Preparation method for concrete release agent

A technology of concrete release agent and mixed solvent, which is applied in the direction of base material, petroleum industry, lubricating composition, etc. It can solve the problems of difficult peeling, mold adhesion, and poor release effect of the release agent, so as to achieve difficult peeling and reinforcement Clogging, the effect of improving the surface water-repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

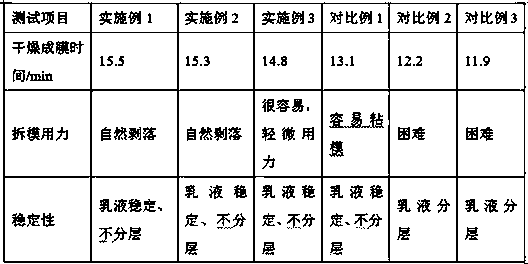

Examples

preparation example Construction

[0030] The preparation method of the additive is as follows: ball mill microcrystalline cellulose, calcium stearate soap, water, ethanolamine and propylene glycol fatty acid ester at a mass ratio of 8 to 12:2:3:2 to 4:3 at 500 r / min, and filter , Collect the filter residue and dry at 50°C for 1 hour to obtain the additive.

[0031] Catalyst A is formed by mixing lithium hydroxide and dibutyltin dilaurate at a mass ratio of 3:1-3.

[0032] The chain extender is any one of 1,4-butanediol and methyldiethanolamine.

[0033] The initiator is any one of benzoyl peroxide and potassium persulfate.

[0034] The cross-linking agent is formed by mixing trimethylolpropane and pentaerythritol in a mass ratio of 3:2-4.

[0035] A preparation method of concrete release agent, the preparation method may further comprise the steps:

[0036] (1) Put tung oil, mixed solvent and additives into the reaction kettle at a mass ratio of 7-9:14-16:2-6, preheat at 50°C for 40 minutes, add a catalyst ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com