Preparation method of dibasic acid chain extension modified epoxy resin

A technology of epoxy resin and dibasic acid, which is applied in the field of preparation of dibasic acid chain extension modified epoxy resin, which can solve the problem of poor adhesion of matrix resin, unstable storage of emulsion, and poor clustering of tows, etc. problems, to achieve the effect of improving initial adhesion, improving clustering, and improving emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

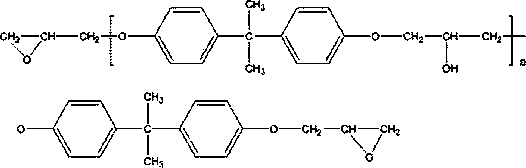

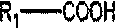

[0036] Embodiment 1, a kind of preparation method of dibasic acid chain extension modified epoxy resin, its steps are as follows:

[0037] 1. Add 200 parts by weight of epoxy resin E51 to the reactor, then add 70 parts by weight of polyethylene glycol PEG-1000, heat and stir at 50°C to make it evenly dispersed, and then add an appropriate amount of compound catalyst to raise Temperature to 120°C, react for 2 hours, and the reaction product is polyethylene glycol modified epoxy resin.

[0038] 2. Add an appropriate amount of mixed acid compounded by lauric acid and adipic acid to the product, wherein the molar ratio of lauric acid and adipic acid is 1:2, then add an appropriate amount of compound accelerator, and react at 110°C for 4 hours. The final product is dibasic acid chain extension modified epoxy resin.

Embodiment 2

[0039] Embodiment 2, a kind of preparation method of dibasic acid chain extension modified epoxy resin, its steps are as follows:

[0040] 1. Add 220 parts by weight of epoxy resin E44 to the reactor, then add 60 parts by weight of polyethylene glycol PEG-1500, heat and stir at 50°C to make it evenly dispersed, and then add an appropriate amount of compound catalyst to raise Temperature to 120°C, react for 2 hours, and the reaction product is polyethylene glycol modified epoxy resin.

[0041] 2. Add an appropriate amount of mixed acid compounded with oleic acid and sebacic acid to the product, wherein the molar ratio of oleic acid and sebacic acid is 1:2, then add an appropriate amount of compound accelerator, and react 4 at 110°C Hours, the final product is dibasic acid chain extension modified epoxy resin.

Embodiment 3

[0042] Embodiment 3, a kind of preparation method of dibasic acid chain extension modified epoxy resin, its steps are as follows:

[0043] 1. Add 230 parts by weight of epoxy resin E51 to the reactor, then add 55 parts by weight of polyethylene glycol PEG-1000, heat and stir at 50°C to make it evenly dispersed, and then add an appropriate amount of compound catalyst to raise Temperature to 120°C, react for 2 hours, and the reaction product is polyethylene glycol modified epoxy resin.

[0044] Two, add the compounded mixed acid of appropriate amount of stearic acid and maleic acid in the product again, wherein the mol ratio of stearic acid and maleic acid is 1:1, then add appropriate polymerization inhibitor and compound accelerator, React at 130°C for 3 hours, and the final product obtained is dibasic acid chain extension modified epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com