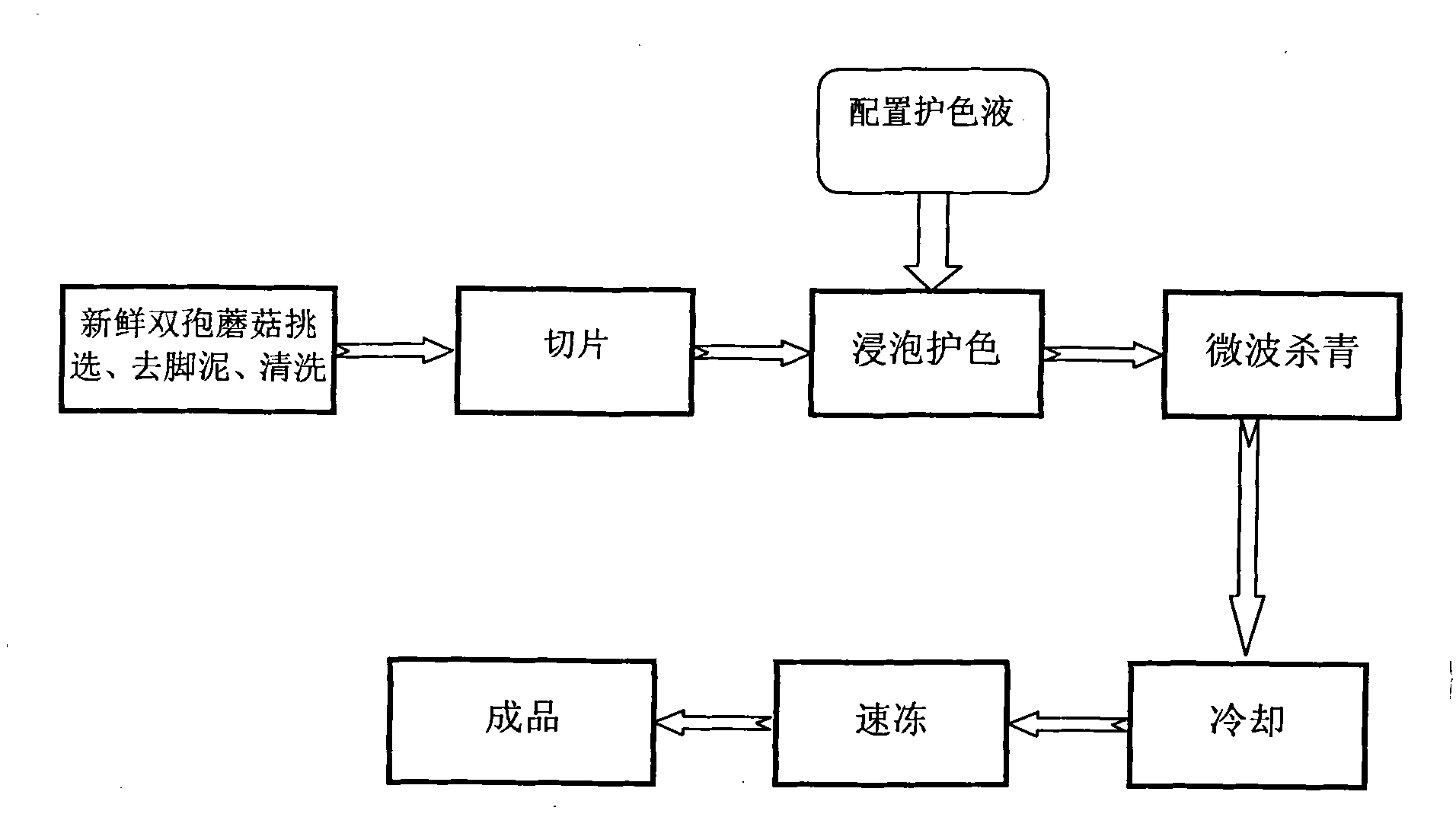

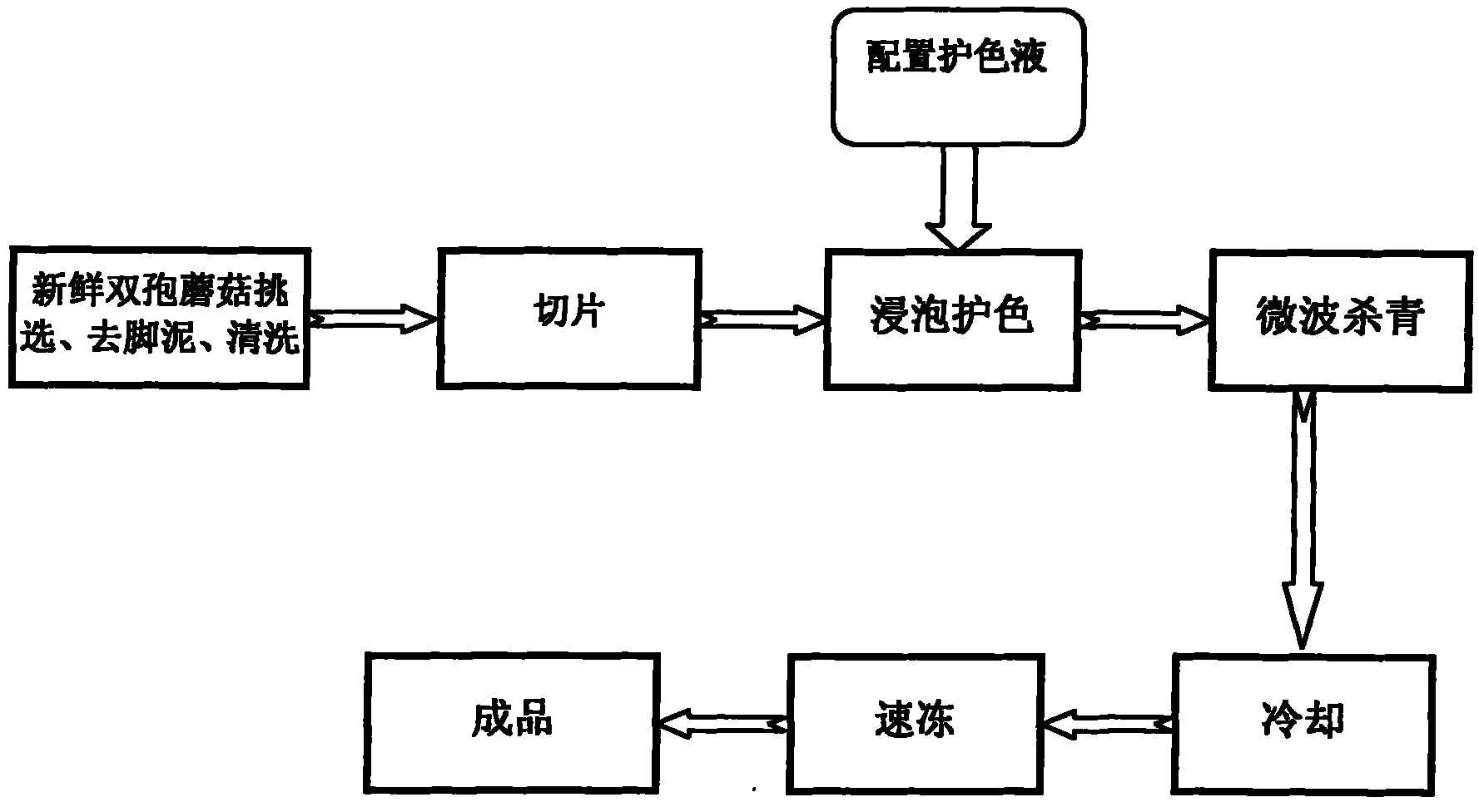

Method for preparing white mushroom slices

A technology of Agaricus bisporus and slicing, which is applied in the directions of food preservation, fruit and vegetable preservation, heating preservation of fruits/vegetables, etc., can solve problems such as loss of nutrients and flavor substances, and achieve less nutrient loss, natural color and less impact on the external environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weighed 10.55kg of fresh Agaricus bisporus, discarded the defective mushrooms and rotten mushrooms after selection, removed the mud feet by hand, rinsed them in a washing machine (avoid soaking), drained and weighed 9.88kg, and then sliced into about 6mm Thick flakes are soaked in 500L of prepared sodium chloride solution with a concentration of 2wt% and kept stirring. After 20 minutes, they are taken out and drained, and then placed in an aluminum belt microwave machine for 3 minutes under the condition of power 4000W for killing. Immediately after finishing, spray with 10-20°C cold water to cool down, and then put it in a cold storage to cool. After 5 minutes, the center temperature of the mushrooms is 8°C, and they are frozen in a quick-freezing tunnel (the temperature at the inlet is 13°C, and the temperature at the outlet is below zero. 25°C). The packaged finished product weighs 7.33kg and is stored in cold storage. The quick-frozen Agaricus bisporus slices pre...

Embodiment 2

[0027] Get 11.20kg of fresh Agaricus bisporus, except that the slice thickness is 7mm, the color protection solution is a concentration of 0.15wt% ascorbic acid solution, and the microwave power is 6000W, and the greening is done for 2min, other operations are the same as in Example 1. After cooling in the cold storage for 4 minutes, the central temperature of the mushrooms was measured to be 10°C, and the mushrooms were frozen through a quick-freezing tunnel (the temperature at the inlet was 16°C, and the temperature at the outlet was minus 24°C). The finished product of packing is 7.53kg altogether through weighing. The quick-frozen fresh Agaricus bisporus slices prepared in this way are also grayish white and shiny in color and plump in appearance. After thawing, it tastes delicious after cooking, and its taste and flavor are similar to those of fresh mushroom bisporus after cooking.

Embodiment 3

[0029] Take 10.30 kg of fresh Agaricus bisporus, except that the slice thickness is 8mm, the color protection solution is a citric acid solution with a concentration of 0.15wt%, and the microwave power is 4500W for 3 minutes, and other operations are the same as in Example 1. After cooling in the cold storage for 5 minutes, the center temperature of the mushrooms was measured to be 9°C, and the mushrooms were frozen through a quick-freezing tunnel (the temperature at the inlet was 12°C, and the temperature at the outlet was minus 28°C). The finished product of packing is 7.26kg altogether through weighing, and is refrigerated. The quick-frozen fresh Agaricus bisporus slices prepared in this way are also grayish white and shiny in color and plump in appearance. After thawing, it tastes delicious after cooking, and its taste and flavor are similar to those of fresh mushroom bisporus after cooking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com