Pouring sealant for power electronic device

A technology for power electronic devices and potting glue, applied in the directions of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of increasing the viscosity of electronic potting materials, affecting the fluidity, mechanical properties and electrical properties, etc. Achieve the effect of reducing interface contact thermal resistance, effective heat conduction and insulation, and reducing production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

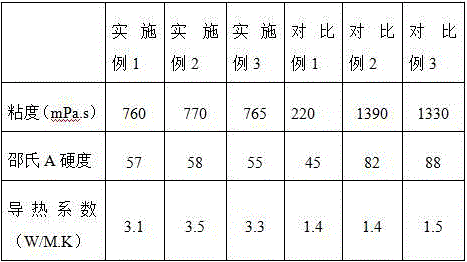

[0022] The present invention will be further described in detail below with reference to the embodiments, so that those skilled in the art can implement it according to the text of the description.

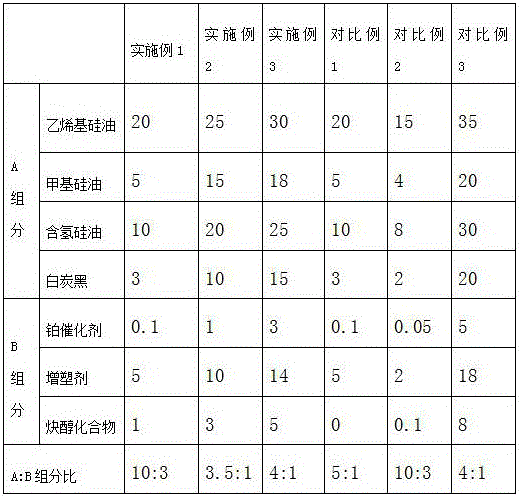

[0023] A potting glue for power electronic devices, said potting glue comprising component A and component B, and the mass ratio of component A to component B is (6-10): (1.5-3), Wherein, the A component includes the following materials in parts by weight:

[0024] 20-30 parts of vinyl silicone oil;

[0025] 5~18 parts of methyl silicone oil;

[0026] 10-25 parts of hydrogen-containing silicone oil;

[0027] 3~15 parts of white carbon black;

[0028] The B component includes the following parts by weight:

[0029] 0.1~3 parts of platinum catalyst;

[0030] Plasticizer 5~14 parts;

[0031] Alkynol compound 1 to 5 parts.

[0032] In this embodiment, the vinyl silicone oil is a linear polydimethylsiloxane with vinyl groups at both ends, the mass percentage of the vinyl group is 0.1% to 0.42%, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com