Block polyether elasticity organosilicone softener and preparation method and application thereof

A silicone softener, block polyether technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of poor product stability and unfavorable wide use, and achieve the effect of excellent elastic feel and style characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

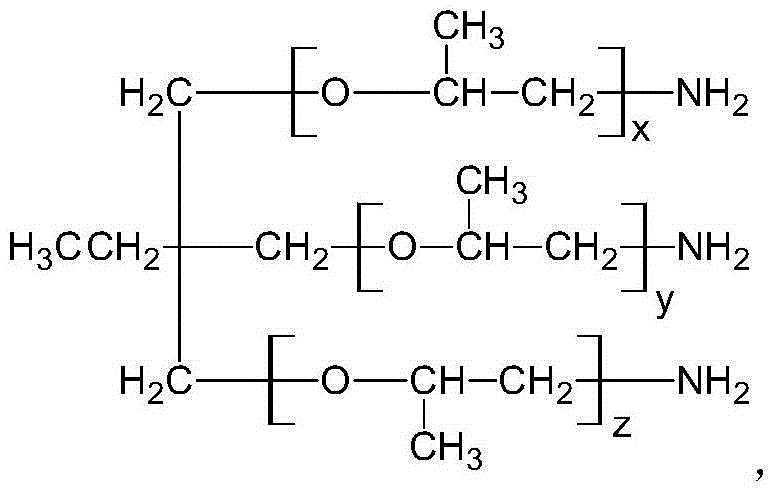

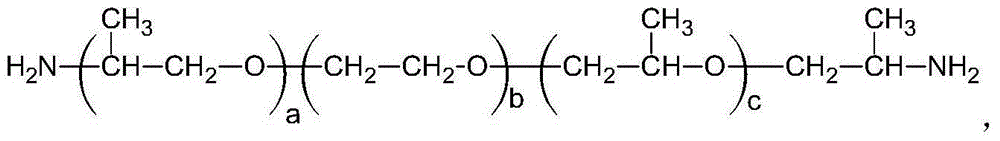

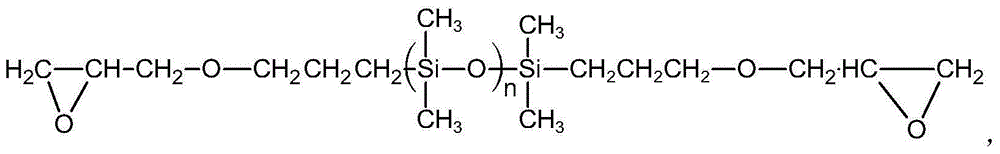

[0028] In a four-necked flask equipped with a thermometer, a reflux condenser and an electric stirrer, add 9g of formula (1) structure 60g formula (2) structure 369g of isopropanol, heated with a water bath, slowly warming up, when the temperature is controlled at 40°C, pre-react for 1 hour, then continue to heat up to 60-70°C, slowly add 300g of formula (3) end epoxy silicone oil dropwise to In the diamino-based polyether (i.e. the substance of the formula (2)) and the tertiary amino-based polyether (i.e. the substance of the formula (1)), the temperature is slowly raised to 70-90°C, and the reaction time is controlled at 5-25 hours. After the end, lower the temperature to below 40°C, add 7 parts of glacial acetic acid, and slowly add 2237 parts of deionized water to obtain a block polyether elastic silicone softener.

[0029]

Embodiment 2

[0031] In a four-necked flask equipped with a thermometer, a reflux condenser and an electric stirrer, add 55g of the formula (4) structure 30g of formula (2) structure 385g of isopropanol, heated in a water bath, and slowly raised the temperature. When the temperature was controlled at 35°C, pre-reacted for 1 hour, and then continued to heat up to 60-70°C, slowly added 300g of formula (5) end epoxy silicone oil to the In the diamino-based polyether (i.e. the substance of formula (2)) and the tertiary amino-based polyether (i.e. the substance of formula (4)), the temperature is slowly raised to 70-90°C, and the reaction time is controlled at 5-25 hours. After the end, lower the temperature to below 40°C, add 7 parts of glacial acetic acid, and slowly add 2303 parts of deionized water to obtain a block polyether elastic silicone softener.

[0032]

Embodiment 3

[0034] In a four-necked flask equipped with a thermometer, a reflux condenser and an electric stirrer, add 55g of formula (4) structure 65g formula (6) structure 420g of isopropanol, heated in a water bath, and slowly raised the temperature. When the temperature was controlled at 45°C, pre-reacted for 1 hour, and then continued to heat up to 60-70°C, slowly added 300g of formula (5) epoxy silicone oil to the In the diamino-based polyether (i.e. the substance of the formula (6)) and the tertiary amino-based polyether (i.e. the substance of the formula (4)), the temperature is slowly raised to 70-90°C, and the reaction time is controlled at 5-25 hours. After the end, lower the temperature to below 40°C, add 7 parts of glacial acetic acid, and slowly add 2513 parts of deionized water to obtain a block polyether elastic silicone softener.

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com