Epoxy resin water-permeable material curing agent and preparation method and application thereof

A water-permeable material and epoxy resin technology, applied in the field of epoxy resin water-permeable material curing agent and its preparation, can solve the problems of multi-phase system that cannot exist stably for a long time, shrinkage or uneven distribution of pores, and lack of water permeability, etc. Achieve the effects of multi-phase stabilization, adjustable pore size and porosity, and excellent air and water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

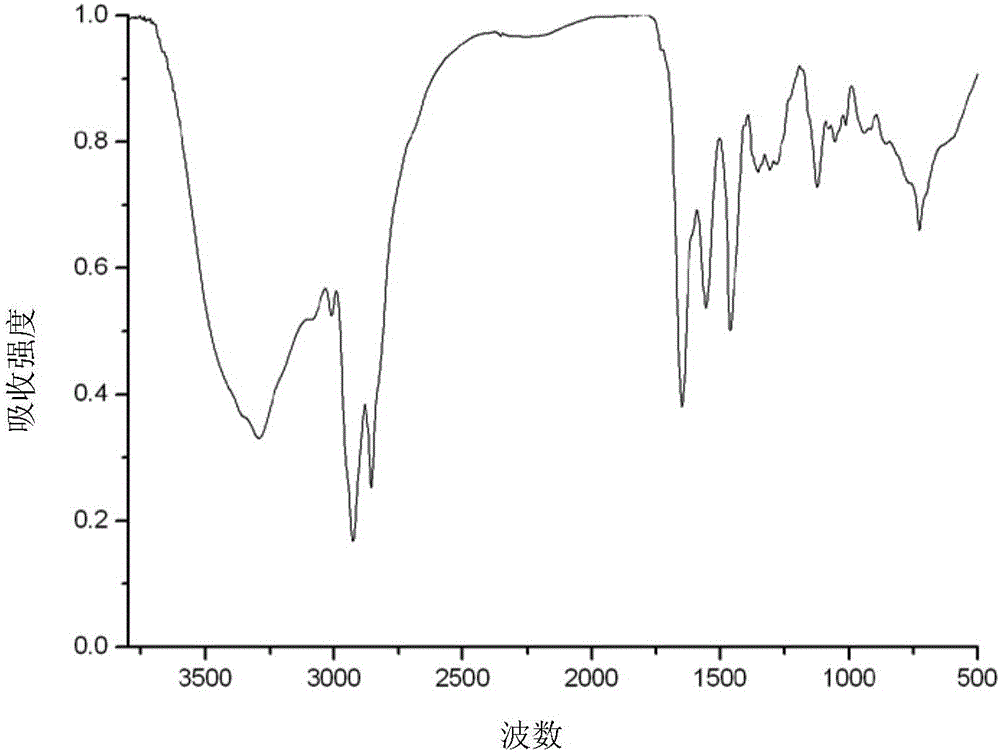

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of curing agent

[0031] Add 144g of ricinoleic acid and 50g of diethylenetriamine into a three-necked flask with stirring and a thermometer, raise the temperature to 110-160°C under stirring, react for 5-10 hours, and remove the continuously produced water to finally get Curing agent 1 was added.

Embodiment 2

[0032] Embodiment 2: the preparation of curing agent

[0033] Add 280g of dimerized ricinoleic acid and 50g of diethylenetriamine into a three-necked flask with stirring and a thermometer, raise the temperature to 130-200°C under stirring, react for 5-10 hours, and remove the continuously produced water, Curing agent 2 was finally obtained.

Embodiment 3

[0034] Embodiment 3: the preparation of curing agent

[0035] Add 220.6g of tetrameric ricinoleic acid and 20g of diethylenetriamine into a three-necked flask with stirring and a thermometer, raise the temperature to 130-200°C under stirring, react for 5-10 hours, and remove the continuously produced water , finally obtained curing agent 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com