End-capped waterborne polyurethane vacuum plastic suction adhesive and preparation method thereof

A water-based polyurethane and vacuum suction technology, applied in the field of water-based polyurethane, can solve the problems of inability to vacuum plastics with soles, no adhesive initial viscosity, low initial viscosity, etc. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

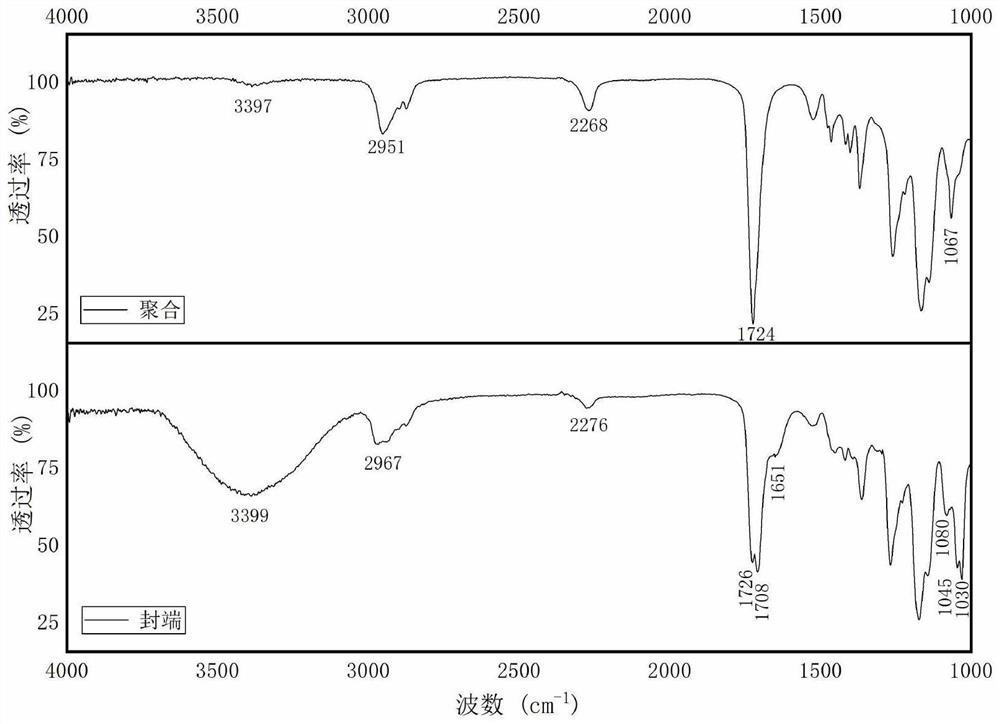

Method used

Image

Examples

Embodiment 1

[0047] Step 1. Add 100 g of polyethylene adipate diol with M=2500 and 100 g of polyethylene adipate diol with M=2300 to a 1L four In a round-bottomed flask with a vacuum degree of -0.09 to (-0.1) MPa, it was kept at 110 to 130 °C for 2 hours of dehydration.

[0048] Step 2. Cool the temperature to 80°C, add 12 g of isophorone diisocyanate, 18 g of hexamethylene diisocyanate, add 10 mg of catalyst, and keep the temperature at 70-90°C for 3 hours.

[0049] Step 3. Cool the temperature to 60°C, add 1.38g of NPG, 50g of acetone mixture, add 10mg of catalyst, and maintain the reflux reaction at 50-60°C for 2h.

[0050] Step 4. Add 50 g of acetone to the system to dilute and cool down to 20°C.

[0051] Step 5. Add 14g capping agent NaHSO 3 A mixed solution of 50 g of water and 50 g of ethanol was added with 8 mg of catalyst benzyl triethyl ammonium chloride, and the reaction was carried out for 30 min under high-speed stirring at 1200 r / min.

[0052] Step 6. After adding 150 g of...

Embodiment 2

[0056] Step 1. Add 133 g of polybutylene adipate diol with M=2500 and 67 g of polybutylene adipate diol with M=3000 to 1L of the 1L equipped with an electric mixer, a condenser and a thermometer. In a four-necked round-bottomed flask, dehydrate at 110-130 °C for 2 h under a vacuum of -0.09 to (-0.1) MPa.

[0057] Step 2: Cool the temperature to 80°C, add 10 g of isophorone diisocyanate, 18 g of hexamethylene diisocyanate, add 10 mg of catalyst, and keep the temperature at 70-90°C for 3 hours.

[0058] Step 3. Cool the temperature to 60 °C, add 2.3 g of butanediol, 50 g of acetone mixed solution, add 10 mg of catalyst, and maintain the reflux reaction at 50-60 °C for 2 hours.

[0059] Step 4. Add 50 g of acetone to the system to dilute and cool down to 20°C.

[0060] Step 5. Add 12g capping agent NaHSO 3 A mixed solution of 50 g of water and 50 g of ethanol was added with 8 mg of catalyst benzyl triethyl ammonium chloride, and the reaction was carried out for 30 min under hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com