Polyester resin applicable to wooden transfer powder coating, preparation method of polyester resin, and wooden transfer powder coating

A powder coating, wood grain transfer technology, applied in the field of polyester resin, can solve the problems of powder coating yellowing, reducing leveling, affecting the appearance of the coating, etc., to achieve high definition, high leveling, full color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

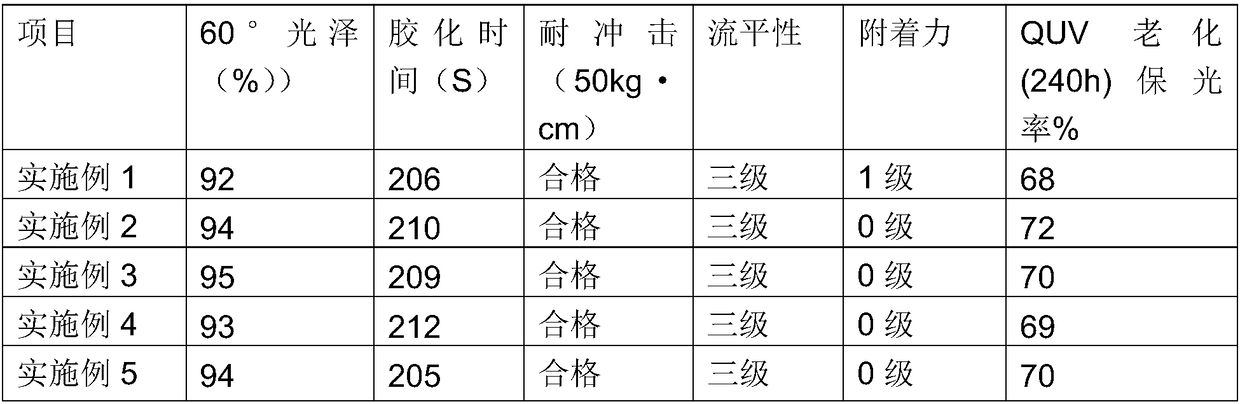

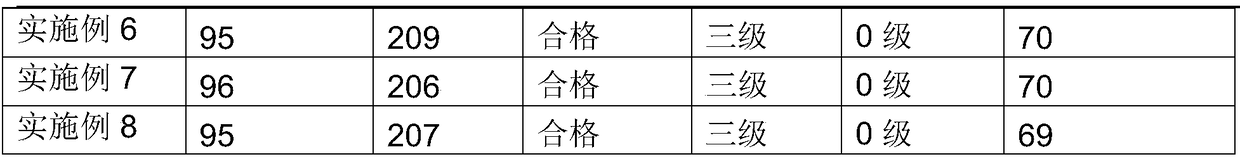

Examples

Embodiment 1

[0024] In the synthesis reactor, put 120 parts of neopentyl glycol, 25 parts of 1,4-cyclohexanedimethanol, 20 parts of diethylene glycol, and 25 parts of trimethylolpropane, open the jacket heat transfer oil valve, and raise the temperature to 110 ℃, until the material is completely melted; put in 200 parts of terephthalic acid, 38 parts of adipic acid, and 1 part of monobutyltin oxide, cover the lid of the kettle, turn on the nitrogen protection, heat up to 240 °C for esterification reaction, and maintain it until The resin is transparent, and the acid value measured by sampling is 32mgKOH / g;

[0025] Lower the temperature to 235°C, add 40 parts of isophthalic acid, continue the reaction for 2 hours, and take a sample to measure the acid value to 50 mgKOH / g. The temperature was lowered to 225° C., and the reaction was carried out under vacuum for 2.5 hours. The acid value was 42 mgKOH / g and the viscosity was 3680 mpa.s (200° C.). Add 1 part of antioxidant 1001, lower the tem...

Embodiment 2

[0028] Put 260 parts of neopentyl glycol, 45 parts of 1,4-cyclohexanedimethanol, 25 parts of trimethylpentanediol, and 50 parts of trimethylolpropane into the synthesis reaction kettle, open the jacket heat transfer oil valve, and raise the temperature to 110°C until all materials are melted; put in 20 parts of terephthalic acid, 30 parts of adipic acid, 20 parts of fumaric acid, and 1.5 parts of monobutyltin oxide, cover the lid of the kettle, turn on the nitrogen protection, and gradually heat up to Carry out esterification reaction at 245°C until the resin is transparent, and the acid value is 37mgKOH / g by sampling;

[0029] The temperature was lowered to 235°C, and 400 parts of isophthalic acid was added, and the reaction was continued for 2 hours. The acid value was 56 mgKOH / g by sampling. The temperature was lowered to 220°C, and the reaction was carried out under vacuum for 3 hours. The acid value was 45mgKOH / g and the viscosity was 3650mpa.s (200°C). Add 1.5 parts of ...

Embodiment 3

[0032] In the synthesis reactor, put 380 parts of neopentyl glycol, 55 parts of trimethylpentanediol, 20 parts of 2-methyl-1,3-propanediol, and 45 parts of trimethylolpropane, and open the jacketed heat transfer oil valve. Raise the temperature to 110°C until all the materials are melted; put in 200 parts of terephthalic acid, 60 parts of adipic acid, 60 parts of fumaric acid, and 3 parts of monobutyltin oxide, cover the lid of the kettle, turn on the nitrogen protection, and gradually heat up Carry out esterification reaction at 245°C, maintain until the resin is transparent, and take a sample to measure the acid value to 40mgKOH / g;

[0033] Cool down to 235°C, add 380 parts of isophthalic acid, continue to react for 2 hours, and take a sample to measure the acid value to 60 mgKOH / g. The temperature was lowered to 225°C, and the reaction was carried out under vacuum for 3 hours. The acid value was 40mgKOH / g and the viscosity was 2950mpa.s (200°C). Add 3 parts of antioxidant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com