Enhanced printing and aluminum plating water-based polyester primer and preparation method thereof

A water-based polyester and water-soluble polyester technology, applied in polyester coatings, coatings, etc., can solve problems such as decreased adhesion, decreased strength of printing layer and aluminized layer, decreased adhesion strength of printed layer and aluminized layer, etc. , to achieve the effect of high water resistance, good water dispersibility and dispersion stability, and excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

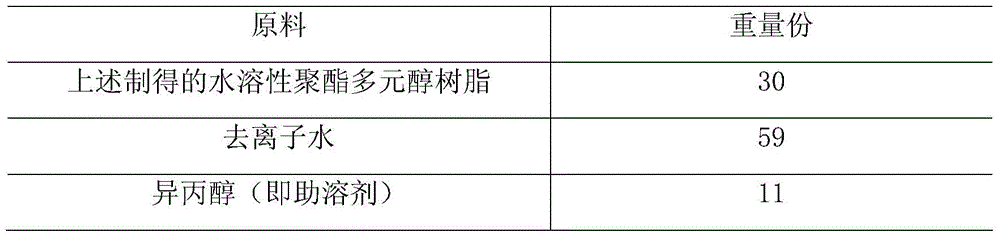

[0020] The embodiment of the present invention also provides a method for preparing the above-mentioned water-based polyester primer for enhanced printing and aluminum plating, comprising the following steps:

[0021] Get each component that forms by above-mentioned water-based primer, each component is water-soluble polyester polyol resin, cosolvent and deionized water;

[0022] Add the deionized water and co-solvent in the raw materials into the dispersing cylinder with a high-speed disperser, turn on the high-speed disperser, control the speed at 2000-3000 rpm, and slowly add the water-soluble polyester polyol resin in multiple times, Disperse at 60-80°C for 3-4 hours, cool down to room temperature after the resin is completely dissolved, and make a product with a solid content of 25-45%, a rotational viscosity of 50-200mPa·s at 25°C, and a pH value of 4-7. Solution, that is, enhanced printing and aluminum plating water-based primer.

[0023] Preferably, the co-solvent is ...

Embodiment 1

[0038] This embodiment provides a water-based polyester primer for enhanced printing and aluminum plating, the preparation method of which is as follows:

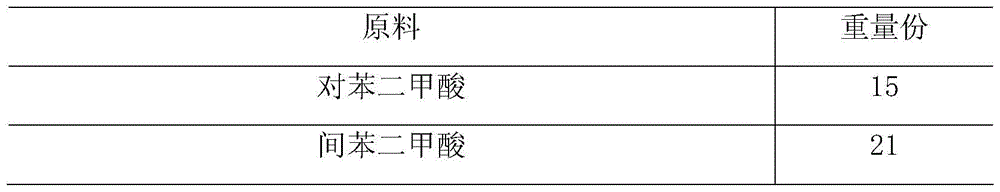

[0039] (1) prepare water-soluble polyester polyol resin, its raw material gets as follows:

[0040]

[0041]

[0042] This water-soluble polyester polyol resin is specifically prepared according to the following steps:

[0043] Add terephthalic acid, 1,4-cyclohexanedicarboxylic acid, 1,3-propanediol, ethylene glycol, antimony acetate and tetrakis[β-(3,5-di-tert-butyl- 4-Hydroxyphenyl) propionate] pentaerythritol ester; vacuumize to -0.1MPa, fill with nitrogen to return to normal pressure, stir well, keep warm at 150°C for 2 hours, then gradually increase the temperature to 210-230°C, and react for 2 hours , complete one-time esterification, and slip out 4 mass parts of water; after one-time esterification reaction is completed, isophthalic acid, isophthalic acid-5-sodium sulfonate, and potassium carbonate are added i...

Embodiment 2

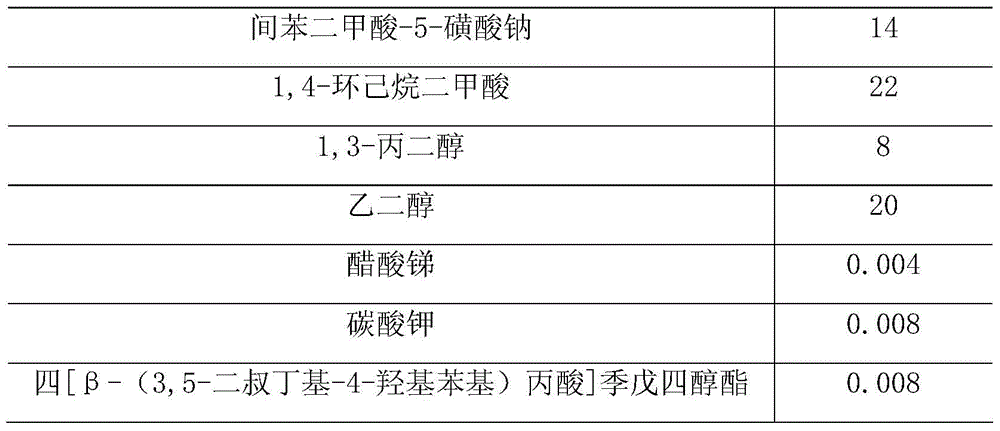

[0050] This embodiment provides a water-based polyester primer for enhanced printing and aluminum plating, the preparation method of which is as follows:

[0051] (1) prepare water-soluble polyester polyol resin, its raw material gets as follows:

[0052]

[0053] This water-soluble polyester polyol resin is specifically prepared according to the following steps:

[0054] Add terephthalic acid, 1,3-propanediol, ethylene glycol, tetra-n-butyl titanate and triphenyl phosphite in sequence in the polyester reactor; vacuumize to -0.1MPa and then fill with nitrogen to return to normal pressure. Fully stir evenly, keep warm at 150°C for 2 hours, then gradually increase the temperature to 210-230°C, react for 3 hours, complete the first esterification, and slip out 5 parts by mass of water; after the first esterification reaction, add isophthalic acid, m-benzene Diformic acid-5-sodium sulfonate and zinc acetate were added to the polyester synthesis kettle, vacuumed to -0.1MPa, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com