Organic silicon adhesive, organic silicon OCA and preparation method and application of organic silicon OCA

An organic silica gel and adhesive technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of low production efficiency, affecting production efficiency, unable to meet diversified applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

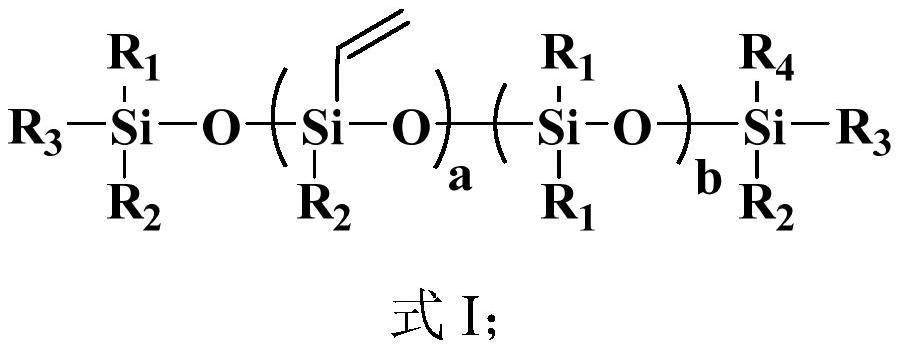

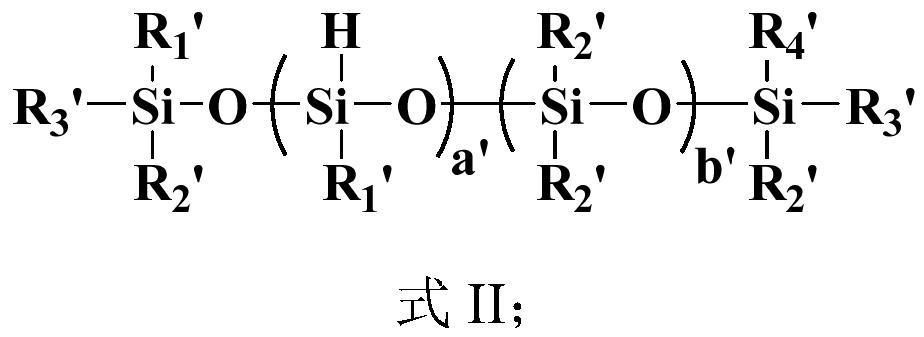

Method used

Image

Examples

Embodiment 1

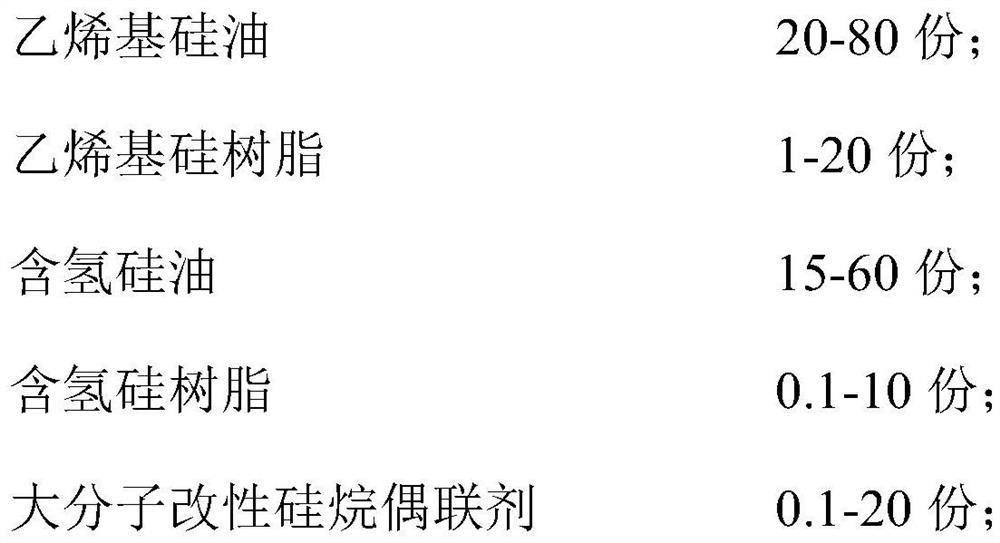

[0094] This embodiment provides a silicone adhesive. The raw materials for the preparation of the silicone adhesive include the following components in parts by weight:

[0095]

[0096]

[0097] The preparation method of the silicone adhesive is as follows: mix the above formula with vinyl silicone oil, vinyl silicone resin, hydrogen-containing silicone oil, hydrogen-containing silicone resin, macromolecule modified silane coupling agent, catalyst and auxiliary agent, and then mix it at 600rpm Stir for 240 min, filter, and stand for defoaming to obtain the silicone adhesive.

Embodiment 2

[0099] This embodiment provides a silicone adhesive. The raw materials for the preparation of the silicone adhesive include the following components in parts by weight:

[0100]

[0101] The preparation method of the silicone adhesive is as follows: mix the above formula with vinyl silicone oil, vinyl silicone resin, hydrogen-containing silicone oil, hydrogen-containing silicone resin, macromolecule modified silane coupling agent, catalyst and auxiliary agent, and then mix it at 600rpm Stir for 240 min, filter, and stand for defoaming to obtain the silicone adhesive.

Embodiment 3

[0103] This embodiment provides a silicone adhesive. The raw materials for the preparation of the silicone adhesive include the following components in parts by weight:

[0104]

[0105]

[0106] The preparation method of the silicone adhesive is as follows: mix the above formula with vinyl silicone oil, vinyl silicone resin, hydrogen-containing silicone oil, hydrogen-containing silicone resin, macromolecule modified silane coupling agent, catalyst and auxiliary agent, and then mix it at 600rpm Stir for 240 min, filter, and stand for defoaming to obtain the silicone adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Pull-out strength | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com