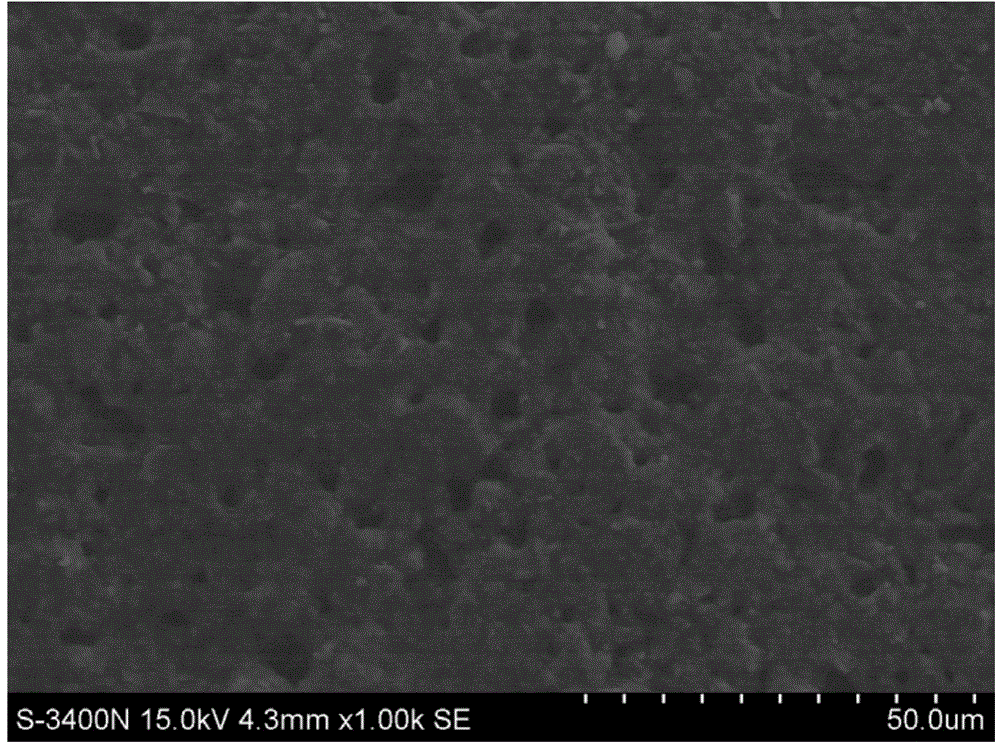

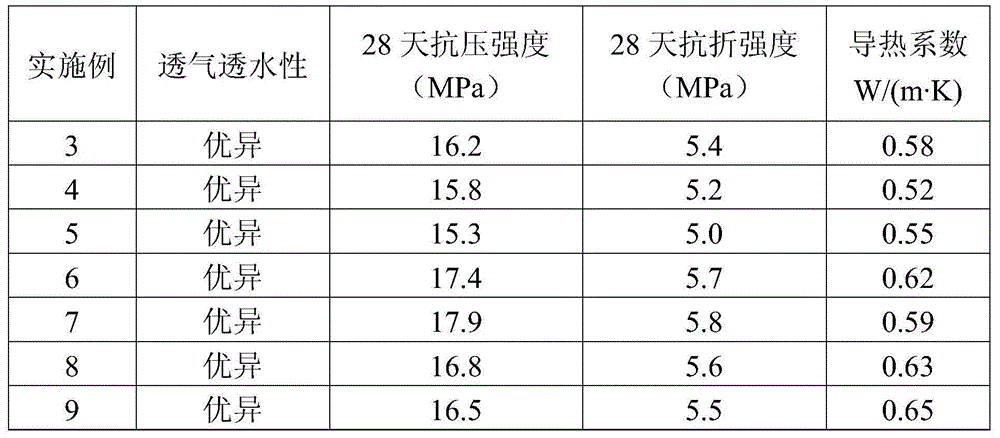

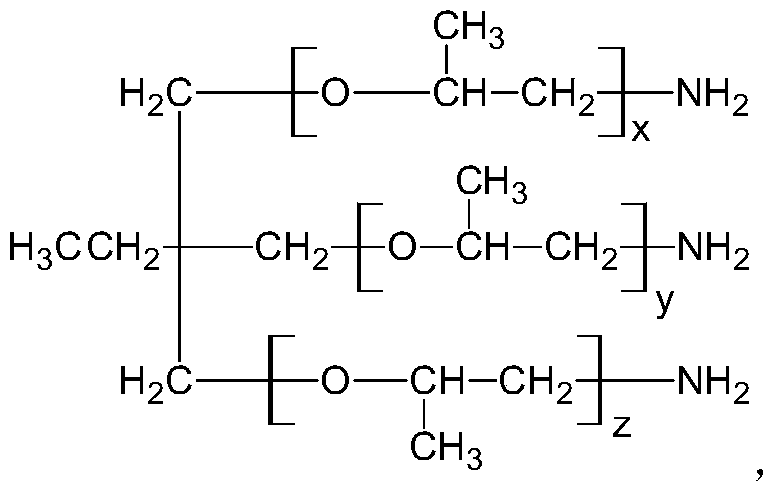

Open-cell type heat-conducting epoxy matrix composite porous material and preparation method and application thereof

The invention discloses an open-cell type heat-conducting epoxy matrix composite porous material and a preparation method and an application of the porous material. The porous material is prepared from 20 to 40wt% of epoxy resin-heat conducting ceramic powder-modified amine pre-mixed solution and 80 to 60wt% of inorganic filler-aqueous suspension; the epoxy resin-heat conducting ceramic powder-modified amine pre-mixed solution is prepared from 100 parts by weight of epoxy resin, 3 to 30 parts by weight of heat conducting ceramic powder and 50 to 100 parts by weight of poly-oxypropylene polyether modified amine curing agent by pre-mixing for 3 to 10 minutes under a temperature of 20 to 35 DEG C. The porous material is of an open-cell structure, remarkable in air and water permeability, and outstanding in toughness and heat conductivity, and has a good application prospect in the ceramics field, the electronic field, the battery diaphragm field, the environmental protection field, the air purifying field, the chemicals field, the building field and other fields.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

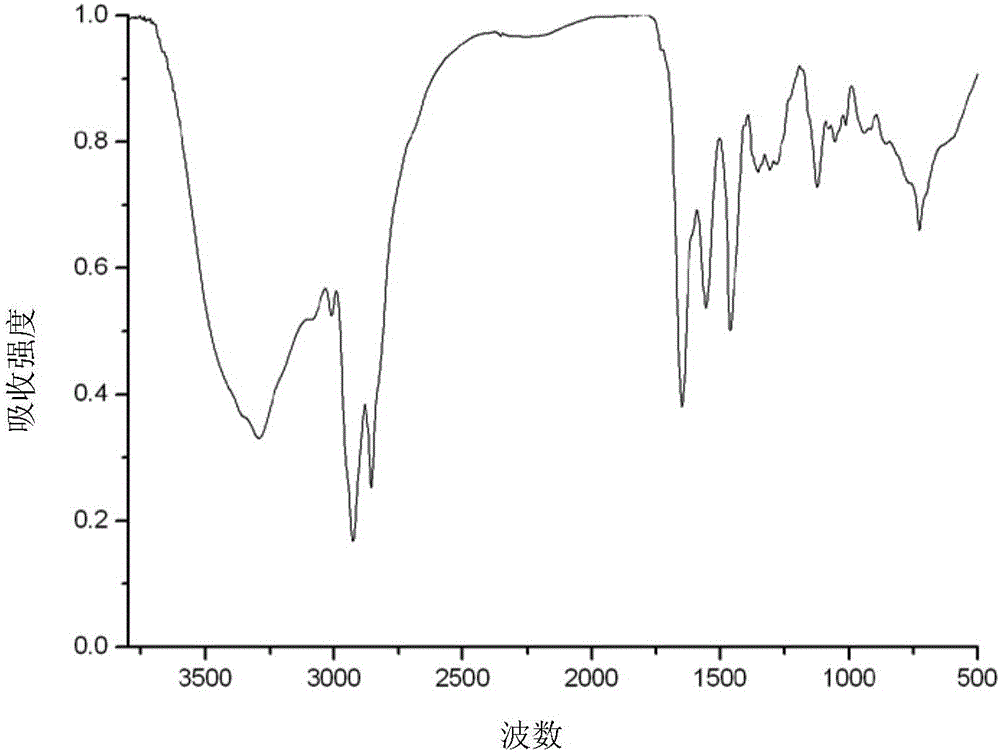

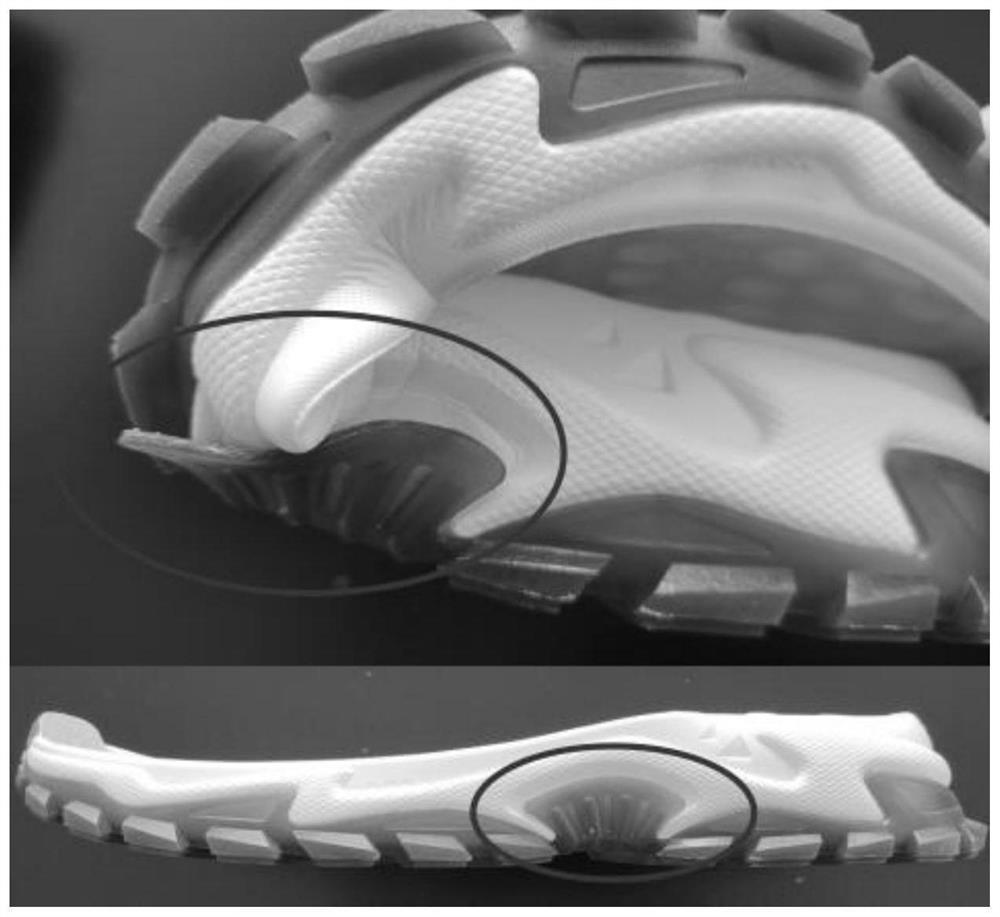

Epoxy resin water-permeable material curing agent and preparation method and application thereof

InactiveCN106046326AExcellent curabilityIncrease water permeability and breathabilityEpoxyRoom temperature

The invention belongs to the technical field of preparation of curing agents, and discloses an epoxy resin water-permeable material curing agent and a preparation method and application thereof. The curing agent is prepared from the following components in percentage by mass: 50-80 percent of ricinoleic acid and / or a polymer thereof, and 20-50 percent of fatty polyamine, alicyclic polyamine or polyoxypropylene polyamine containing a polypropylene oxide chain segment. The curing agent provided by the invention is a waterborne curing agent, has superior curing performance, and can be cured at the room temperature; a cured product has superior water permeability and air permeability, and can be applied to curing of an epoxy water-permeable material to prepare an epoxy ceramic forming mold or an epoxy water-permeable material. A fatty polyamine, polyoxypropylene polyamine or alicyclic polyamine curing agent is modified, so that the curing agent contains hydrophobic long-chain alkyl, hydrophilic hydroxyl, an amino group, acylamino and an ester group, has self-emulsifying performance, and can also be taken as a curing agent; a gap and a channel are formed between the epoxy resin and inorganic filler through a hydrophobic group, so that the obtained epoxy material has superior water permeability and air permeability.

Owner:NANXIONG MATERIAL PRODION BASE OF CHINESE ACADEMY OF SCI GUANGZHOU CHEM +1

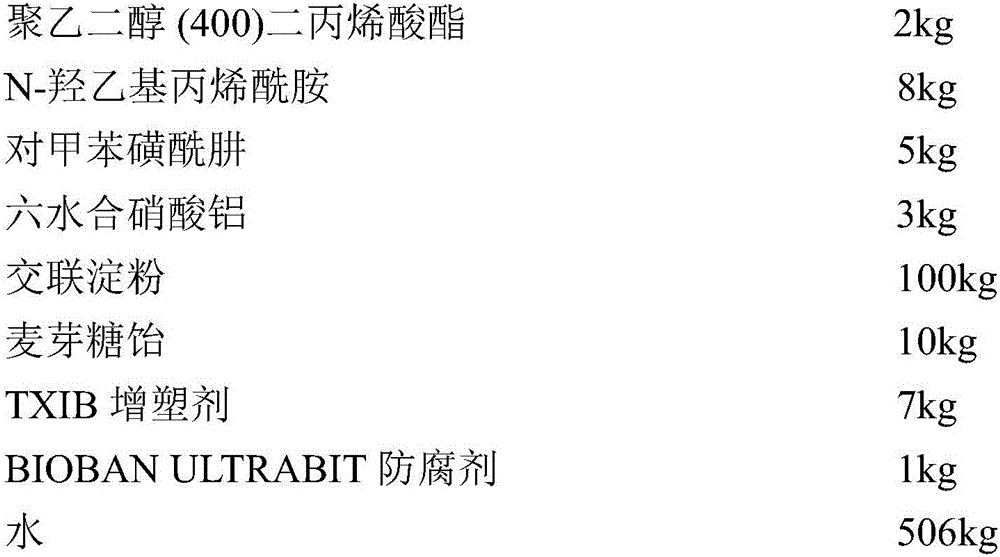

Biodegradable aqueous emulsion-type polylactic acid adhesive and its preparation method

The invention relates to a biodegradable aqueous emulsion-type polylactic acid adhesive and its preparation method. As a water dispersible emulsion, every 100 parts by weight of the adhesive at least contains 5-45 parts by weight of a polyethylene glycol grafted polylactic acid copolymer, 5-40 parts by weight of vinyl acetate grafted starch, and 0.5-30 parts by weight of an ethylene-vinyl acetatecopolymer. The aqueous emulsion-type polylactic acid adhesive provided in the invention is biodegradable, has high bonding fastness, adjustable filter rod hardness as well as good moulding performance, and simultaneously has filter rod adsorption enhancing and harm reduction performances.

Owner:长沙乐远化工科技有限公司

Mineral oil defoaming agent for waterborne coating and preparation method of mineral oil defoaming agent

The invention discloses a mineral oil defoaming agent for a waterborne coating and a preparation method of the mineral oil defoaming agent. The mineral oil de-foaming agent for the waterborne coating comprises the following components in percentage by weight: 5-15 percent of modified organic polyether, 5-25 percent of white oil, 10-25 percent of wax, 15-40 percent of octyl alcohol, 30-55 percent of sulfonated castor oil, 2-10 percent of an emulsifying agent, 0.1-0.2 percent of a catalyst, 0.1-0.3 percent of a sterilizing agent and 0.6-0.8 percent of a dispersing agent. The mineral oil de-foaming agent for the waterborne coating is formed by refining an organic polyether ester, mineral oil and alcohol composite product through a special process. The mineral oil de-foaming agent has the performance such as self-emulsification, easy dispersion, strong universality, good de-foaming, and lasting foam inhibition; the surface defect cannot be generated or the film-forming property cannot be affected; the mineral oil de-foaming agent has a special effect on the waterborne coating.

Owner:广东中联邦精细化工有限公司

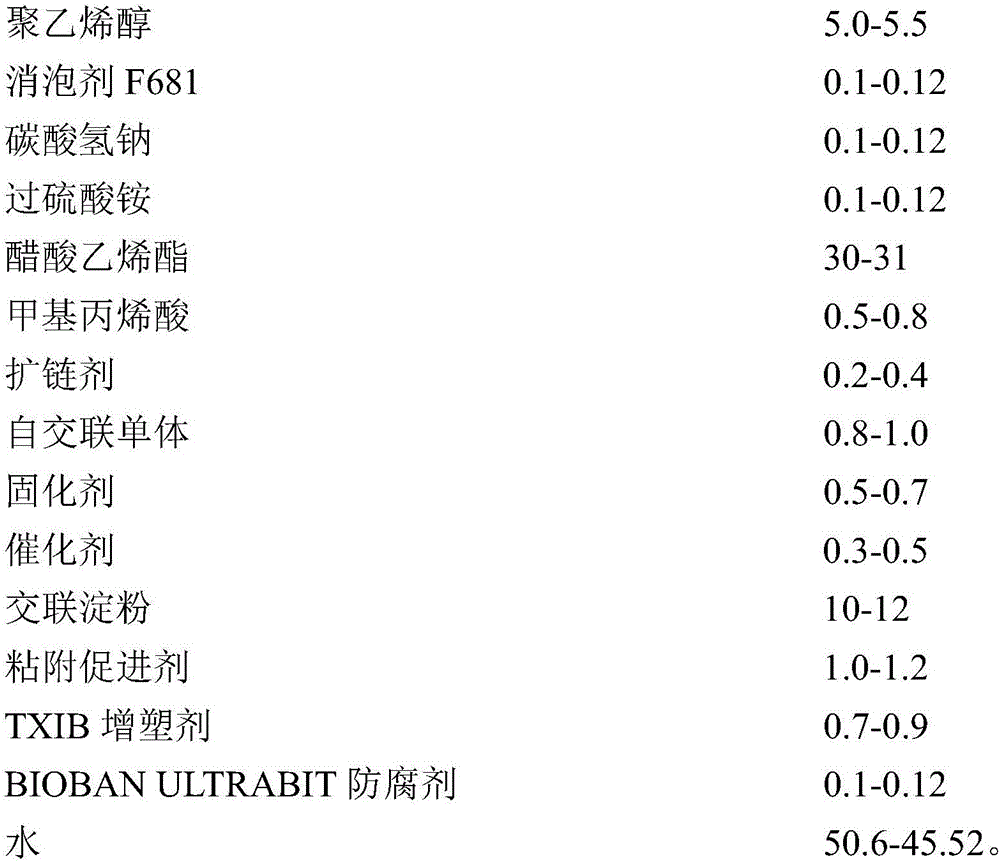

Seam cracking prevention hot pressing wooden veneering adhesive and preparation method thereof

InactiveCN106065301ASelf-emulsifyingReduce usageMacromolecular adhesive additivesGraft polymer adhesivesSodium bicarbonateCross-link

The invention discloses a seam cracking prevention hot pressing wooden veneering adhesive and a preparation method thereof. The adhesive mainly comprises water, polyvinyl alcohol, an antifoaming agent F681, sodium bicarbonate, ammonium persulfate, vinyl acetate, methacrylic acid, a chain extender, self-crosslinking monomers, a curing agent, a catalyst, cross-linked starch, an adherence promoter, a TXIB plasticizer and an BIOBAN ULTRABIT antiseptic. The chain extender is used in the preparation process to increase the molecular weight of latex particles and reduce influences of chain transfer of system chain free radicals to an initiator and a reaction system on the molecular weight, and hydrazide, maltose and other assistants are added to a copolymerization emulsion and are mixed to prepare the hot pressing wooden veneering adhesive, so the cracking problem of common hot pressing wooden veneering adhesives in wooden seams is solved, and the product quality is improved.

Owner:TAIZHOU UNIV +1

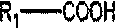

Preparation method of binary acid chain extension modified epoxy resin

The invention relates to the field of high molecular materials, and specifically relates to a preparation method of binary acid chain extension modified epoxy resin. The preparation method comprises the following steps: adding epoxy resin and dihydric alcohol into a reactor, enabling the molar ratio of epoxy resin to poly dihydric alcohol to be (2: 1) to (10: 1), heating and stirring, so that themixture is dispersed uniformly, using a hydrochloric acid-acetone method to measure an initial epoxy number, then adding a catalyst, raising the temperature until 110 to 175 DEG C, reacting for 2 to 3h, using the hydrochloric acid-acetone method to measure an epoxy number remaining after the reaction to reach an expected epoxy number, then adding mixed acid compounded with monobasic acid and binary acid into the product, raising the temperature, stirring and mixing uniformly, enabling the molar ratio of monobasic acid to binary acid is (1: 1) to (1: 5), then adding an accelerant, reacting for3 to 5 h at the temperature of 110 to 150 DEG C, and finally obtaining the product being binary acid chain extension modified epoxy resin. The preparation method solves the problem that an existing carbon fiber sizing agent is complex in emulsification technology, unstable in emulsion storage, low in strand bundling after sizing, hardened in strands, low in adhesiveness with matrix resin and thelike.

Owner:WEIHAI TUOZHAN FIBER

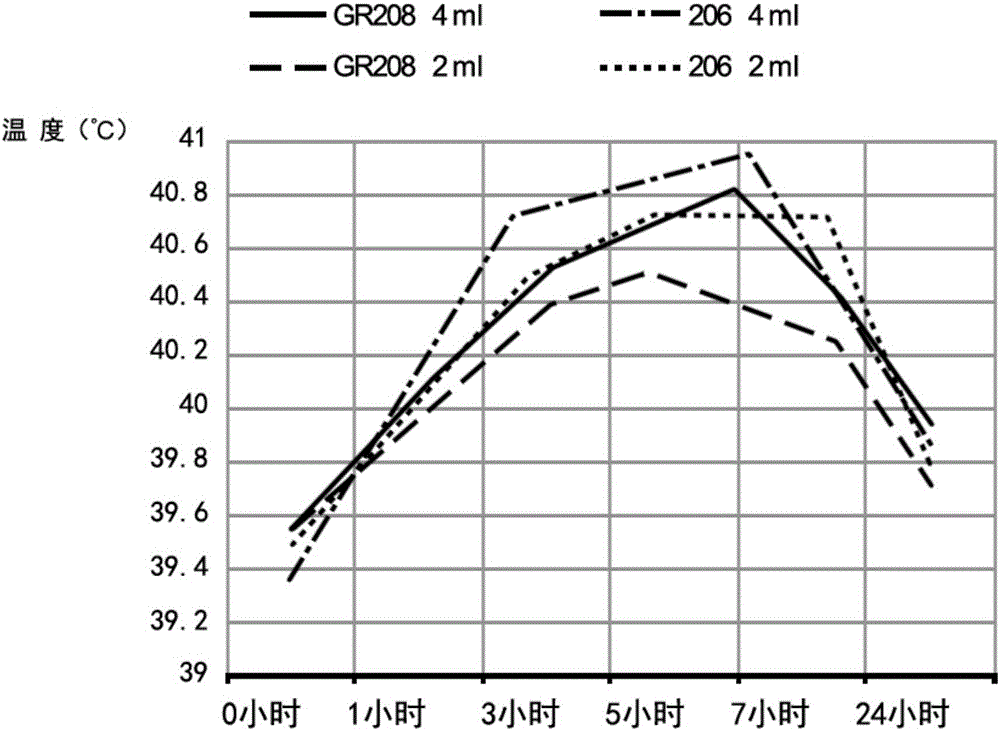

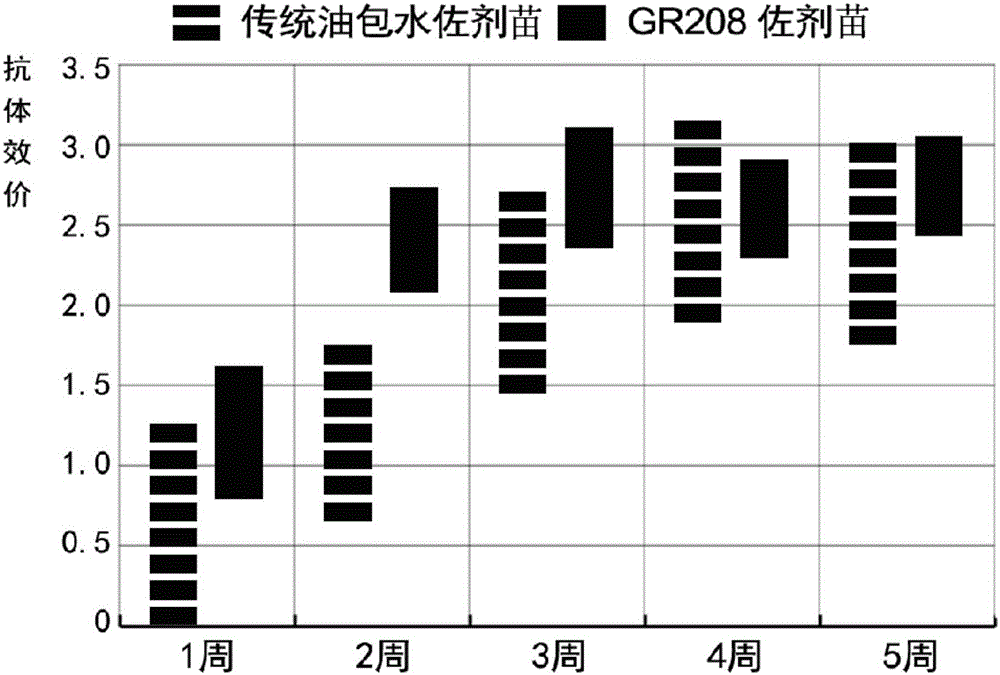

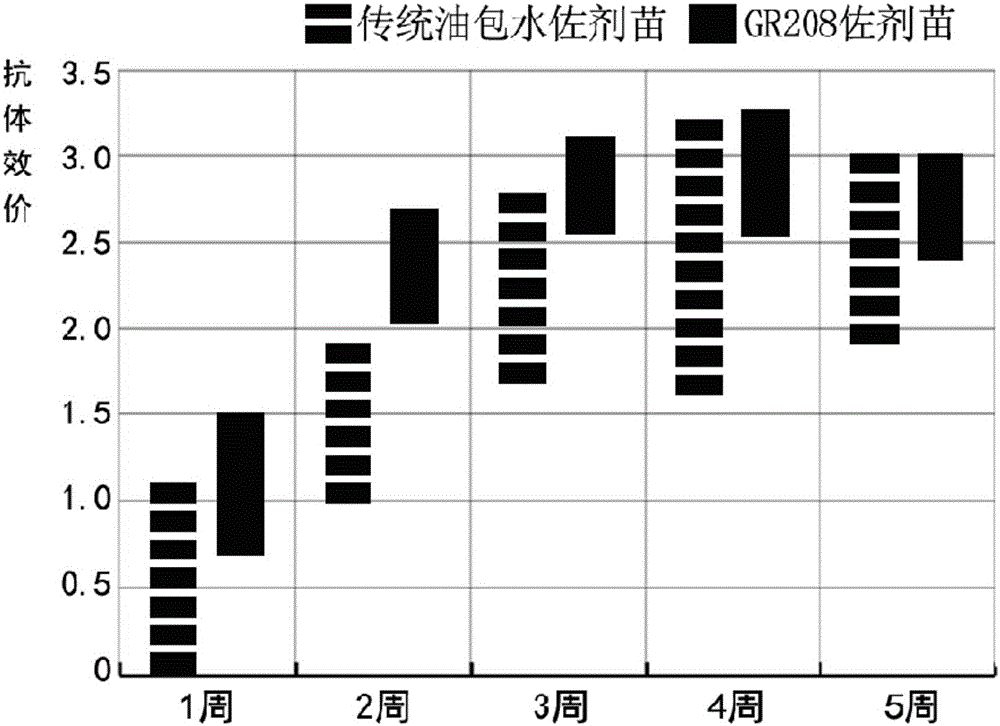

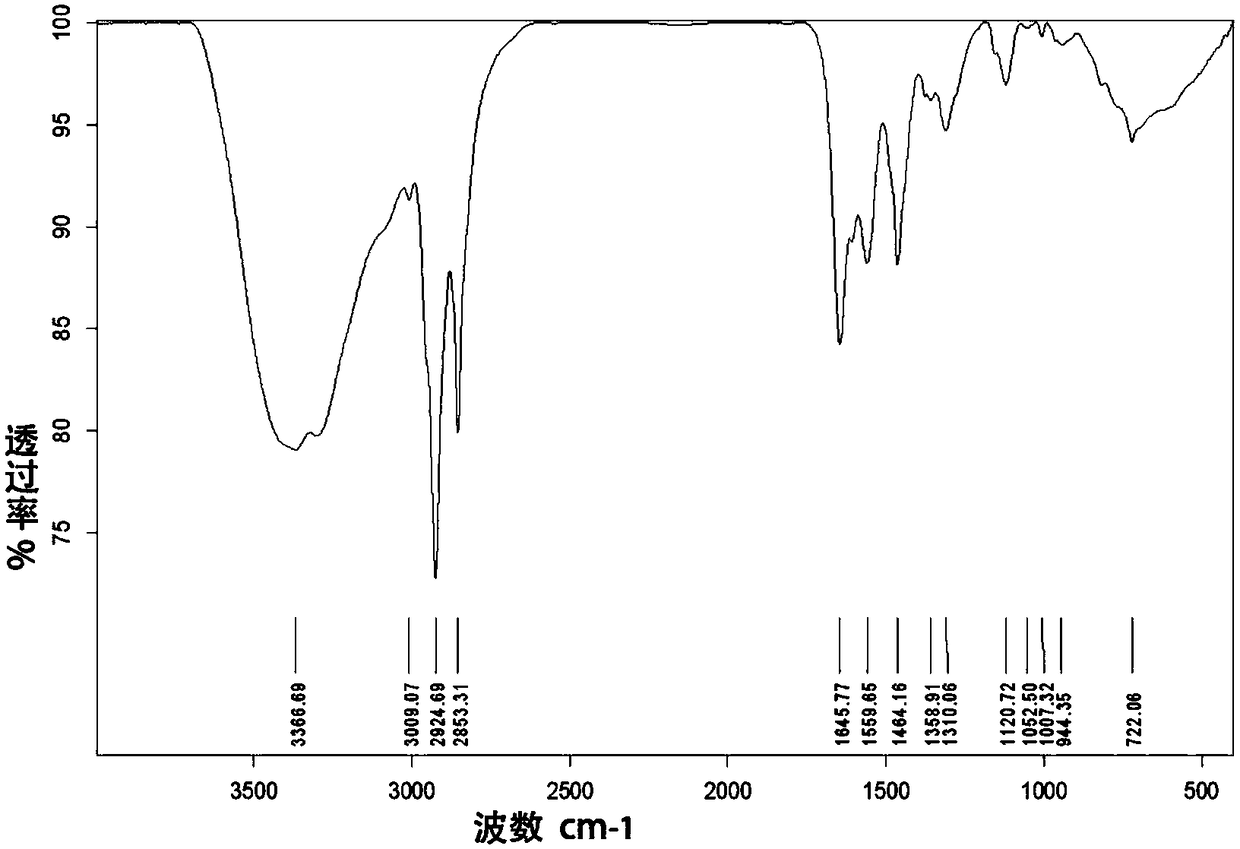

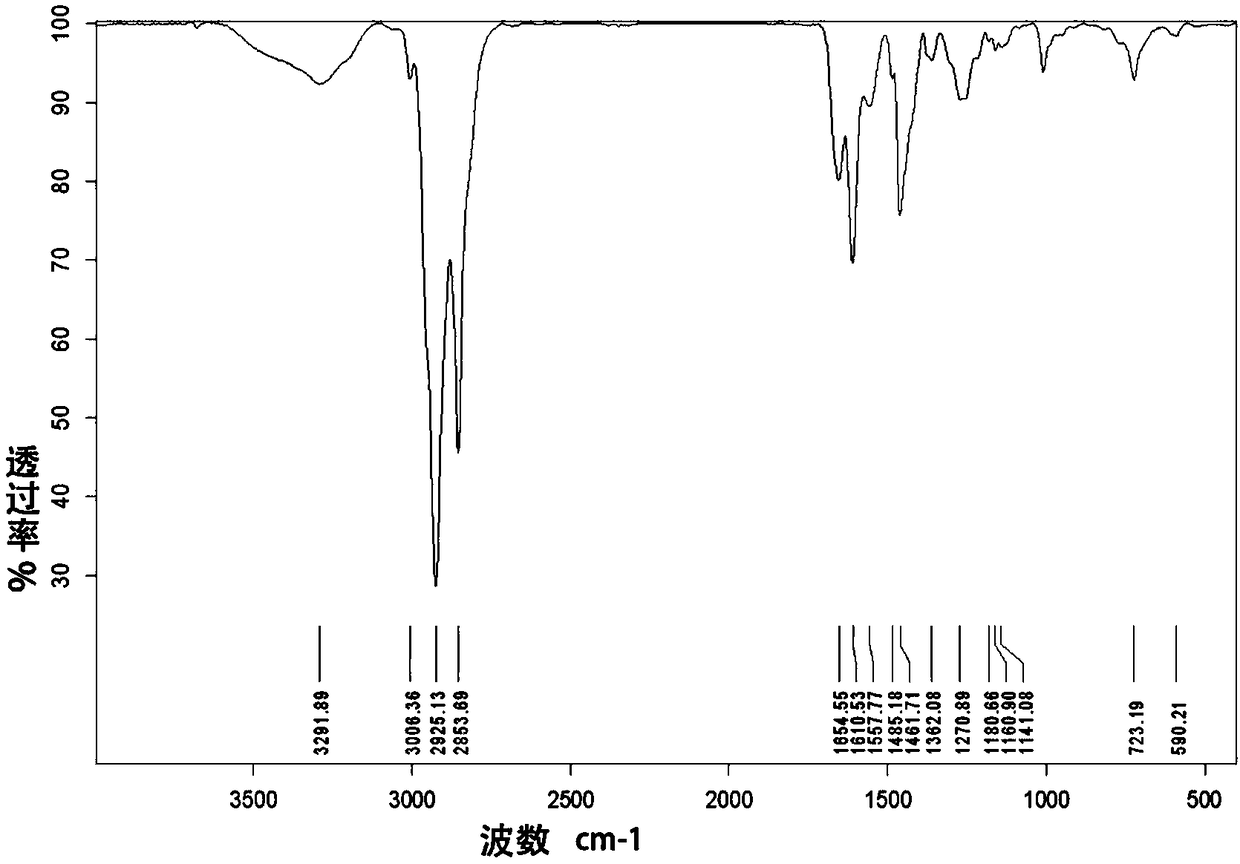

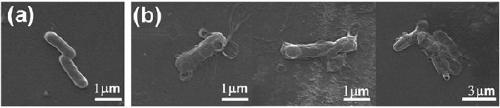

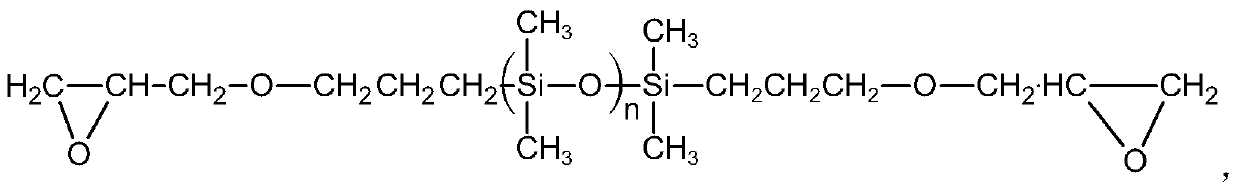

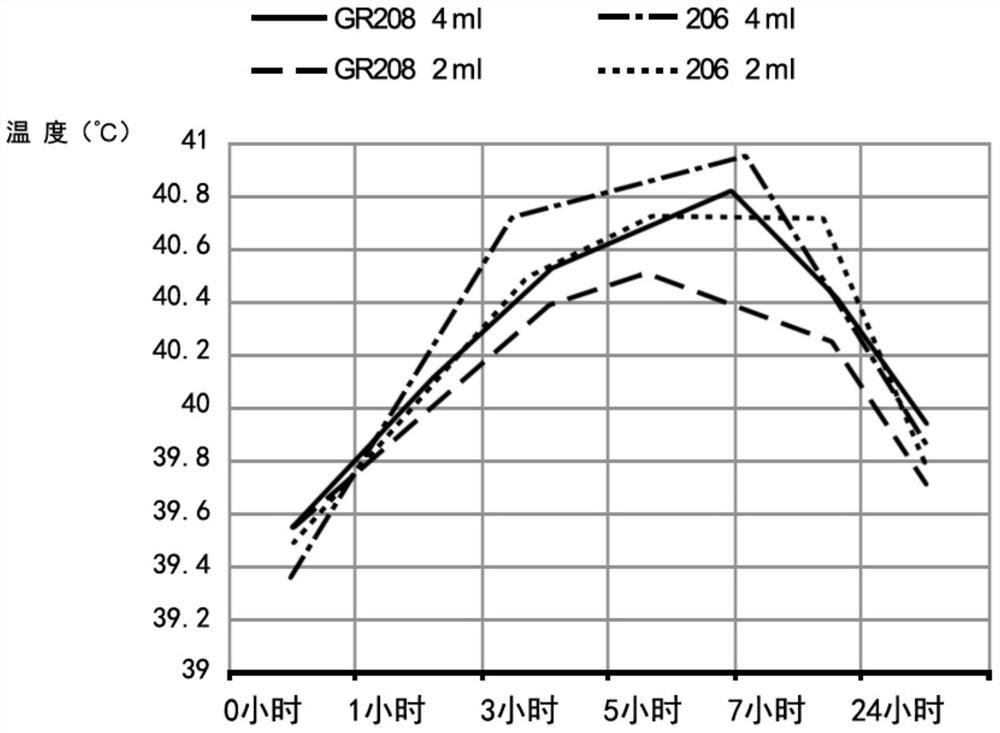

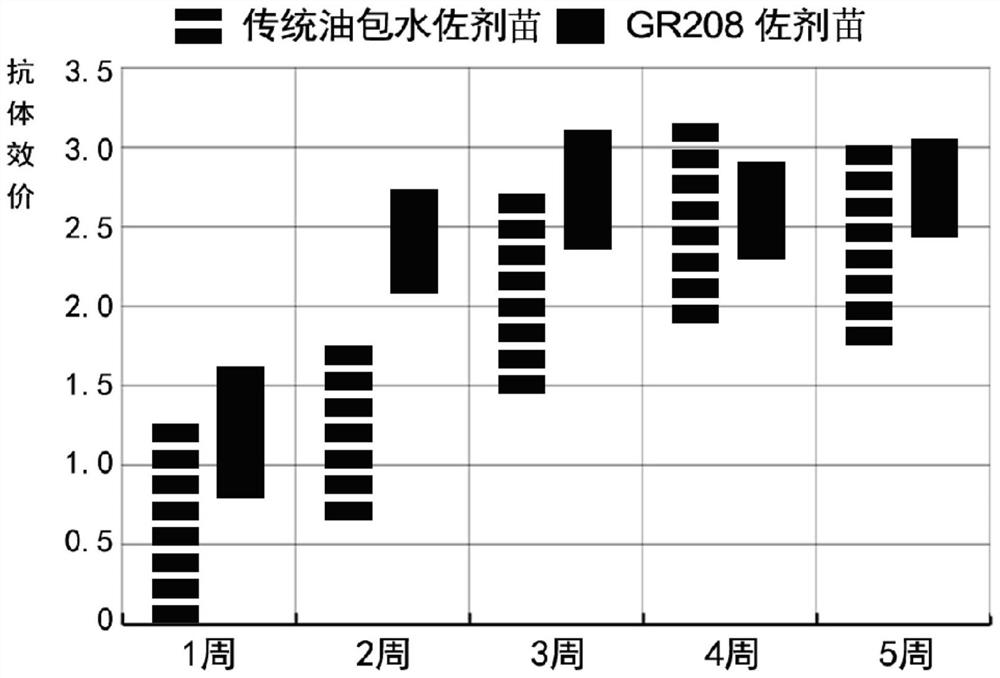

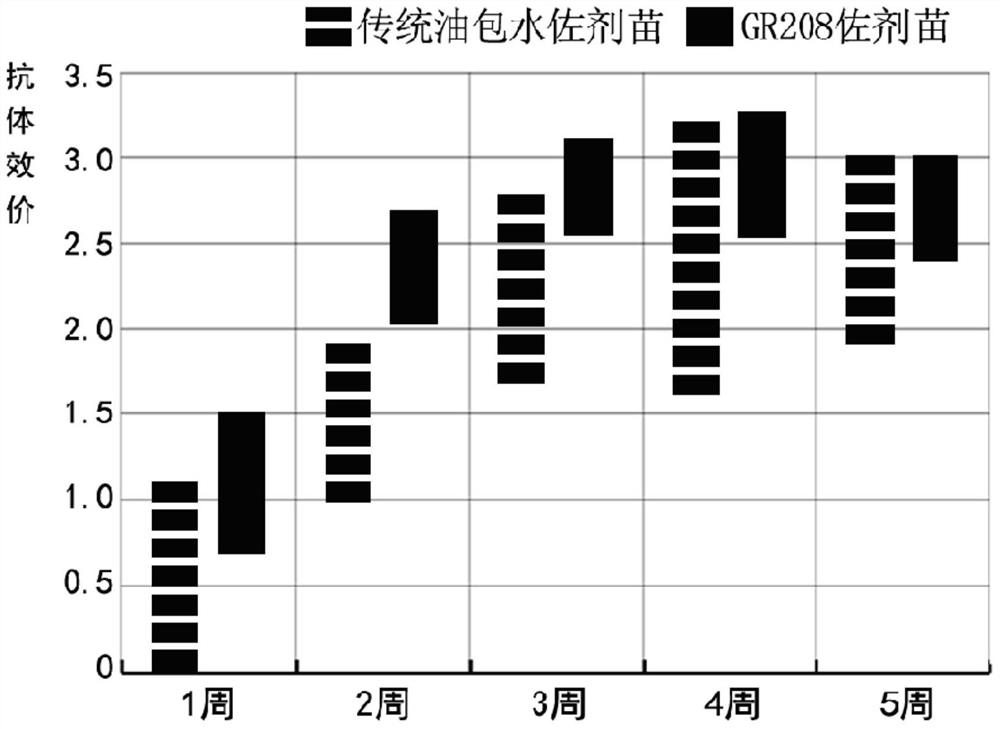

Adjuvant for animal vaccines, and preparation method and application thereof

ActiveCN106692966AReduce allergic reactionsRapid immune responseEmulsion deliveryAntibody medical ingredientsAdjuvantAnimals vaccines

The invention discloses an adjuvant for animal vaccines, and a preparation method and application thereof. The adjuvant for animal vaccines comprises the following raw materials by volume: 75 to 90% of low-density mineral oil, 1 to 10% of octyl and decyl glycerate and Span-80, 0.5 to 5% of glycerin and polyglycerol isostearate and 1 to 10% of polyethylene glycol-12-hydroxystearate-15, Tween-80 and propylene glycol, wherein the amount of Tween-80 is in a range of 0 to 5%. The preparation method comprises the following steps: weighing the low-density mineral oil; then adding octyl and decyl glycerate, Span-80, glycerin, polyglycerol isostearate, 1 to 10% of polyethylene glycol-12-hydroxystearate-15, Tween-80 and propylene glycol; and carrying out mixing and standing. The adjuvant provided by the invention has safety, stability and self-emulsifying performance, has low sensitivity to temperature in the process of emulsification, can form a water-in-oil-in-water spatial structure, and is extensively applicable to preparation of animal vaccines.

Owner:长沙国瑞生物科技有限公司

Preparation method of grinding-resistant aqueous cigarette packet printing ink resin

The invention discloses a preparation method of grinding-resistant aqueous cigarette packet printing ink resin. The preparation method comprises the following steps: carrying out vacuum dehydration on 5-10 molar parts of polycarbonate polyol and 5-15 molar parts of acrylic acid grafted modified polyester polyol at 100-150 DEG C for 1-4 hours, cooling to the room temperature, adding 10-20 molar parts of isophorone diisocyanate and 5-15 molar parts of hexamethylene diisocyanate, adding acetone to dissolve, heating to 80-90 DEG C, dropwise adding 0.2-0.25 molar part of an initiator, and reacting for 1.5-3 hours, so as to obtain a prepolymer; adding 2-5 molar parts of small-molecule dihydric alcohol and 1-3 molar parts of dimethylolpropionic acid into the prepolymer, heating to 60-75 DEG C, and carrying out chain extension for 1-1.5 hours; and after cooling to the room temperature, adding 1-3 molar parts of triethylamine under a high-speed stirring condition, stirring for 5-10 minutes, and adding water to emulsify the product, so as to obtain the grinding-resistant aqueous cigarette packet printing ink resin. The VOC content of the prepared grind-resistant aqueous cigarette packet printing ink resin is extremely low, and the grinding resistance, the film-forming performance and the color-developing performance in the preparation of printing ink are relatively good.

Owner:ANHUI SINOGRACE CHEM

Air-dry room temperature curing water-based epoxy waterproof paint and preparation method and application thereof

ActiveCN108250899AExcellent surface waterproof performanceSelf-emulsifyingEpoxy resin coatingsWater basedCarboxylic salt

The invention belongs to the technical field of paint, and discloses an air-dry room temperature curing water-based epoxy waterproof paint and a preparation method and application thereof. The preparation method of the waterproof paint comprises the steps of: premixing an epoxy resin system, a compound amine curing agent and an organometallic carboxylate drier, adding aqueous-phase slurry, performing even stirring, and carrying out curing at room temperature to obtain the waterproof paint; the compound amine curing agent comprises bi-active polyamide, a reactive diluent, a polyamine-epoxy adduct, polyamine, phenolic amine and an assistant. The waterproof paint has excellent waterproof performance, and can be used as anticorrosive paint, interface treatment agents, pore-sealing agents, grouting materials and porous moulds with pore-sealed surfaces.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

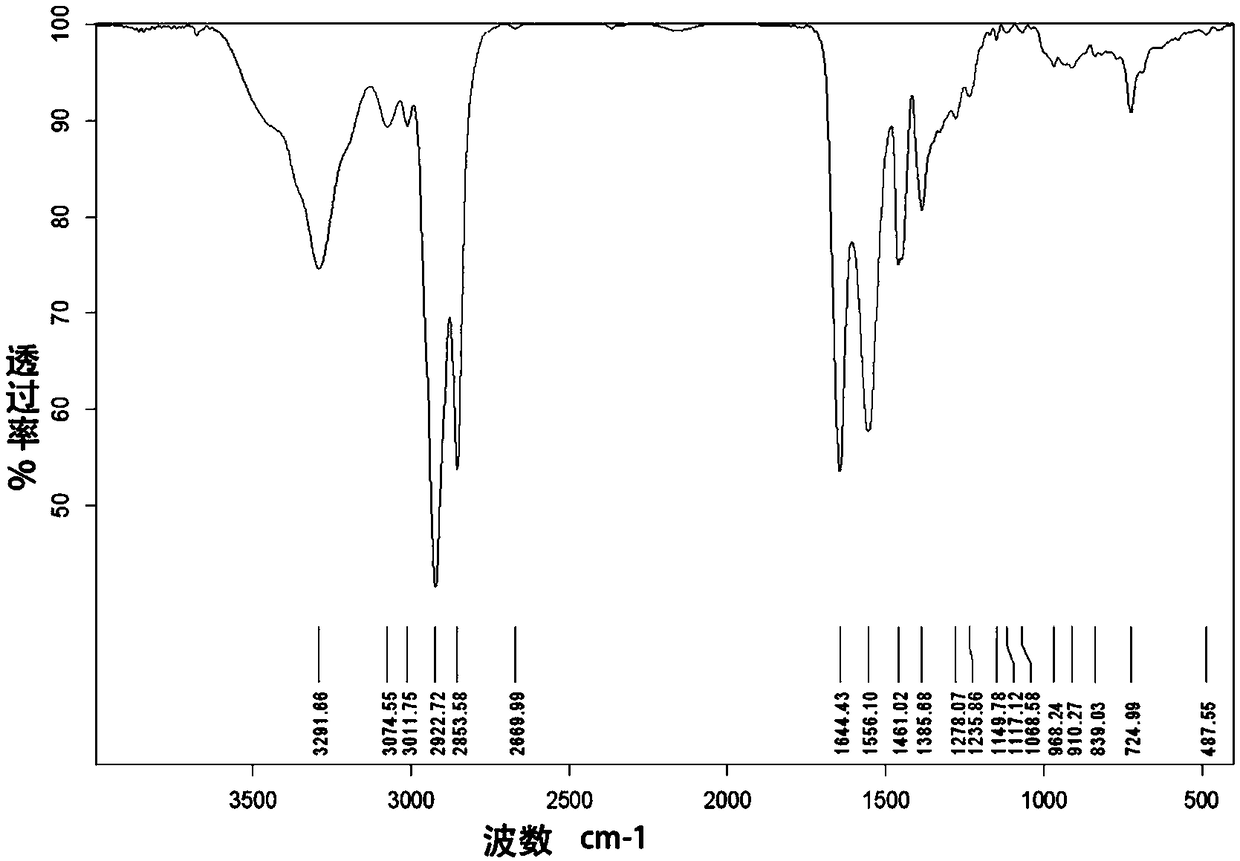

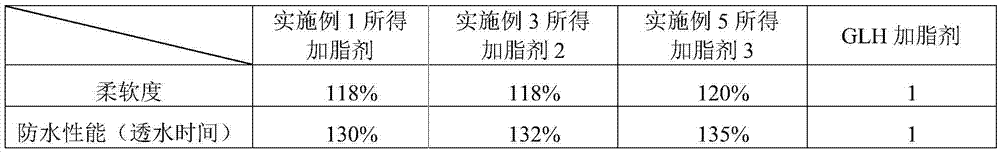

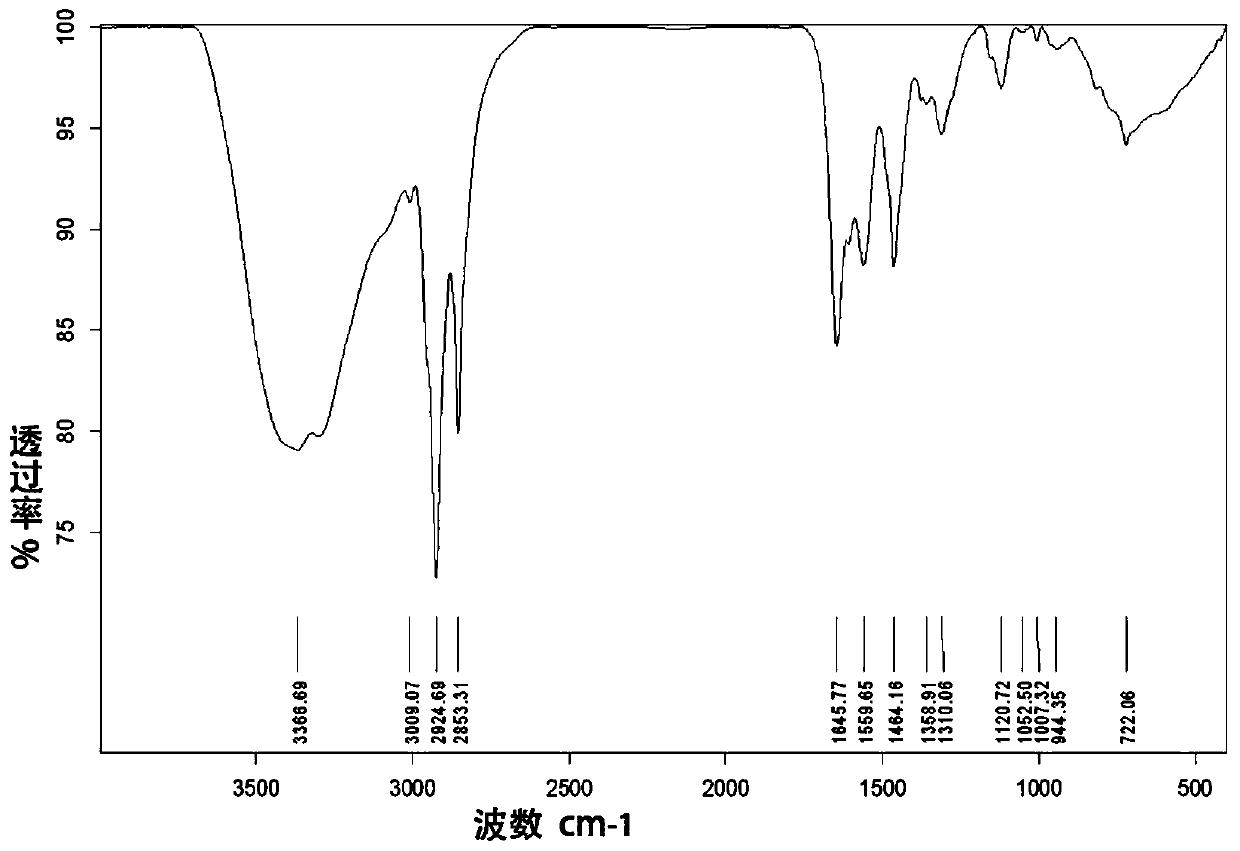

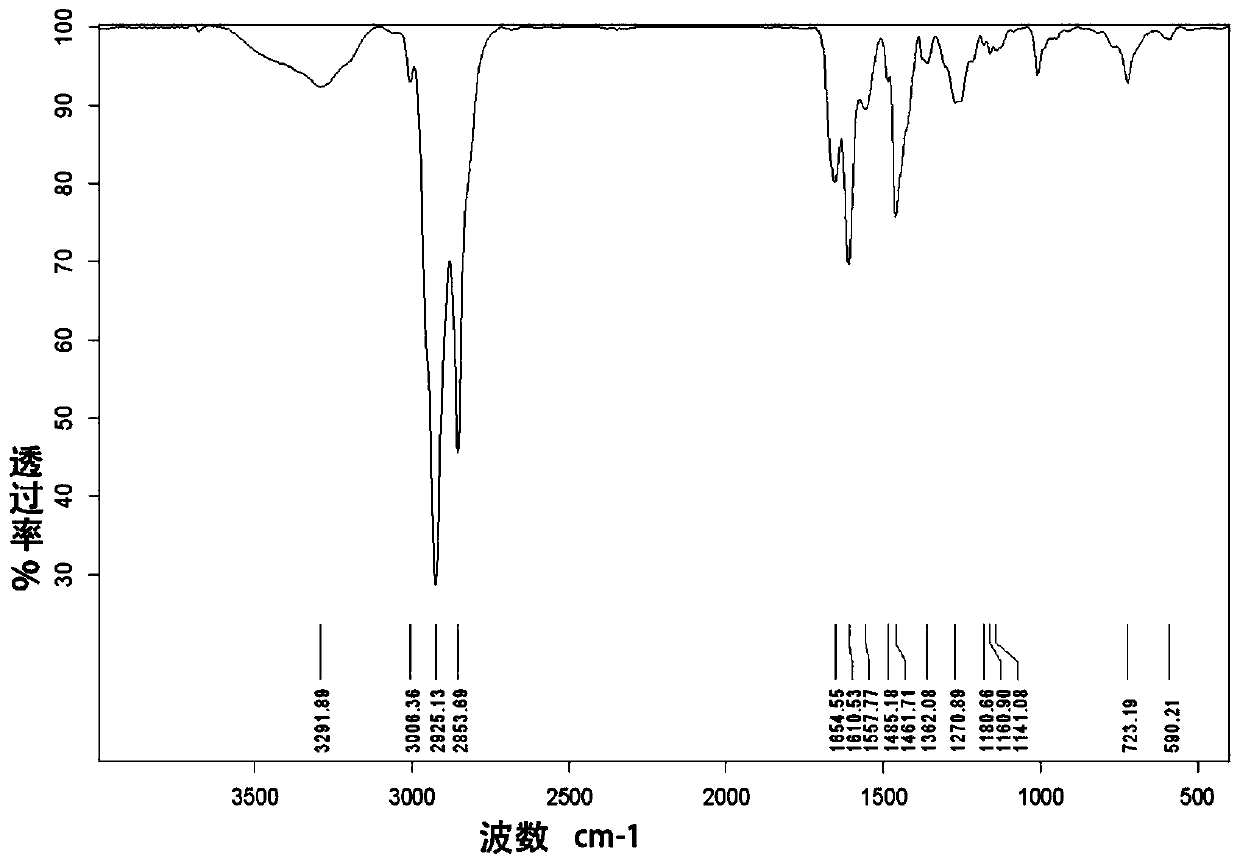

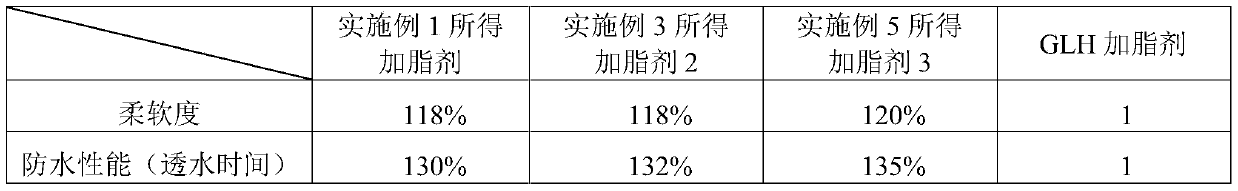

Composite fatliquor and preparation method thereof

The invention belongs to the technical field of the leather chemical industry, and discloses composite fatliquor and a preparation method thereof. Long carbon alkane, maleic anhydride, high-carbon alcohol and fatty alcohol-polyoxyethylene ether serve as raw materials. Firstly, the long carbon alkane and maleic anhydride are subjected to a grafting reaction; then, the high-carbon alcohol and the fatty alcohol-polyoxyethylene ether are subjected to an esterification reaction with the excessive maleic anhydride; and finally, the composite fatliquor is obtained by sulfonating sodium sulfite and adjusting pH and solid contents. According to the preparation method of the composite fatliquor, the self-emulsifying performance of the long carbon alkane is improved through graft modification, and the application of the raw materials in the leather fatliquor is widened significantly. The composite fatliquor is good in dielectric resistance; after fatliquoring, leather is light, puffy, soft and free of peculiar smell and has a certain waterproof effect.

Owner:四川亭江新材料股份有限公司

A kind of air-drying room temperature curing waterborne epoxy waterproof coating and its preparation method and application

ActiveCN108250899BExcellent surface waterproof performanceSelf-emulsifyingEpoxy resin coatingsPolymer sciencePolyamide

The invention belongs to the technical field of paint, and discloses an air-dry room temperature curing water-based epoxy waterproof paint and a preparation method and application thereof. The preparation method of the waterproof paint comprises the steps of: premixing an epoxy resin system, a compound amine curing agent and an organometallic carboxylate drier, adding aqueous-phase slurry, performing even stirring, and carrying out curing at room temperature to obtain the waterproof paint; the compound amine curing agent comprises bi-active polyamide, a reactive diluent, a polyamine-epoxy adduct, polyamine, phenolic amine and an assistant. The waterproof paint has excellent waterproof performance, and can be used as anticorrosive paint, interface treatment agents, pore-sealing agents, grouting materials and porous moulds with pore-sealed surfaces.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

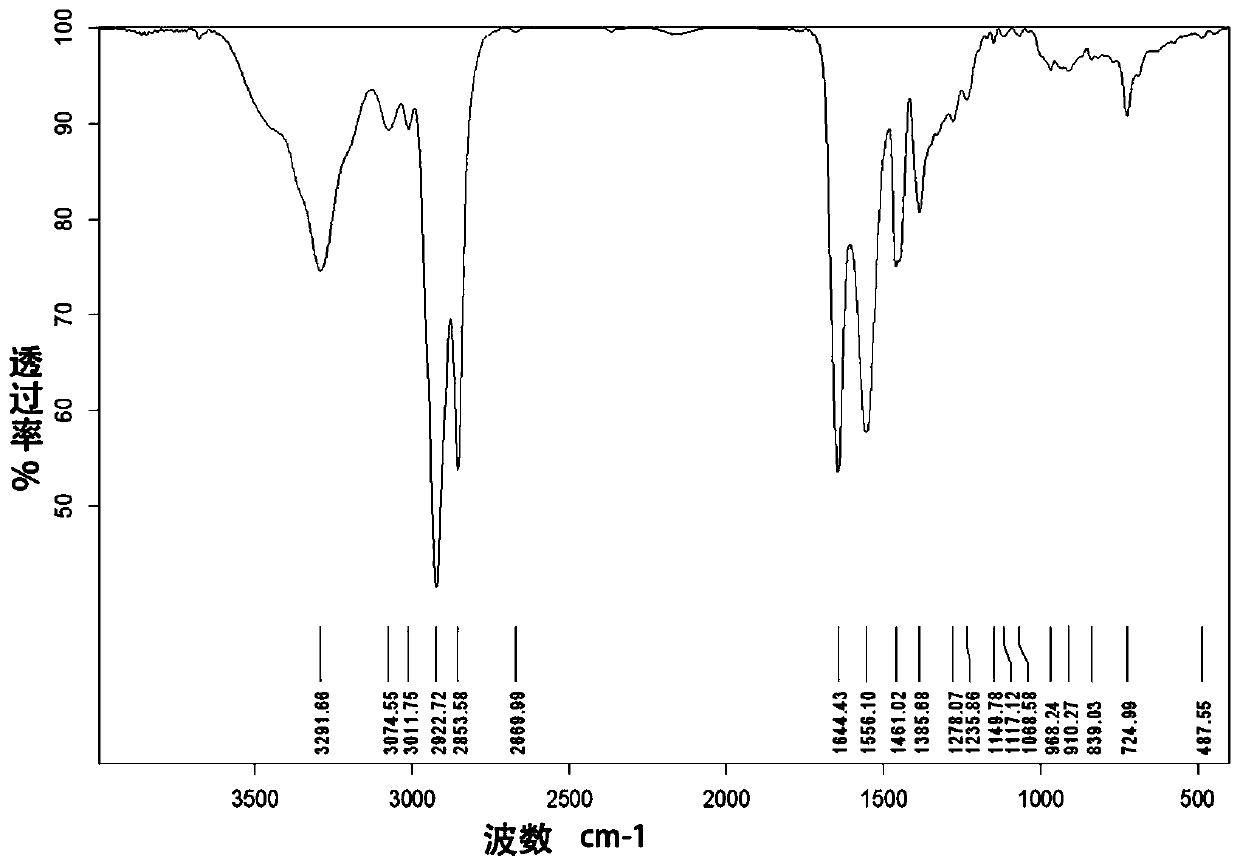

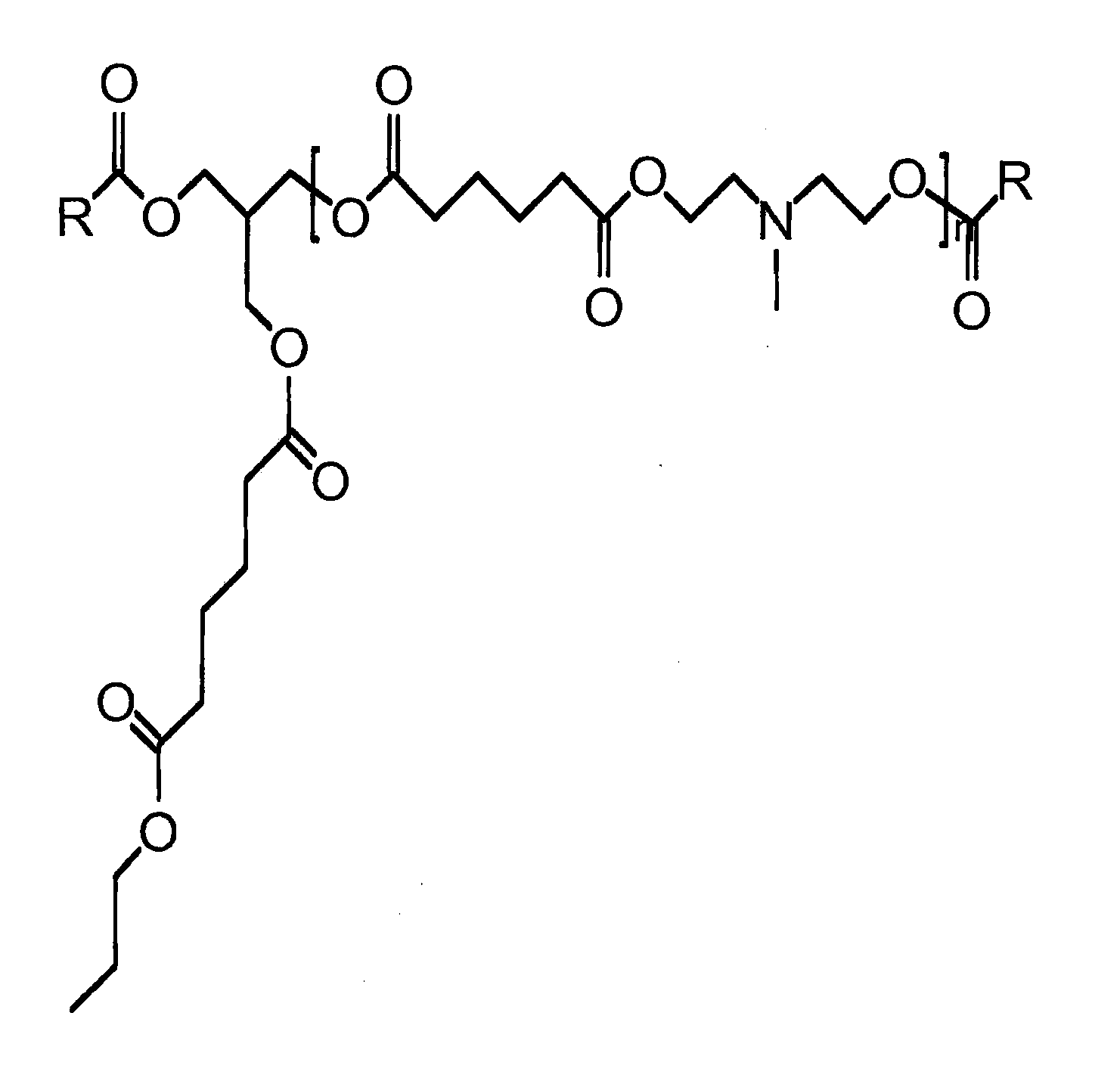

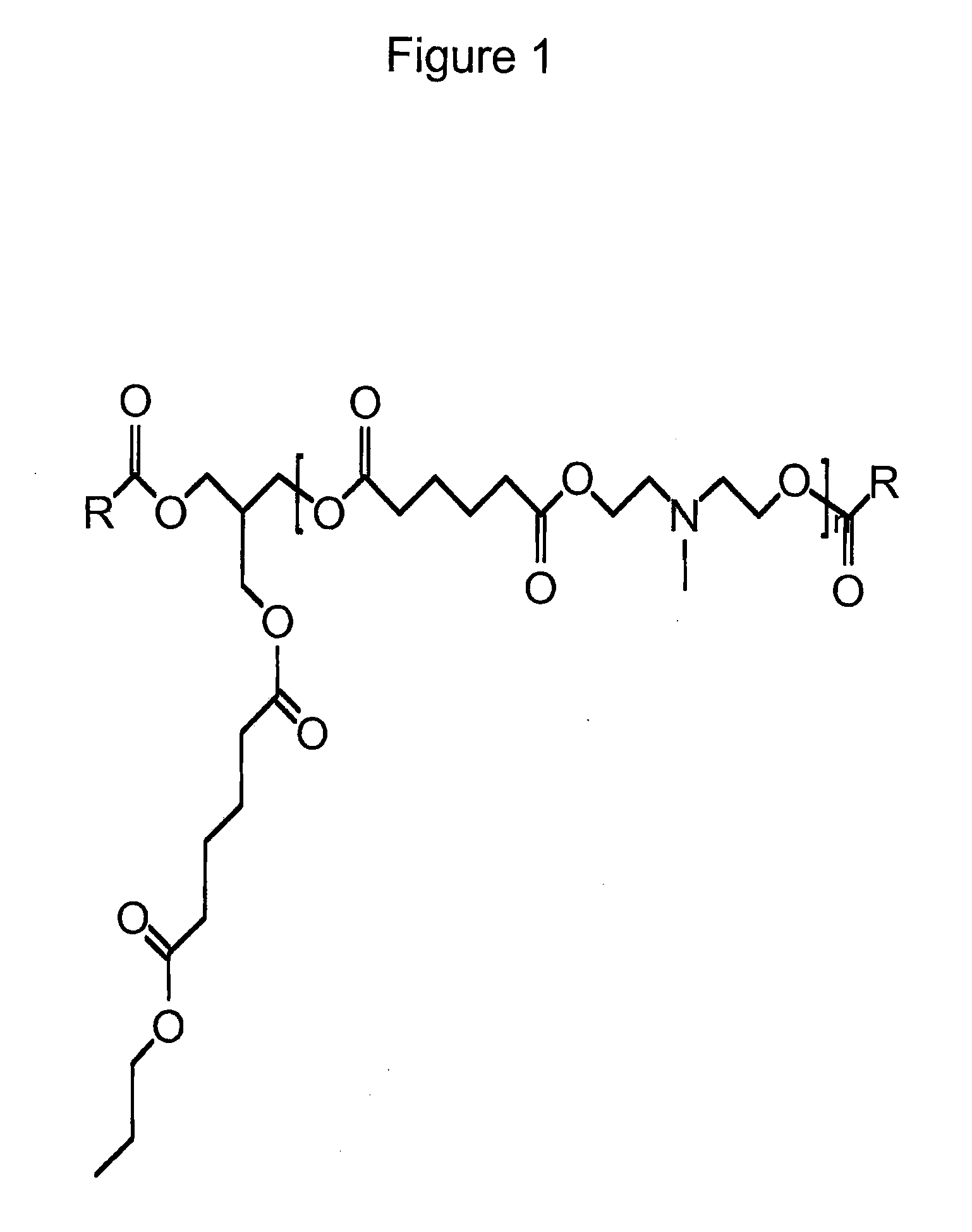

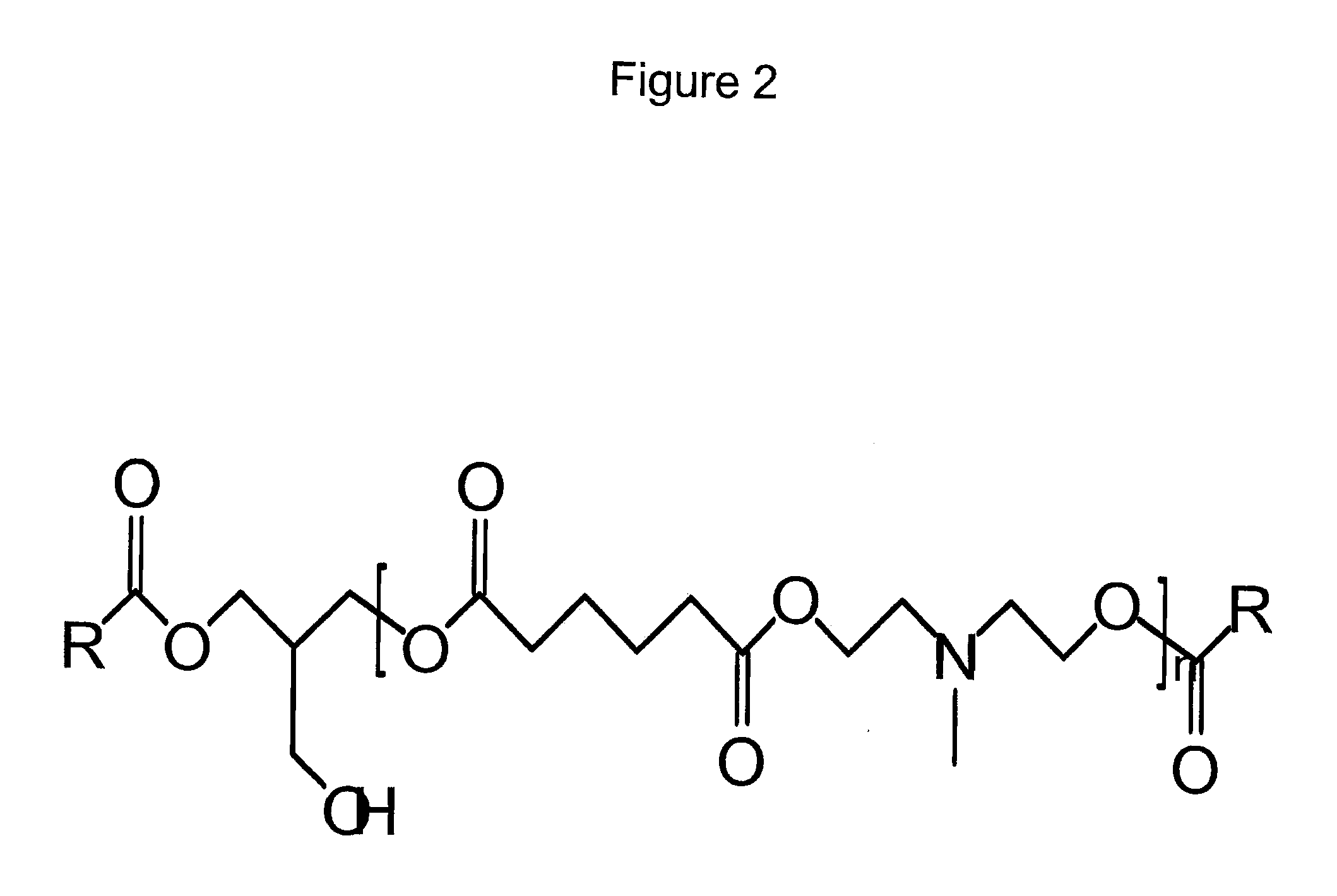

Tertiary Amine Functional Complex Polyester Polymers And Methods Of Production And Use

InactiveUS20080279795A1Good substantivityGood conditionerOrganic active ingredientsCosmetic preparationsPolyesterAlcohol

A polyesteramine comprises at least one tertiary amine group, at least one ester linkage and at least one alkyl chain. It is produced by reacting at least one tertiary amine functional polyol, at least one polyfunctional carboxylic acid and at least one monofunctional carboxylic acid or monofunctional alcohol. The polyesteramine can be used in cosmetic and lubricant applications as a result of its substantivity and lubricity properties.

Owner:BURGO ROCCO VINCENT +2

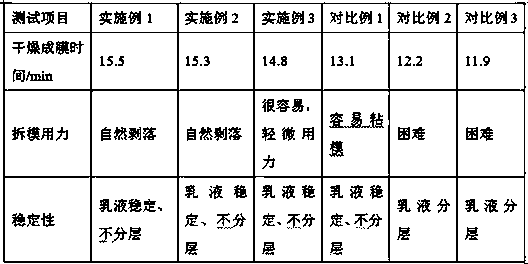

Preparation method for concrete release agent

PendingCN110003974AImprove water repellencyImprove surface water repellencyBase-materialsSolid waste managementSolventStrong acids

The invention belongs to the technical field of concrete, and particularly relates to a preparation method of a concrete release agent. The method comprises the steps that tung oil as a basic raw material is mixed with a mixed solvent, under the action of a catalyst, an esterification reaction is carried out first, and an ester mixture partly containing benzene ring derivatives is formed; under the action of strong acid, the ester mixture and ethyl alcohol are subjected to an alkylation reaction so that the hydrophobic performance can be effectively improved; the mixture obtained in the last step is mixed with a mixed monomer and the like, and under the actions of an initiator, a catalyst and the like, polymerization is conducted. In the polymerization process, grafting of modified tung oil is achieved, crosslinking is conducted by using a cross-linking agent, and therefore, the preparation method for the concrete release agent is implemented. The problems are effectively solved that the release efficiency of an existing release agent is poor, and the existing release agent easily adheres to a mould and is not prone to stripping.

Owner:陈蓉蓉

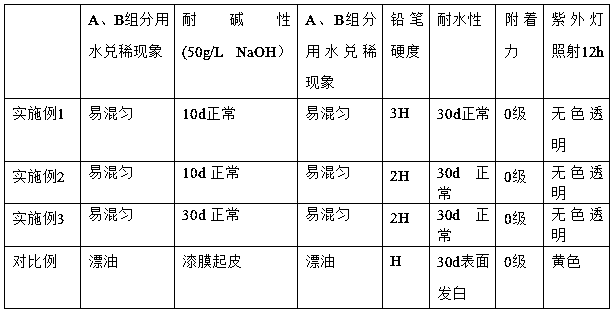

Self-emulsifying fluorosilicone modified dual-component waterborne epoxy floor coating

The invention relates to self-emulsifying fluorosilicone modified dual-component waterborne epoxy floor coating. The floor coating is characterized in that the floor coating includes an A component and a B component; the A component includes, by weight, 30-40 parts of an amine curing agent, 3-5 parts of a zirconate coupling agent and 0-20 parts of an alcohol diluent; the B component includes 50-80parts of emulsifiable organic fluorosilicone epoxy resin, 0.5-1 part of a leveling agent, 0.8-1.5 parts of a wetting and dispersing agent, 0.1-0.3 part of a defoamer and 15-50 parts of a pigment filler; the emulsifiable organic fluorosilicone epoxy resin is used for the waterborne epoxy floor coating so that the floor coating has a self-emulsifying property, can be directly emulsified with waterand diluted and is waterborne and environmentally friendly; through modification with fluorosilicone, water resistance, corrosion resistance and hydrophobicity of the floor coating are improved; and the process is simple, convenient to operate and prone to industrial production.

Owner:SHAOGUAN HEZHONG CHEM CO LTD +1

A kind of synthetic fatliquoring agent and preparation method thereof

The invention belongs to the technical field of the leather chemical industry, and discloses composite fatliquor and a preparation method thereof. Long carbon alkane, maleic anhydride, high-carbon alcohol and fatty alcohol-polyoxyethylene ether serve as raw materials. Firstly, the long carbon alkane and maleic anhydride are subjected to a grafting reaction; then, the high-carbon alcohol and the fatty alcohol-polyoxyethylene ether are subjected to an esterification reaction with the excessive maleic anhydride; and finally, the composite fatliquor is obtained by sulfonating sodium sulfite and adjusting pH and solid contents. According to the preparation method of the composite fatliquor, the self-emulsifying performance of the long carbon alkane is improved through graft modification, and the application of the raw materials in the leather fatliquor is widened significantly. The composite fatliquor is good in dielectric resistance; after fatliquoring, leather is light, puffy, soft and free of peculiar smell and has a certain waterproof effect.

Owner:四川亭江新材料股份有限公司

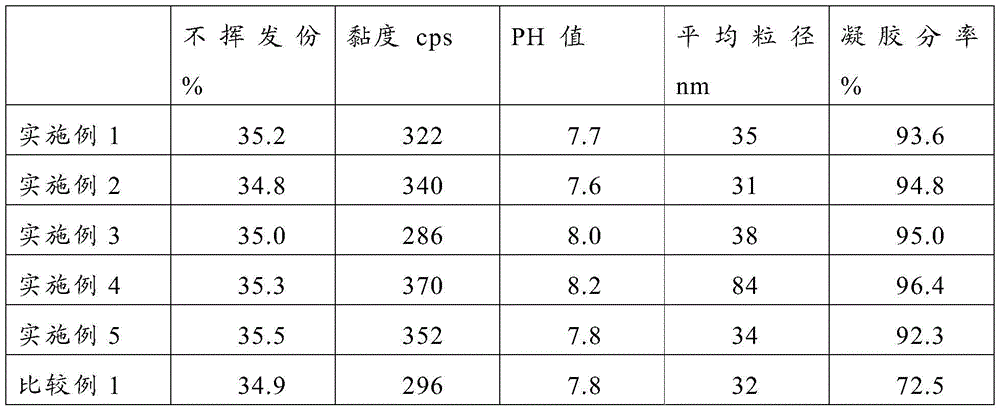

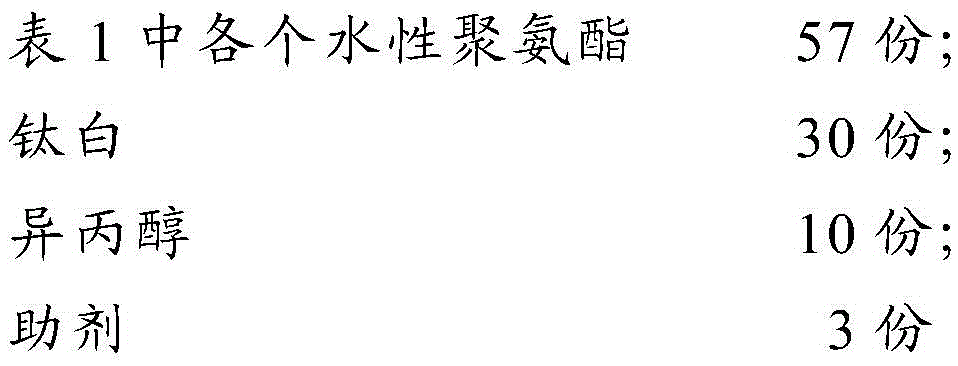

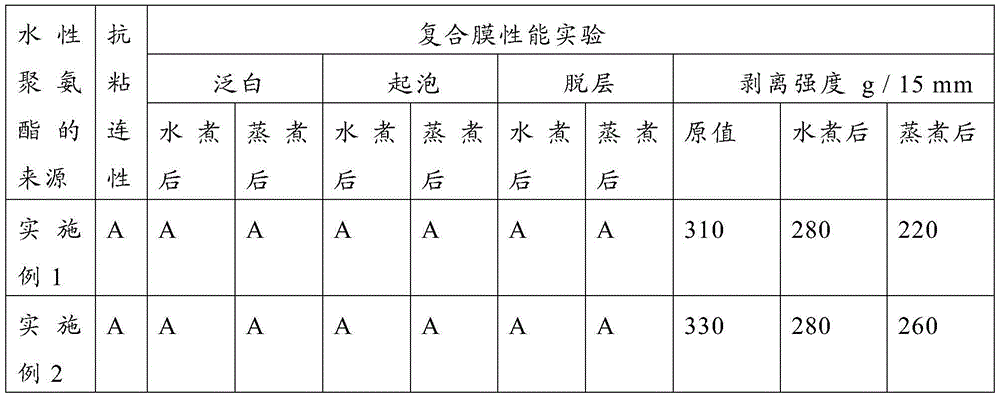

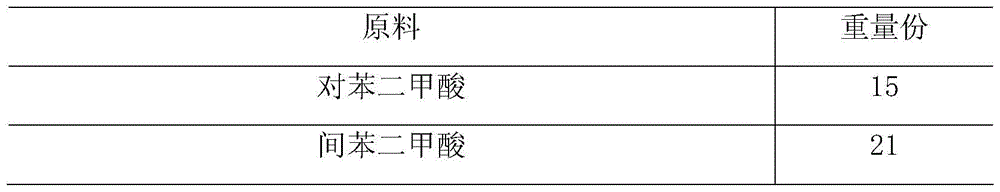

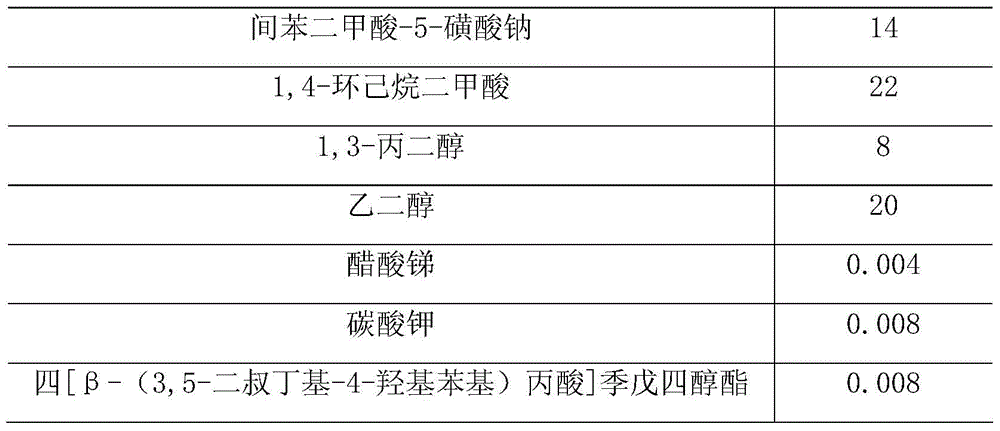

A kind of preparation method of aqueous polyurethane

ActiveCN103524693BImprove water resistanceSelf-emulsifyingPolyureas/polyurethane adhesivesInksPolyurethane dispersionPolyol

The invention provides a preparation method for aqueous polyurethane. diisocyanate, polyols and hydrophilic chain extenders are reacted under the action of catalysts, a prepolymer solution with self emulsibility is obtained; the prepolymer solution is added with water for emulsification, then a chain extension reaction is carried out by utilization of polyamines, and aqueous polyurethane dispersions with internal crosslinking are obtained. The polyamines comprise at least above 10wt% of high-molecular amines. Because each molecule of the high-molecular amines contains a plurality of primary amine and secondary amine functional groups, when the high-molecular amines are selected as chain extenders and internal crosslinking agents, the obtained molecules after chain extension have net structures and appropriate crosslinking degree. When the molecules are dried and a compact membrane with good water resistance and storage stability can be formed. By utilization of an internal crosslinking method, the problem of contradiction of hydrophilcity and water resistence of aqueous polyurethane is solved. The aqueous polyurethane can be applied in intaglio printing oil, and can meet the requirements of boiling resistance (100 DEG C / 30min) and steaming resistance (121 DEG C / 30min).

Owner:BAUHINIA VARIEGATA INK & CHEM (ZHONGSHAN) LTD

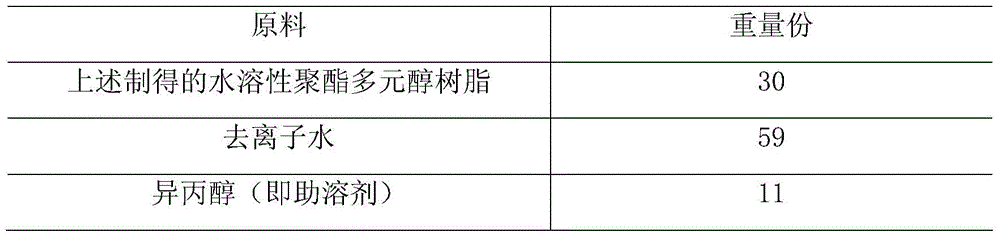

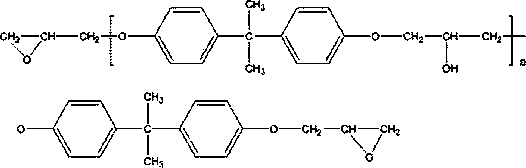

Enhanced printing and aluminum plating water-based polyester primer and preparation method thereof

ActiveCN104231879BSolve the problem of decreased adhesionImprove water resistancePolyester coatingsPolyesterRotational viscosity

The invention discloses a water-based polyester primer for enhanced printing and aluminum plating and a preparation method thereof, belonging to the field of chemical primer preparation. The primer is composed of the following components by weight: 25-45 water-soluble polyester polyol resins, 42-70 deionized water and 5-13 cosolvents; The molecular mass is 12000-18000, the acid value is less than 2mgKOH / g, the hydroxyl value is 5-10mgKOH / g, and the glass transition temperature is 60-70°C. The primer has a solid content of 25-45 percent, a rotational viscosity of 50-200 mPa·s at 25° C. and a pH value of 4-7. The water-based primer has excellent bonding strength with the PET film, ink layer, and aluminum-coated layer. The PET printing film and PET aluminum-plated film using the water-based primer have excellent water resistance, high temperature resistance, and internal resistance. Stress shrinkage and other properties.

Owner:NANTONG GAOMENG NEW MATERIAL

Biodegradable aqueous emulsion-type polylactic acid adhesive and its preparation method

The invention relates to a biodegradable aqueous emulsion-type polylactic acid adhesive and its preparation method. As a water dispersible emulsion, every 100 parts by weight of the adhesive at least contains 5-45 parts by weight of a polyethylene glycol grafted polylactic acid copolymer, 5-40 parts by weight of vinyl acetate grafted starch, and 0.5-30 parts by weight of an ethylene-vinyl acetate copolymer. The aqueous emulsion-type polylactic acid adhesive provided in the invention is biodegradable, has high bonding fastness, adjustable filter rod hardness as well as good moulding performance, and simultaneously has filter rod adsorption enhancing and harm reduction performances.

Owner:长沙乐远化工科技有限公司

Preparation method of dibasic acid chain extension modified epoxy resin

The invention relates to the field of high molecular materials, and specifically relates to a preparation method of binary acid chain extension modified epoxy resin. The preparation method comprises the following steps: adding epoxy resin and dihydric alcohol into a reactor, enabling the molar ratio of epoxy resin to poly dihydric alcohol to be (2: 1) to (10: 1), heating and stirring, so that themixture is dispersed uniformly, using a hydrochloric acid-acetone method to measure an initial epoxy number, then adding a catalyst, raising the temperature until 110 to 175 DEG C, reacting for 2 to 3h, using the hydrochloric acid-acetone method to measure an epoxy number remaining after the reaction to reach an expected epoxy number, then adding mixed acid compounded with monobasic acid and binary acid into the product, raising the temperature, stirring and mixing uniformly, enabling the molar ratio of monobasic acid to binary acid is (1: 1) to (1: 5), then adding an accelerant, reacting for3 to 5 h at the temperature of 110 to 150 DEG C, and finally obtaining the product being binary acid chain extension modified epoxy resin. The preparation method solves the problem that an existing carbon fiber sizing agent is complex in emulsification technology, unstable in emulsion storage, low in strand bundling after sizing, hardened in strands, low in adhesiveness with matrix resin and thelike.

Owner:WEIHAI TUOZHAN FIBER

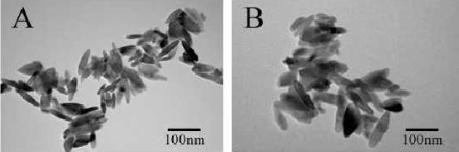

Preparation method of antibacterial nano material

The invention relates to a preparation method of an antibacterial nano material. The preparation method of the antibacterial nano material comprises the following steps: 1) after heating and stirringan adhesive, dehydrating to obtain a resultant A; 2) after stirring a spherical antiblocking agent, silver oxide, polyhexamethylguanidine stearate and the resultant A, heating and carrying out vacuumtreatment, dehydrating after vacuum treatment, then guiding in a rubber mixing mill and adding N-methyl diethanolamine to obtain a resultant B; 3) after grinding and stirring a nano iron and titaniumdioxide composite material, a surfactant and deionized water, adding copper oxide and limestone, and stirring to obtain a resultant C; and 4) after uniformly stirring the resultant B, the resultant C,2,6-toluene diisocyanate, a hydrophilic chain extender and a salt-forming agent, and carrying out extrusion and forming to obtain the antibacterial nano material. The problem that nano titanium dioxide is easy to agglomerate in the existing prepared antibacterial nano material is obviously avoided, and meanwhile, the prepared antibacterial nano material is excellent in antibacterial property andlong in service life and resists stretching.

Owner:DONGGUAN UNIV OF TECH

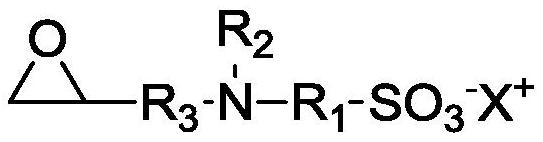

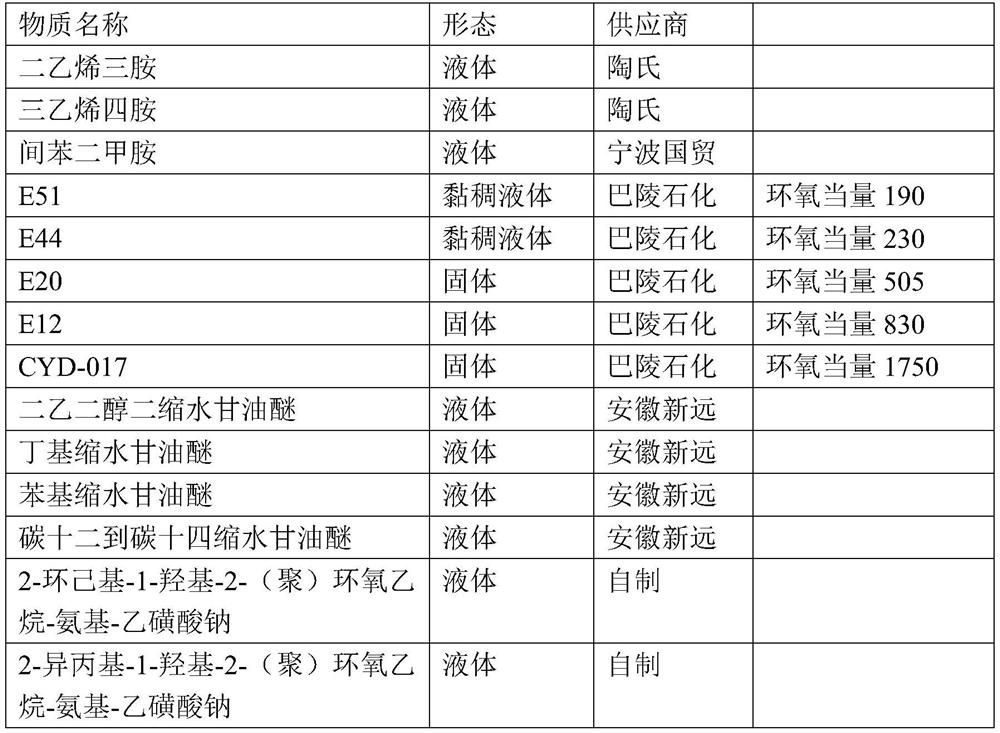

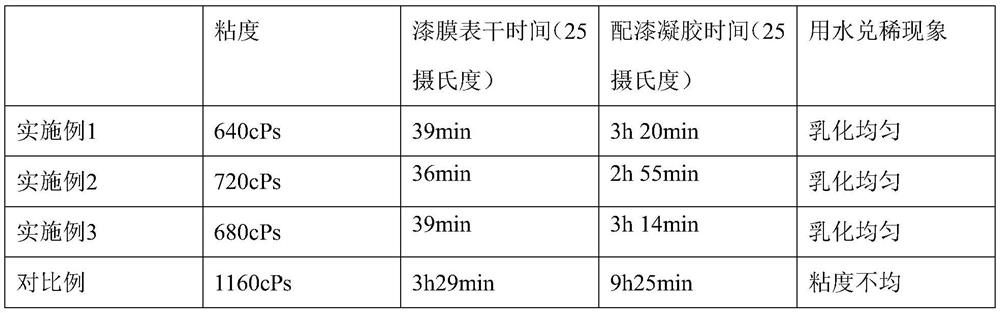

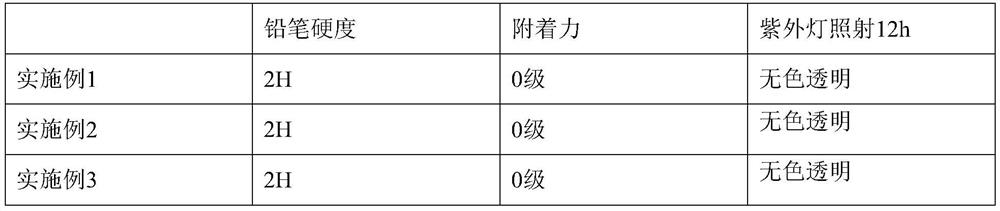

A room temperature quick-drying epoxy curing agent dispersion, its preparation method and application

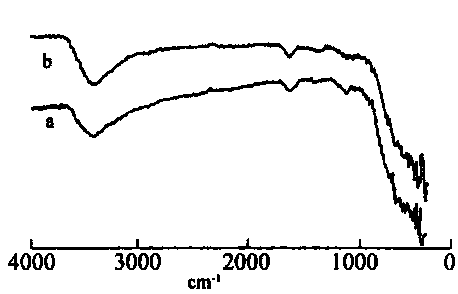

ActiveCN112646124BSelf-emulsifyingImprove salt spray resistanceAnti-corrosive paintsEpoxy resin coatingsSulfonatePolymer science

The invention discloses a method for preparing a room temperature fast-drying epoxy curing agent dispersion, which is characterized in that at least one sulfonate and at least one nonionic polyether structure are introduced into the curing agent structure, which can realize the self-curing of the curing agent. emulsification. The preparation of the curing agent described in the present invention has many advantages such as simple synthesis process, excellent salt spray resistance, fast drying at room temperature, stable particle size, low VOC, etc., and can be used in but not limited to the curing of epoxy dispersions in the field of heavy anticorrosion Such as construction machinery, rail transit, steel structure applications.

Owner:WANHUA CHEM GRP CO LTD +1

A cationic self-emulsifying water-based epoxy resin quick-drying curing agent

The invention relates to a cationic self-emulsifying water-based epoxy resin fast-drying curing agent, which contains hydrophilic quaternary ammonium salt cations and non-ionic long-chain water-based groups in its molecular structure; multiple fatty amines are located in the curing agent The branch position can react with epoxy resin for curing. The molecular structure of the curing agent of the present invention contains repeated hydrophilic quaternary ammonium salt cations and non-ionic long-chain water-based groups; the multi-component fatty amine that can react with epoxy resin has self-emulsifying properties, and at the same time the multi-component fatty amine The amine structure makes it react with epoxy resin with higher crosslinking density and faster surface drying, so that it has the characteristics of fast curing speed. The epoxy resin cured by the present invention has the advantages of high hardness and sufficient toughness.

Owner:广州御达电子科技有限公司

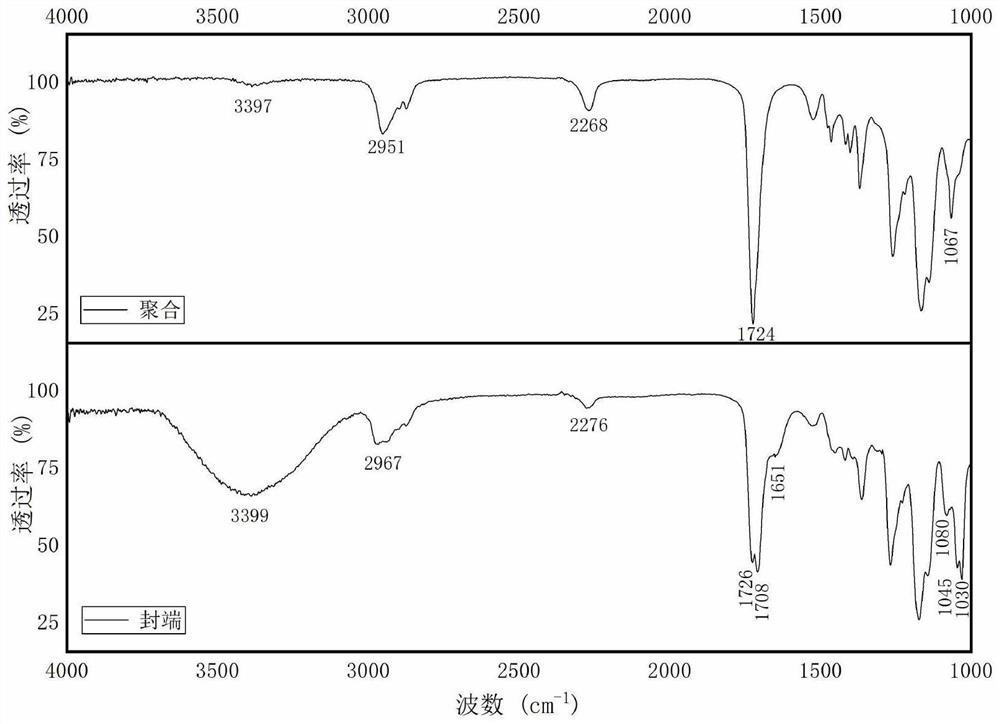

End-capped waterborne polyurethane vacuum plastic suction adhesive and preparation method thereof

PendingCN114752341AImprove heat resistanceGood crystallinityPolyureas/polyurethane adhesivesPrepolymerPolyester

The invention discloses an end-capped waterborne polyurethane vacuum plastic suction adhesive and a preparation method thereof, and belongs to the technical field of waterborne polyurethane. The end-capped waterborne polyurethane vacuum plastic suction adhesive is prepared from the following raw materials: polyester polyol, aliphatic diisocyanate, a micromolecular hydroxyl-terminated chain extender, an end-capping reagent, Na2CO3, a defoaming agent, an antibacterial agent, a wetting agent and a thickening agent. The preparation method comprises the following steps: synthesizing a prepolymer by using mixed polyester polyol, mixed isocyanate and a chain extender, then introducing an end-capping reagent into a waterborne polyurethane system, carrying out end capping on part of NCO groups in the prepolymer and providing hydrophilicity, and after emulsification, carrying out chain extension on uncapped NCO and water to form a macromolecular waterborne polyurethane system. The adhesive not only has certain initial viscosity, but also can provide NCO groups for reaction crosslinking in the later period, so that the heat resistance and hydrolysis resistance of a finished product are improved.

Owner:河北邦泰氨纶科技有限公司 +1

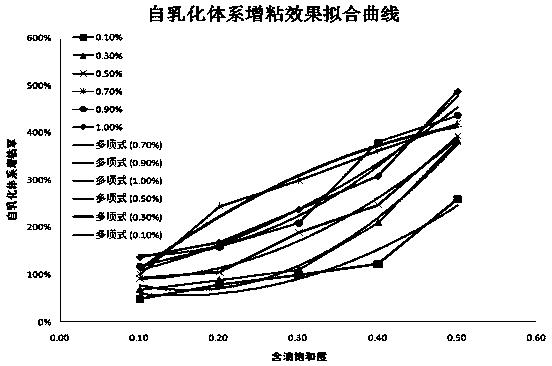

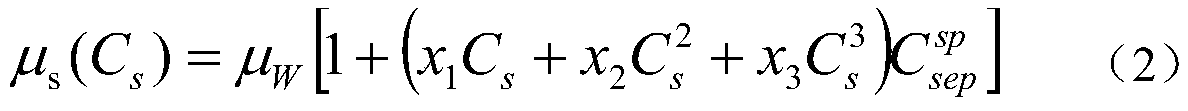

Self-emulsifying system viscosity-concentration relationship description method

ActiveCN110929395AReasonable descriptionAccurate predictionClimate change adaptationDesign optimisation/simulationMathematical modelResidual oil

The invention relates to the field of oil and gas field development and oil reservoir recovery ratio improvement, in particular to a self-emulsifying system viscosity-concentration relationship description method. The description method comprises the following steps: acquiring test data; solving a viscosity parameter by utilizing least square method regression; and establishing a description modelof the relationship between the viscosity of the self-emulsifying system and the saturation of the underground residual oil according to the obtained viscosity parameters. According to the method, self-emulsifying concentration and influence parameters of underground residual oil saturation on water-phase viscosity are introduced according to a basic seepage law of combination flooding, a mathematical model for describing self-emulsifying flooding viscosity is established, and a method for describing influence of underground residual oil saturation on viscosity of a self-emulsifying system isprovided. According to the method, the viscosity change of the self-emulsifying system under different oil saturation conditions can be described more accurately and reasonably, so that the effect ofimproving the recovery ratio is accurately predicted.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel waterborne epoxy curing agent production process

The invention provides a production process of a novel waterborne epoxy curing agent. The novel waterborne epoxy curing agent is prepared from the following raw materials in parts by weight: 0.075-0.225 part of triethylene tetramine, 0.14-0.42 part of polypropylene glycol diglycidyl ether, 0.04-0.12 part of Nanya 128 resin, 0.015-0.045 part of diethylene glycol mono-methyl ether, 0.001-0.03 part of a waterborne defoaming agent and 0.229-0.687 part of tap water. According to the method, harmful waste treatment is not needed, the process is simpler, only two-step reaction is carried out, and the production process is adjusted to be carried out for two days, so that the reaction in each stage is carried out completely, and the epoxy conversion rate is high enough; in addition, the production process is adjusted to be carried out in two days, so that the reaction in each stage is carried out completely, the epoxy conversion rate is high enough, meanwhile, the reaction heat in the first stage can be completely released, the reaction in the second stage is not influenced, and the gel scrap risk caused by overlarge reaction heat is avoided; the curing agent finished product produced by the method is low in viscosity, good in mixing performance with resin and high in emulsification width.

Owner:广东顺德巍龙复合材料有限公司

A kind of block polyether elastic silicone softener and its preparation method and application

The invention relates to a block polyether elastic silicone softener and its preparation method and application. An existing silicone softener with a body structure has good softness and smoothness of the fabric treated with it, and has excellent elasticity, but this softener needs to be emulsified with a large amount of emulsifier, and the product stability is not good. Therefore, it is not conducive to widespread use. The present invention adopts three kinds of compounds having general formula A, general formula B and general formula C to prepare a kind of organic silicon softener of novel network structure through epoxy addition reaction, change softener structure to (An1Bn2Cn3)p, n1 is 1‑3, n2 is 1‑3, n3 is 1‑3, p is 1‑10. The block polyether silicone softener of the present invention can endow the fabric with a soft, slippery, fluffy and elastic hand feel, especially its excellent elastic hand feel style characteristics, and has self-emulsification and excellent acid, alkali and salt resistance. properties such as chemical stability.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

Adjuvant for animal vaccine and its preparation method and application

ActiveCN106692966BReduce allergic reactionsRapid immune responseEmulsion deliveryAntibody medical ingredientsAdjuvantAnimals vaccines

The invention discloses an adjuvant for animal vaccines, and a preparation method and application thereof. The adjuvant for animal vaccines comprises the following raw materials by volume: 75 to 90% of low-density mineral oil, 1 to 10% of octyl and decyl glycerate and Span-80, 0.5 to 5% of glycerin and polyglycerol isostearate and 1 to 10% of polyethylene glycol-12-hydroxystearate-15, Tween-80 and propylene glycol, wherein the amount of Tween-80 is in a range of 0 to 5%. The preparation method comprises the following steps: weighing the low-density mineral oil; then adding octyl and decyl glycerate, Span-80, glycerin, polyglycerol isostearate, 1 to 10% of polyethylene glycol-12-hydroxystearate-15, Tween-80 and propylene glycol; and carrying out mixing and standing. The adjuvant provided by the invention has safety, stability and self-emulsifying performance, has low sensitivity to temperature in the process of emulsification, can form a water-in-oil-in-water spatial structure, and is extensively applicable to preparation of animal vaccines.

Owner:长沙国瑞生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com