Open-cell type heat-conducting epoxy matrix composite porous material and preparation method and application thereof

A porous material and thermal conductivity technology, applied in the field of porous materials, can solve the problems that do not involve the strength of porous materials, the limited number of reusable times, the influence of material strength, etc., and achieve the effects of excellent air permeability and water permeability, good thermal conductivity, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

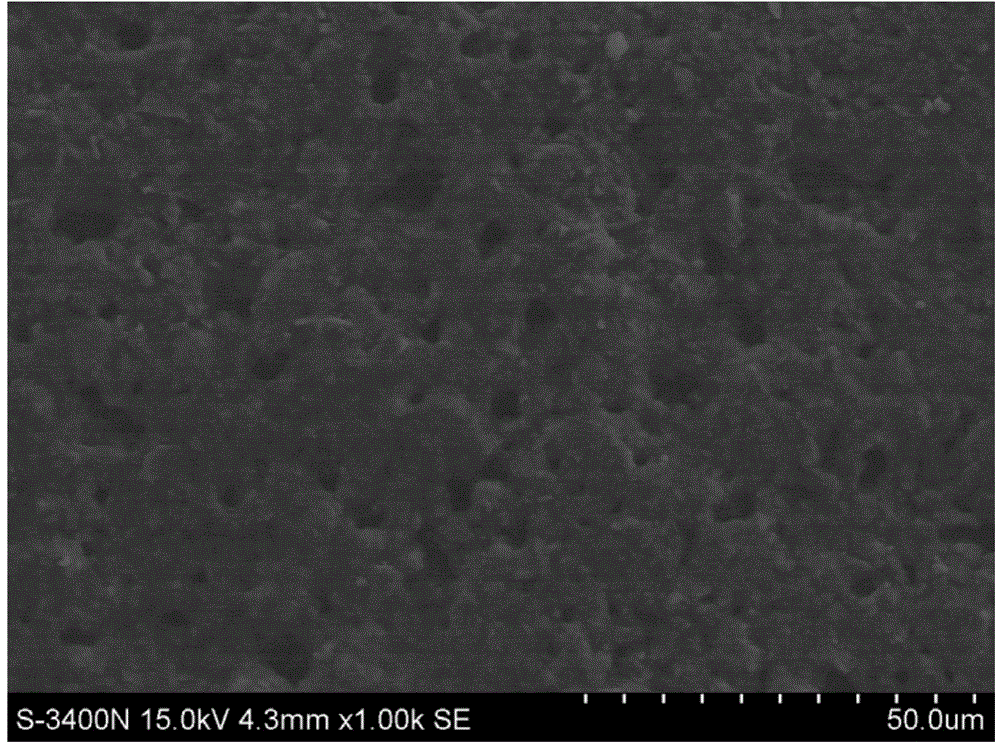

Image

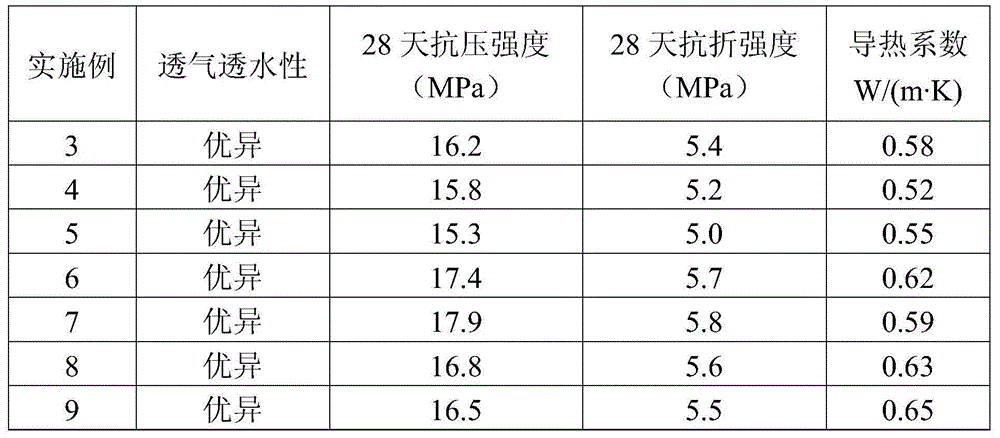

Examples

Embodiment 1

[0043]Preparation of polyoxypropylene polyether modified epoxy resin:

[0044] Add 800g of polyether N210 into a 5000mL three-necked flask, then add 167g of TDI under stirring, and raise the temperature to 90°C for 3 hours. Then, 2500 g of E-44 epoxy resin was added, and the reaction was continued at 90° C. for 3 hours, and cooled to obtain modified epoxy resin E1 with a polyoxypropylene polyether percentage content of 23.1 wt%.

Embodiment 2

[0046] Preparation of modified amine curing agent:

[0047] (1) Amino-terminated dendritic polyamide-amine (PAMAM)

[0048] Add 0.3mol (34.86g) of 1,6-hexanediamine and 150g of anhydrous methanol into a 500mL three-necked flask, slowly add 1.2mol (103.2g) of methyl acrylate dropwise at room temperature, and drop it within 1 hour. Stirring was continued at room temperature for 4 hours, and then the temperature was raised to 70° C. for reflux reaction for 5 hours. Then distilled under reduced pressure to remove methanol. Cool, then add 1.2mol (139.44g) of 1,6-hexanediamine and 5g of methanol, heat up to 70°C for reflux reaction for 2 hours, distill under reduced pressure, remove methanol, and cool to obtain the first generation of dendrites with terminal amino groups Polyamidoamine PAMAM, counted as PAMAM1.

[0049] Take out 1 / 4 weight of PAMAM1, add 150g of anhydrous methanol again, slowly add 1.2mol (103.2g) of methyl acrylate dropwise at room temperature, drop it within 1 ...

Embodiment 3

[0062] An open-cell thermally conductive epoxy-based composite porous material is prepared through the following steps:

[0063] (1) At a room temperature of 35°C, add 50 g of silicon oxide with an average particle size of 100 μm, 200 g of silicon carbide of 30 μm, 65 g of montmorillonite of 10 μm and 175 g of water in sequence into a 1000 mL plastic measuring cup, and stir evenly (the stirring time is 10min, stirring speed is 500r / min), obtain filler-water suspension 490g;

[0064] (2) At a room temperature of 35°C, add 93g of the polyoxypropylene polyether modified epoxy resin E1 prepared in Example 1, 15g of aluminum hydroxide with an average particle size of 3μm, and an average particle size of 12g of silicon carbide with a diameter of 30μm and 90g of the modified polyamide PAM2 prepared in Example 2 were stirred rapidly at a stirring speed of 1000r / min for 3 minutes at 35°C to obtain epoxy resin-thermally conductive ceramic powder-modified 210g of amine premix;

[0065]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com