High transparent anti-yellowing curing accelerator for epoxy resin and preparation method thereof

A technology of changing epoxy resin and curing accelerator, which is applied in the field of epoxy resin curing accelerator and its preparation, can solve the problem of not making the yellowing resistance of the cured product, not making the optical performance of the cured product, and limiting the practical application of the accelerator, etc. problem, to achieve the effect of excellent yellowing resistance, excellent yellowing resistance and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

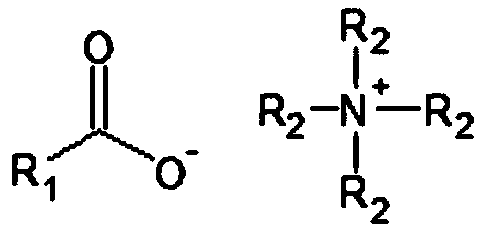

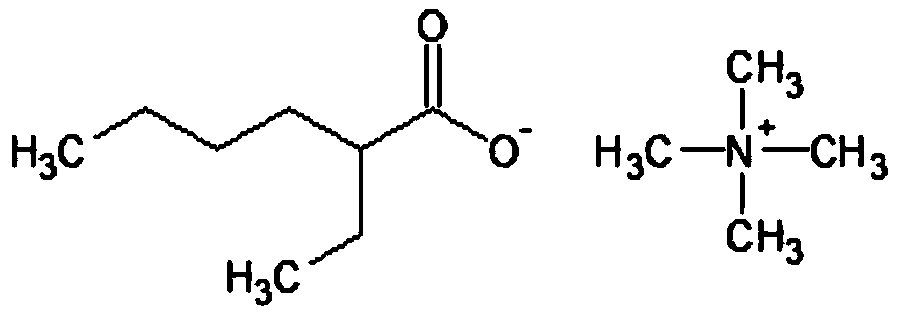

[0025] A kind of epoxy resin curing accelerator, its chemical formula is:

[0026]

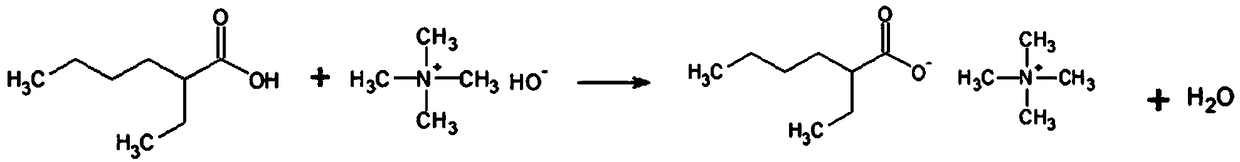

[0027] A kind of preparation method of epoxy resin curing accelerator is:

[0028] Weigh 1 mol of tetramethylammonium hydroxide and dissolve it in water to form a tetramethylammonium hydroxide solution, put it in a beaker, add diethylene glycol and mix well, then slowly add 1.0mol of 2-ethylhexanoic acid into tetramethylammonium hydroxide In the mixture of aqueous solution of methyl ammonium hydroxide and diethylene glycol, while controlling the temperature at 20-60°C, aqueous solution of tetramethylammonium hydroxide, diethylene glycol and 2-ethylhexyl acid mixture. Add the aqueous solution of tetramethylammonium hydroxide, the mixed solution of diethylene glycol and 2-ethylhexanoic acid into the reaction kettle, replace the oxygen in the reaction kettle with inert gas, and then vacuumize and heat to reduce Pressure distillation to remove water while controlling the temperature at 90-100...

Embodiment 2

[0037] Weigh 1 mol of tetraethylammonium hydroxide and dissolve it in water to form tetraethylammonium hydroxide solution, put it in a beaker, add octanol to mix well, then slowly add 1.2mol of 2-methylheptanoic acid into tetraethylammonium hydroxide In the mixed solution of ammonium oxide aqueous solution and octanol, while controlling the temperature at 20-60°C, a mixed solution of tetraethylammonium hydroxide aqueous solution, octanol and 2-methylheptanoic acid is obtained. Add the mixed solution of tetraethylammonium hydroxide aqueous solution, octanol and 2-methylheptanoic acid in the reactor, replace the oxygen in the reactor with inert gas, then vacuumize, heat, and carry out decompression distillation to remove water. At the same time, the temperature is controlled at 90-100°C for 12 hours, and the residue in the reaction kettle after distillation is the epoxy resin curing accelerator.

[0038] Mix e51 epoxy resin, 4-methylhexahydrophthalic anhydride, and curing accele...

Embodiment 3

[0040] Weigh 1 mol of tetrapropylammonium hydroxide and dissolve it in water to form tetrapropylammonium hydroxide solution, place it in a beaker, add propanol and mix evenly, then slowly add 1.3mol of heptanoic acid into tetrapropylammonium hydroxide aqueous solution and In the mixed solution of propanol, while controlling the temperature at 20-60°C, a mixed solution of quaternary ammonium hydroxide aqueous solution, propanol and heptanoic acid is obtained. Add the mixed solution of tetrapropylammonium hydroxide aqueous solution, propanol and heptanoic acid in the reactor, replace the oxygen in the reactor with inert gas, then vacuumize, heat, and carry out decompression distillation to remove water, and control the temperature at the same time. 90-100°C for 12 hours, the residue in the reactor after distillation is the curing accelerator for epoxy resin.

[0041]Mix e51 epoxy resin, 4-methylhexahydrophthalic anhydride, and curing accelerator at a mass ratio of 100:90:1.4, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com