TPU (thermoplastic polyurethane) master batch and preparation method thereof

A technology of master batch and nano-silver particles, applied in the field of TPU master batch, can solve the problems of poor adhesion between functional film and TPU material, fast failure of functional film, complicated preparation steps, etc., and achieves low production cost and finished product. The effect of good stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

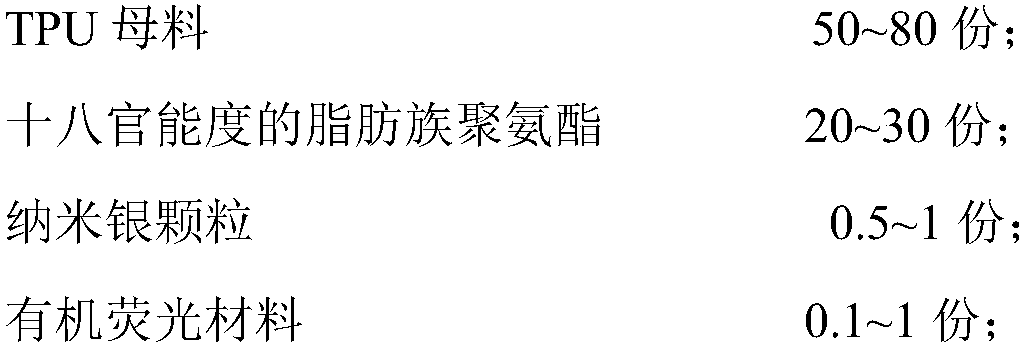

[0023] A kind of TPU masterbatch, it comprises following raw material component by weight:

[0024]

[0025] Wherein, the organic fluorescent material is a triphenylamine derivative; the colorful powder is a 40 μm color-changing glass microsphere grafted with an amino group.

[0026] Preparation:

[0027] 1) Dry the above raw material components at a temperature of 70-80°C for 1-2 hours;

[0028] 2) Put the dried TPU masterbatch, eighteen-functionality aliphatic polyurethane and hydrogen-containing silicone oil into the twin-screw extruder and mix evenly. The mixing time is 0.5-1h, and then add nano-silver particles, organic fluorescent materials, The colorful powder, polyethylene wax, lubricant and defoamer are continuously stirred and mixed, the stirring temperature is 120-160°C, and the stirring time is 1-1.5h, and then granulated by a granulator to obtain the finished product of TPU masterbatch in Example 1.

Embodiment 2

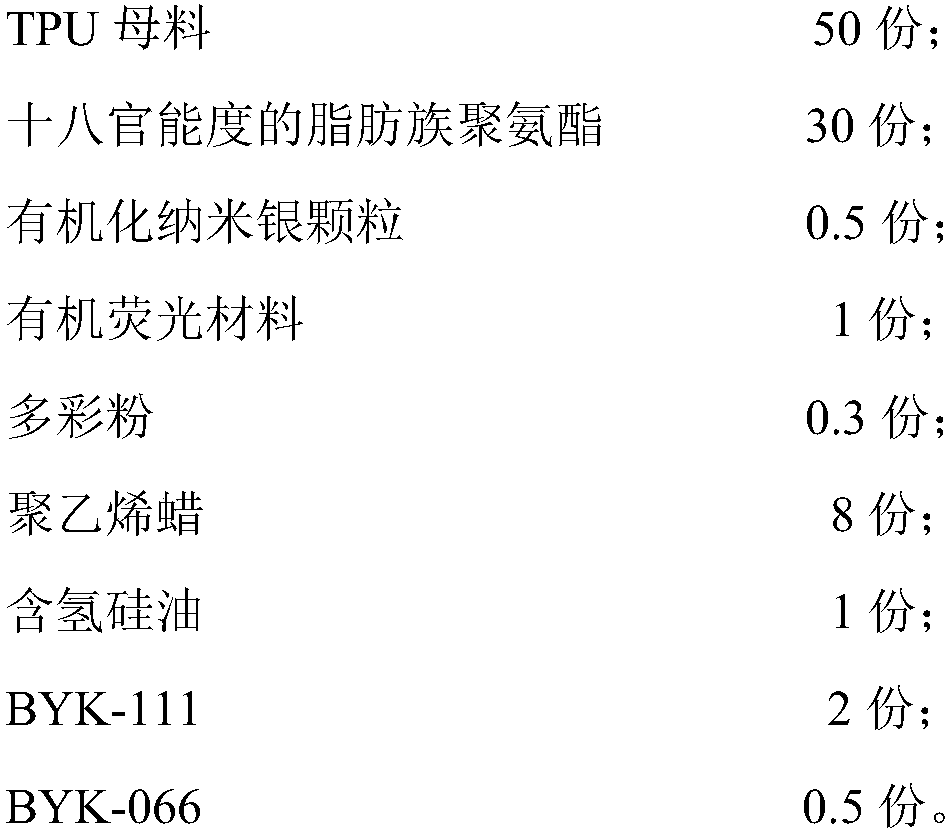

[0030] A kind of TPU masterbatch, it comprises following raw material component by weight:

[0031]

[0032]

[0033] Wherein, the organic fluorescent material is selected from the compound of triphenylamine derivatives and porphyrin compounds; the colorful powder is 80 μm color-changing glass microspheres grafted with carboxyl groups.

[0034] The preparation method of this embodiment is the same as the preparation method of embodiment 1, and the finished TPU masterbatch of embodiment 2 is prepared.

Embodiment 3

[0036] A kind of TPU masterbatch, it comprises following raw material component by weight:

[0037]

[0038] The organic fluorescent material is a thiazole derivative; the colorful powder is a 60 μm color-changing glass microsphere grafted with an amino group and a carboxyl group.

[0039] The preparation method of this example is the same as that of Example 1, and the finished TPU masterbatch of Example 3 is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com