A kind of preparation method of aqueous polyurethane

A water-based polyurethane and prepolymer technology, applied in the field of polyurethane, can solve the problems of easy gelation and poor thermal storage stability of polyurethane, achieve good water resistance, solve the contradiction between hydrophilicity and water resistance, and store stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

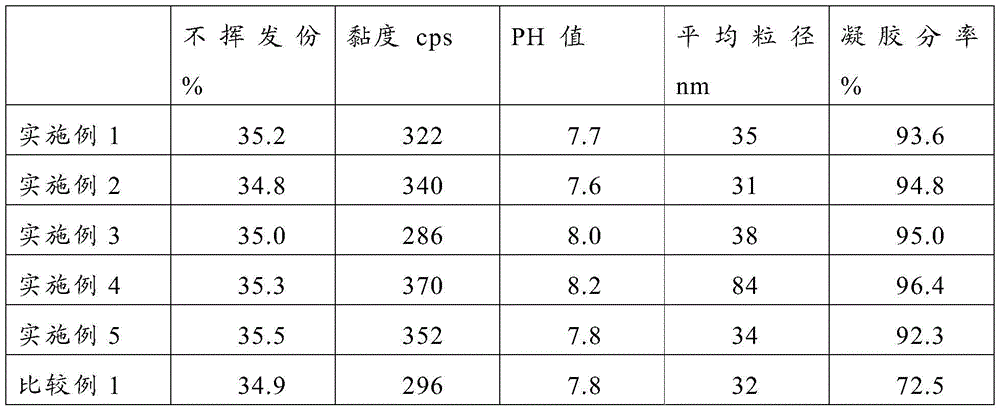

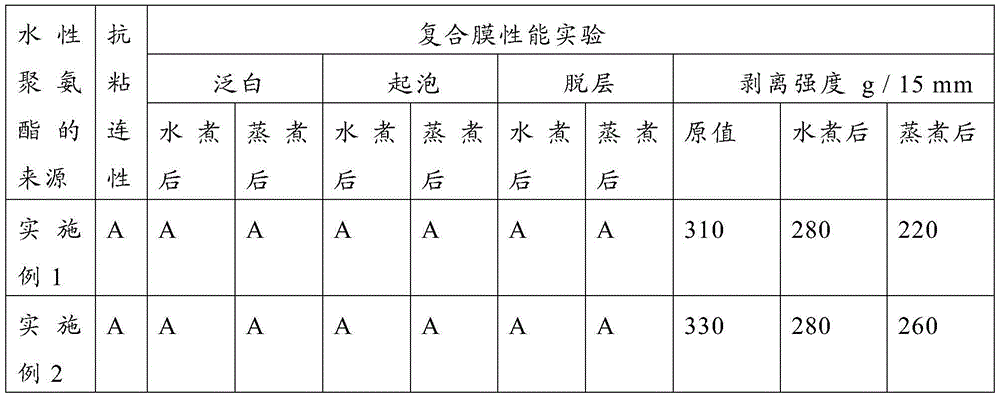

Examples

preparation example Construction

[0021] The embodiment of the present invention discloses a kind of preparation method of waterborne polyurethane, comprises the following steps:

[0022] (A) A prepolymer solution with self-emulsifying property by reacting diisocyanate, polyol, and hydrophilic chain extender under the action of a catalyst;

[0023] (B) adding water to the prepolymer solution to emulsify it, and then reacting with polyamine to obtain waterborne polyurethane;

[0024] The polyamines include at least 10 wt% of polymer amines.

[0025] According to the present invention, firstly, a prepolymer solution is prepared by using diisocyanate, polyol and hydrophilic chain extender as raw materials under the action of a catalyst. The diisocyanate is preferably aliphatic diisocyanate, alicyclic diisocyanate, aromatic diisocyanate, more preferably ethylene diisocyanate, 1,6-hexamethylene diisocyanate, 2,2,4-trimethyl Hexamethylene diisocyanate, 2,6-diisocyanatocaproic acid, isophorone diisocyanate, hydroge...

Embodiment 1

[0036] Add 48.6g of vacuum-dehydrated polycarbonate diol (molecular weight: 1000) and IPDI32.6g into the four-neck flask, heat while stirring, under the protection of nitrogen, completely melt the polycarbonate diol, and raise the temperature to 85°C. Reaction, when the NCO content reaches the theoretical value of 10.1%. Then, 6.5 g of DMPA, 0.1 g of dibutyltin laurate, and 25 g of acetone were added to the reaction container, and reacted at 80° C. for 2 hours. Then, 42 g of acetone was added to obtain a solution of a urethane prepolymer having an NCO group at the end. At this time, the NCO content is 4.7% in terms of solids. This prepolymer is designated A1.

[0037] Add 5.0 g of triethylamine to the prepolymer A1, and then mix it with 344 g of deionized water to obtain an O / W emulsion. Add 50 g of acetone solution of polyamide 651, including 45 g of acetone and 5 g of polyamide 651, mix and stir evenly, raise the temperature to 60° C. after the addition, and continue stir...

Embodiment 2

[0040] Add butylene adipate diol (molecular weight is 1250) 60.9g, IPDI32.6g in the four-necked flask of vacuum dehydration, heat while stirring, under nitrogen protection, make butylene adipate diol Completely melt, heat up to 85°C for reaction, when the NCO content reaches the theoretical value of 8.8%. Then, 6.5 g of DMPA, 0.1 g of dibutyltin laurate, and 25 g of acetone were added to the reaction container, and reacted at 80° C. for 2 hours. Then, 42 g of acetone was added to obtain a solution of a urethane prepolymer having an NCO group at the end. At this time, the NCO content is 4.2% in terms of solids. This prepolymer is designated A2.

[0041] Add 5.0 g of triethylamine to the prepolymer A2, and then mix it with 344 g of deionized water to obtain an O / W emulsion. Add 50g of polyamide 651 and diethylenetriamine-acetone mixed solution, including 45g of acetone, 3g of polyamide 651, and 2g of diethylenetriamine, mix and stir evenly, heat up to 60°C after addition, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com