A room temperature quick-drying epoxy curing agent dispersion, its preparation method and application

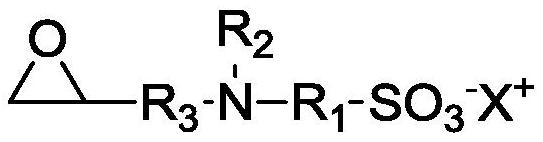

An epoxy curing agent and curing agent technology, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of insufficient emulsion stability, large amount of emulsifier, and unfavorable quick drying of the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

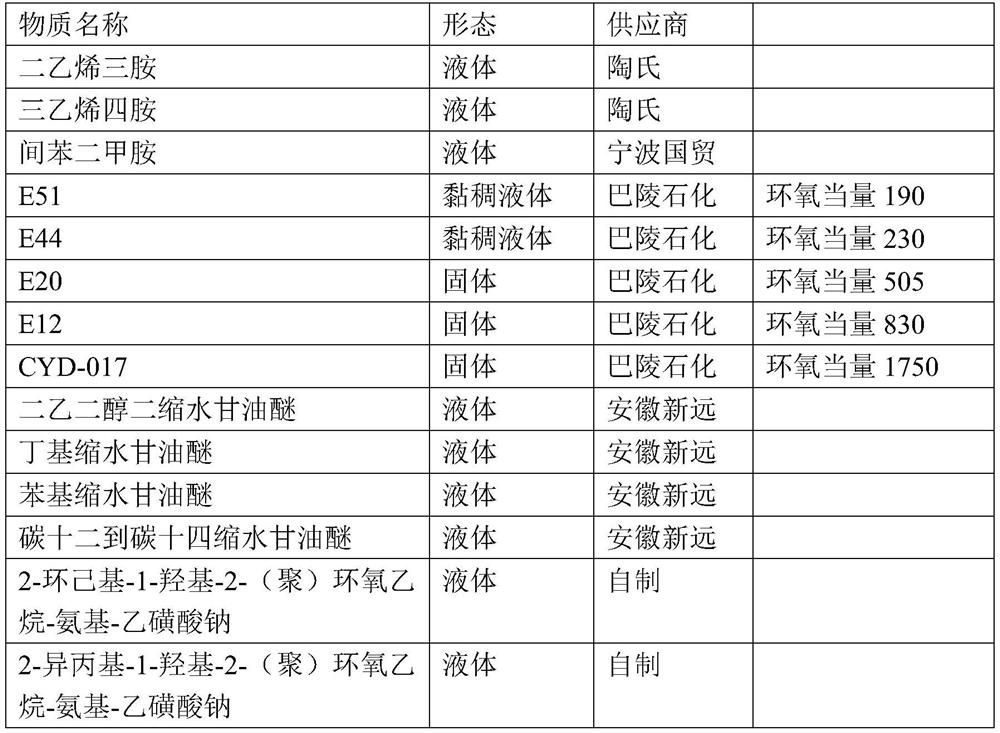

Embodiment example 1

[0095] Implementation Case 1: Add 400g of diethylenetriamine to the reaction flask, preheat the temperature to 80°C, and gradually drop 140g of epoxy E51 and E20 mixed liquid (mass ratio 1:1) into the reaction flask using a peristaltic pump. Adding time lasts for 1 hour, continue to keep warm for half an hour, use vacuum pump to carry out reduced pressure distillation, remove excess amine, then add 50g propylene glycol methyl ether to the system for dispersion, and then use peristaltic pump to gradually drop 50g butyl glycidyl ether Put it into the reaction bottle, add dropwise for 1 hour, keep warm for half an hour, slowly add 3g of 2-cyclohexyl-1-hydroxyl-2-oxirane-amino-ethanesulfonate sodium A into the system, and discharge after 10 minutes of reaction. Stir mechanically with a disperser, add 200 g of water slowly, and obtain 568 g of curing agent dispersion after phase inversion.

[0096] Curing agent dispersion viscosity: 3700cP Particle size: 720nm Solid content: 56.0% ...

Embodiment example 2

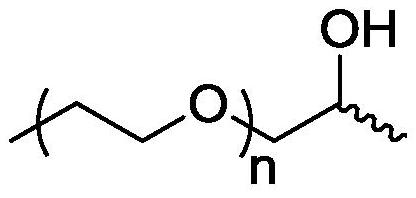

[0097] Example 2: Add 320g of triethylenetetramine to the reaction flask, preheat the temperature to 80°C, and gradually drop 120g of epoxy E20 and E44 mixed liquid (mass ratio 1:2) into the reaction flask using a peristaltic pump. Adding time lasts for 1 hour, continue to keep warm for half an hour, use vacuum pump to carry out reduced pressure distillation, remove excess amine, then add 60g propylene glycol methyl ether to the system for dispersion, and then use peristaltic pump to gradually drop 80g phenyl glycidyl ether Put into the reaction bottle, add dropwise for 1 hour, keep warm for half an hour, put 25g 2-cyclohexyl-1-hydroxyl-2-polyethylene oxide-amino-ethanesulfonate sodium B (the polyethylene oxide structure contains 20 EO structure, molecular weight 500) was slowly added into the system, reacted for 10 minutes and discharged, mechanically stirred by a disperser, slowly added 200g of water, and 565g of curing agent dispersion was obtained after phase inversion.

...

Embodiment example 3

[0099] Example 3: Add 260g of diethylenetriamine to the reaction bottle, preheat the temperature to 80°C, add 180g of epoxy E12 and E51 mixed liquid (mass ratio 2:1) into the reaction bottle in five batches, and the total The time lasts for 1 hour, and the heat preservation is continued for 1 hour. Use a vacuum pump to carry out reduced pressure distillation to remove excess amine, then add 90g of acetone to the system for dispersion, and then use a peristaltic pump to shrink 100g of carbon dodecyl to carbon tetradecyl Glycerin ether is gradually dropped into the reaction bottle, the time of dropping is half an hour, and the temperature is kept for half an hour. Slowly add 15g of 2-cyclohexyl-1-hydroxy-2-oxirane-amino-ethanesulfonate sodium A into the system and react for 10 minutes After discharging, use a disperser to mechanically stir, slowly add 400g of water, and remove the acetone after phase inversion to obtain 765g of curing agent dispersion.

[0100] Curing agent disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com