High-functionality polyurethane acrylate as well as preparation method and application thereof

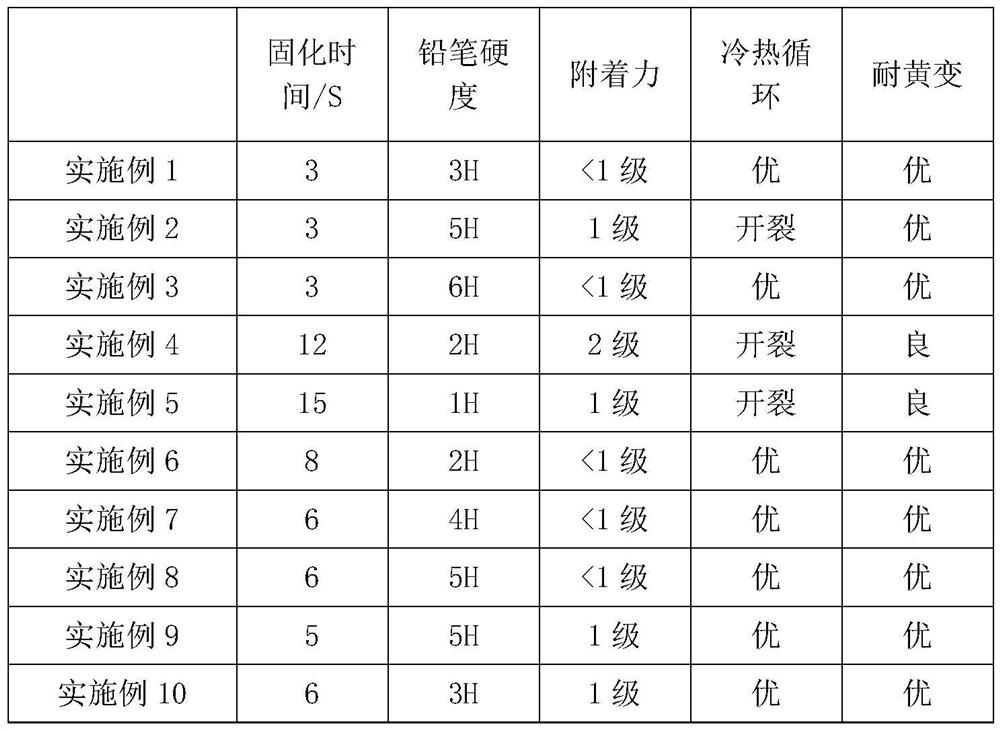

A polyurethane acrylate, high-functionality technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problem of poor adhesion and reaction rate of polyurethane acrylate, poor flexibility of polyurethane acrylate, and can not be used outdoors for a long time and other problems, to achieve the effect of excellent pencil hardness, excellent yellowing resistance, and accelerated curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Second aspect of the present invention provides a kind of preparation method of high-functionality urethane acrylate, the preparation step of described urethane acrylate comprises:

[0055] (1) take isocyanate, acrylic resin, polymerization inhibitor, catalyzer of corresponding weight part;

[0056] (2) Add isocyanate and polymerization inhibitor in a four-necked flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, and then add acrylic resin and catalyst mixed solution dropwise to the system to maintain the reaction temperature at 40-50°C, After 1-2 hours of dropping, the system is slowly raised to 80-90°C after the dropping, kept for 3-5 hours, cooled to room temperature and discharged to obtain high-functionality polyurethane acrylate.

[0057] After a lot of research, the applicant found that according to the addition sequence and reaction temperature of the present invention, the performance of the polyurethane acrylate prepared when...

Embodiment 1

[0064] Embodiment 1 of the present invention provides a kind of high-functionality urethane acrylate, the raw material of described high-functionality urethane acrylate comprises, by weight, 22.3 parts of isocyanate, 63 parts of acrylic resin, 0.086 part of polymerization inhibitor, catalyst 0.0086 copies;

[0065] The isocyanate is hexamethylene diisocyanate trimer; the viscosity of the hexamethylene diisocyanate trimer at 23°C is 3000mPa·s; the hexamethylene diisocyanate trimer is German Bayer N3300;

[0066] The acrylic resin has a branched structure; the functionality of the acrylic resin is 4; the viscosity of the acrylic resin at 25°C is 1200mPa·s; the acrylic resin is pentaerythritol tetraacrylate (CAS No.: 4986-89- 4);

[0067] The polymerization inhibitor is p-hydroxyanisole (CAS No.: 150-76-5);

[0068] The catalyst is dibutyltin dilaurate (CAS No.: 77-58-7);

[0069] The preparation step of described urethane acrylate comprises: (1) take the isocyanate of corres...

Embodiment 2

[0072] Embodiment 2 of the present invention provides a kind of high-functionality urethane acrylate, the raw material of described high-functionality urethane acrylate comprises, by weight, 10 parts of isocyanate, 74.3 parts of acrylic resin, 0.086 part of polymerization inhibitor, catalyst 0.0086 copies;

[0073] Described isocyanate is with embodiment 1;

[0074] The acrylic resin has a branched structure; the functionality of the acrylic resin is 6; the viscosity of the acrylic resin at 25°C is 1200mPa·s; the acrylic resin is dipentaerythritol hexaacrylate, purchased from Tianjin Jiurixin Materials Co., Ltd.;

[0075] Described polymerization inhibitor is with embodiment 1;

[0076] Described catalyzer is with embodiment 1;

[0077] The preparation steps of the polyurethane acrylate are the same as in Example 1.

[0078] The prepared high-functionality urethane acrylate is pale yellow and transparent, with NCO%<0.05% (molar concentration), viscosity of 4200cps / 40°C and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com