A kind of low surface energy moisture curing polyurethane hot melt adhesive and preparation method thereof

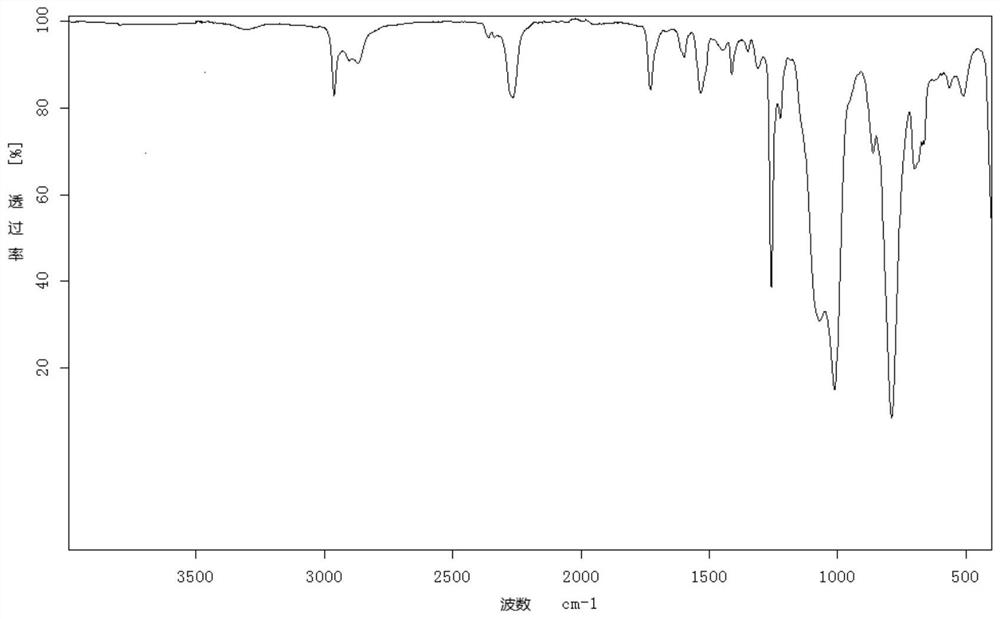

A polyurethane hot-melt adhesive, low surface energy technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of reducing the NCO content of the finished adhesive, high melt viscosity, initial tack and final tack strength Low problems, to achieve the effect of improving the curing speed, simplifying the reaction process and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

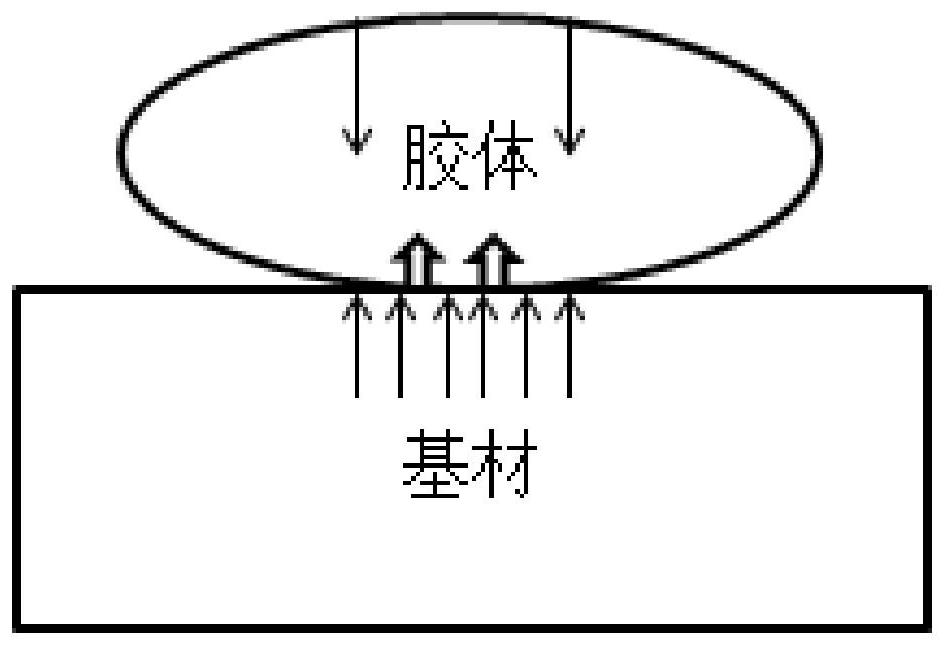

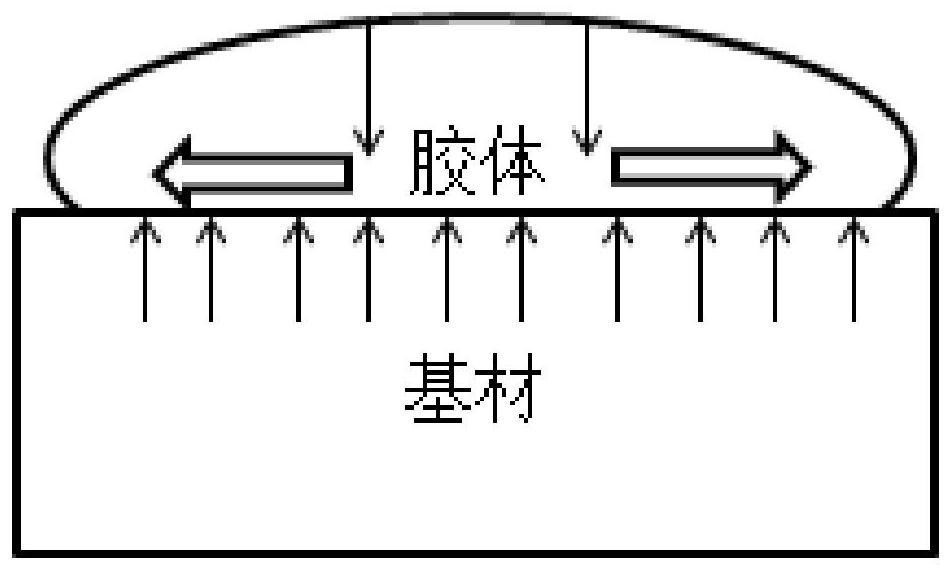

Method used

Image

Examples

Embodiment 1

[0032] A preparation method for low surface energy moisture-cured polyurethane hot-melt adhesive, comprising the following steps:

[0033] Step 1: In parts by weight, take the following raw materials: 79.70 parts of silicone polyol with molecular weight of 2000g / mol, 10 parts of silane-terminated polyether with molecular weight of 5000g / mol, 20.25 parts of diphenylmethane diisocyanate, antioxidant 0.5 part of 1010, 0.05 part of stannous octoate and 1 part of white carbon black;

[0034] Step 2: Add silicone polyol and silane-terminated polyether into the reaction kettle, start stirring, and vacuum dehydrate at 120°C and -0.1Mpa for 2 hours to obtain the first mixture;

[0035] Step 3: Take a sample of the first mixture to test that the moisture is less than 100ppm, lower the temperature in the kettle to 75-85°C, add diphenylmethane diisocyanate under the protection of an inert gas, and react at a speed of 400 rpm for 2 hours to obtain the second mixture;

[0036] Step 4: Add...

Embodiment 2

[0038] A kind of preparation of low surface energy moisture curing polyurethane hot-melt adhesive, comprises the following steps:

[0039] Step 1: In parts by weight, take the following raw materials: 84 parts of silicone polyols with a molecular weight of 3000 g / mol, 15 parts of silane-terminated polyether with a molecular weight of 3000 g / mol, 15 parts of diphenylmethane diisocyanate, antioxidant 1.0 parts of 168, 0.03 parts of dibutyltin dilaurate and 1.5 parts of white carbon black;

[0040] Step 2: Add silicone polyol and silane-terminated polyether into the reaction kettle, start stirring, and vacuum dehydrate at 120°C and -0.1Mpa for 2 hours to obtain the first mixture;

[0041] Step 3: Take a sample of the first mixture to test that the moisture is less than 100ppm, lower the temperature in the kettle to 75-85°C, add diphenylmethane diisocyanate under the protection of an inert gas, and react at a speed of 500 rpm for 2 hours to obtain the second mixture;

[0042] St...

Embodiment 3

[0044] A kind of preparation of low surface energy moisture curing polyurethane hot-melt adhesive, comprises the following steps:

[0045] Step 1: In parts by weight, take the following raw materials: 85.7 parts of silicone polyols with a molecular weight of 3300 g / mol, 16 parts of silane-terminated polyurethane with a molecular weight of 8000 g / mol, 14.2 parts of diphenylmethane diisocyanate, and 1010 parts of antioxidant 0.5 part, 0.5 part of antioxidant 168, 0.08 part of stannous octoate and 2 parts of white carbon black;

[0046] Step 2: Add silicone polyol and silane-terminated polyurethane into the reaction kettle, start stirring, and vacuum dehydrate at 120°C and -0.1Mpa for 2 hours to obtain the first mixture;

[0047] Step 3: Take a sample of the first mixture to test that the moisture is less than 100ppm, lower the temperature in the kettle to 75-85°C, add diphenylmethane diisocyanate under the protection of an inert gas, and react at a speed of 450 rpm for 2 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com