Adhesive special for solar cell module and preparation method of adhesive

A technology for solar cells and modules, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the elongation, tensile strength and bonding strength of silicone adhesive Adhesive is prone to moisture and heat aging, affecting the sealing performance of solar cell modules, etc., so as to improve the performance and ensure the sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

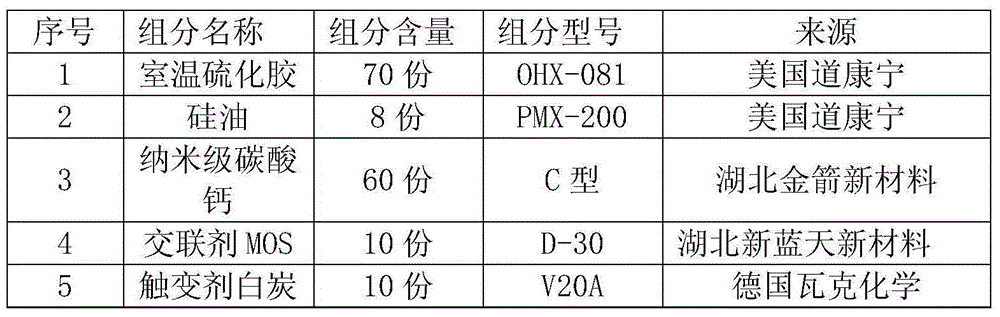

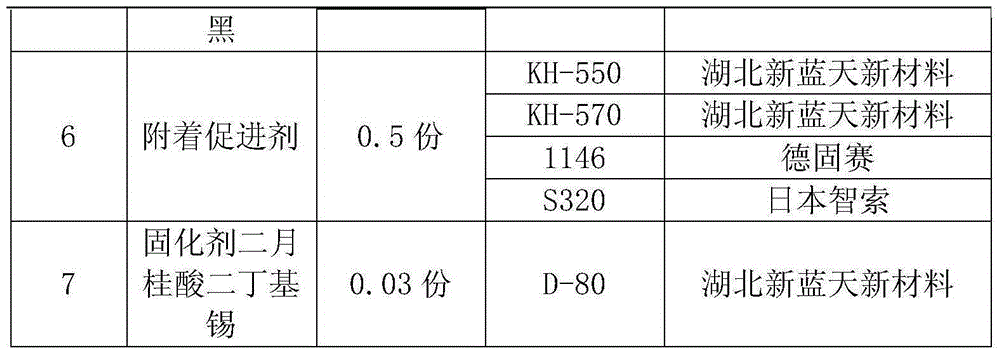

[0021] A special adhesive for solar cell modules of the present embodiment includes the components in the following table 1 in parts by weight:

[0022] Table 1

[0023]

[0024] The preparation method of the solar cell module special glue of the present embodiment comprises the following steps:

[0025] Step 1: dehydrating room temperature vulcanizing rubber, silicone oil and nano calcium carbonate at 135°C for 3 hours in a vacuum state to prepare the base material;

[0026] Step 2: Add crosslinking agent MOS, thixotropic agent white carbon black, adhesion promoter and curing agent dibutyltin dilaurate to the base material, stir and mix evenly at 55°C under vacuum state, and then get special solar cell module glue.

Embodiment 2

[0028] A special adhesive for solar cell modules of the present embodiment includes the components in the following table 2 in parts by weight:

[0029] Table 2

[0030]

[0031]

[0032] The preparation method of the solar cell module special glue of the present embodiment comprises the following steps:

[0033] Step 1: dehydrating RTV rubber, silicone oil and nano calcium carbonate at 140°C for 3.5 hours in a vacuum state to prepare the base material;

[0034] Step 2: Add crosslinking agent MOS, thixotropic agent white carbon black, adhesion promoter and curing agent dibutyltin dilaurate to the base material, stir and mix evenly at 45°C under vacuum state, and then get special solar cell module glue.

Embodiment 3

[0036] A special adhesive for solar cell modules of the present embodiment includes the components in the following table 3 in parts by weight:

[0037] table 3

[0038]

[0039] The preparation method of the solar cell module special glue of the present embodiment comprises the following steps:

[0040] Step 1: dehydrating RTV rubber, silicone oil and nano calcium carbonate at 145°C for 4 hours in a vacuum state to prepare base material;

[0041] Step 2: Add cross-linking agent MOS and cross-linking agent VOS, thixotropic agent silica, adhesion promoter and curing agent dibutyltin dilaurate to the base material, and stir and mix evenly at 35°C under vacuum state, that is Get special glue for solar cell modules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com