Seam cracking prevention hot pressing wooden veneering adhesive and preparation method thereof

An adhesive and veneer technology, applied in the direction of adhesives, graft polymer adhesives, adhesive types, etc., can solve the problems of affecting product quality, existence of formaldehyde release, endangering the health of users, etc., to reduce external emulsification The effect of improving adhesive strength and improving adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

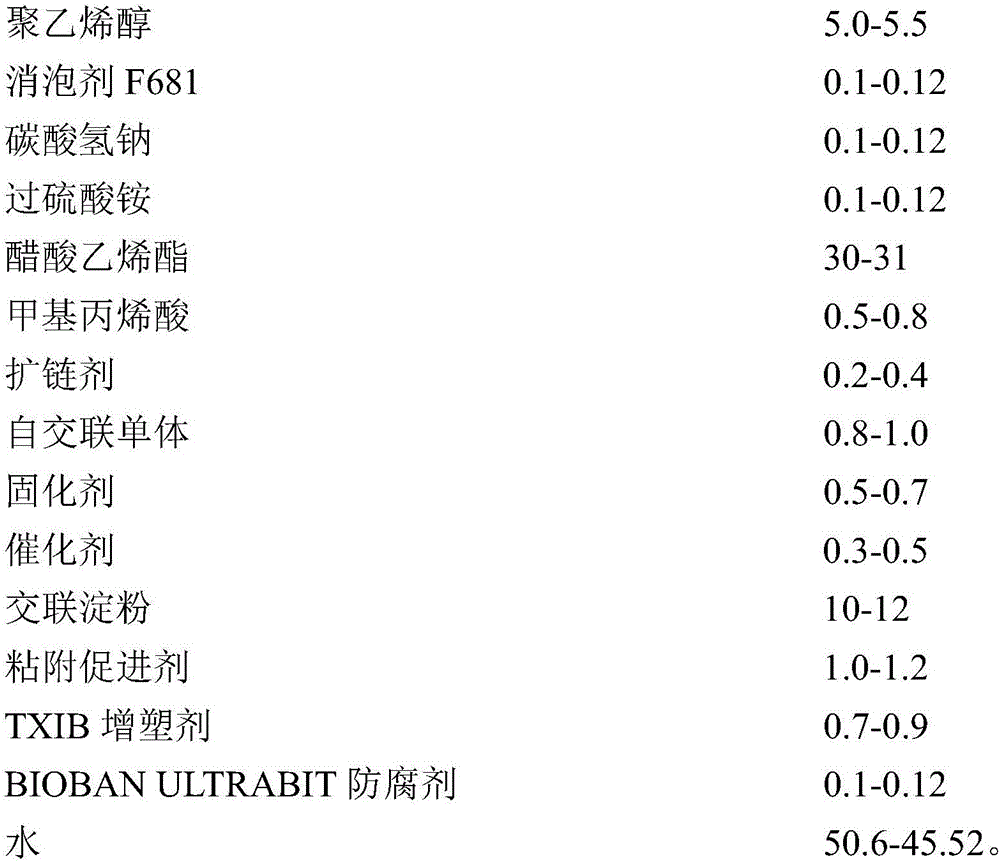

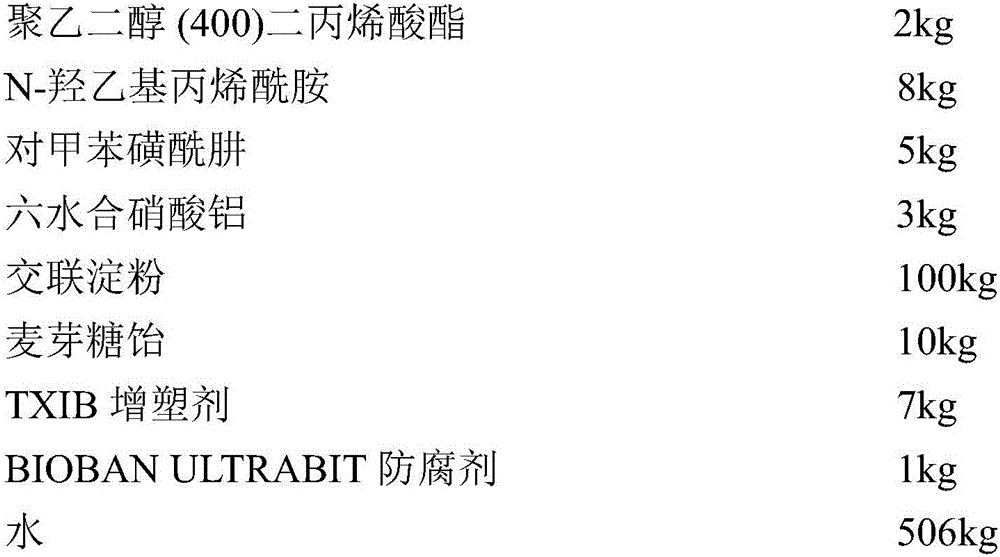

[0023] Embodiment 1 Total amount=1000kg

[0024]

[0025]

[0026] Production Process:

[0027] a, 1kg ammonium persulfate is dissolved in 19kg water to obtain 20kg ammonium persulfate aqueous solution;

[0028] b. Mix and stir 287.4kg vinyl acetate, 5kg methacrylic acid, 2kg polyethylene glycol (400) diacrylate and 8kg N-hydroxyethyl acrylamide to form 302.4kg mixed monomer;

[0029] c. Add 487kg of water, 1kg of defoamer F681, and 1kg of sodium bicarbonate into the reaction kettle, start stirring, add 40kg of PVA2488, 10kg of PVA1788, raise the temperature to 90°C and keep it for 50 minutes to dissolve polyvinyl alcohol. Then cool down to 73°C, add 12.6kg of vinyl acetate, stir and emulsify for 5 minutes, add 10kg of the ammonium persulfate aqueous solution prepared in step a, and incubate at 78°C for 20 minutes;

[0030] d. After the condenser has no reflux, start to drop the 302.4kg mixed monomer prepared by step b and the ammonium persulfate aqueous solution prepa...

Embodiment 2

[0032] Embodiment two total amount=1000kg

[0033]

[0034]

[0035] Production Process:

[0036] A, 1.1kg ammonium persulfate is dissolved in 20.9kg water, obtains 22kg ammonium persulfate aqueous solution;

[0037] b. Mix and stir 292.1kg vinyl acetate, 6kg methacrylic acid, 3kg polyethylene glycol (400) diacrylate and 9kg N-hydroxyethyl acrylamide to form 310.1kg mixed monomer;

[0038] c. Add 459.7kg of water, 1.1kg of defoamer F681, and 1.1kg of sodium bicarbonate into the reactor, start stirring, add 35kg of PVA2488, 18kg of PVA1788, raise the temperature to 91°C and keep it for 55 minutes to dissolve polyvinyl alcohol. Then cool down to 73°C, add 12.9kg of vinyl acetate, stir and emulsify for 5 minutes, add 11kg of ammonium persulfate aqueous solution prepared in step a, and keep warm at 78°C for 20 minutes;

[0039] d. After the condenser has no reflux, start to drop the 310.1kg mixed monomer prepared by step b and the ammonium persulfate aqueous solution prepa...

Embodiment 3

[0041] Embodiment three total amount=1000kg

[0042]

[0043]

[0044] Production Process:

[0045] A, 1.2kg ammonium persulfate is dissolved in 22.8kg water, obtains 24kg ammonium persulfate aqueous solution;

[0046] b. Mix and stir 296.7kg vinyl acetate, 8kg methacrylic acid, 4kg polyethylene glycol (400) diacrylate and 10kg N-hydroxyethylacrylamide to form 318.7kg mixed monomer;

[0047] c. Add 432.4kg of water, 1.2kg of defoamer F681, and 1.2kg of sodium bicarbonate into the reactor, start stirring, add 35kg of PVA2488, 20kg of PVA1788, raise the temperature to 92°C and keep it for 60 minutes to dissolve polyvinyl alcohol. Then cool down to 73°C, add 13.3kg of vinyl acetate, stir and emulsify for 5 minutes, add 12kg of ammonium persulfate aqueous solution prepared in step a, and incubate at 78°C for 20 minutes;

[0048] d. After the condenser has no reflux, start to drop the 318.7kg mixed monomer prepared by step b and the ammonium persulfate aqueous solution prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com