A cationic self-emulsifying water-based epoxy resin quick-drying curing agent

A water-based epoxy resin, cationic technology, used in epoxy resin coatings, coatings, etc., can solve problems such as slow drying speed, and achieve the effects of fast curing speed, high hardness and high cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

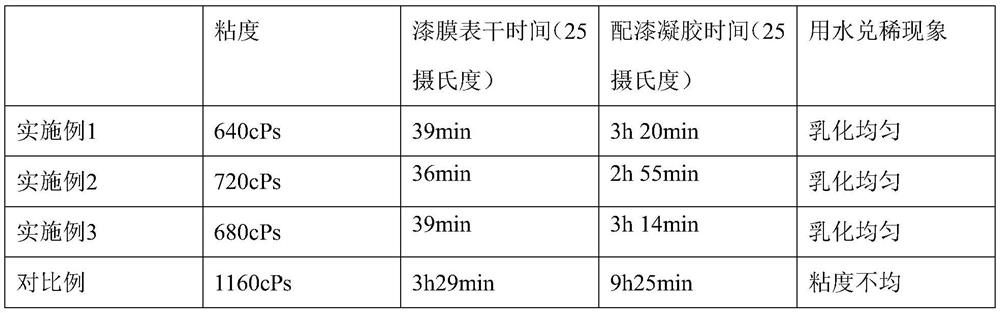

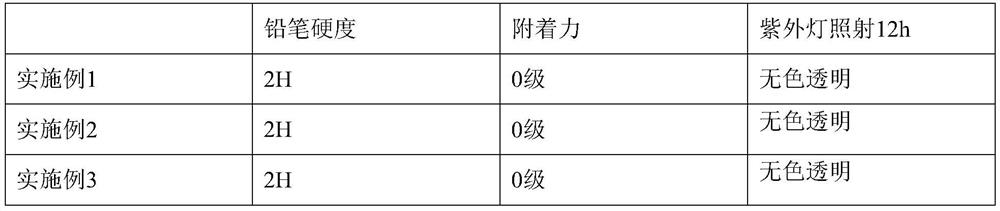

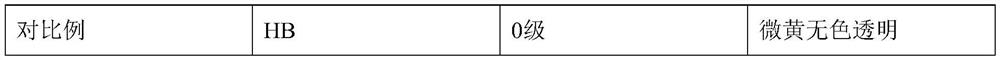

Examples

Embodiment 1

[0021] A cationic self-emulsifying water-based epoxy resin quick-drying curing agent, its molecule contains hydrophilic quaternary ammonium salt cations and non-ionic long-chain water-based groups; the polybasic aliphatic amines that can react with epoxy resins are located in the The branched chain position of the curing agent reacts with the epoxy resin to have a higher cross-linking density and faster surface drying.

[0022] In parts by weight, the free radical polymerization method of the cationic self-emulsifying water-based epoxy resin quick-drying curing agent comprises the following steps:

[0023] (1) Preparation of multi-component aliphatic amine monomer: Add 12 parts of 3,4-dihydroxy-1-butene to the reaction device under nitrogen and ice bath conditions, and then dropwise add 8 parts of p-toluenesulfonyl chloride, during the reaction process, absorb the acid gas released during the reaction through a calcium hydroxide drying tube. The temperature in the whole proces...

Embodiment 2

[0026] A cationic self-emulsifying water-based epoxy resin quick-drying curing agent, its molecule contains hydrophilic quaternary ammonium salt cations and non-ionic long-chain water-based groups; the polybasic aliphatic amines that can react with epoxy resins are located in the The branched chain position of the curing agent reacts with the epoxy resin to have a higher cross-linking density and faster surface drying.

[0027] In parts by weight, the free radical polymerization method of the cationic self-emulsifying water-based epoxy resin quick-drying curing agent comprises the following steps:

[0028] (1) Preparation of multi-component aliphatic amine monomer: Add 10 parts of 2,3-dihydroxy-1-butene to the reaction device under nitrogen and ice bath conditions, and then dropwise add 4 parts of chlorosulfonic acid, during the reaction process, the acid gas released during the reaction is absorbed through a sodium hydroxide drying tube. The temperature of the whole process d...

Embodiment 3

[0031] A cationic self-emulsifying water-based epoxy resin quick-drying curing agent, its molecule contains hydrophilic quaternary ammonium salt cations and non-ionic long-chain water-based groups; the polybasic aliphatic amines that can react with epoxy resins are located in the The branched chain position of the curing agent reacts with the epoxy resin to have a higher cross-linking density and faster surface drying.

[0032] In parts by weight, the free radical polymerization method of the cationic self-emulsifying water-based epoxy resin quick-drying curing agent comprises the following steps:

[0033] (1) Preparation of multi-component aliphatic amine monomer: Add 10.5 parts of trans-1,4-dihydroxy-2-butene to the reaction device under nitrogen and ice bath conditions, and then add it dropwise to the reactor under stirring conditions Add 5 parts of p-toluenesulfonic acid dropwise. During the reaction process, the acid gas released during the reaction is absorbed through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com