A kind of air-drying room temperature curing waterborne epoxy waterproof coating and its preparation method and application

A room temperature curing, waterproof coating technology, applied in the field of coatings, can solve the problems of complex process, unsatisfactory performance, low strength, etc., achieve the effect of reducing VOC, excellent surface water resistance, and conducive to the formation of dense coating film and curing molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation of embodiment 1 bisactive polyamide

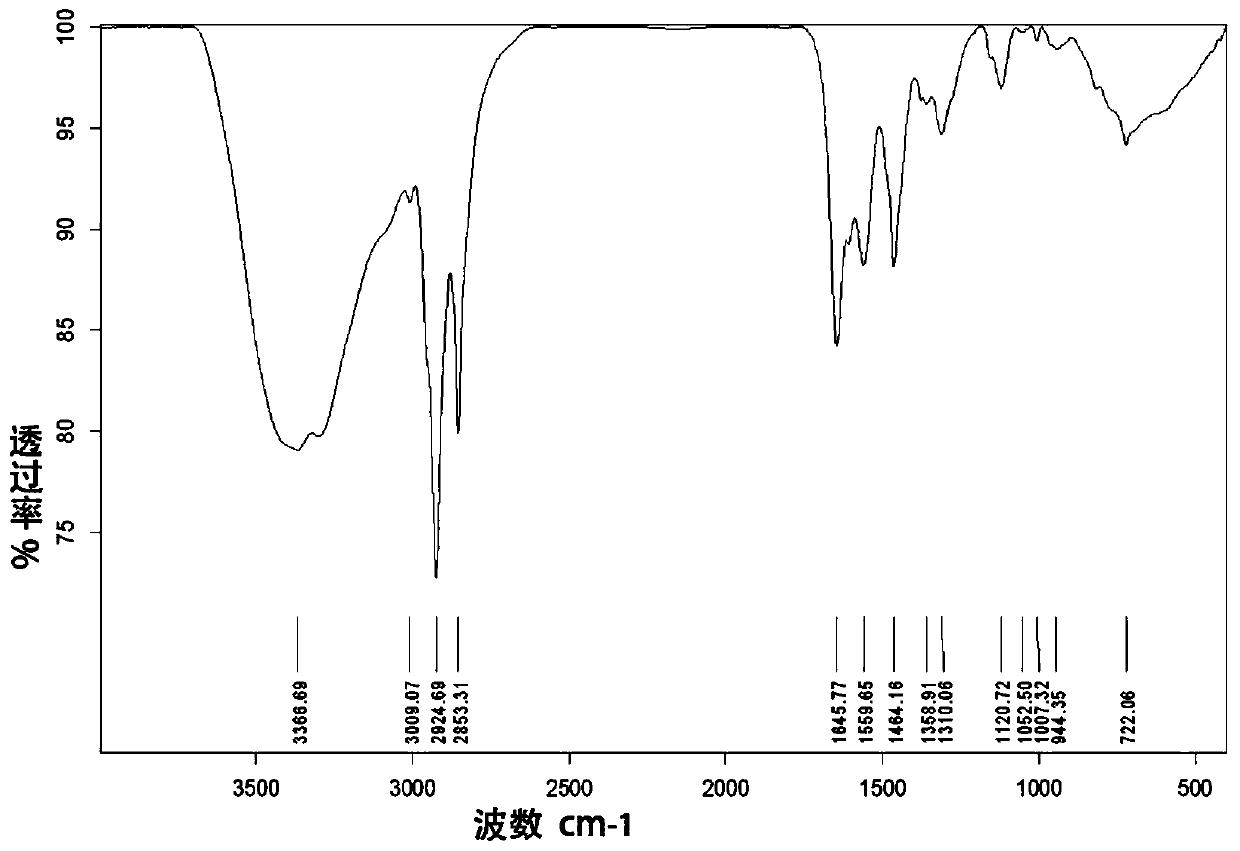

[0045] Add 2.2 moles of tetraethylenepentamine 415.8 grams and 564 grams of high-purity dimer acid ATUREX 1001 (dimer C 36 Dibasic acid content 99.1wt%, Jiangxi Aiturek Industrial Co., Ltd., 1 mole) and 56 grams of linoleic acid (reagent, purity 97%), heated to 150 ° C for 2 hours, then heated to 180 ° C for 2 hours And remove water, cool, obtain double active polyamide PA1, standby. Tested by infrared spectroscopy, it is obtained as figure 1 The infrared spectrum shown. figure 1 Medium 1645.77cm -1 Absorption peak of amide bond, 3009cm -1 is the C-H absorption peak on the unsaturated C=C double bond; from figure 1 It can be seen that PA1 has the active N-H that reacts with epoxy groups, and the active C=C that catalyzes the oxidation reaction of metals, that is, PA1 has dual activities, and can undergo ring-opening polymerization with epoxy resins, and can also contact air. Catalytic oxidation curing, that is,...

Embodiment 2

[0046] The preparation of embodiment 2 bisactive polyamide

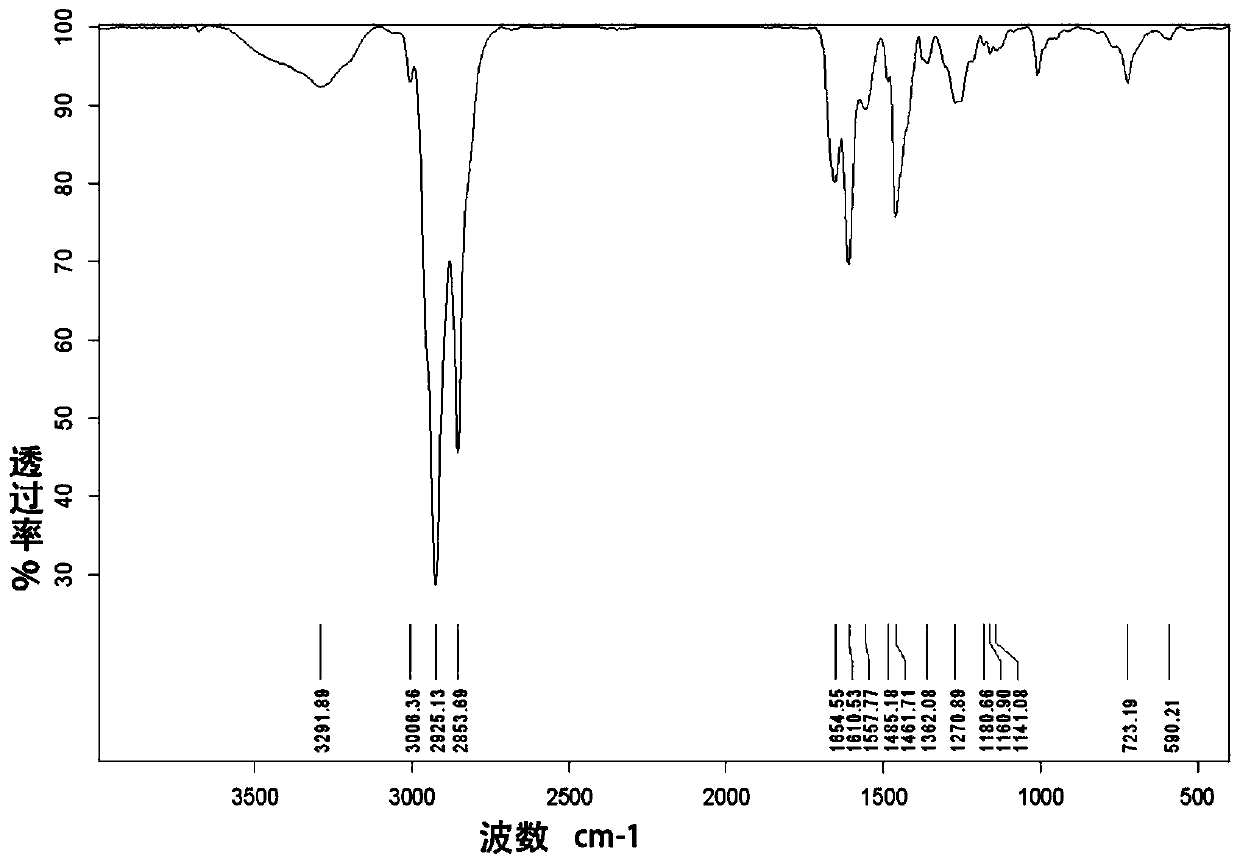

[0047] Add 2.1 moles of tetraethylenepentamine 396.9 grams and 504 grams of high-purity dimer acid ATUREX 1001 and 28.2 grams of linolenic acid (reagent, purity 95%) in the there-necked flask of 2000 milliliters, be warming up to 150 ℃ of reaction 2 hours, then Raise the temperature to 200°C for 2 hours, 260°C for 2 hours, remove the water, and cool to obtain bisactive polyamide PA2, which is ready for use. Tested by infrared spectroscopy, we get figure 2 The infrared spectrum shown. figure 2 Middle 1654cm -1 It is the amide bond absorption peak, 1610cm -1 It is part of the amide bond and the N-H on the amine group for further high-temperature dehydration or cyclization to form the C=N absorption peak on the imidazoline ring, 3006cm -1 is the C-H absorption peak on the unsaturated C=C double bond; from figure 2 It can be seen that PA2 has both active N-H that reacts with epoxy groups and active C=C that catal...

Embodiment 3

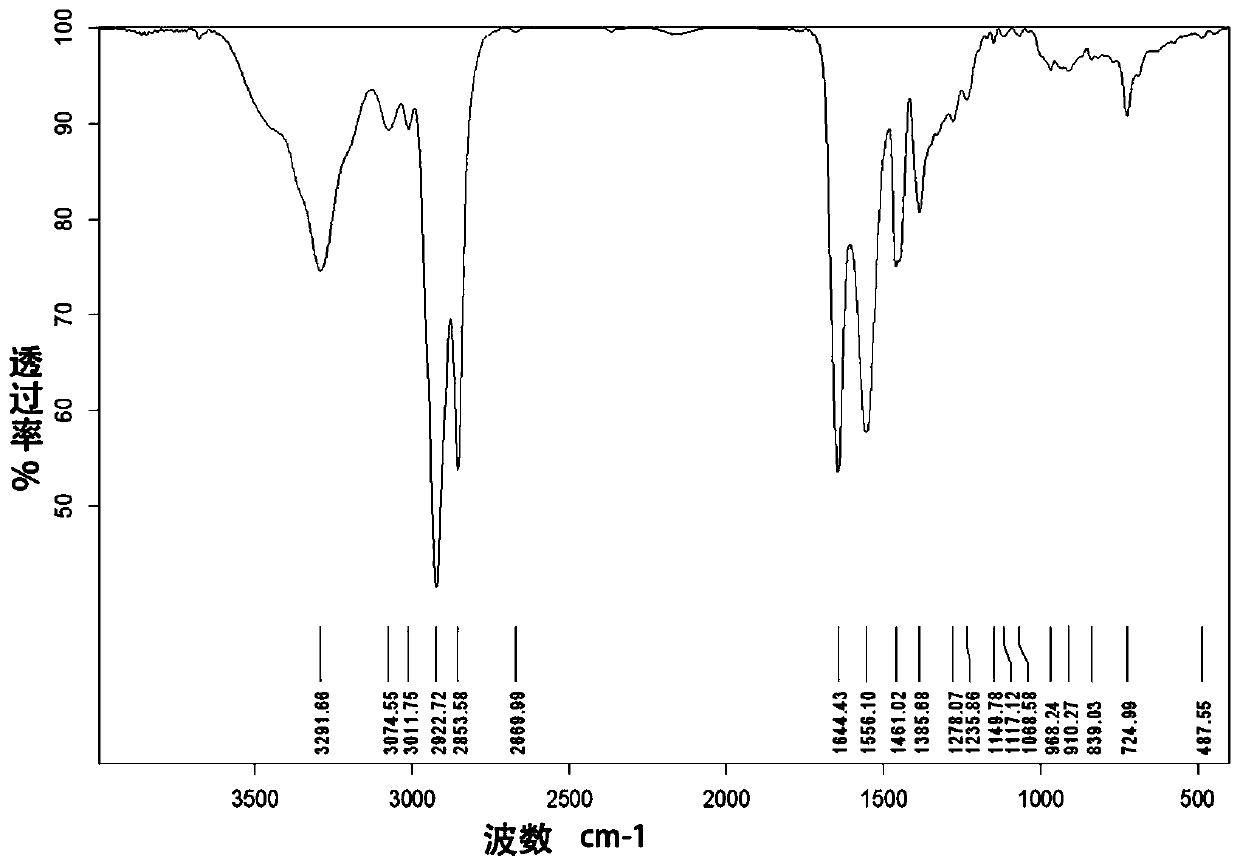

[0048] Embodiment 3 preparation of bisactive polyamide

[0049] Add 378 grams of tetraethylenepentamine, 146 grams of triethylenetetramine, 77.5 grams of N-aminoethylpiperazine and 564 grams of high-purity dimer acid ATUREX 1001 and 460 grams of industrial linolenic acid (fatty acid) in a three-necked bottle of 2000 milliliters Composition: 56wt% of linolenic acid, 17wt% of linoleic acid, 25wt% of oleic acid, 2wt% of other fatty acids), heated up to 180°C for 8 hours and removed water, cooled to obtain bisactive polyamide PA3, set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com