Patents

Literature

80results about How to "Anti-yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophilic block polyether amino silicone oil with amino branched chain, and preparation method and application thereof

The invention discloses hydrophilic block polyether amino silicone oil with an amino branched chain and a preparation method thereof. The hydrophilic block polyether amino silicone oil with the amino branched chain has the following structure as shown in the specification, wherein R1 is represented by formulas shown in the specification. The preparation method comprises the following steps: carrying out mixing reaction of tetramethyl dihydro disiloxane, polysiloxane and concentrated sulfuric acid, neutralizing with anhydrous sodium carbonate, carrying out reduced pressure pumping to remove a low-boiling-point substance, and thus obtaining silicone oil with the end containing hydrogen; carrying out mixing reaction of the silicone oil with the end containing hydrogen, allyl epoxy polyether and a catalyst, and thus obtaining epoxy silicone oil; carrying out mixing reaction of the epoxy silicone oil, polyether amine and a solvent, and thus obtaining block polyether amino silicone oil; and carrying out mixing reaction of the block polyether amino silicone oil, a silane coupling agent hydrolysate and an alkali catalyst, neutralizing with glacial acetic acid, and thus obtaining the hydrophilic polyether amino silicone oil with the amino branched chain.

Owner:江阴市诺科科技有限公司

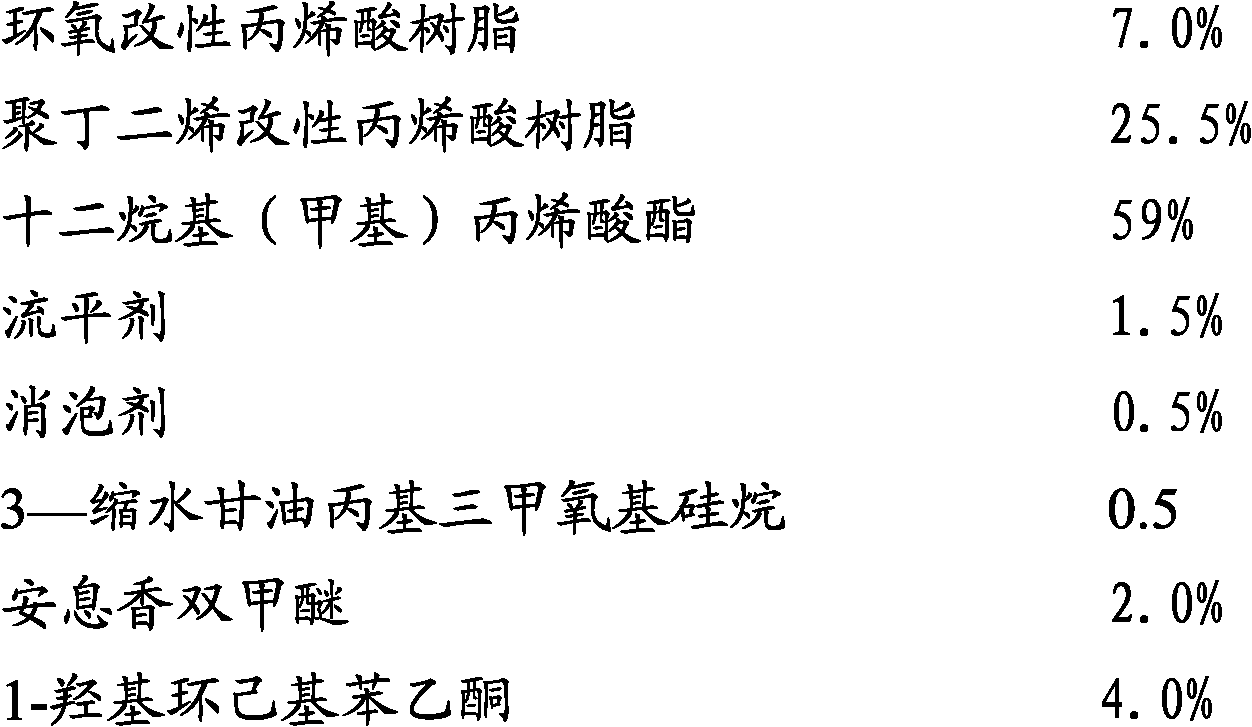

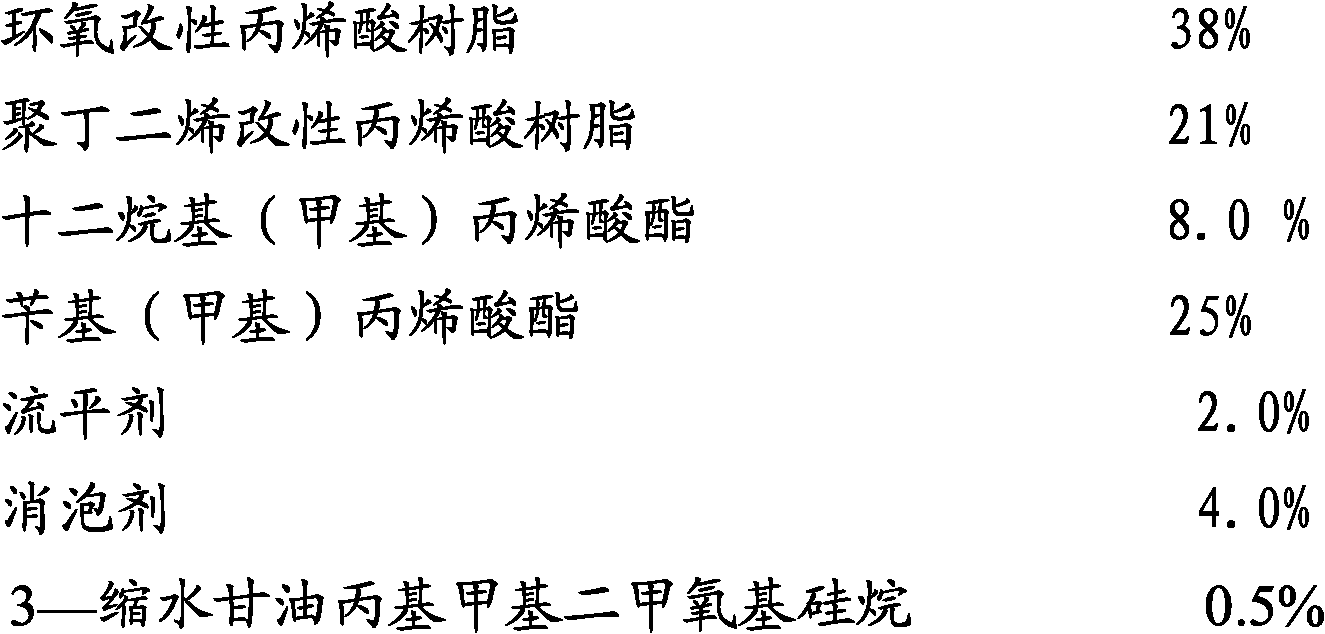

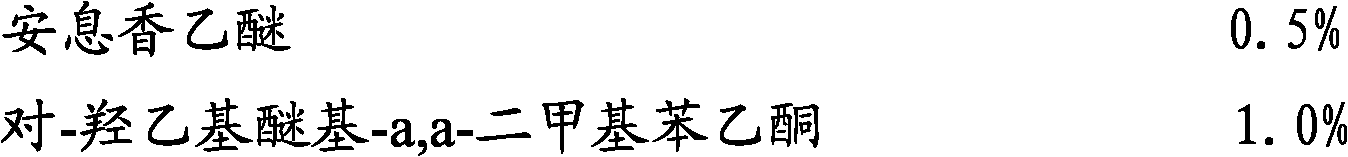

Ultraviolet curable adhesive with high light transmittance

ActiveCN102516889AThe overall space occupied is smallIncrease productivityOrganic non-macromolecular adhesiveUV curingOptical property

The invention discloses an ultraviolet curable adhesive with high light transmittance. The ultraviolet curable adhesive provided by the invention is prepared from the following raw materials of: by weight, 5.8-59% of modified acrylic acid oligomer resin, 5.8-59% of an acrylic acid monomer, 2-10% of an auxiliary agent, 0.5-15% of a silane coupling agent, and 1.5-10.5% of a photoinitiator. With the adoption of the above components in proportions, the adhesive provided by the invention has fast curing rate and excellent optical properties, the glue solution is colorless and transparent, its light transmittance after curing is greater than 95%, cure shrinkage is small, the internal stress is low, and caking capability is strong.

Owner:SHENZHEN PROSPER DOBOND TECH

Polyester resin composition for reflectors of light emitting devices and molded article using same

The present invention provides a polyester resin composition for reflectors of light emitting devices and a molded article using the same. The polyester resin composition includes: (A) a polyester resin having a crystallization temperature of about 200 DEG C to about 400 DEG C; (B) a polyester resin having a crystallization temperature of about 100 DEG C to less than about 200 DEG C; (C) a white pigment; (D) a filler; (E) a nucleating agent; and (F) a chain extender. The polyester resin composition can have superior heat resistance, impact resistance, cooling efficiency, reflectivity, yellowing resistance, and / or fluidity. The polyester resin composition is suitable for reflectors of light emitting devices.

Owner:LOTTE ADVANCED MATERIALS CO LTD

PVC stabilizing agent and preparation method thereof

The invention discloses a PVC stabilizing agent, which comprises 50 to 75 weight parts of organic weak-acidic rare-earth salt and 25 to 50 weight parts of zeolite reactor. The organic weak-acidic rare-earth salt is prepared by reacting 1 mole part of organic weak acid with 1 to 5 mole parts of natural rare-earth compound under an alkaline conduction, wherein the organic weak acid is one or more than two of phenylformic acid, oleic acid, stearic acid and stearic acid; and the rare-earth compound is one or more than two of the natural compounds of lanthanum, cerium, neodymium and europium. The zeolite reactor is that zeolites absorbing maleic anhydrides are arranged in a channel and a cage. The PVC stabilizing agent of the invention has the advantages of small dosage, self-lubrication, yellowing resistance, no pock and the like; and the PVC material prepared by the stabilizing agent of the invention has good thermal stability and plasticity.

Owner:GUANGZHOU UNIVERSITY

LED photocured inkjet ink suitable for high-speed ink jetting

InactiveCN104845451AImprove anti-aging propertiesImprove adsorption fastnessInksUltraviolet lightsEngineering

The invention discloses and provides LED photocured inkjet ink suitable for high-speed ink jetting, which does not evaporate a solvent, can reduce energy consumption, can reduce environmental pollution and is suitable for cold light source LEDs. The inkjet ink comprises the following components in parts by weight: 1-10 parts of a nanoscale pigment, 2-5 parts of an ultraviolet light absorber, 1-10 parts of a super dispersion agent, 2-10 parts of a quick initiator, 2-20 parts of a macromolecular prepolymer, 0.1-2 parts of a wetting and leveling agent, 0.1-1 part of a defoaming agent, 0.1-10 parts of an adhesion promoter, 5-10 parts of a combined monomer and 30-70 parts of a UV active diluent. According to the formula of the ink, the viscosity of the ink can be reduced, a spray head of a printer cannot be blocked, ultraviolet lights can be absorbed, curing energy can reach 130 mj / cm<2>, the curing speed of the ink can be increased, the curing time can be controlled within 5-20 seconds, and meanwhile, the transfer rate of printing pattern is improved; the LED photocured inkjet ink has long-acting antioxidative and anti-yellowing performances, high luster sensation and marresistance.

Owner:珠海欣威科技有限公司

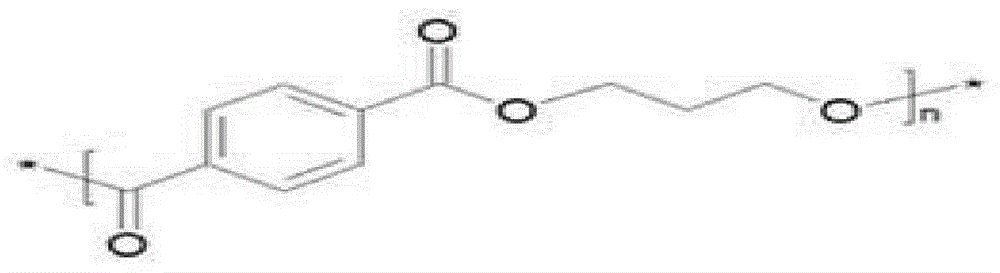

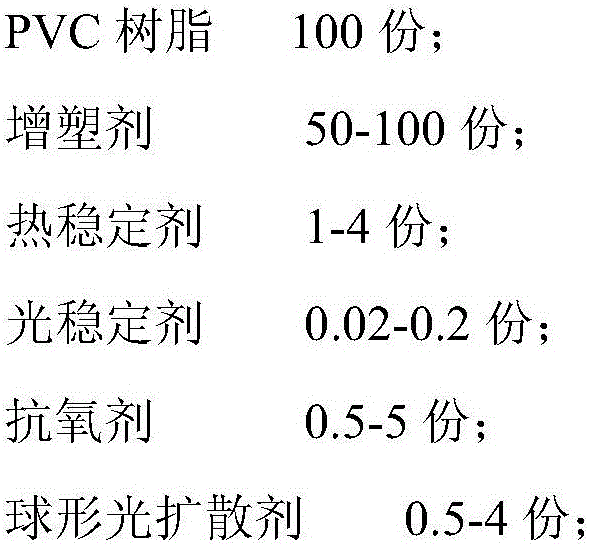

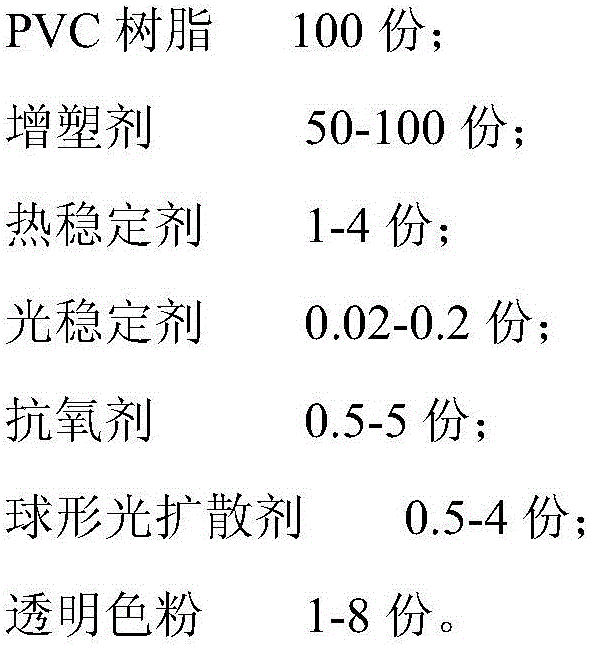

Photodiffusion-type flexible colored PVC (polyvinyl chloride) composition and application thereof

The invention relates to the technical field of high-polymer materials, and discloses a photodiffusion-type flexible colored PVC (polyvinyl chloride) composition and application thereof in photodiffusion-type flexible colored LED (light-emitting diode) decorative lamp bars. The composition comprises the following components in parts by weight: 100 parts of PVC resin, 50-100 parts of plasticizer, 1-4 parts of heat stabilizer, 0.02-0.2 part of light stabilizer, 0.5-5 parts of antioxidant, 1-4 parts of photodiffusant agent and 1-8 parts of transparent toner. The composition is prepared by the following steps: uniformly dispersing and mixing the components in a high-speed mixing machine, and carrying out screw extrusion granulation while controlling the screw temperature at 120-180 DEG C. The thickness of the rubber strip extruded by the extruder is 2mm, the haze is greater than or equal to 90%, and the light transmittance is greater than or equal to 70%. By using the high-yield low-price PVC resin as the main material and adding the cheap plasticizer and the composition composed of the heat stabilizer, light stabilizer, antioxidant, spherical photodiffusant, transparent toner and other aids, the prepared photodiffusion-type flexible PVC rubber strip has the advantages of low price and bright color, and overcomes the defects in PC (polycarbonate), PMMA (polymethyl methacrylate) and PS (polystyrene).

Owner:广东中联新材科技有限公司

Anti-yellowing high-temperature resistant wallpaper printing ink

Owner:LETONG CHEM CO LTD

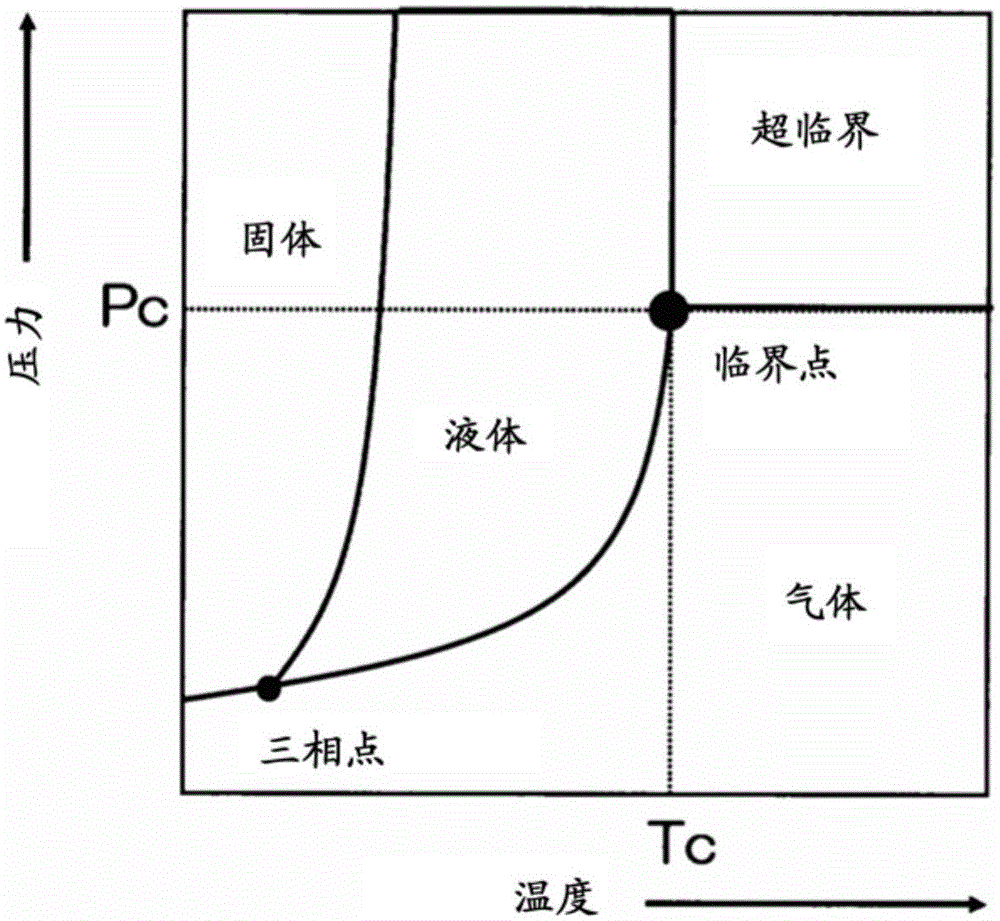

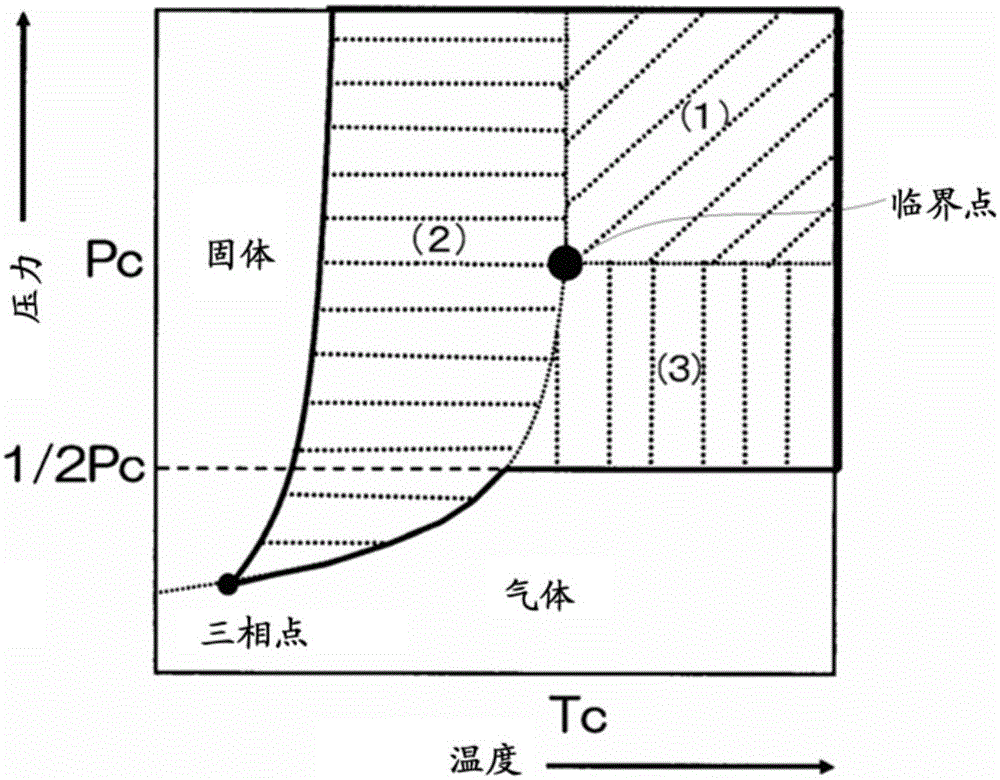

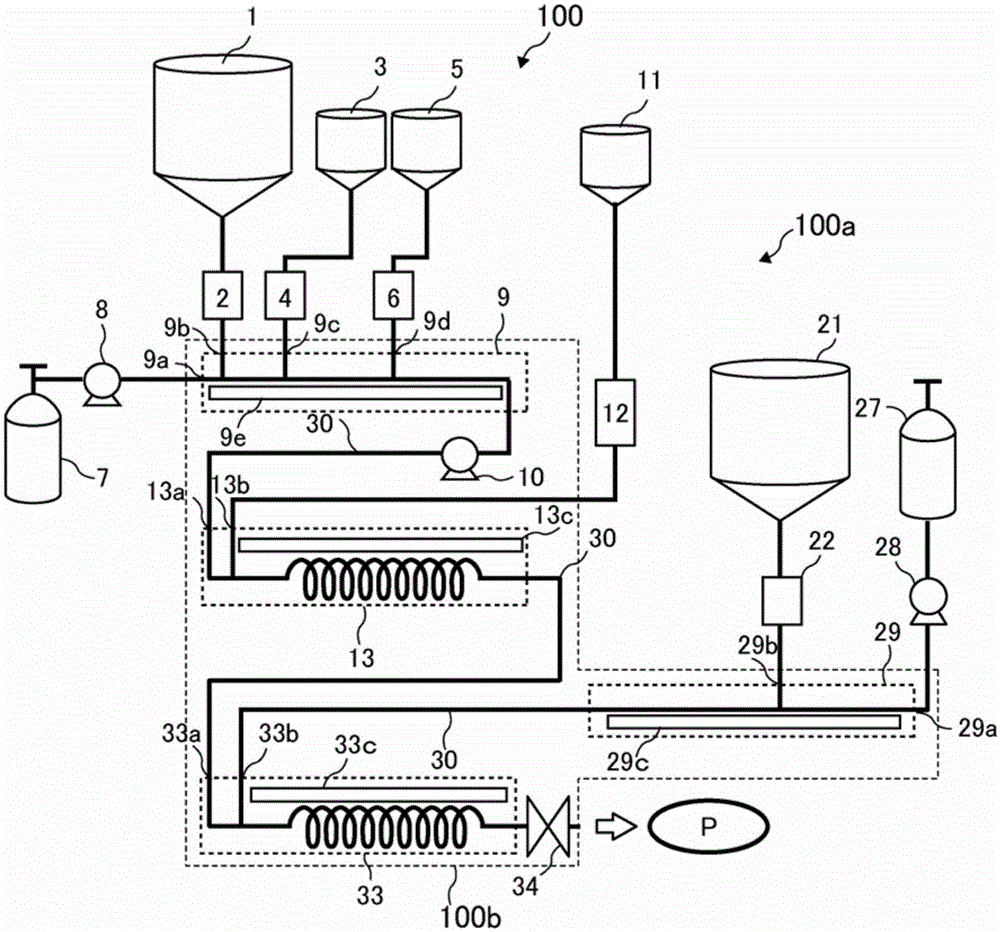

Polylactic acid composition, and production method and production apparatus of the same

Owner:RICOH KK

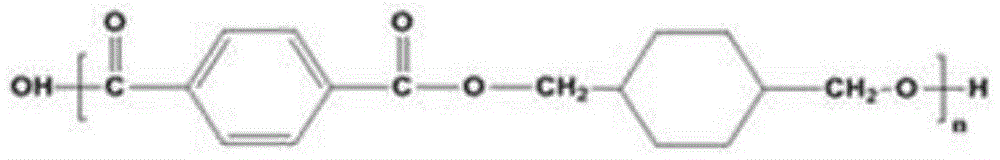

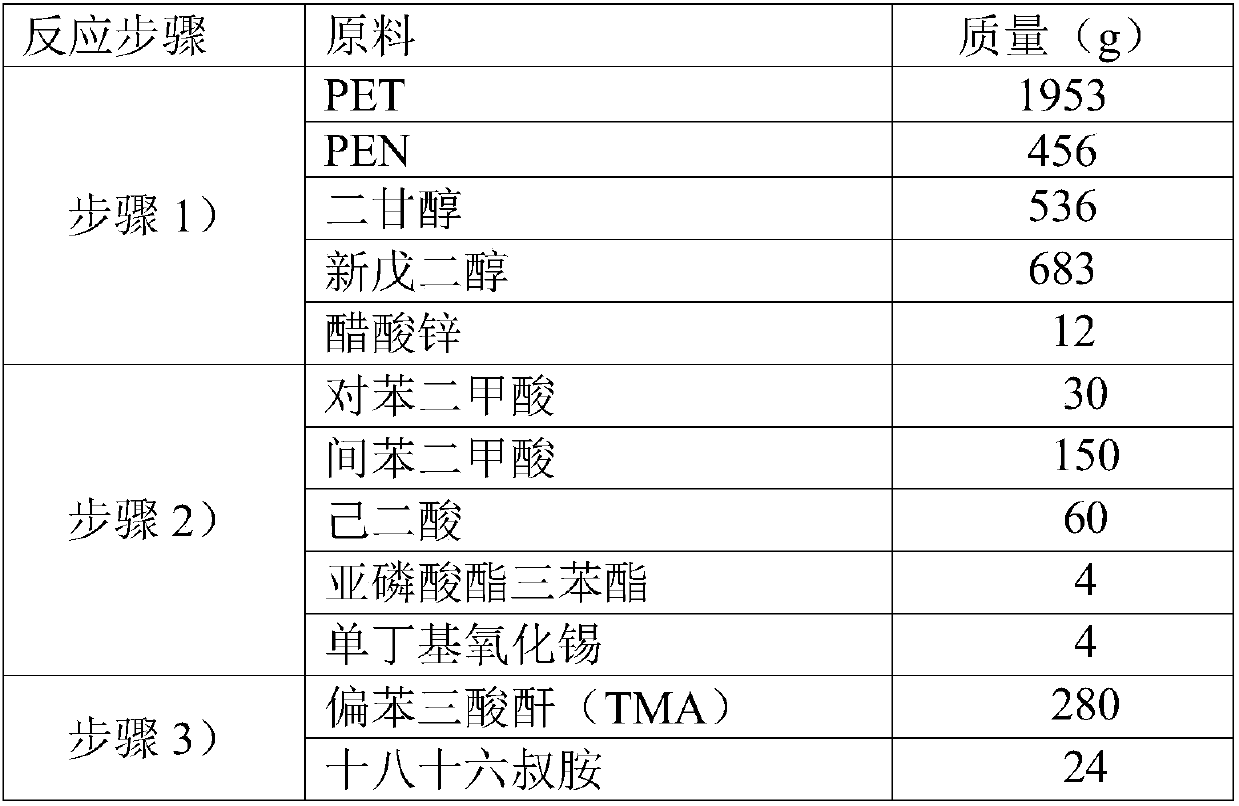

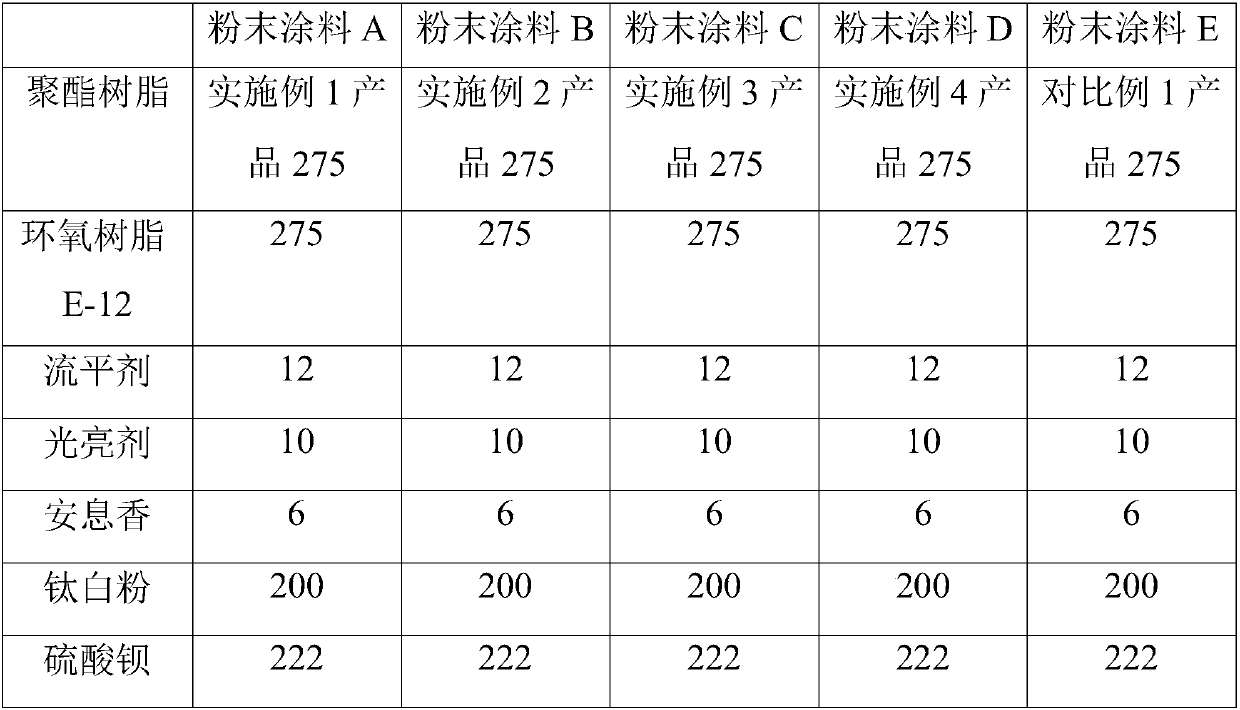

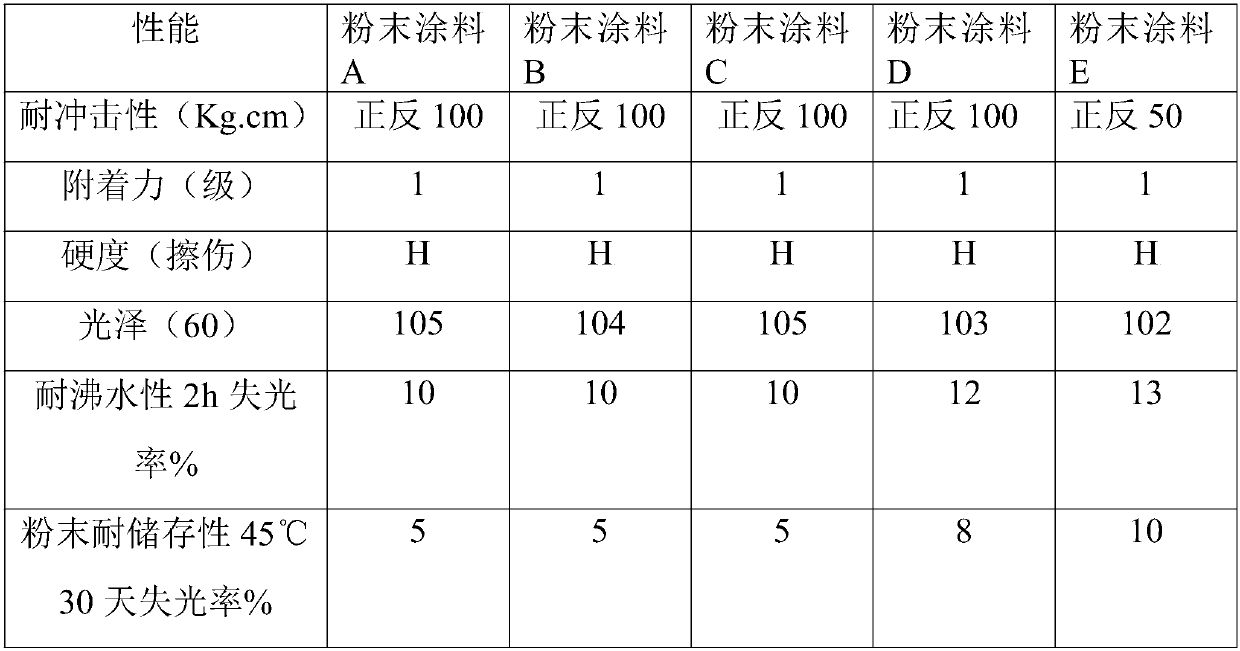

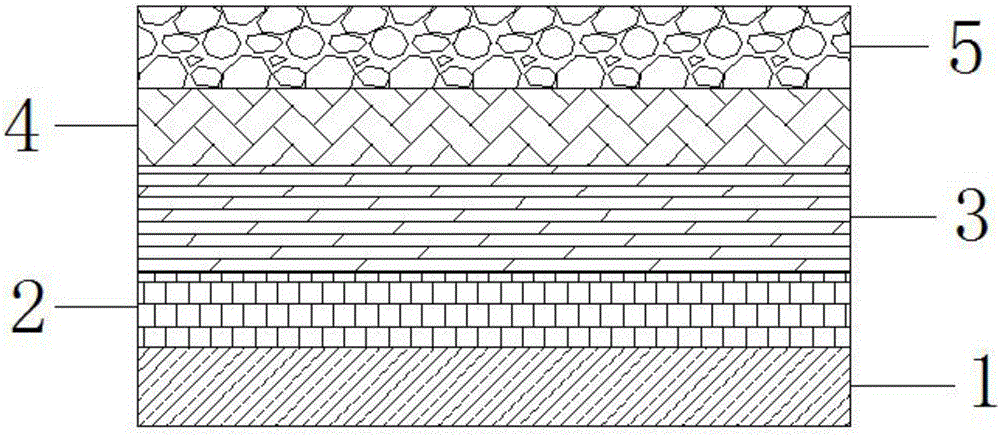

PEN modified polyester resin for epoxy polyester mixed powder paint and preparation method thereof

InactiveCN107603427AAchieve recyclingReduce generationPlastic recyclingPowdery paintsGlass transitionChemistry

The invention discloses a PEN modified polyester resin for epoxy polyester mixed powder paint. The PEN modified polyester resin for epoxy polyester mixed powder paint has an acid value of 68-75mgKOH / g, a viscosity of 2000-5500mPa.s / 200DEG C or an acid value of 48-55mgKOH / g, a viscosity of 3000-5500mPa.s / 200DEG C or an acid value of 32-35mgKOH / g, and a viscosity of 4000-6000mPa.s / 200DEG C. The preparation method includes: conducting alcoholysis on a mixture of PET and PEN in a mass ratio of 2.5-3:1 by polyol, then carrying out ester exchange reaction and / or esterification reaction with polyol,polyacid / anhydride, then carrying out decompression polycondensation reaction and trimellitic anhydride end-capping reaction, thus obtaining the polyester resin. The resin has the characteristics of ahigh glass transition temperature Tg above 58DEG C and high storage stability, and a board prepared from the polyester resin according to the standard formula has the characteristics of yellowing resistance, baking resistance, salt fog resistance and the like peculiar to powder paint produced by high quality polyester resin synthesis, and also has good gloss (greater than 105% (60DEG C glossmetertest)), and impact resistance (resistance to + / -100Kg.cm impact).

Owner:江苏宝田新材料股份有限公司

Potassium titanate crystal whisker composite quartz plate product and preparation method of composite quartz plate product

The invention discloses a potassium titanate crystal whisker composite quartz plate product. The potassium titanate crystal whisker composite quartz plate product is prepared from the following raw materials: a particle raw materials with a particle diameter of 0.045-5mm, quartz powder with a particle diameter of 0.005-0.045mm, decoration colored pigment, 0.1%-1% of a silane coupling agent, unsaturated polyester resin, potassium titanate crystal whiskers and a curing agent. According to the potassium titanate crystal whisker composite quartz plate product, the crystal whiskers are high in microscopic filling and reinforcing functions, and excellent in dispersibility in the resin; potassium hexatitanate crystal whiskers are used as a reinforcing agent and the unsaturated resin is used as a substrate for preparing light-weight, high-specific-strength, abrasion-resistant and high-surface-finishment composite quartz plate product. The composite quartz plate product is good in practicability and high in cost performance, and can be applied to the places such as airports, hospitals, office building, shops, restaurants, stadiums and the fields such as home decoration and construction decoration and the like.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

Organic silicon pouring sealant for LED (Light Emitting Diode) flexible lamp bar and preparation method thereof

ActiveCN105255440AHigh strengthImprove adhesionNon-macromolecular adhesive additivesPigment treatment with organosilicon compoundsSealantLight-emitting diode

The invention discloses an organic silicon pouring sealant for an LED (Light Emitting Diode) flexible lamp bar and a preparation method thereof. The raw material formula of the organic silicon pouring sealant for the LED flexible lamp bar comprises a component A and a component B, wherein the components A and B are both formed by kneading the vinyl silicon oil with the white carbon black subjected to in-situ treatment. According to the invention, the white carbon black subjected to in-situ treatment is taken as a reinforcing padding, so that the pouring sealant is endowed with excellent strength and transparency and has the characteristics of excellent caking property, ageing resistance, yellowing resistance, good light transmission, and the like. The cost of the pouring sealant is much lower than that of the system reinforced by silicon resin; the flexibility of the LED flexible lamp bar is obviously increased; the preparation method is simple and feasible; the dosage of the expensive thickening agent is less; no silicon resin is adopted; the cost performance is high; the viscosity is moderate; the sealant has excellent operability; the organic silicon pouring sealant contains no volatile solvent, is safe and non-toxic and is environmentally friendly and odor-free.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Fluororesin oil paint with weather resistance, temperature resistance and color retention

InactiveCN103694882AStrong adhesionBright and full colorAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinEthylene glycol bis

The invention relates to oil paint and particularly relates to fluororesin oil paint with weather resistance, temperature resistance and color retention. The fluororesin oil paint comprises the following materials in parts by weight: 20-24 parts of fluororesin, 12-15 parts of thermoplastic acrylic resin, 2-3 parts of sodium diacetate, 1-2 parts of ethylene glycol bis-glycidyl ether, 3-4 parts of isocyanuric acid tri-glycidyl ether, 10-12 parts of tripropylene glycol diacryate, 1-2 parts of europium trifluoroacetylacetone, 25-30 parts of urethane acrylate, 2-3 parts of polyacrylamide, 1-2 parts of ferrocene, 2-3 parts of isocyanate, 5-8 parts of epoxidized soybean oil, 1-2 parts of zinc naphthenate, 3-4 parts of diaminodiphenyl-methane, 5-6 parts of additive, 10-12 parts of dimethylbenzene and 10-12 parts of butyl acetate. The fluororesin oil paint has the advantages that the adhesive force of a paint film is strong, the color is bright and full, the color retention is lasting and yellowing resistance is achieved, also has the advantages of weather resistance, ageing resistance, temperature change resistance, anti-corrosion and anti-rusting performances and brushing resistance and the like and can be widely applied in protective decoration of articles in various environments.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

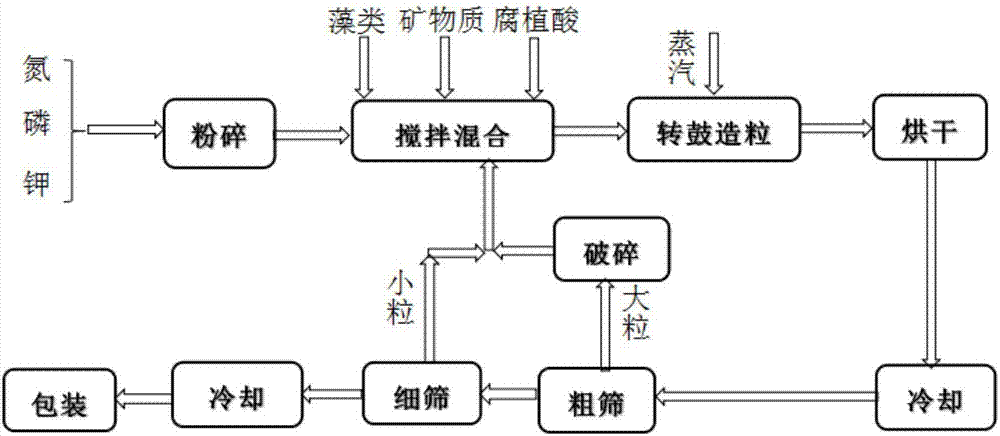

Compound fertilizer rich in mineral substances and production process of compound fertilizer

ActiveCN107382535ANo need for manual compoundingSimple structureExcrement fertilisersFertilizer mixturesCombustionMineral particles

The invention discloses a compound fertilizer rich in mineral substances. The compound fertilizer rich in mineral substances comprises the following raw materials in percentages by weight: A, 10-80% of mineral particles which are separated from coal or coal gangue before combustion or chemical conversion of the coal or coal gangue; B, 0-10% of an organic chelating agent; C, 5-40% of animal dung / algae raw materials which are treated biochemically; and optional D, 5-50% of at least one of a nitrogen fertilizer, a phosphatic fertilizer and a potash fertilizer. The mineral particles are rich in at least one of B, Ca, Cl, Cu, Fe, Mg, Mn, Mo, S and Zn which are necessary secondary and microelements for growth of plants. Mineral wastes in the coal chemical industry can be utilized economically and efficiently. The invention further discloses a preparation method of the compound fertilizer rich in the mineral substances.

Owner:SHENZHEN REVELATION TECH CO LTD

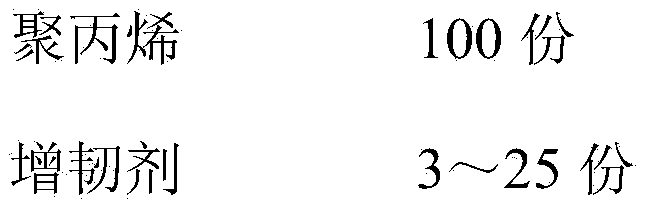

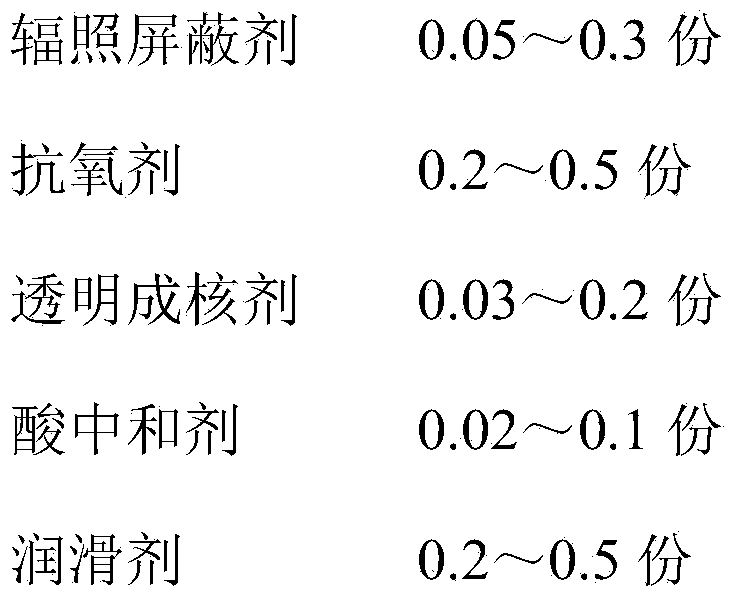

High-efficiency electron beam irradiation-resistant composite polypropylene material

The invention discloses a high-efficiency electron beam irradiation-resistant composite polypropylene material which is characterized by taking polypropylene resin as a base material and containing the following components in parts by weight: 0.05-0.3 part of irradiation screening agents and 100 parts of polypropylene resin, wherein the irradiation screening agents are compound mixtures of trans-1,2-diphenyl ethylene oxide and acenaphthylene, and the weight ratio of trans-1,2-diphenyl ethylene oxide to acenaphthylene is 1:(0.2-0.5). The high-efficiency electron beam irradiation-resistant composite polypropylene material disclosed by the invention has yellowing-resistant property, is capable of keeping the molecular transparency and ensuring that the transparency of the material can not be reduced, and can achieve the yellow index less than 1 by reducing the integrated mechanical property of the material within 5% and achieve the yellow index less than 1.3 by being naturally aged at normal temperature for 6 months. According to the prepared medical irradiation-resistant composite polypropylene material, the impact resistant property of a base material is enhanced before and after irradiation; and the physical property, chemical property and biological property can completely meet the requirements of an international YY / T0242-2007 'special material for polypropylene for medical transfusion, blood transfusion and syringes'.

Owner:上海新上化高分子材料有限公司

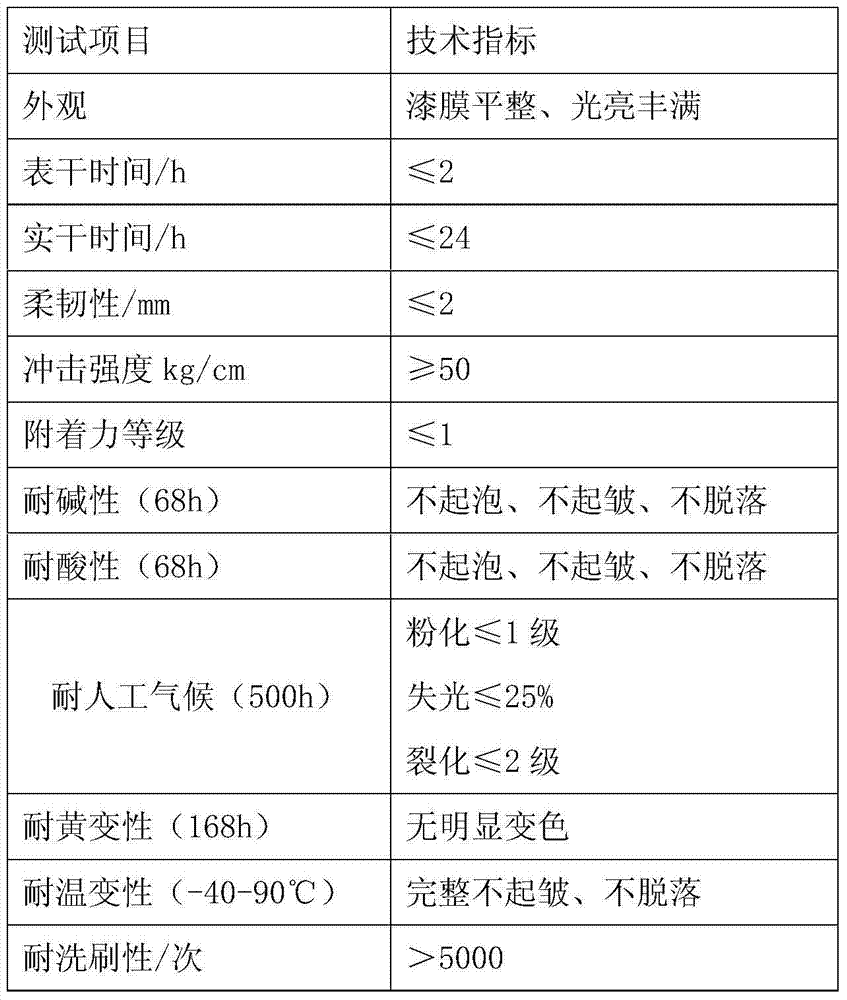

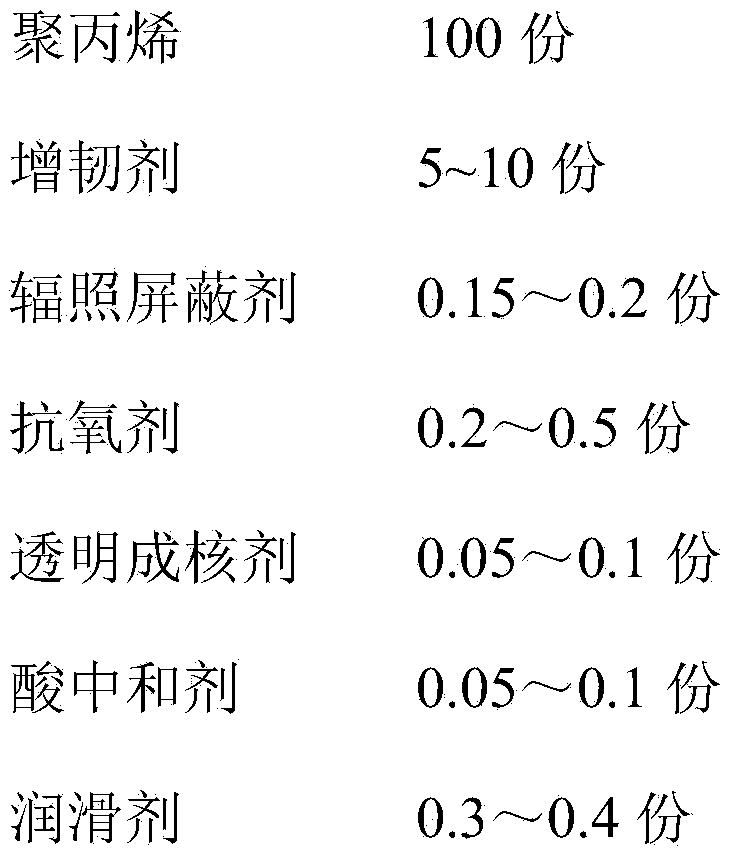

Super anti-stain soft-light wall paint

InactiveCN103073966ALow VOC contentHas super stain resistanceAntifouling/underwater paintsPaints with biocidesEmulsionSolvent

The invention discloses a super anti-stain soft-light wall paint, which comprises the following components in parts by weight: components A, B, C and D, wherein the component A comprises water A1, a thickener A2, a dispersant A3, a defoamer A4, a film coalescing aid A5, a bactericide A6, a wetter A7, a solvent A8 and a pH adjuster A9; the component B comprises rutile titanium dioxide B1, nanometer barium sulfate B2 and filler B3; the component C comprises a polyurethane thickener C1, a solvent C2, water C3, a defoamer C4 and an emulsion C5; and the component D comprises a hydrophobic modified alkali swelling thickener D1, water D2, an anti-stain aid D3 and a mould-proof anti-algae agent D4. The super anti-stain soft-light wall paint has the advantages as follows: (1) the wall paint meets the international environmental protection standard and is low in VOC (volatile organic compound) content; (2) the wall paint can be used for covering fine cracks on the wall surface, is superior in stain resistance and yellowing resistance and long in service life, and can be applied to inner and outer walls; and (3) the wall paint is convenient for construction, soft and uniform in luster, free from after-tack and excellent in long-term storage property.

Owner:ZHONGSHAN TAILAI PAINT CHEM

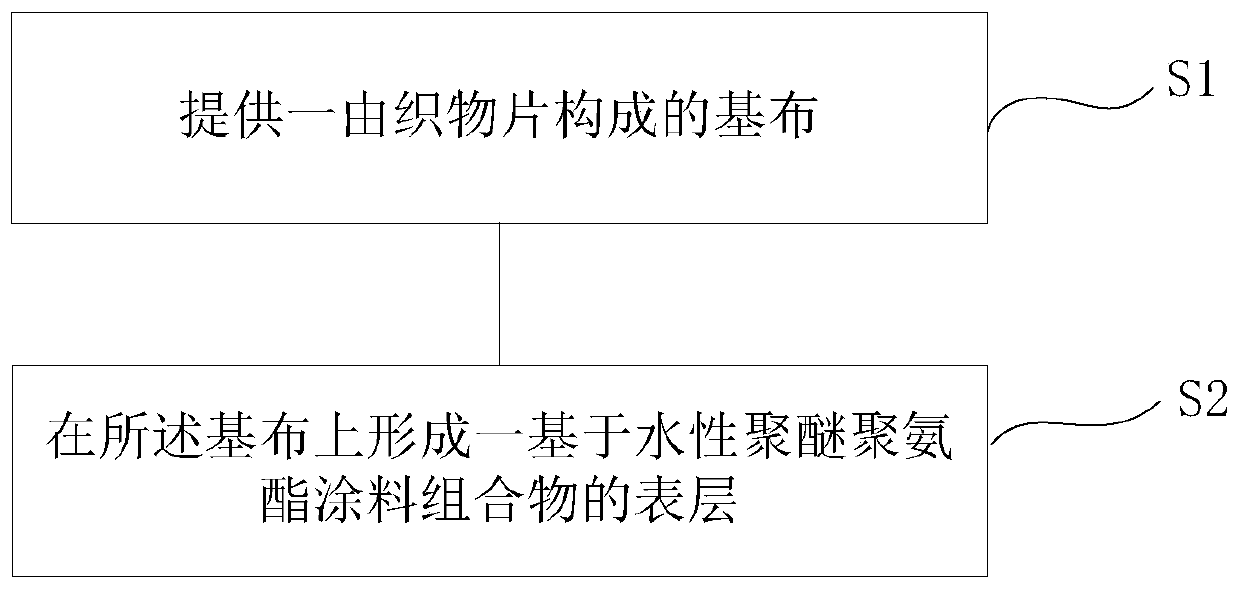

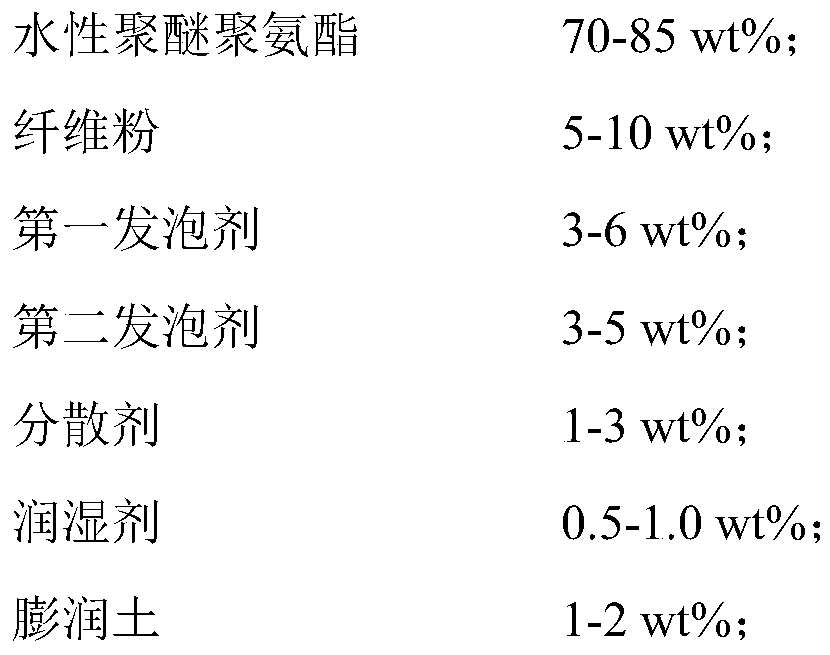

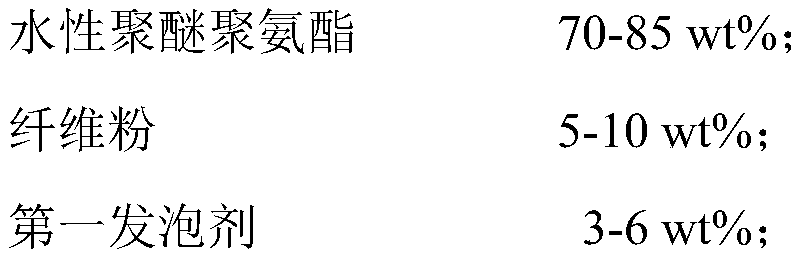

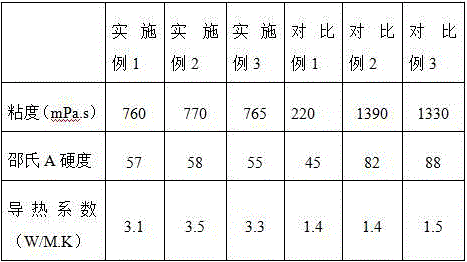

Wet-process Yangbuck synthetic leather and preparation method thereof

ActiveCN111206432AThe preparation method is simple, safe and reliableGood fleeceTextiles and paperCelluloseFiber

The present invention provides wet-process Yangbuck synthetic leather and a preparation method thereof. The wet-process Yangbuck synthetic leather comprises base cloth composed of fabric pieces and anaqueous polyether polyurethane coating composition based surface layer positioned on the base cloth. The surface layer has the porosity of 80-90%. The aqueous polyether polyurethane coating composition comprises 70-85wt% of aqueous polyether polyurethane, 5-10wt% of fiber powder, 3-6wt% of a first foaming agent, 3-5wt% of a second foaming agent, 1-3wt% of a dispersing agent, 0.5-1.0wt% of a wetting agent and 1-2wt% of bentonite, wherein the fiber powder consists of 95-97wt% of cellulose and 3-5wt% of fatty acid ester. The wet-process Yangbuck synthetic leather provided by the invention has excellent air permeability and moisture permeability, ideal yellowing resistance and delicate velvet surface.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

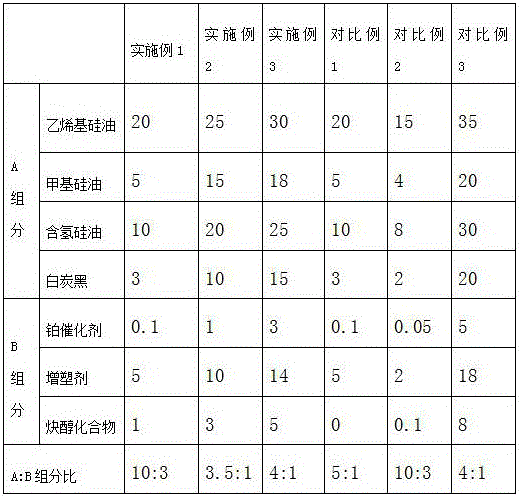

Pouring sealant for power electronic device

InactiveCN105969300AImprove thermal conductivityReduce production stepsNon-macromolecular adhesive additivesExtensibilityHydrogen

This case discloses a potting compound for power electronic devices. The potting compound includes component A and component B, and the mass ratio of component A to component B is (6-10): (1.5- 3), wherein, the A component includes the following materials: vinyl silicone oil, methyl silicone oil, hydrogen-containing silicone oil, white carbon black; the B component includes the following materials: platinum catalyst, plasticizer, acetylenic alcohol compound. The object of the present invention is to provide a potting glue for power electronic devices, which can obtain uniform structure, high light transmittance, large refractive index, extensibility, A potting compound with good tensile strength and bonding strength, as well as excellent thermal conductivity and dielectric properties.

Owner:苏州市奎克力电子科技有限公司

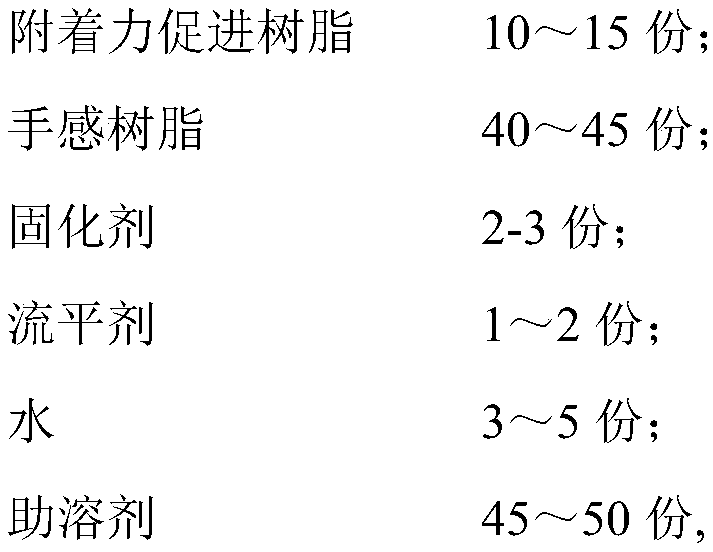

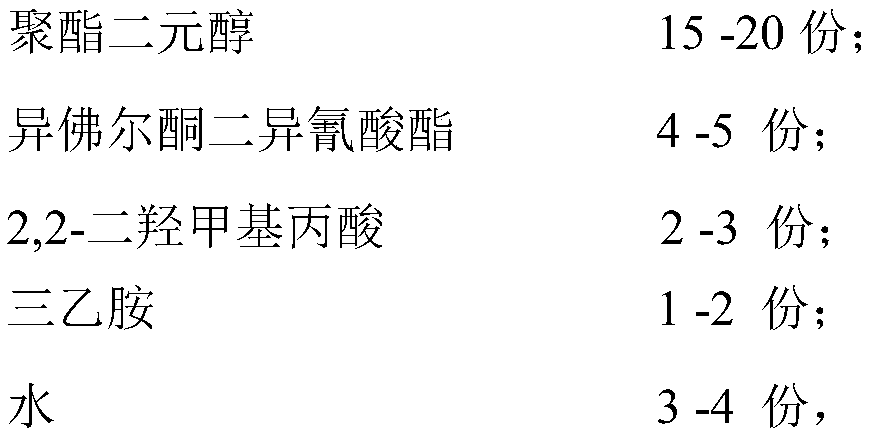

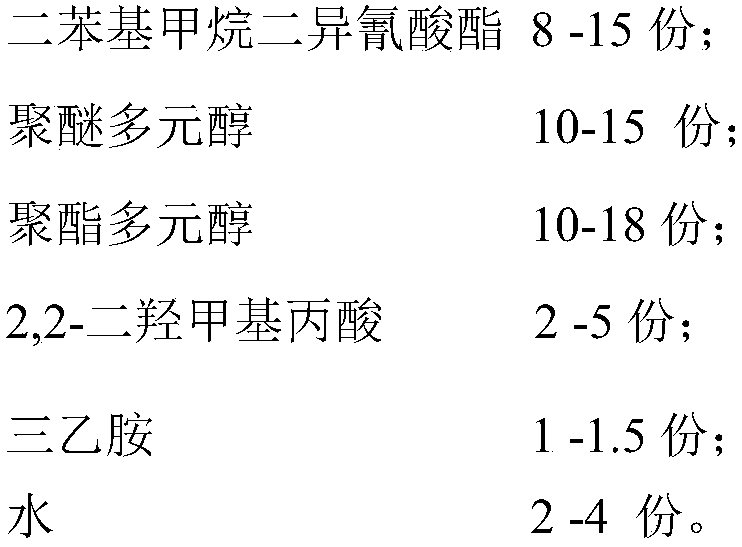

Skin feeling aqueous polyurethane coating and preparation method thereof

ActiveCN109593455ARich choiceGuaranteed adhesionPolyurea/polyurethane coatingsWeather resistanceSolvent

The invention provides a skin feeling aqueous polyurethane coating and a preparation method thereof. The aqueous polyurethane coating is prepared from the following components in parts by mass: 10-15parts of adhesive force promoted resin, 40-45 parts of hand feeling resin, 2-3 parts of a curing agent, 1-2 parts of a flatting agent, 3-5 parts of water and 45-50 parts of a cosolvent. The aqueous polyurethane coating has the advantages of being scratch-resistant, solvent-resistant, waterproof, yellowing-resistant and good in weather resistance, is moderate in price and wide in application range,and can improve the material living standard of people greatly.

Owner:运研材料科技(上海)有限公司

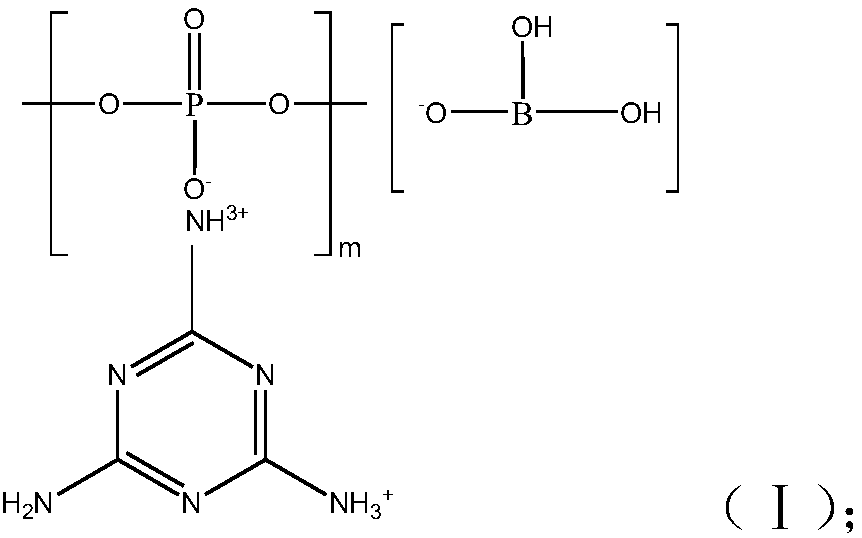

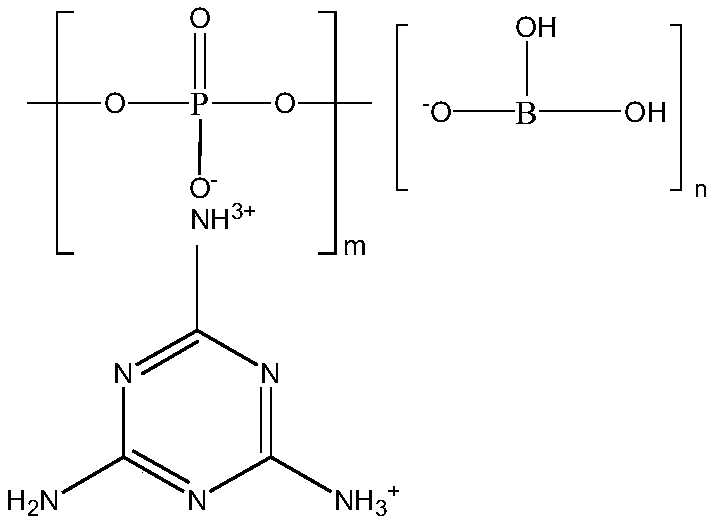

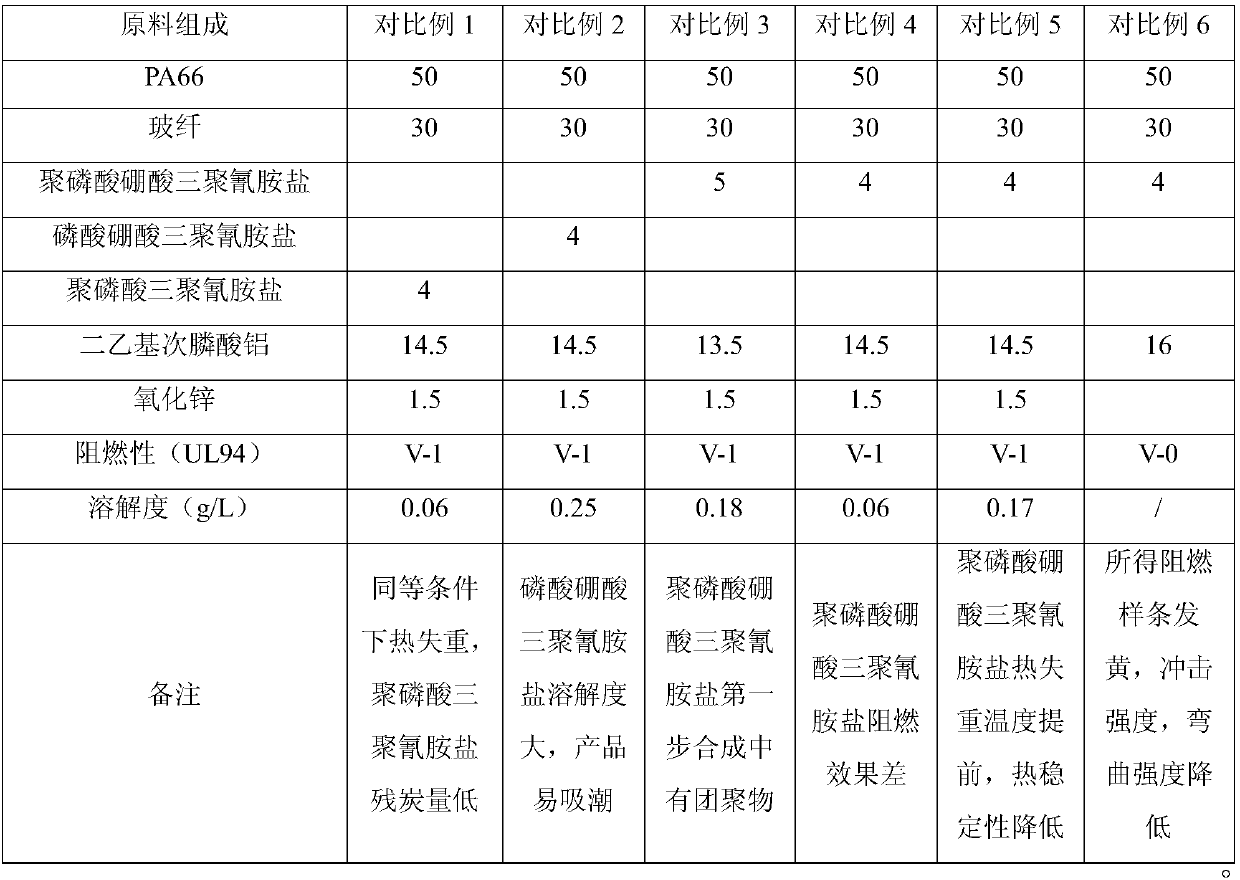

Halogen-free flame-retardant glass fiber reinforced nylon

The invention discloses halogen-free flame-retardant glass fiber reinforced nylon. The halogen-free flame-retardant glass fiber reinforced nylon comprises, by weight, 30-60% of nylon, 20-40% of glassfiber and 10-30% of a halogen-free flame-retardant compound system, wherein the halogen-free flame-retardant compound system comprises, by weight, 60-85% of organic hypophosphite, 13-35% of polyphosphoboric acid melamine salt and 2-8% of a charring agent. The structural formula of the polyphosphoboric acid melamine salt is shown in the formula (I); in the formula, m refers to the molar ratio of two structural units including polyphosphoric acid melamine and boric acid, and m is equal to 3-6. The halogen-free flame-retardant glass fiber reinforced nylon adopts the novel halogen-free flame-retardant compound system, and the halogen-free flame-retardant compound system is low in solubility and high in char yield, so that the prepared halogen-free flame-retardant glass fiber reinforced nylon has an excellent flame-retardant effect and can reach the flame-retardant standard of UL94-V0(1.6mm). The formula is shown in the description.

Owner:江苏利思德新材料股份有限公司

Waterborne wood enamel seal primer and preparation method thereof

InactiveCN107502109ANo cumulative effectHigh solidityFireproof paintsAntifouling/underwater paintsEmulsionUltraviolet absorption

The embodiment of the invention discloses a waterborne wood enamel seal primer and a preparation method thereof. The waterborne wood enamel seal primer is prepared from the following components in percentage by mass: 30 to 50 percent of waterborne nanometer enamel seal emulsion, 5 to 8 percent of waterborne nanometer flame-retardant dispersion slurry, 0.5 to 1 percent of waterborne nanometer silver dispersion slurry, 10 to 20 percent of waterborne polyurethane emulsion, 1 to 3 percent of a waterborne wetting dispersant, 5 to 10 percent of a lead-free filler, 1 to 3 percent of a penetrant, 0.5 to 1 percent of a solubilizing stabilizer, 0.3 to 0.5 percent of an ultraviolet absorption stabilizer, 0.2 to 0.5 percent of a mildew preventive, 0.5 to 2 percent of an anti-fouling agent, 1 to 3 percent of an amine neutralizer, 2 to 5 percent of an antifreezing agent, 0.5 to 2.5 percent of a coalescing agent and 10 to 25 percent of deionized water. The waterborne wood enamel seal primer has excellent properties such as water resistance, early compression resistance, reinforcement expansion resistance and sanding property; the burning of wood products can be effectively prevented and reduced; and the waterborne wood enamel seal primer has active mildew-resisting and antibacterial properties.

Owner:珠海市盟友化工有限公司

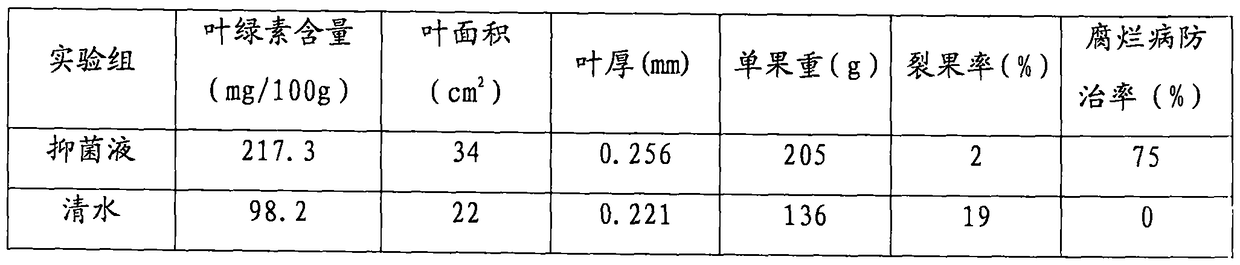

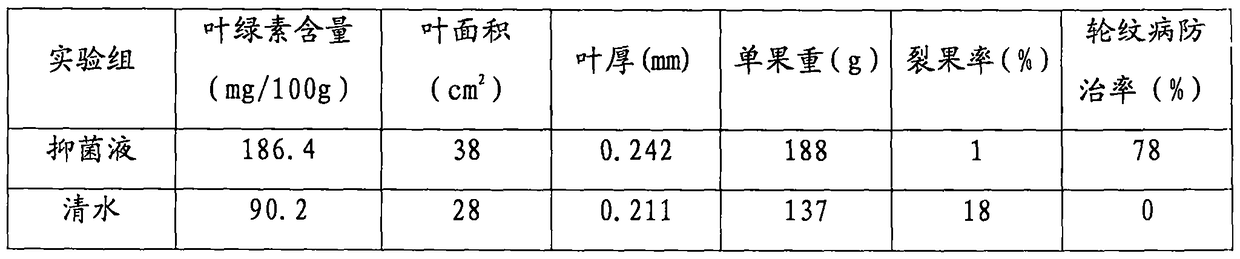

Disinfection liquid for rejuvenation and greening of fruit trees and preparation method of disinfection liquid

PendingCN108409410AImprove nutritional statusImprove iron deficiency symptomsBiocidePlant growth regulatorsDiseaseBenzoic acid

The invention belongs to the technical field of biological control, particularly relates to disinfection liquid for rejuvenation and greening of fruit trees and a preparation method of the disinfection liquid. The disinfection liquid is prepared from raw materials: by weight, 10-15% of urea, 5-10% of monopotassium phosphate, 15-20% of saccharose, 10-12% of ferrous sulfate, 3-5% of sodium borate, 2-4% of EDTA chelated zinc, 0.01-0.02% of benzoic acid, 20-40% of walnut green seedcase extract liquid, 0.5-1% of concentrated sulfuric acid, 0.5-1% of absolute ethyl alcohol and the balance being distilled water. The disinfection liquid can improve nutrition condition of the fruit tree, improve symptom iron-deficiency, improve stress resistance of fruit trees, effectively prevent diseases such asring rot, decay, alternaria leaf spot of fruit trees, and achieve rejuvenation of tree bodies and improve yield and income.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

Blue glass filter with high pass rate of visible light

InactiveCN106680924AIncrease the average transmittanceExtended service lifeOptical filtersSodium fluoridePass rate

The invention discloses a blue glass filter with a high pass rate of visible light in the technical field of optical devices, which comprises a blue glass substrate with a light finishing layer adhering to the top. The top of the light finishing layer is provided with a complex film. The top of a high temperature resistant film is provided with a protecting film using the blue glass as the substrate, which can filter infrared effectively in a manner of absorption. The light finishing layer can effectively correct the light and is difficult to generate the problem of imaging interference. A high refractive index film and a low refractive index film which are respectively prepared from LaTiO3 material and magnesium fluoride, aluminum fluoride or sodium fluoride materials, improve the mean transmissivity of light and the stray light can be effectively cut from infrared and ultraviolet. The high temperature resistant film enables the blue glass filter with high pass rate of visible light to be applied to the field with higher temperature. The setting of the protecting film enables the filter to have the advantages of scratch resistance, yellow resistance and super toughness, and the service life of the filter is improved.

Owner:HUBEI W OLF PHOTOELECTRIC TECH CO LTD

Finishing method for manufacturing yellowing resisting patent leather

ActiveCN105178054AAnti-yellowingMeet the needs of useTextiles and paperChemical compositionMaterials science

The invention relates to the technology field of a method for finishing leather, and provides a finishing method for manufacturing yellowing resisting patent leather. The finishing method comprises the following process steps in order: ironing crust leather, grinding surface, grinding back, mending blemishes, grinding surface, blowing ash and cleaning surface, carrying out spaying for once, carrying out roller coating for once, carrying out ironing, carrying out the roller coating for twice, and carrying out the roller coating for twice, wherein the roller coating steps are carried out with yellowing resisting materials. According to the physical mode provided by the invention, the yellowing resisting materials can effectively penetrate and be attached to a crust leather surface structure, so the yellowing resisting coating is effectively formed on the crust leather surface, the yellowing resisting coating is not easy to be peeled, and the yellowing resisting function of the crust leather is effectively realized. The method has the advantages of simple process steps and operation convenience, and the finishing method is suitable for large-scale production; the yellowing resisting materials selected for the coating have simple compositions, and do not contain unnecessary chemical components, so that damage to other performances of the crust leather caused by unnecessary chemical components is avoided; accordingly, a finished product leather processed by the method has original leather performances and yellowing resistance at the same time, so that usage demands of the patent leather are satisfied, and the practicality is high.

Owner:XINGYE LEATHER TECH CO LTD

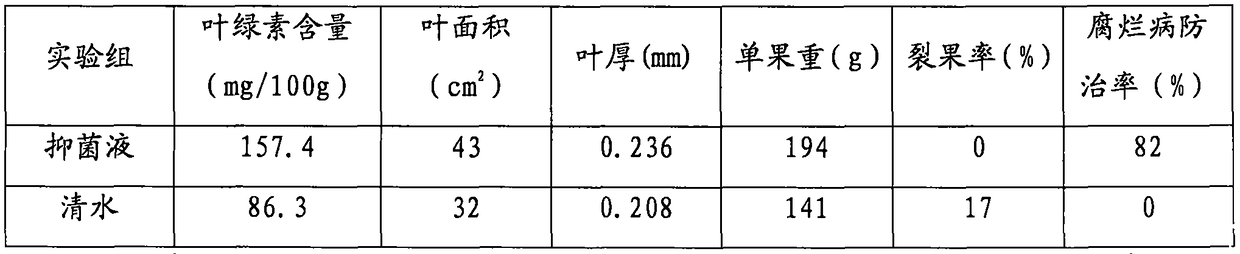

Polyester resin applicable to wooden transfer powder coating, preparation method of polyester resin, and wooden transfer powder coating

ActiveCN108948335AFull colorImprove the level ofEmulsion paintsPolyester coatingsCross-linkAntioxidant

The invention relates to a polyester resin applicable to a wooden transfer powder coating, a preparation method of the polyester resin, and the wooden transfer powder coating. The polyester resin applicable to the wooden transfer powder coating is characterized by comprising reaction products of terephthalic acid, m-phthalic acid, adipic acid and / or fumaric acid and dihydric alcohol under the effects of a cross-linking agent and a catalyst, as well as antioxidants. The polyester resin contains the following raw materials in parts by weight: 20-200 parts of terephthalic acid, 40-400 parts of m-phthalic acid, 10-100 parts of adipic acid, 10-100 parts of fumaric acid, 100-500 parts of dihydric alcohol, 20-200 parts of a cross-linking agent, 0.5-4 parts of a catalyst and 0.5-4 parts of an antioxidant. Compared with the prior art, the wooden transfer powder coating prepared from the polyester resin disclosed by the invention has the advantages that the layer transfer effects of the coatinginclude the advantages of being full in color, high in leveling property, high in definition and excellent in yellowing resistance and tearing resistance.

Owner:黄山佳杰新材料科技有限公司

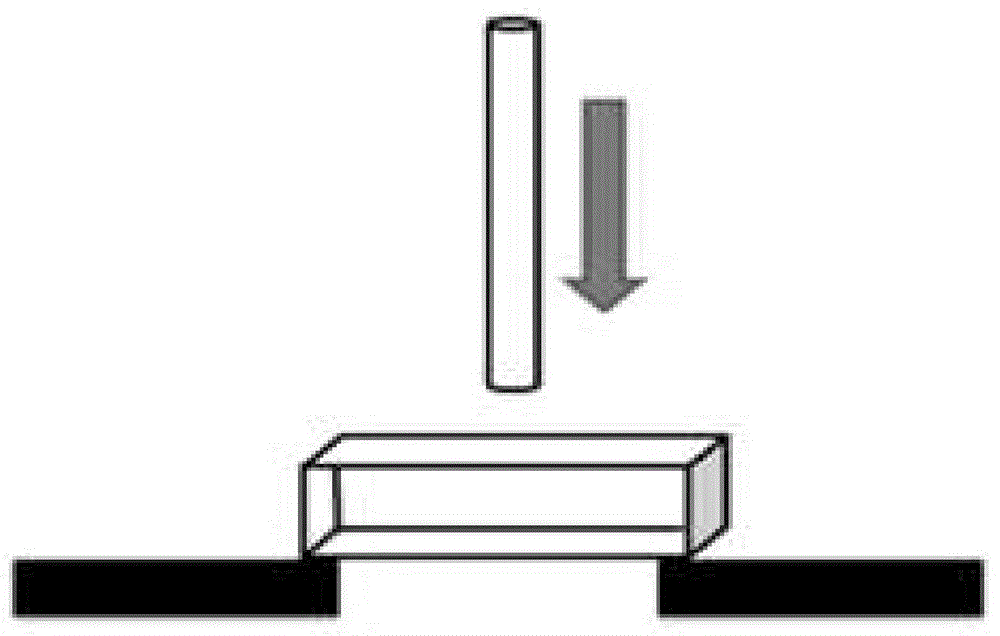

Photosensitive acrylic AED resin and negative photoresist composition comprising same, and preparation method thereof

InactiveCN103819616AUniform thicknessTightly boundPhotosensitive materials for photomechanical apparatusIonResist

The invention discloses a negative photoresist composition which is prepared by an anodic electrodeposition process. The photoresist composition mainly contains deionized water, (A) a photosensitive acrylic AED (Anodic Electrodeposition) base material, (B) a polyfunctional reactive diluent, (C) antalkali, (D) a photo-initiation body and (E) a water-based colour paste. A photoresist has high degree of automation through an AED method, and a film layer is thin and compact, has uniform thickness, and is tightly combined with the surface of an electrode. The photoresist can have enough and strong adhesive force on a filament during refining, the reliability during development and etching can be increased, and VOC emission is reduced to a great extent. The photoresist material can be applied to the fields of etching-resisting imaging printing ink, color filters of liquid crystal displays and the like.

Owner:JIANGYIN MORE CHEM NEW MATERIALS

Weather-resistant and temperature-resistant color-retaining fluororesin paint

InactiveCN103881558AStrong adhesionBright and full colorPolyurea/polyurethane coatingsResistAcrylic resin

The invention relates to paint, in particular to weather-resistant and temperature-resistant color-retaining fluororesin paint. The paint is made from the following raw materials in parts by weight: 20-24 parts of fluororesin, 12-15 parts of thermoplastic acrylic resin, 2-3 parts of sodium diacetate, 1-2 parts of glycol diglycidyl ether, 3-4 parts of triglycidyl isocyanurate, 10-12 parts of tri(propyleneglycol)diacrylate, 1-2 parts of europium trifluoroacetylacetone, 25-30 parts of urethane acrylate, 2-3 parts of polyacrylamide, 1-2 parts of dicyclopentadienyl iron, 2-3 parts of isocyanate, 5-8 parts of epoxidized soybean oil, 1-2 parts of zinc naphthenate, 3-4 parts of diaminodiphenyl-methane, 5-6 parts of aid, 10-12 parts of dimethylbenzene and 10-12 parts of butyl acetate. The paint is high in paint film adhesion and bright and full in color, retains color for a long time and resists yellowing, has the advantages of weather resistance, ageing resistance, temperature change resistance, corrosion resistance, rust resistance, erosion resistance and the like, and can be widely applied to protection and decoration of articles in various environments.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

High-performance artificial quartz plate

The invention discloses a high-performance artificial quartz plate, made from, by weight, 25-30 parts of quartz sand, 15-20 parts of glass sand, 20-25 parts of quartz powder, 10-15 parts of Maifan stone powder, 4-7 parts of acrylic resin, 4-6 parts of polyurethane resin, 3-5 parts of dibenzoyl peroxide, 2-5 parts of calcium sulfate whiskers, 1-3 parts of a pigment and 0.2-0.7 part of a coupling agent. The properties of the high-performance artificial quartz plate are improved at the premise of lowering its production cost, and profit of enterprises is increased; the high-performance artificialquartz plate has the advantages of low production cost, high production efficiency and good economy. The high-performance artificial quartz plate produced herein has the advantages of corrosion resistance, ultraviolet resistance, yellowing resistance, wear resistance, heat resistance and insulation, high impact resistance, good strength, rarity of deforming or breaking, and good comprehensive performance.

Owner:佛山市欧泊石业有限公司

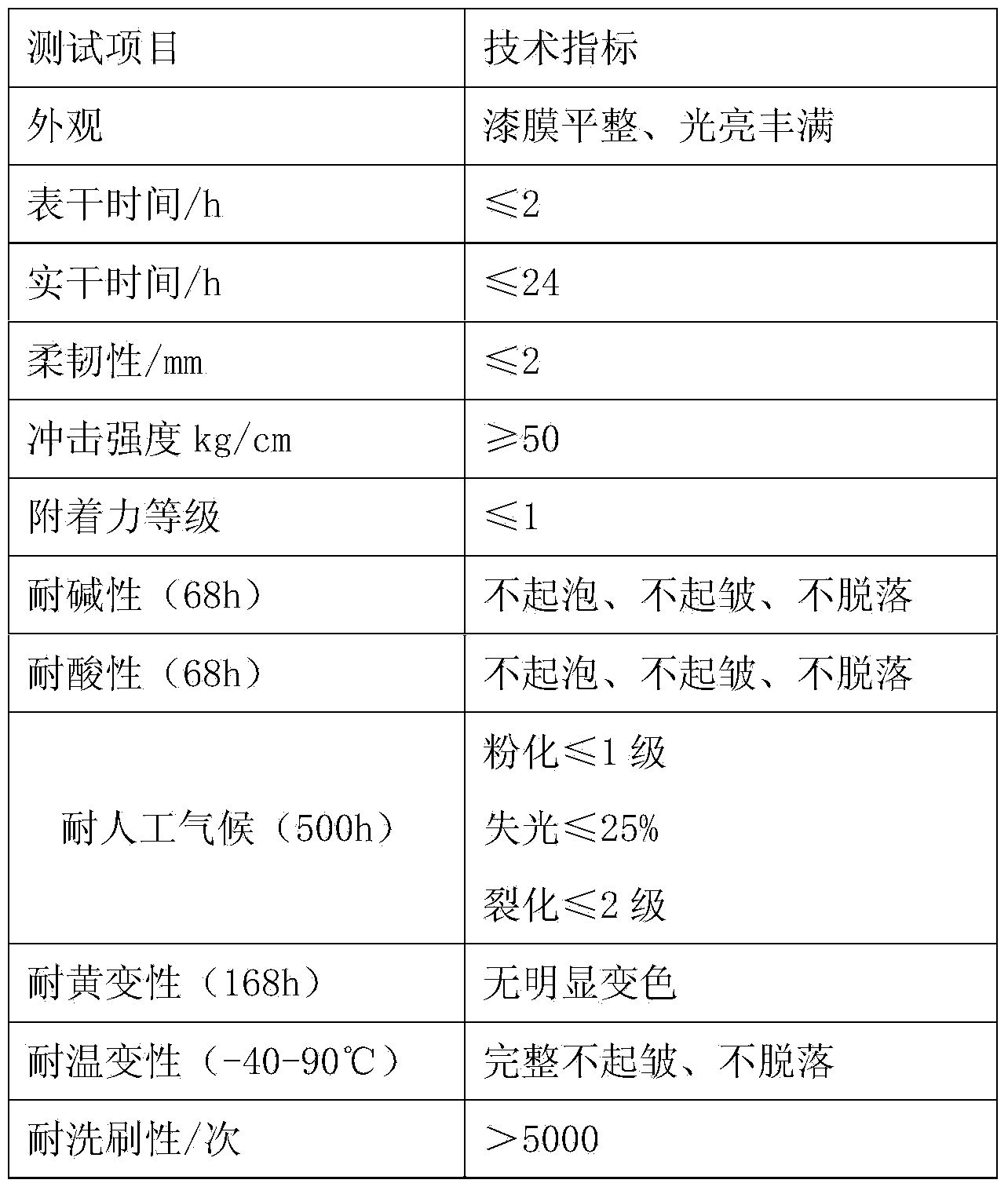

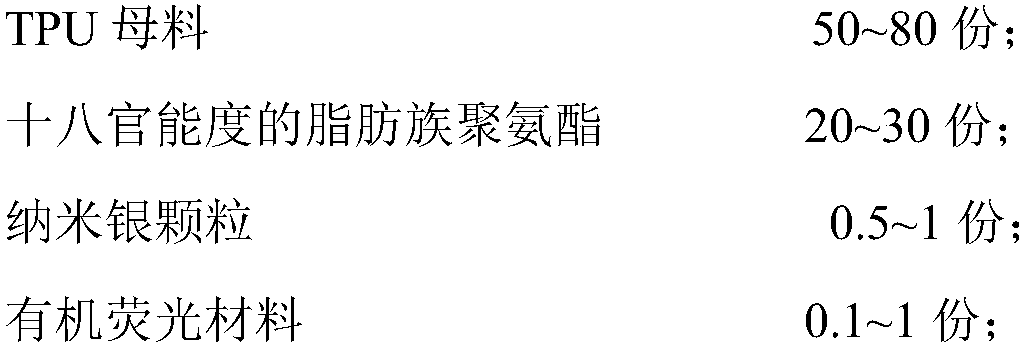

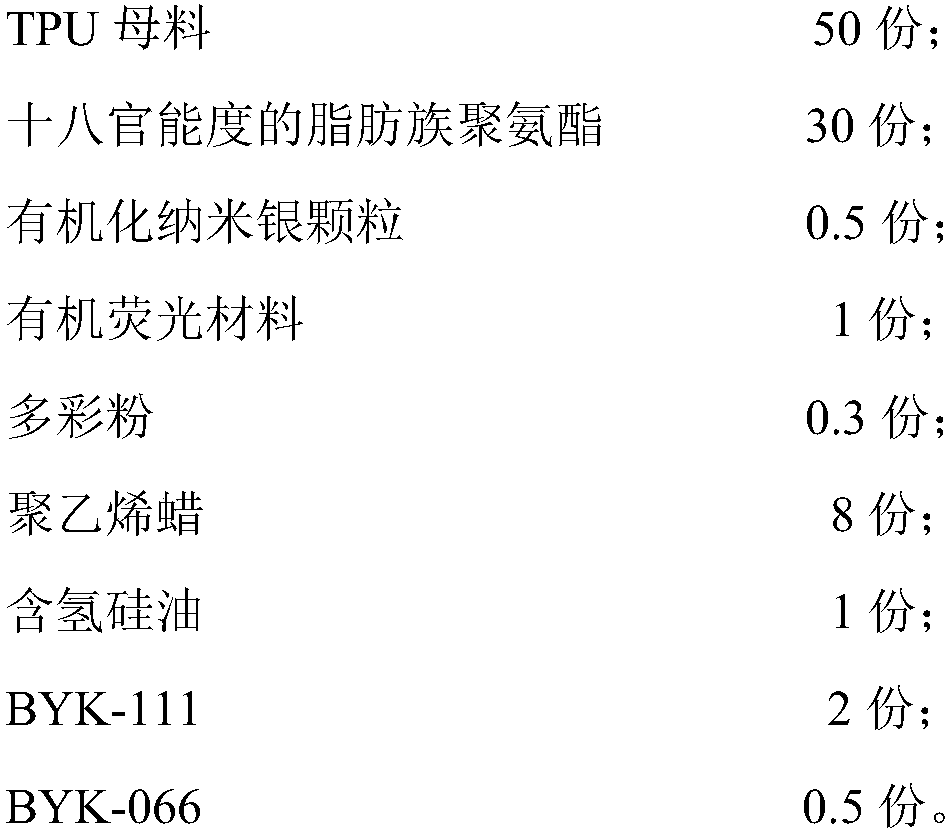

TPU (thermoplastic polyurethane) master batch and preparation method thereof

The invention discloses a TPU master batch. The TPU master batch is prepared from the following raw material components in parts by weight: 50-80 parts of TPU master batch, 20-30 parts of aliphatic polyurethane with 18 functionality, 0.5-1 part of nano silver particles, 0.1-1 part of organic fluorescent material, 0.3-3 parts of colorful powder, 1-8 parts of polyethylene wax, 1-5 parts of hydrogen-containing silicone oil, 0.5-2 parts of lubricating agent and 0.5-2 parts of defoaming agent. The TPU master batch and aliphatic polyurethane with 18 functionality are compounded to serve as substrateresin, so that the TPU master batch has the excellent anti-yellowing function, meanwhile, nano silver, the organic fluorescent material and the colorful powder are added, polyethylene wax is utilizedto make the functional material be uniformly dispersed in the substrate resin, and the prepared TPU master batch does not only maintain the excellent mechanical performance of the common TPU material, but also has the various kinds of functions such as wear resistant, yellowing resistant, fluorescent and antibacterial. The invention further discloses the preparation method of the TPU master batch, the technology is simple, the production cost is low, the stability of the finished product is good, and large-scale industrialized production is facilitated.

Owner:佛山市三水联美化工有限公司

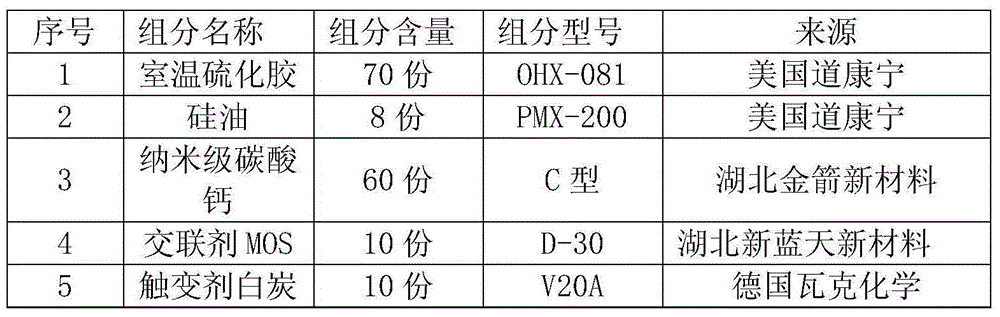

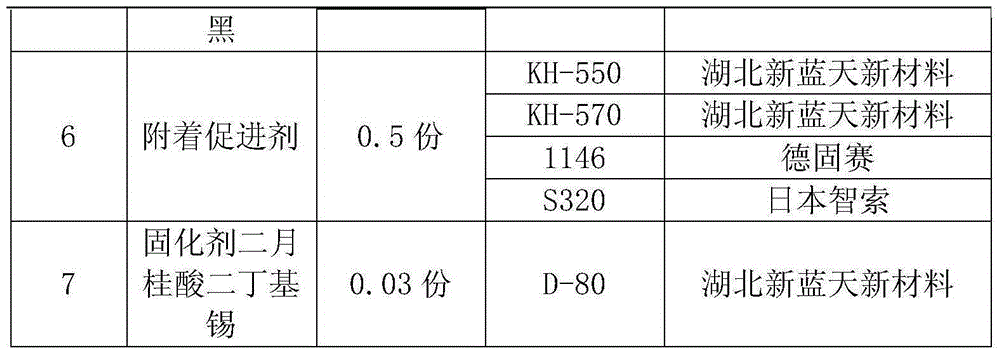

Adhesive special for solar cell module and preparation method of adhesive

InactiveCN105038697AGuaranteed tightnessAnti-moisture agingNon-macromolecular adhesive additivesRoom temperatureSolar cell

The invention provides an adhesive special for a solar cell module. The adhesive comprises, by weight, 50-80 parts of room temperature vulcanized rubber, 2-20 parts of silicone oil, 40-80 parts of calcium carbonate, 2-10 parts of cross-linking agents, 0.5-15 parts of thixotropic agents, 0.1-1 part of adhesion promoter and 0.01-0.05 part of curing agents. The adhesive special for the solar cell module has the advantages of resisting damp-heat ageing, resisting ultraviolet ageing and resisting xanthochromia, the use performance of the adhesive special for the solar cell module is improved, and the sealing performance of the solar cell module can be guaranteed.

Owner:SUZHOU DATONG ADVANCED MATERIAL

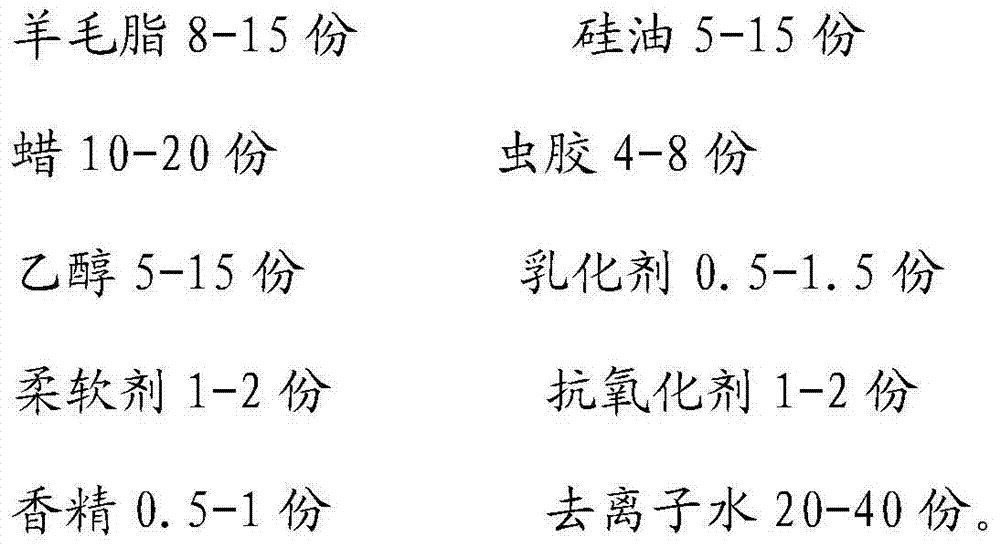

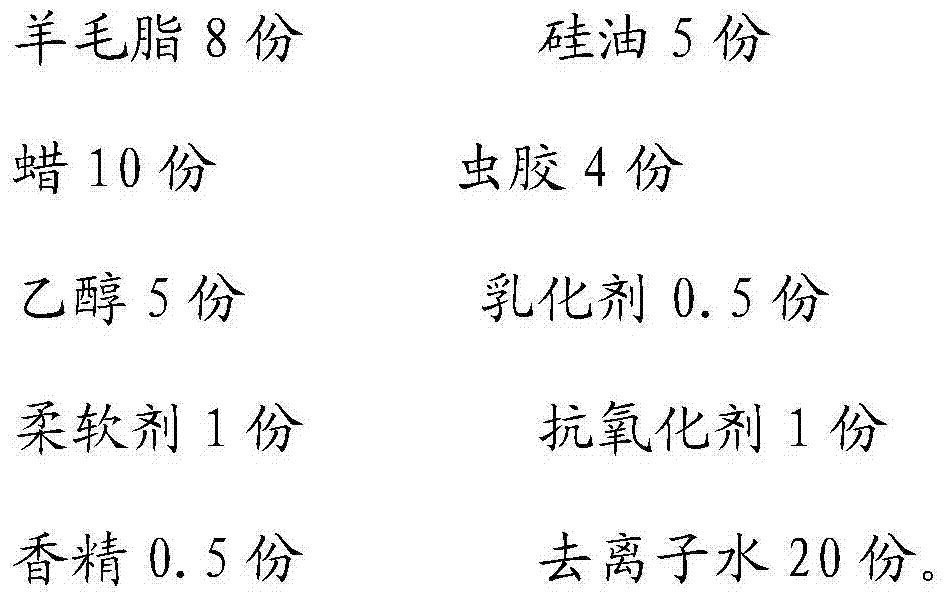

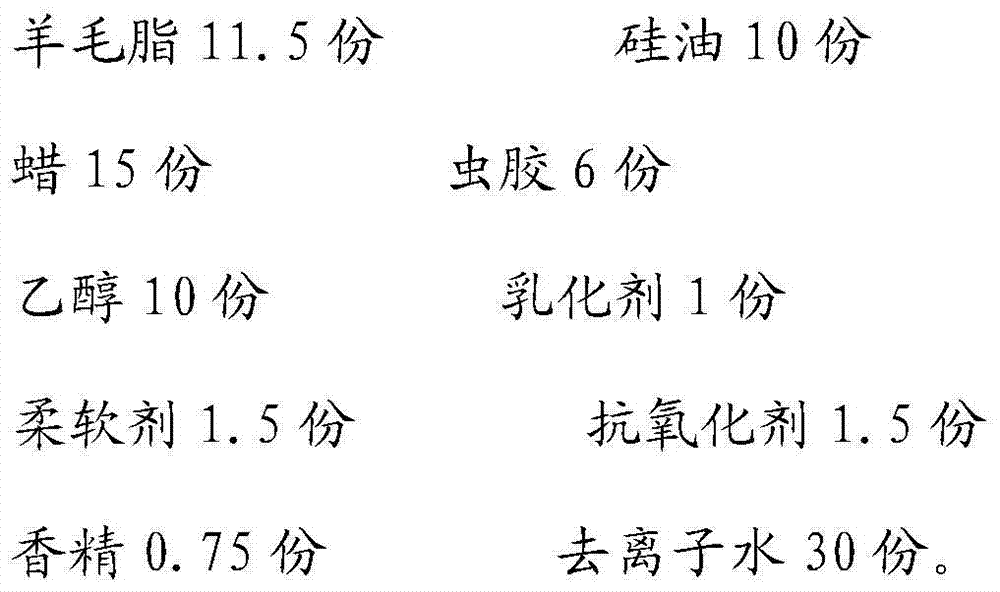

Leather nursing oil

The invention discloses a leather nursing oil, which is composed of the following raw materials in parts by weight: 8 to 15 parts of lanolin, 5 to 15 parts of silicone oil, 10 to 20 parts of wax, 4 to 8 parts of shellac, 5 to 15 parts of ethanol, 0.5 to 1.5 part of emulsifying agent, 1 to 2 parts of softening agent, 1 to 2 parts of antioxidant, 0.5 to 1 part of essence, and 20 to 40 parts of deionized water. The provided leather nursing oil can deeply moisten the fibers in the corium layer, forms an oil film, and can prevent leather yellowing and mildew due to the addition of softening agent and antioxidant, which have the anti-yellowing, sterilizing, and disinfecting effects.

Owner:周华庆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com