Patents

Literature

225 results about "TETRAETHYLAMMONIUM HYDROXIDE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SACHEM’s Tetraethylammonium Hydroxide (TEAH) is quaternary ammonium compound that has a variety of applications. SACHEM has manufacturing facilities in America, Europe and Asia and can ship our product globally.

Process for preparing crystalline aluminosilicate compositions using charge density matching

A process for preparing crystalline alumino-silicate compositions has been developed. The process involves preparing a charge density mismatch reaction mixture comprising sources of aluminum, silicon, optionally an E metal and at least one charge density mismatch (CDM) template. The CDM template is an organic nitrogen containing template, in the hydroxide form, e.g. tetraethylammonium hydroxide and is characterized in that it is incapable of inducing crystallization. To this mixture there is added a solution comprising a second templating agent termed a crystallization template (CT). The CT can be an organic template different from the CDM template, an alkali metal, an alkaline earth metal and mixtures thereof.

Owner:UOP LLC

Process for preparing crystalline aluminosilicate compositions using charge density matching

ActiveUS20050095195A1Aluminium compoundsMolecular sieve catalystsAlkaline earth metalVolumetric Mass Density

A process for preparing crystalline alumino-silicate compositions has been developed. The process involves preparing a charge density mismatch reaction mixture comprising sources of aluminum, silicon, optionally an E metal and at least one charge density mismatch (CDM) template. The CDM template is an organic nitrogen containing template, in the hydroxide form, e.g. tetraethylammonium hydroxide and is characterized in that it is incapable of inducing crystallization. To this mixture there is added a solution comprising a second templating agent termed a crystallization template (CT). The CT can be an organic template different from the CDM template, an alkali metal, an alkaline earth metal and mixtures thereof.

Owner:UOP LLC

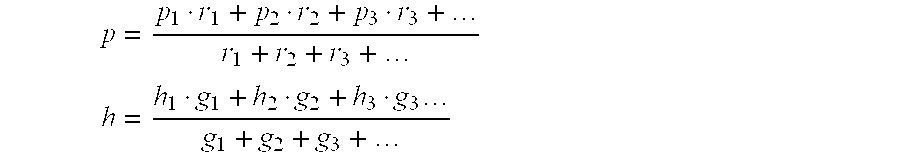

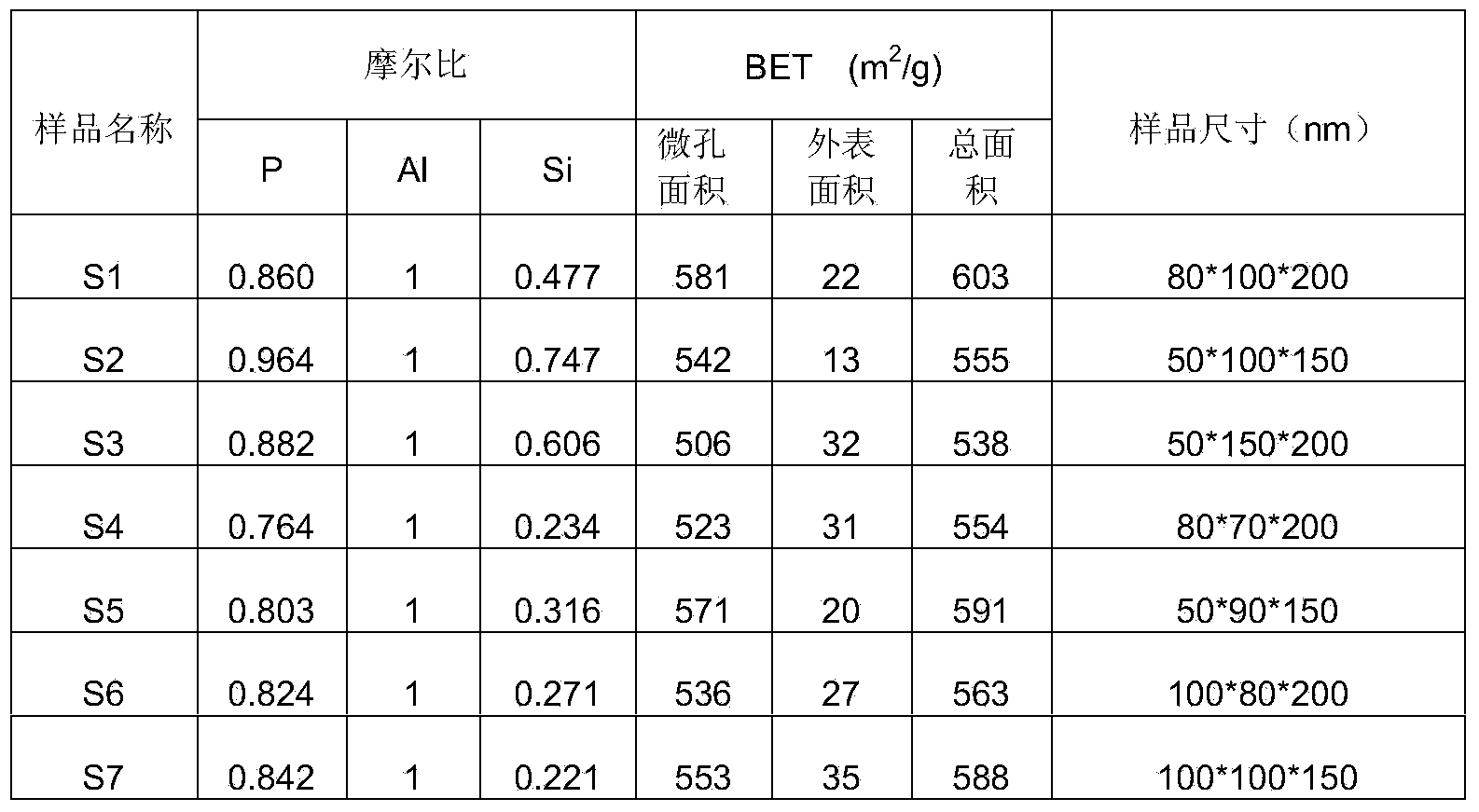

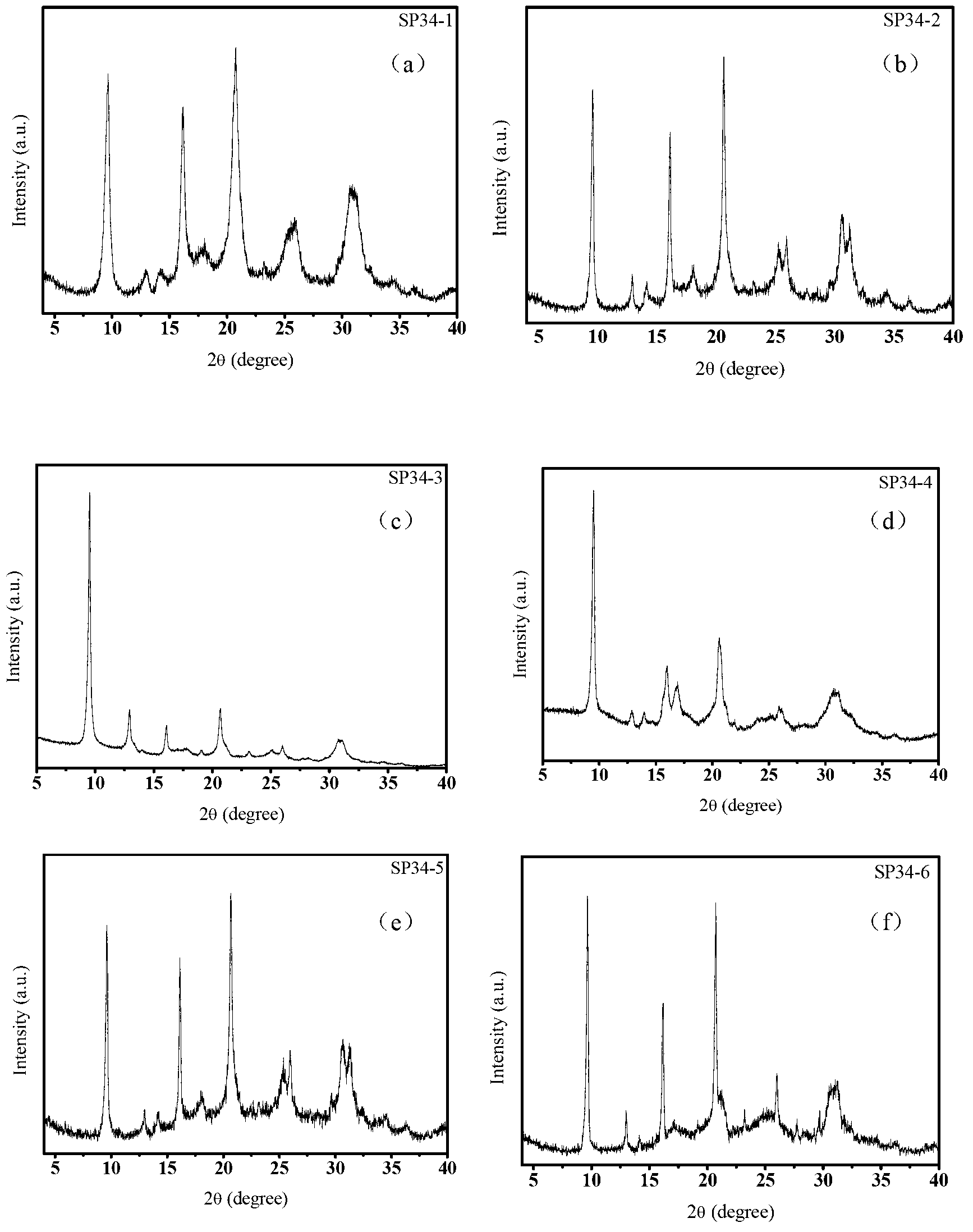

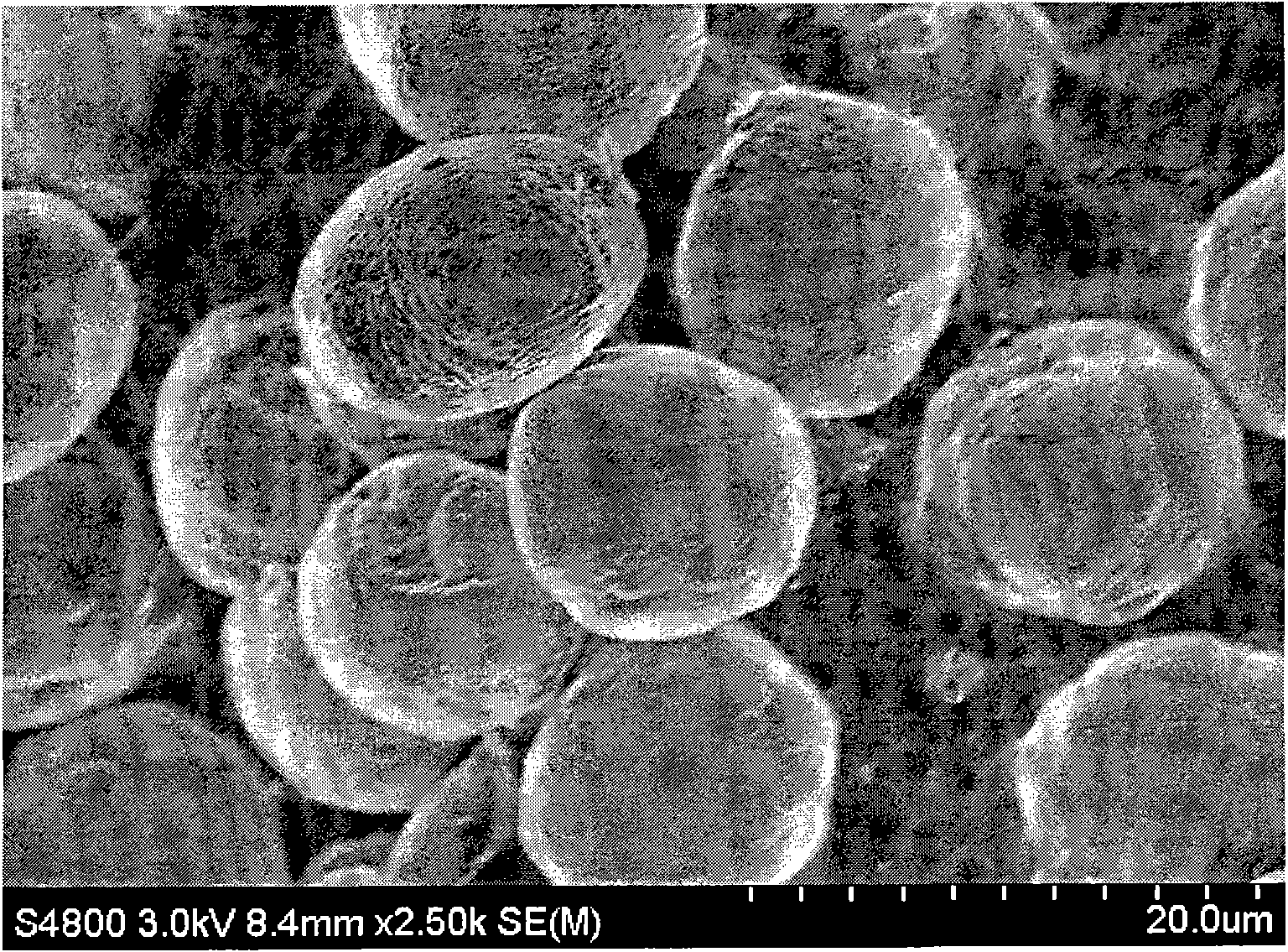

Slice-shaped nanometer SAPO-34 molecular sieve with relatively low silicon content, preparation method and application thereof

ActiveCN103641131ALong catalyst lifeIncreased diffusion rateMaterial nanotechnologyMolecular sieve catalystsGranularitySolvent

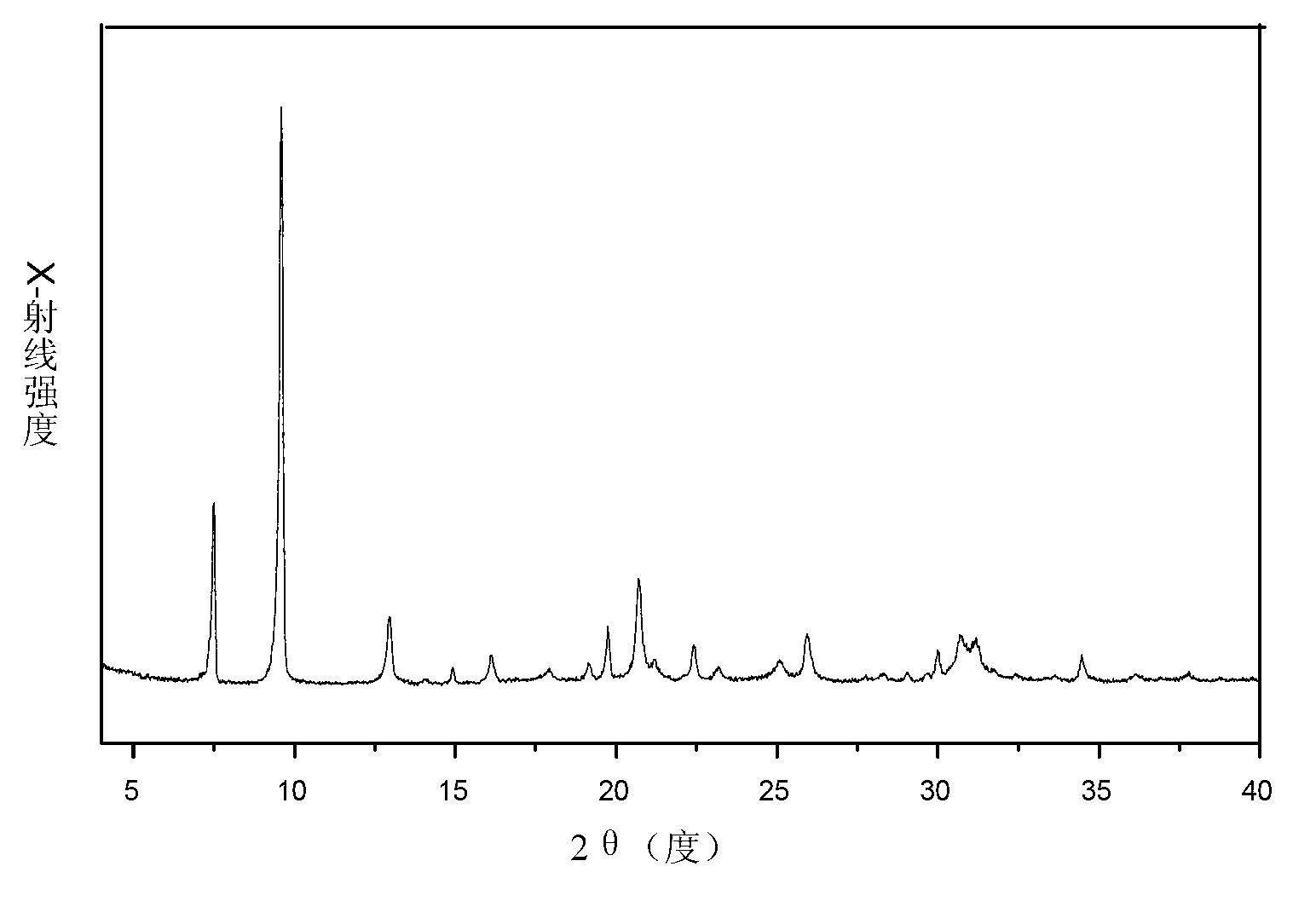

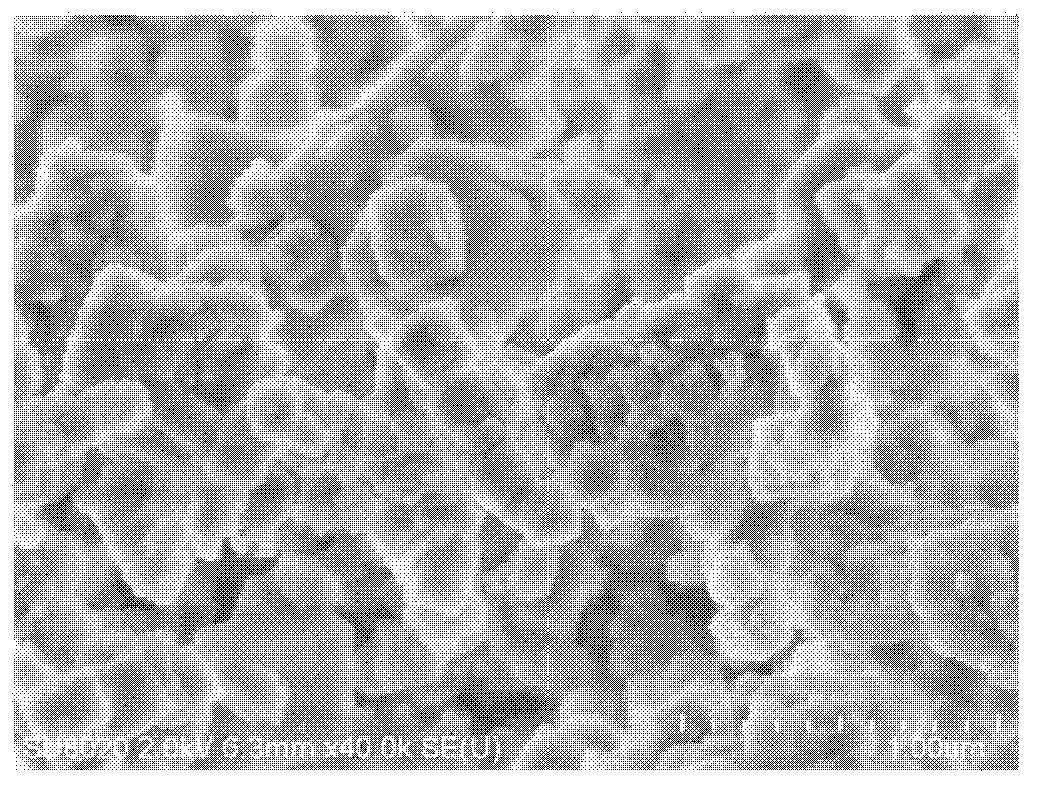

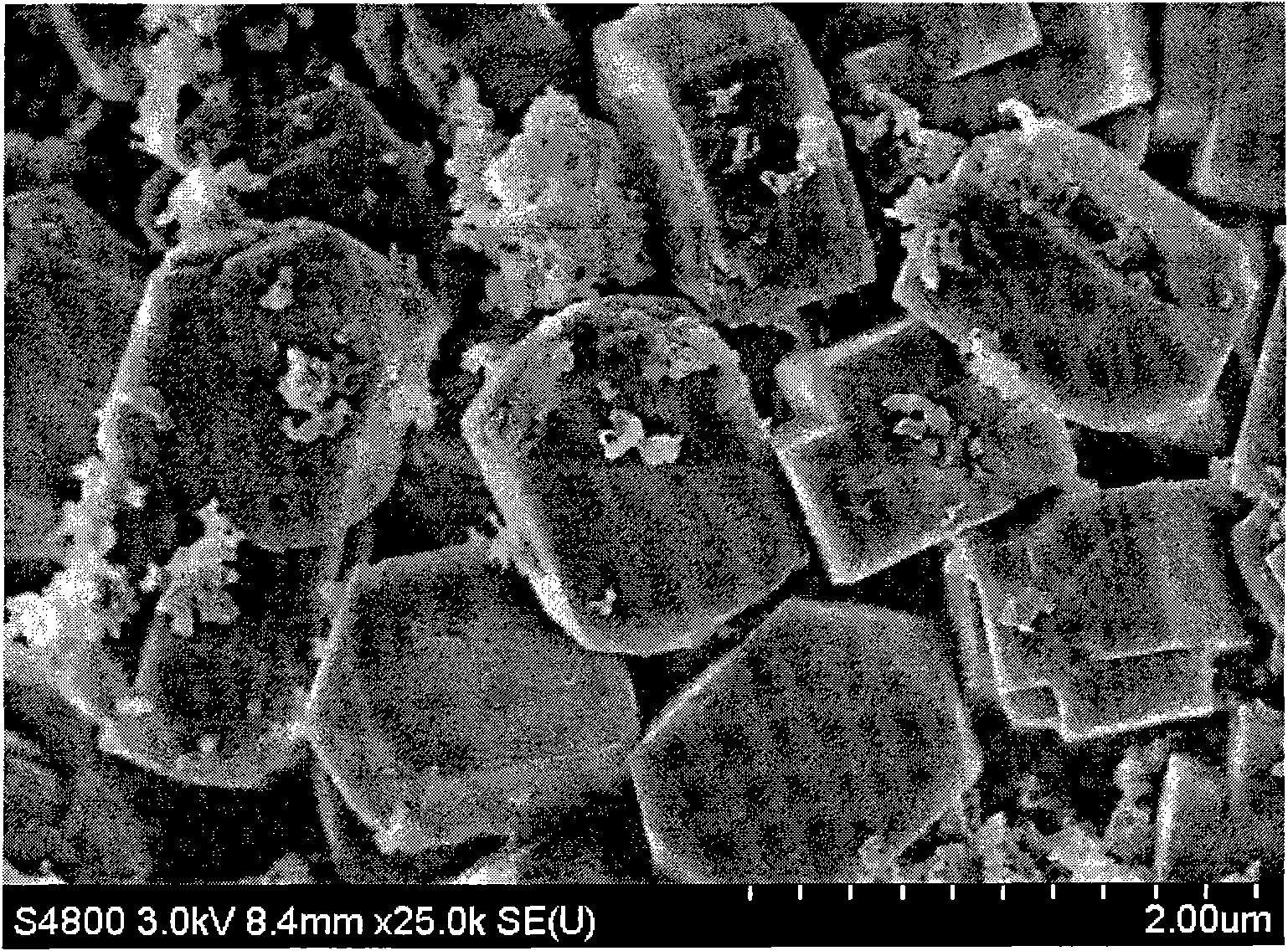

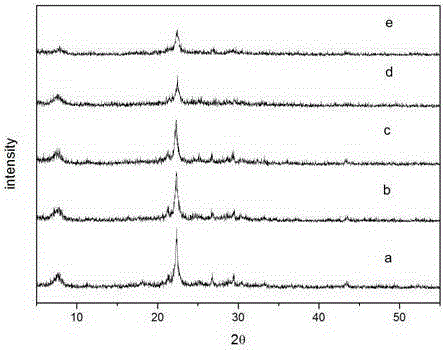

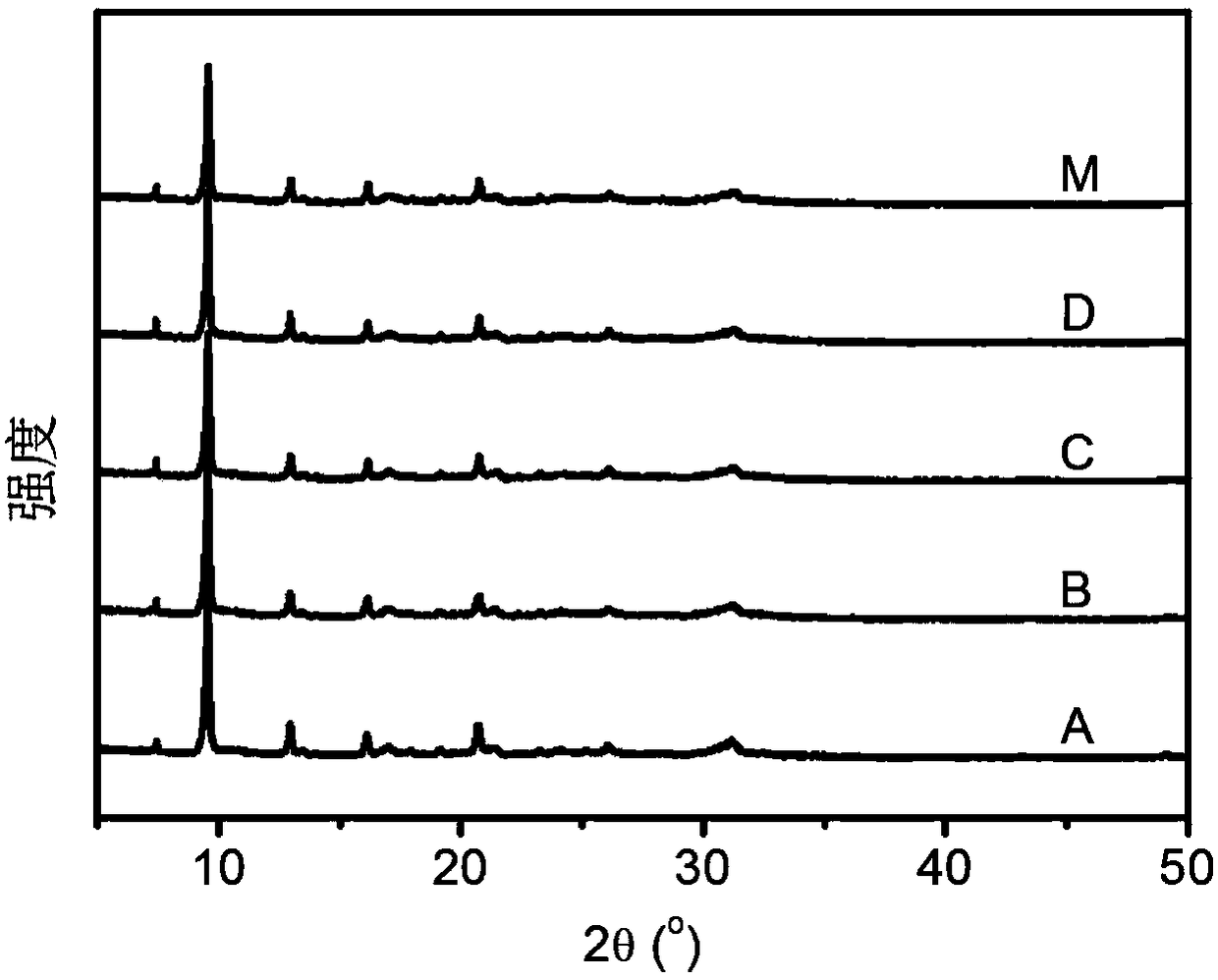

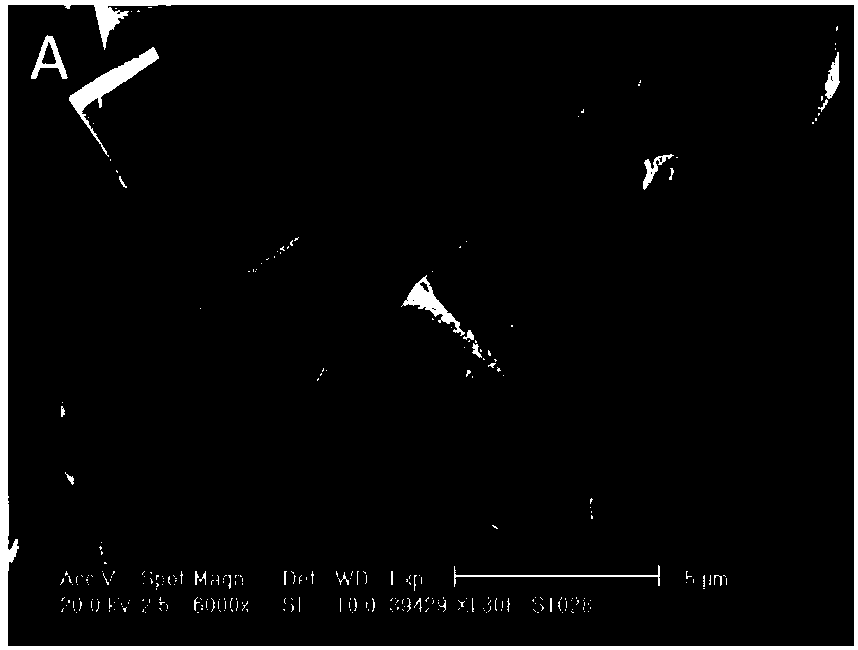

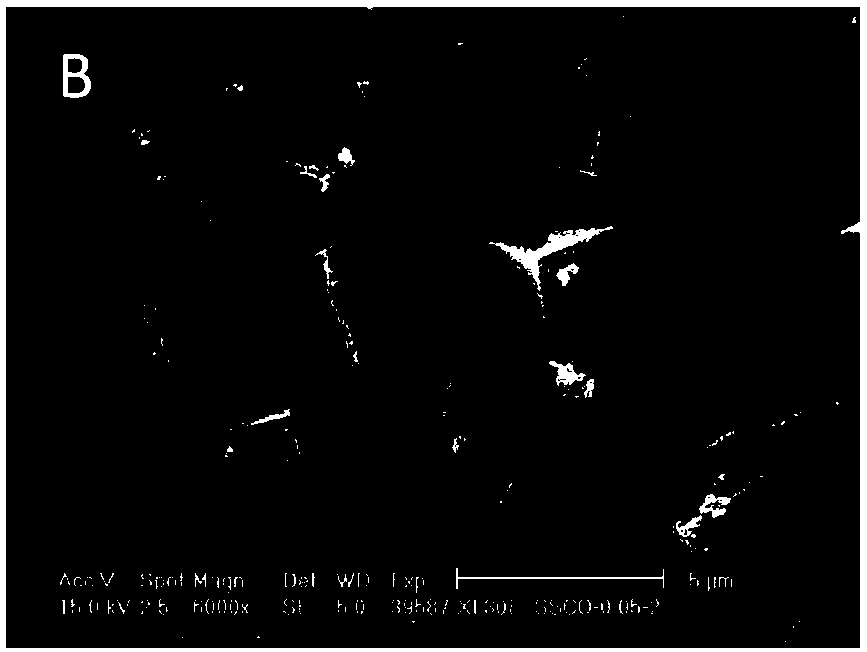

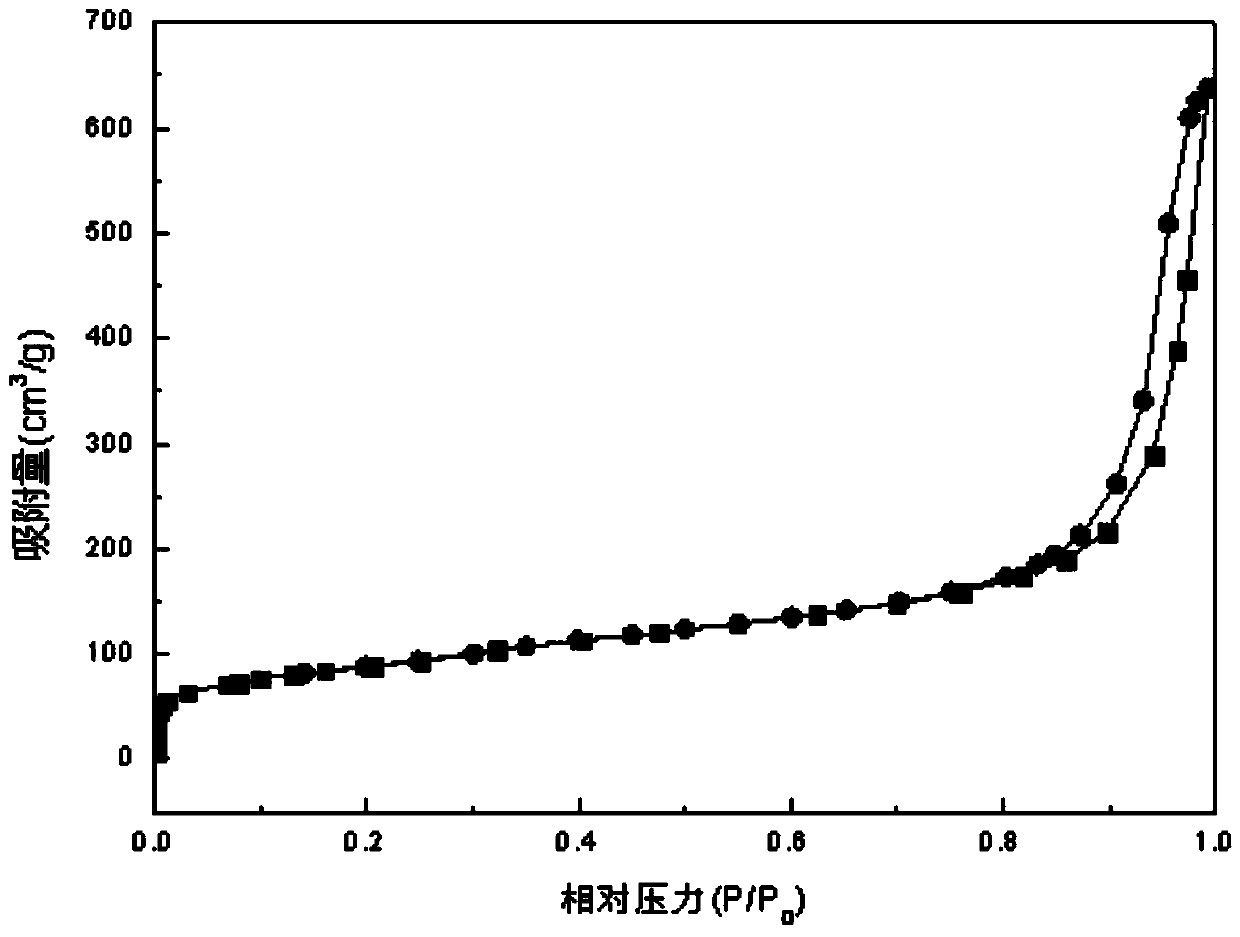

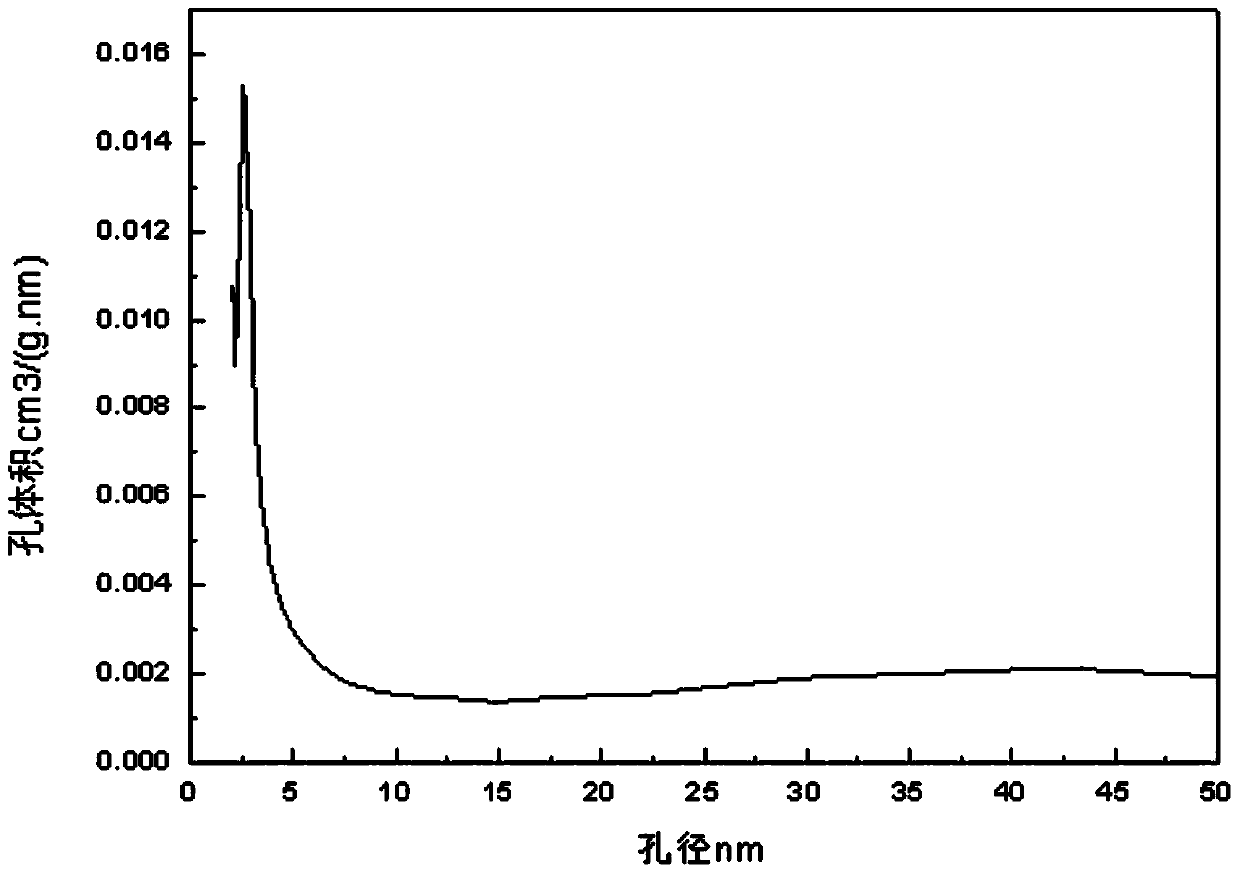

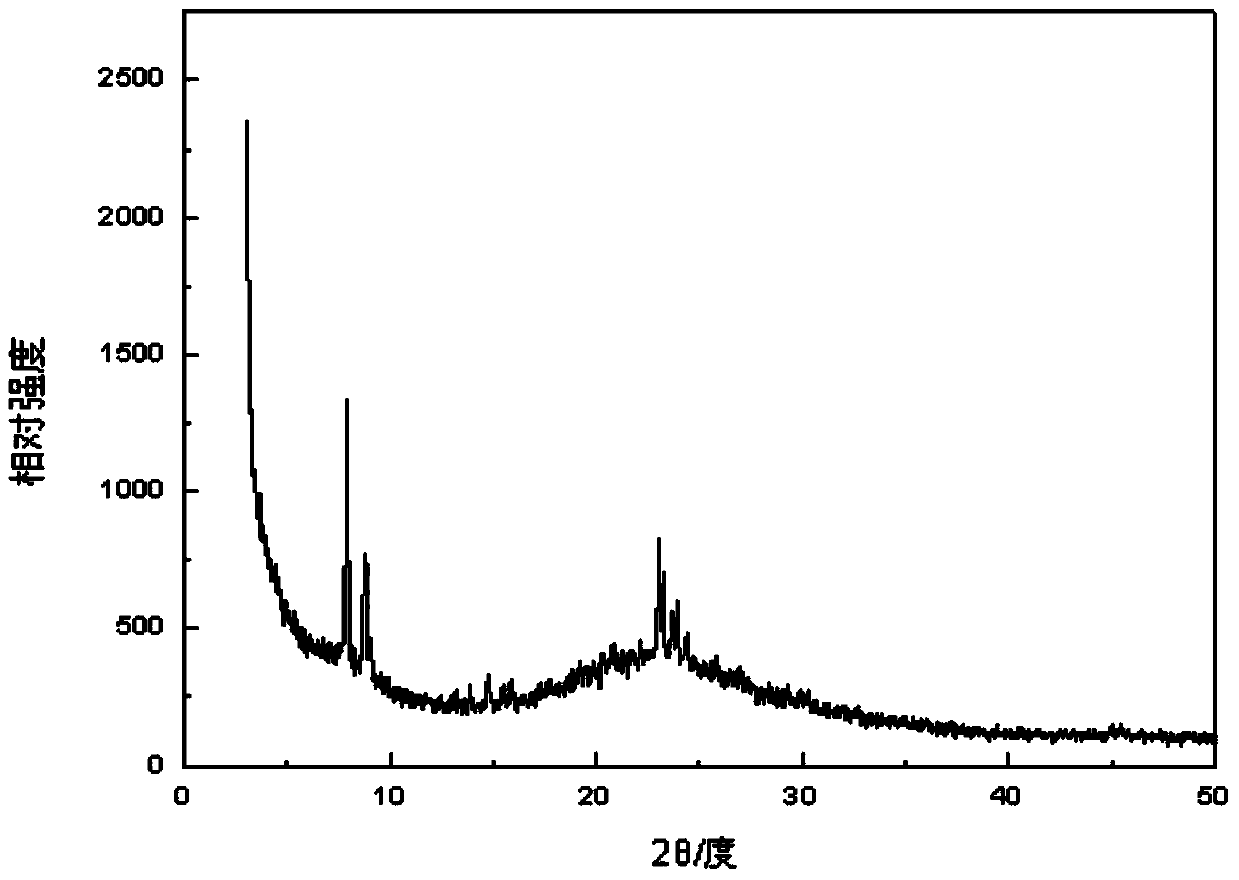

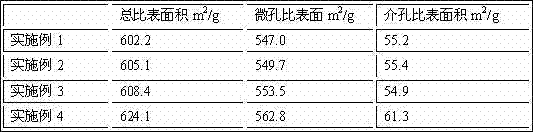

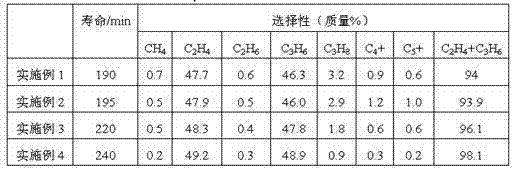

The invention discloses a slice-shaped nanometer SAPO-34 molecular sieve with relatively low silicon content, a preparation method and an application thereof, and belongs to the technical field of molecular sieves. Tetraethylammonium hydroxide is used as a template, the slice-shaped nanometer SAPO-34 molecular sieve with relatively low silicon content is synthesized by using the traditional hydrothermal method or a solvothermal synthesis method. The synthesized nanometer SAPO-34 sample is a slice-shaped feature, of which the average crystal granularity size is 50-250nm and the thickness is 50-100nm. The synthetic method is simple and efficient; the solvent consumption is low; the yield of the synthesized nanometer SAPO-34 sample is extremely high and can be up to 85-90 percent; the synthesized nanometer SAPO-34 sample is high in low carbon olefin selectivity during reaction of methanol to olefin (MTO), particularly, the total yield of ethylene and propylene can be up to more than 83 percent, and the molecular sieve is very suitable for industrial amplification application.

Owner:JILIN UNIV

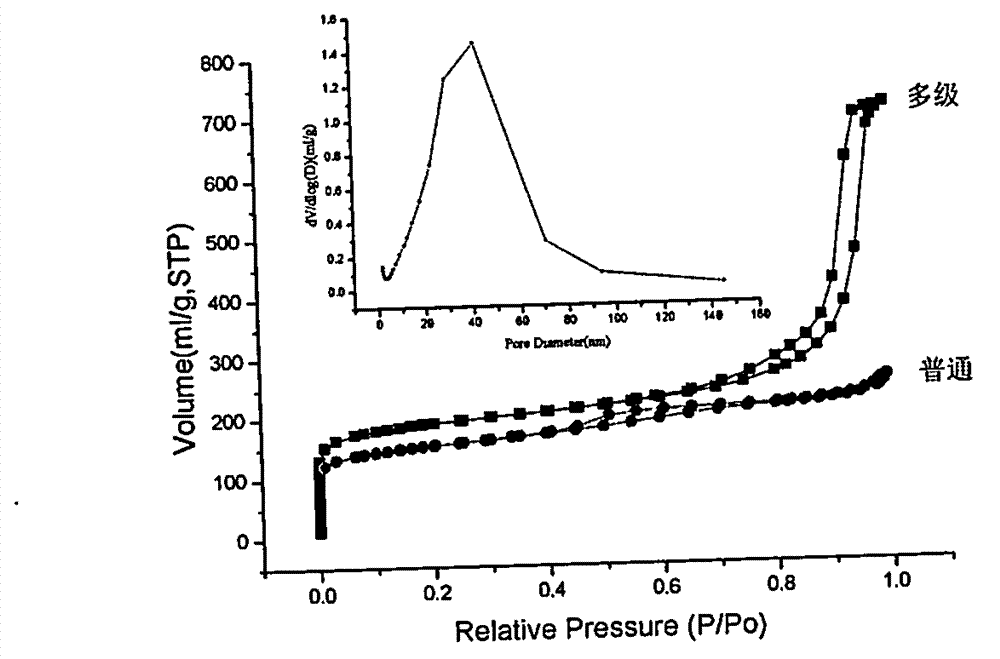

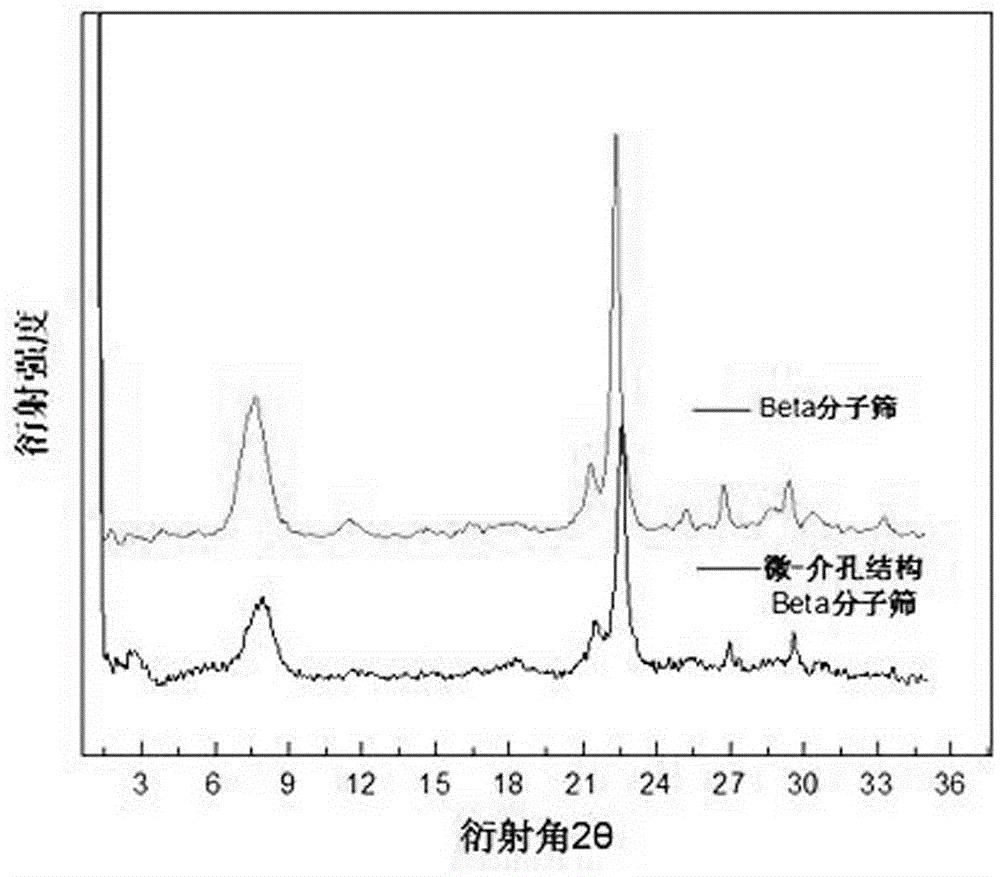

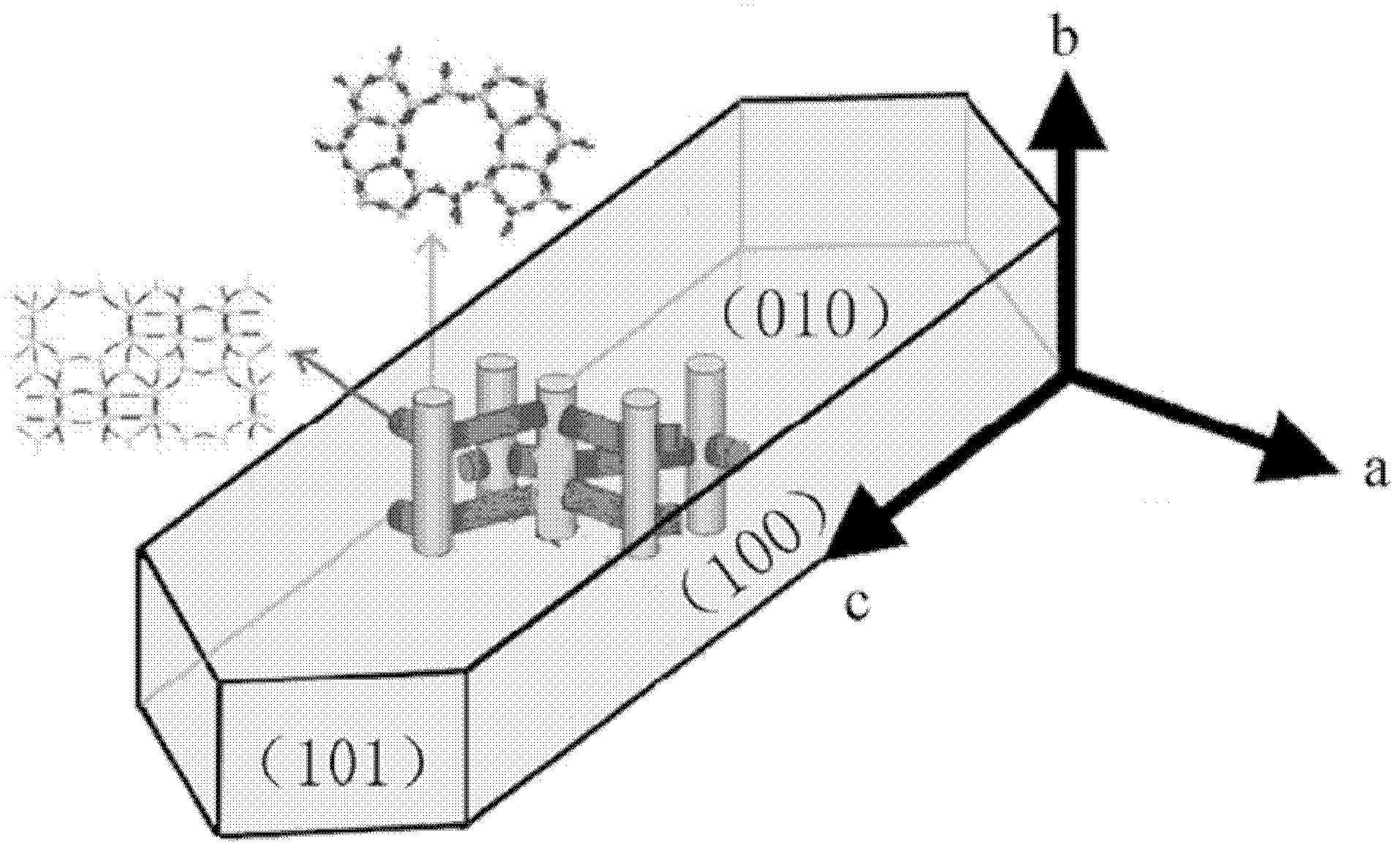

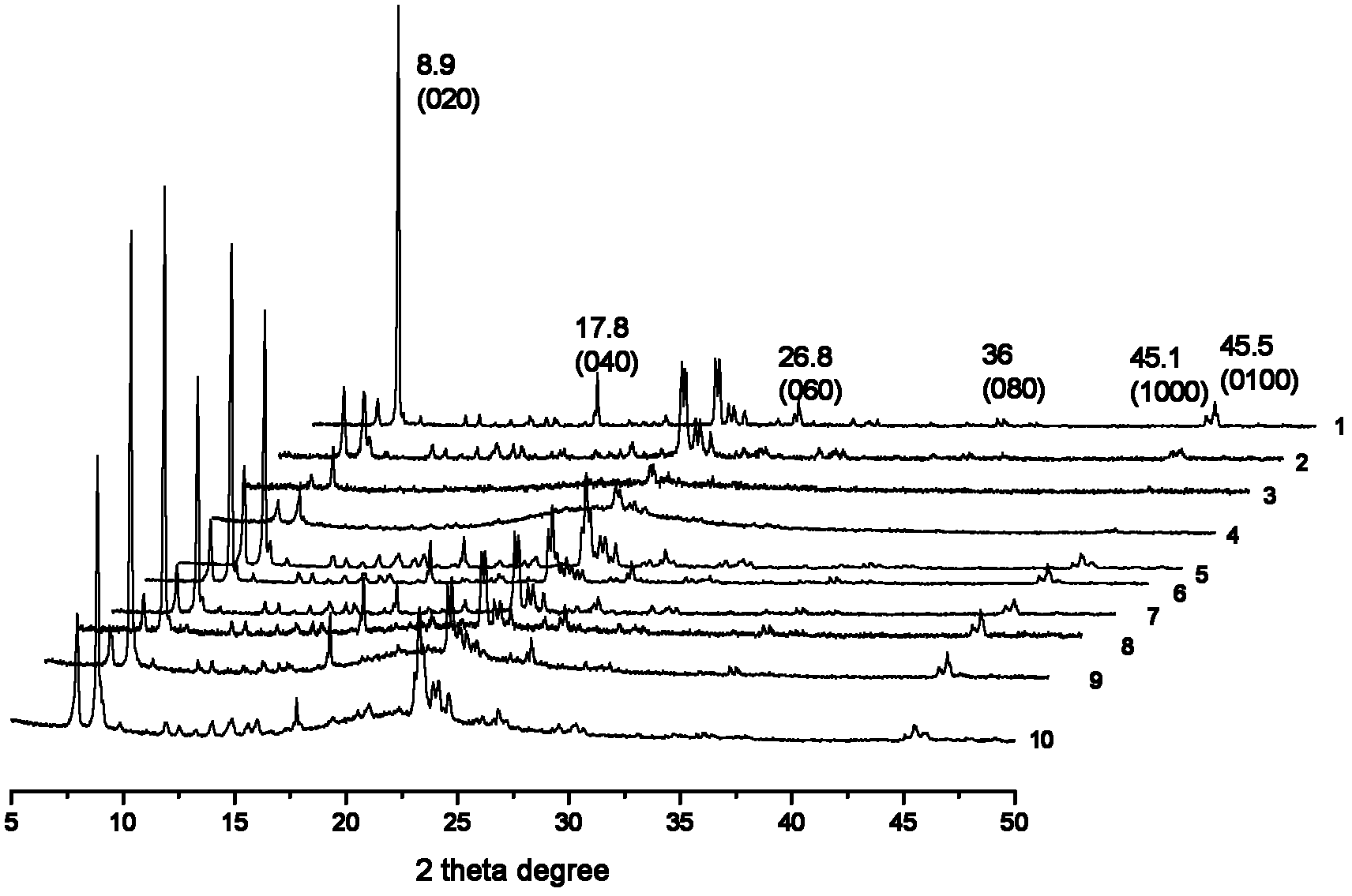

Preparation method of beta zeolite with multilevel pore canals

InactiveCN103318911AReduce dosageGood for growth controlCrystalline aluminosilicate zeolitesSilanesPhysical chemistry

A preparation method of beta zeolite with multilevel pore canals is disclosed by the invention, and comprises: uniformly mixing a silicon source, a tetraethylammonium hydroxide solution, sodium hydroxide and a complete dissolved aluminium source, stirring at a certain constant temperature, and forming a xerogel; carrying out a first hydrothermal treatment for the obtained xerogel, cooling, grinding, and adding a proper amount of a silane coupling agent; and carrying out a second hydrothermal treatment, cooling, filtering, roasting, and obtaining the beta zeolite with multilevel pore canals. The preparation method and the post-processing method are simple, yield is high, and industrial amplification production is easy to realize.

Owner:EAST CHINA UNIV OF SCI & TECH

One-step preparation method for hydrogen type multistage pore molecular sieve with SAPO-5 and SAPO-34 symbiosis

InactiveCN103011195ASlow down the rate of carbonizationLong catalyst lifeMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesHydrogenSurface-active agents

The invention belongs to the technical field of preparation of inorganic multistage pore materials, and relates to a one-step preparation method for a hydrogen type multistage pore molecular sieve with SAPO-5 and SAPO-34 symbiosis. According to the invention, tetraethylammonium hydroxide (TEAOH) is used as atemplate agent, and an organic silicon surface active agent (STSAC) is used at the same time to prepare a hydrogen type micropore-mesopore composite molecular sieve with SAPO-5 and SAPO-34 symbiosis in one step through the hydrothermal method, so that the acid exchange step is avoided, and the cost is reduced. The molecular sieve is used as catalyst for preparing low-carbon olefin with methanol, so that the limitations to aspects of dispersion and mass transfer can be overcome, the caking speed is reduced, the catalysis life is possibly prolonged, and wide application foreground is anticipated in industrial catalysis.

Owner:JILIN UNIV

Silicon solar cell front face electrode lead-free silver paste and preparing method thereof

InactiveCN104157332AImprove compactnessImprove smoothnessNon-conductive material with dispersed conductive materialCable/conductor manufactureTetramethylammonium hydroxidePotassium

The invention discloses silicon solar cell front face electrode lead-free silver paste and a preparing method thereof. The silicon solar cell front face electrode lead-free silver paste is characterized in that inorganic glass powder is not contained in the silver paste, and the silver paste comprises, by mass, 75-85 percent of conductive silver powder, 1-5 percent of antireflective film corrosive, 10-20 percent of organic vehicle and 1-5 percent of additive; the conductive silver powder is formed by mixing micro silver powder and nano silver powder with the mass ratio of 10:1-2; the antireflective film corrosive comprises one or more of potassium fluotitanate, potassium fluoroaluminate, potassium fluosilicate and potassium fluoborate; the additive comprises one or more of ethanol amine, diethanol amine, triethanol amine, tetramethylammonium hydroxide, tetraethylammonium hydroxide and tetramethylammonium hydroxide. According to the silicon solar cell front face electrode lead-free silver paste and the preparing method thereof, lead-free silver paste printing and antireflective film removing are conducted in one step, sintering can be conducted at a low temperature, the compactness and the smoothness of a silver electrode film are improved, and the photoelectric conversion efficiency of a silicon cell piece is improved.

Owner:TIANJIN VOCATIONAL INST

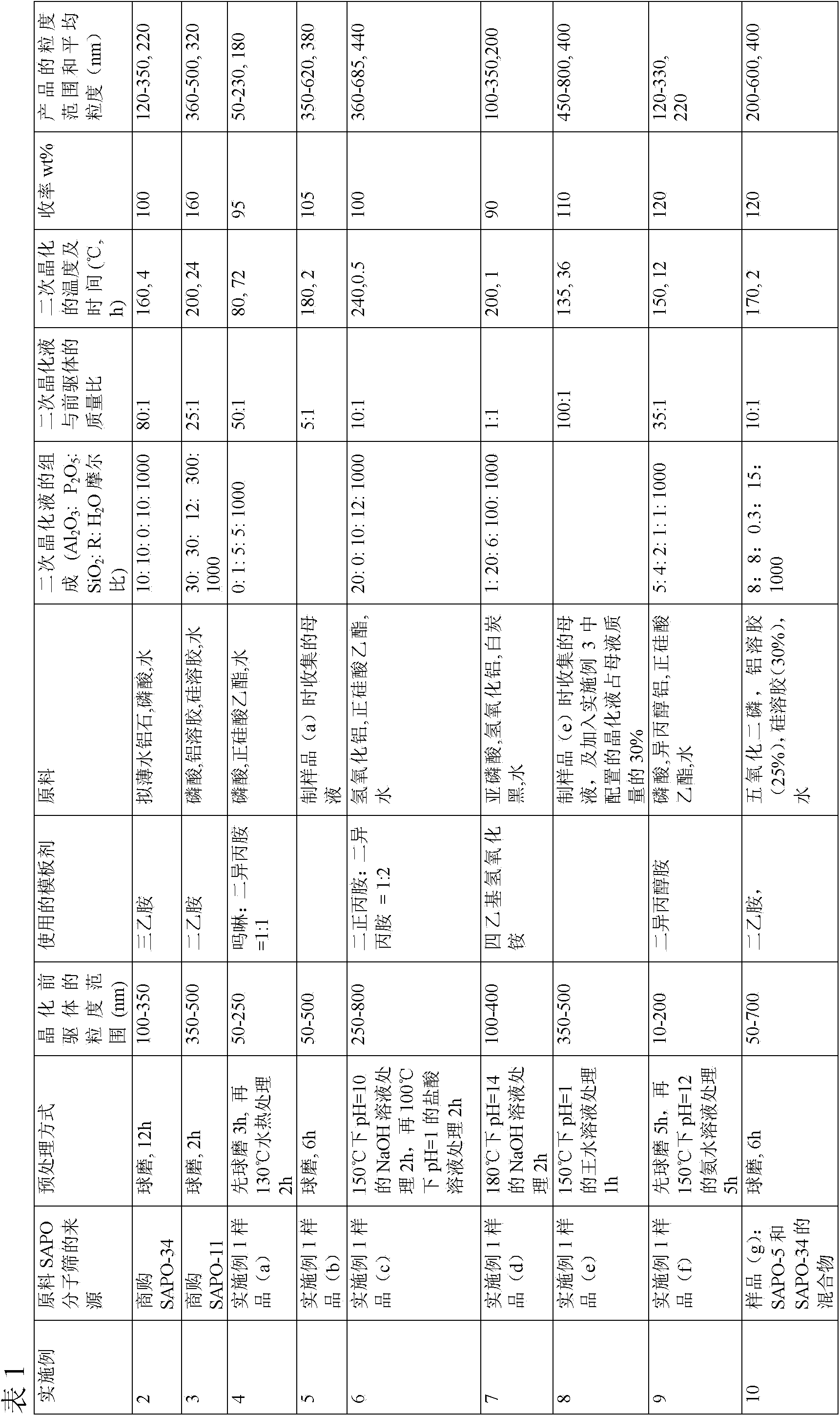

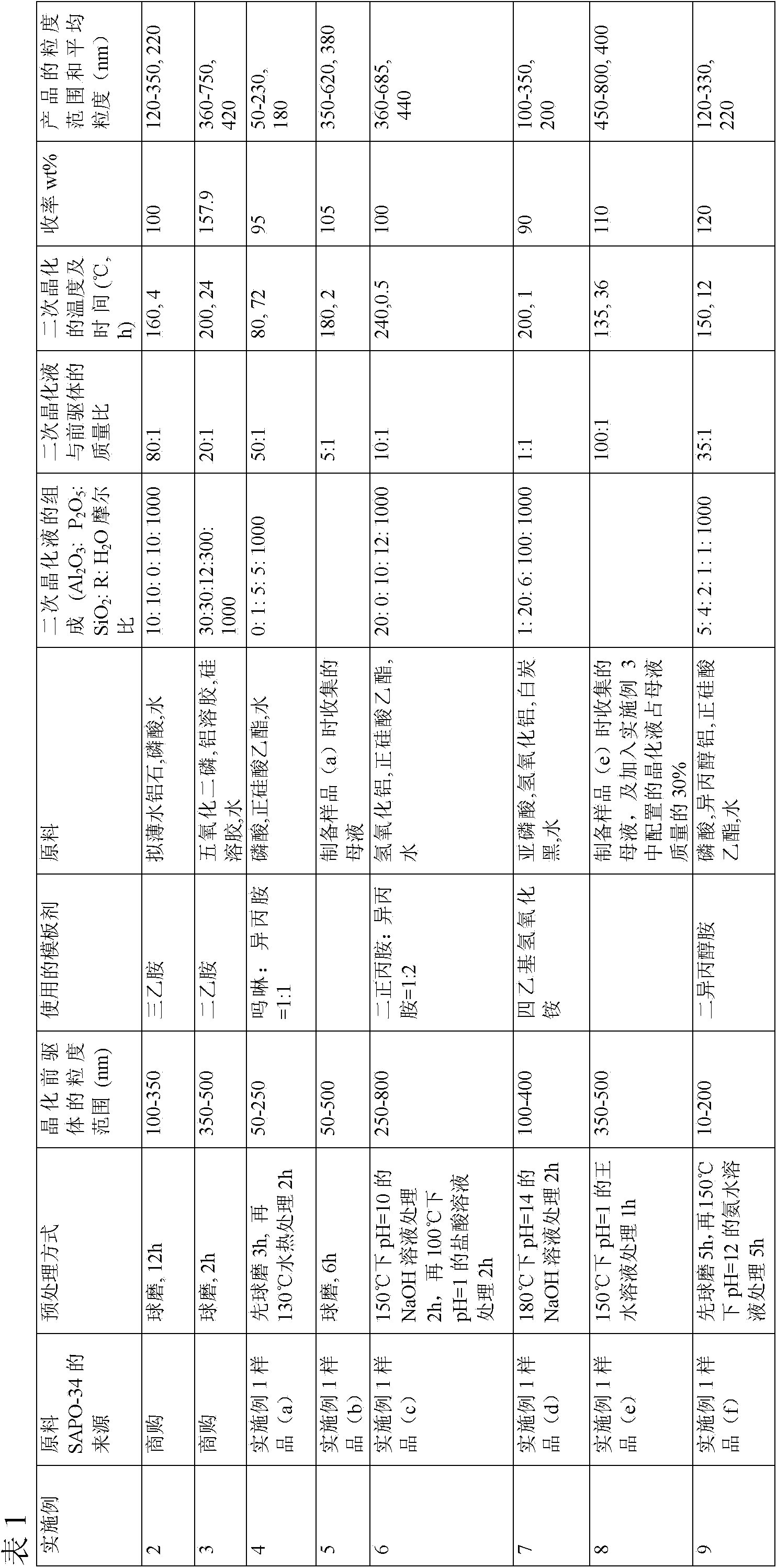

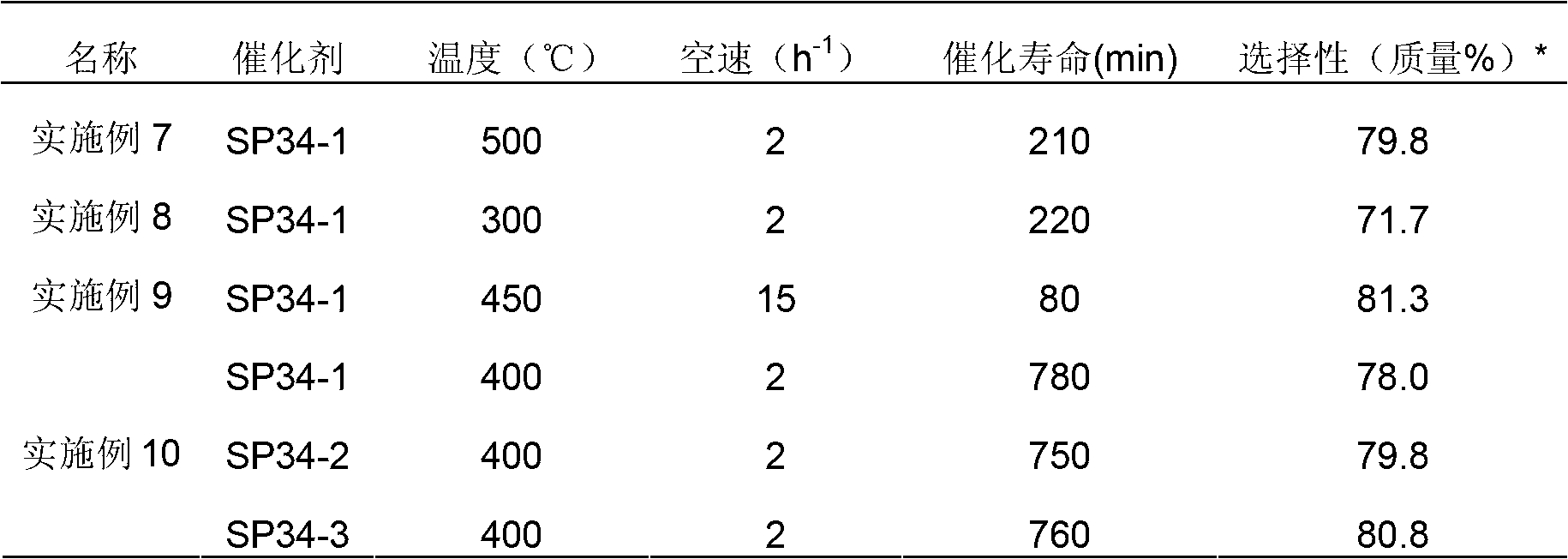

Method for preparing small granulated SAPO molecular sieve, product prepared through method, and use of product

ActiveCN104340985AEffective regulation of granularityHigh catalytic activityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsGranularityOxygen

The invention relates to a method for preparing a small granulated SAPO molecular sieve, a product prepared through the method, and a use of the product. The method concretely includes the following steps: preprocessing a raw material SAPO molecular sieve to form granules with the granularity of 10-800nm in order to obtain a crystallization precursor with low crystallization degree; mixing an organic amine template R and water with optional silicon, aluminum and phosphorus sources to prepare a crystallization liquid, or using a mother liquor obtained after separating a product in the preparation process of the SAPO molecular sieve as the crystallization liquid; and mixing the crystallization precursor with the crystallization liquid, carrying out a hydrothermal reaction, and separating to obtain the small granulated SAPO molecular sieve. The method allows the small granulated SAPO molecular sieve to be simply prepared without using an organic amine template tetraethylammonium hydroxide, and the product prepared in the invention has the advantages of obvious prolongation of the catalysis life of a reaction of oxygen-containing compounds, such as methanol, to olefin as a catalyst, and obvious selectivity increase as a catalyst.

Owner:中科催化新技术(大连)股份有限公司

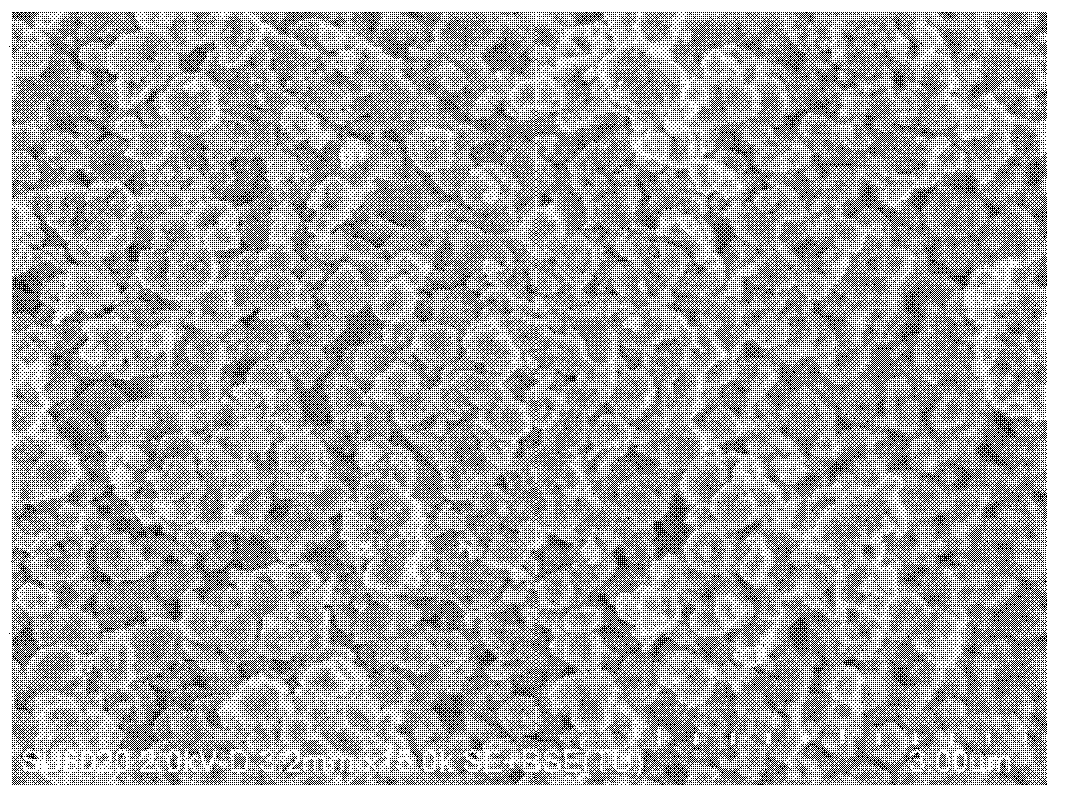

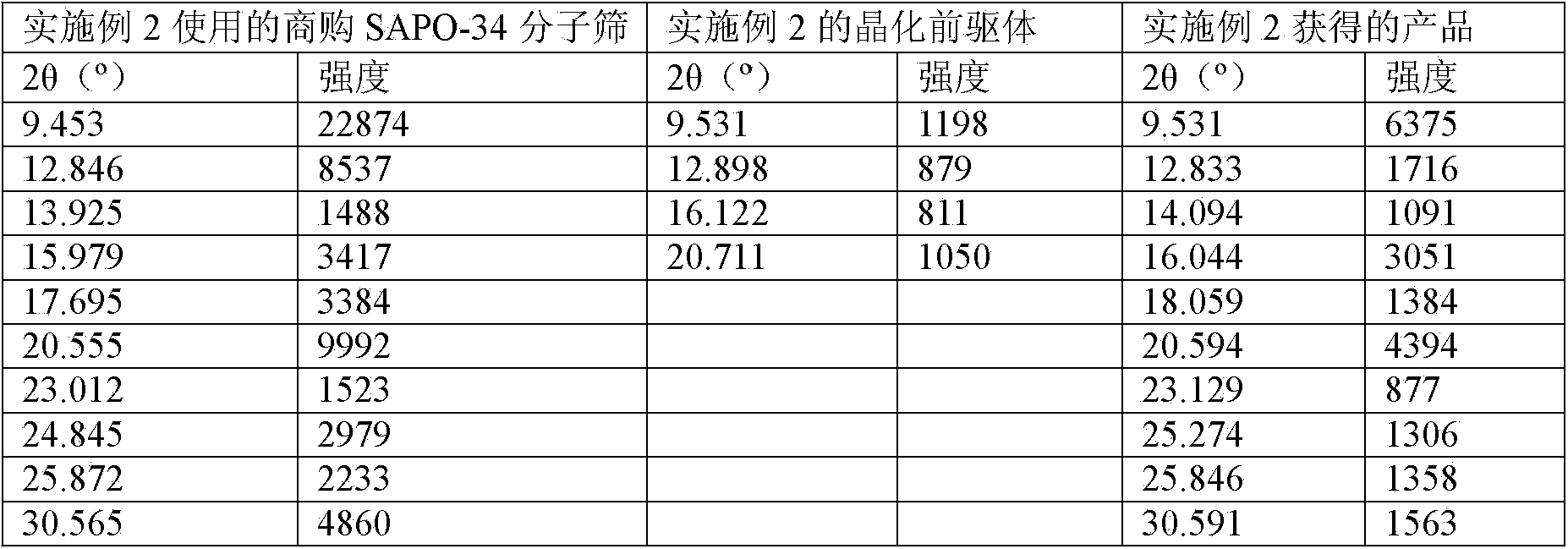

Method for preparing small granulated SAPO-34 molecular sieve, product prepared through method, and use of product

ActiveCN104340986AHigh crystallinityEasy to prepareMolecular sieve catalystsHydrocarbon from oxygen organic compoundsGranularityCrystallinity

The invention relates to a method for preparing a small granulated SAPO-34 molecular sieve, a product prepared through the method, and a use of the product. The method concretely includes the following steps: preprocessing a raw material SAPO-34 molecular sieve to form granules with the granularity of 10-800nm in order to obtain a crystallization precursor with low crystallization degree; mixing an organic amine template R and water with optional silicon, aluminum and phosphorus sources to prepare a crystallization liquid, or using a mother liquor obtained after separating a product in the preparation process of the SAPO-34 molecular sieve as the crystallization liquid; and mixing the crystallization precursor with the crystallization liquid, carrying out a hydrothermal reaction, and separating to obtain the small granulated SAPO-34 molecular sieve. The method allows the small granulated SAPO-34 molecular sieve to be simply prepared without using an organic amine template tetraethylammonium hydroxide, and the product prepared in the invention has the advantages of obvious prolongation of the catalysis life of a reaction of oxygen-containing compounds, such as methanol, to olefin as a catalyst, and obvious selectivity increase as a catalyst.

Owner:中科催化新技术(大连)股份有限公司

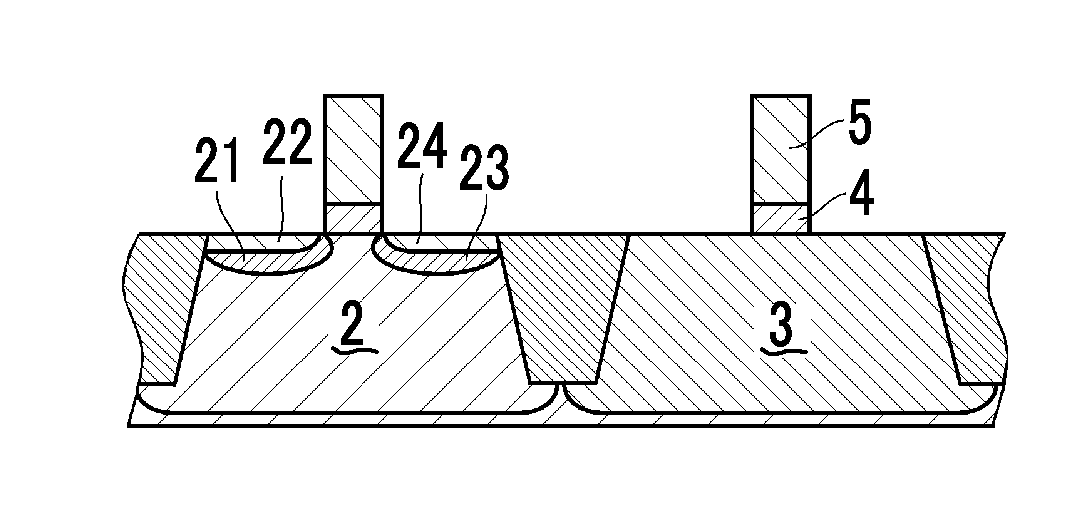

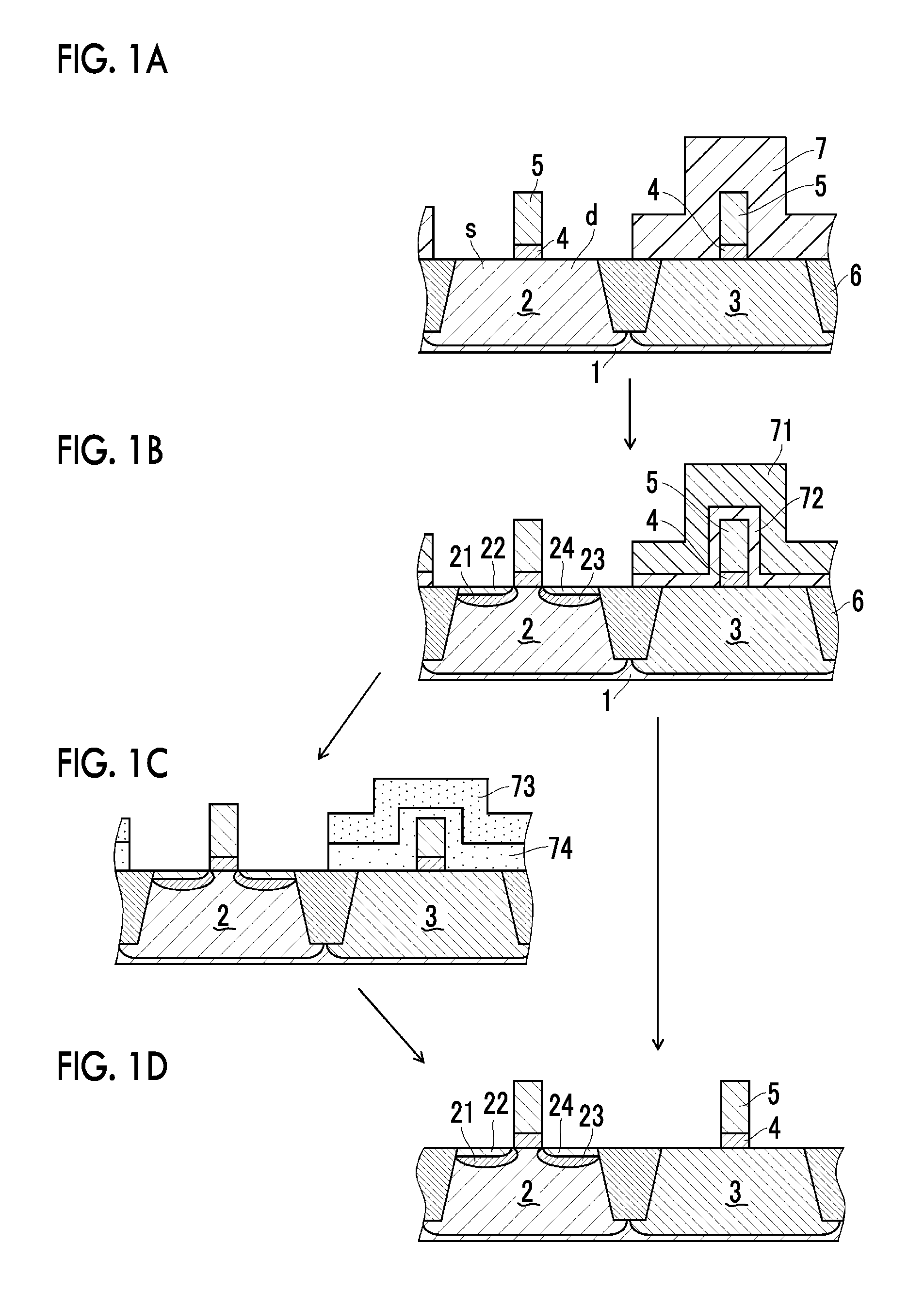

Method for stripping modified resist, modified-resist stripper used therefor, and method for manufacturing semiconductor-substrate product

InactiveUS20160254164A1Suppressing preventing damageImprove applicabilitySolid-state devicesSemiconductor/solid-state device manufacturingResistTetrabutylammonium hydroxide

Provided is a stripping method for stripping a modified resist from a semiconductor substrate by applying an etching solution to the semiconductor substrate, in which the etching solution contains an alcohol compound and a quaternary ammonium hydroxide compound and the quaternary ammonium hydroxide compound is at least one of tetraethylammonium hydroxide and tetrabutylammonium hydroxide.

Owner:FUJIFILM CORP

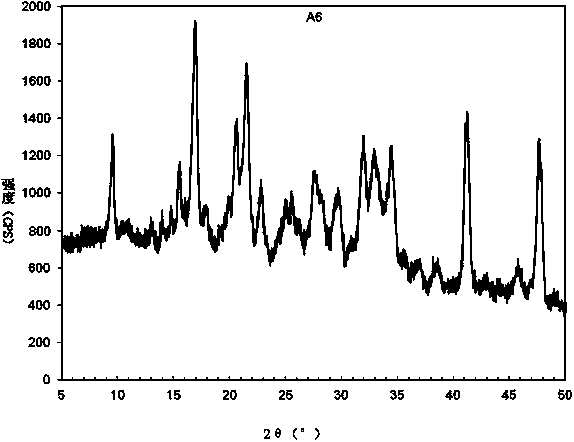

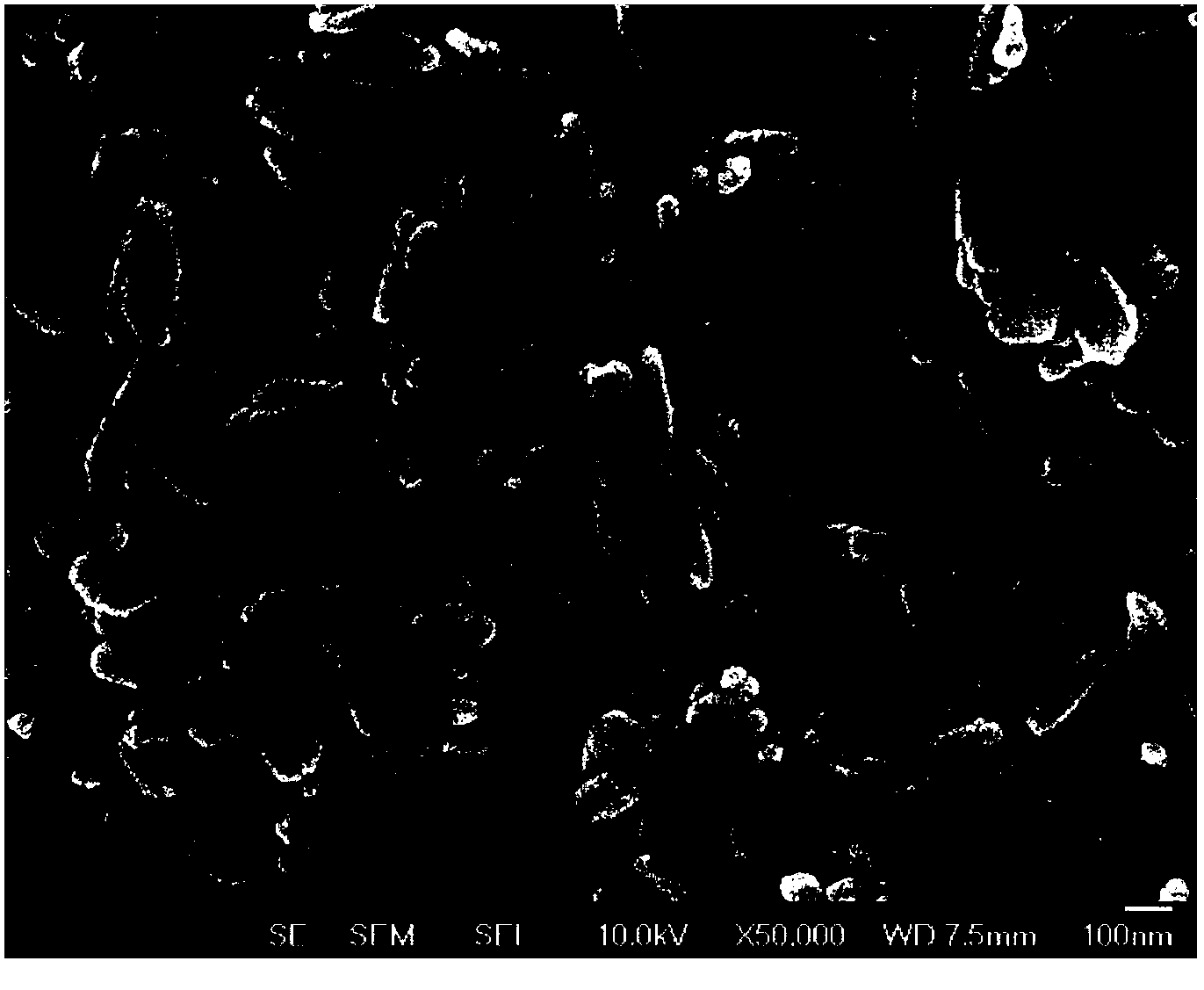

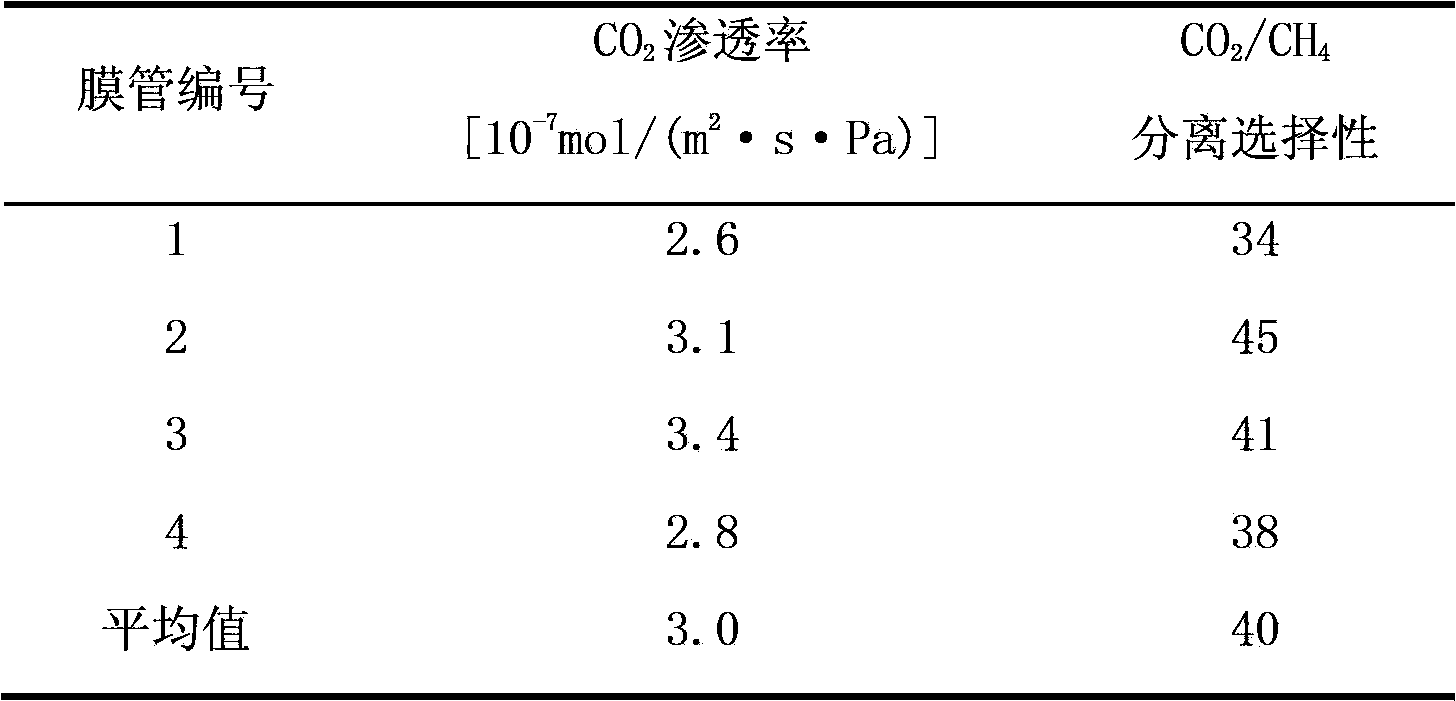

Preparation method of AlPO-18 molecular sieve membrane

InactiveCN103449475AHigh separation selectivityGood repeatabilityNanotechnologyMolecular-sieve aluminophosphatesPhosphoric acidMembrane synthesis

The invention discloses a preparation method of an AlPO-18 molecular sieve membrane. The preparation method comprises following steps: (1) mixing and dissolving aluminum source, tetraethylammonium hydroxide, and phosphoric acid in water, then carrying out hydro-thermal synthesis reactions to obtain AlPO-18 molecular sieve crystal seed; (2) coating the AlPO-18 molecular sieve crystal seed on the inner surface of a porous ceramic tube carrier; (3) mixing and dissolving aluminum source, tetraethylammonium hydroxide, and phosphoric acid in water to obtain molecular sieve membrane synthesis mother liquid, putting the ceramic tube, which has been coated with the AlPO-18 molecular sieve crystal seed, in a reactor, adding the molecular sieve membrane synthesis mother liquid, and then carrying out a hydrothermal crystallization treatment so as to obtain an AlPO-18 molecular sieve membrane after aging; (4) burning the membrane tube to remove the template agent so as to obtain an activated AlPO-18 molecular sieve membrane. The AlPO-18 molecular sieve membrane synthesized by the preparation method is capable of being applied to separations of CO2 / CH4 and CO2 / H2, and has a high selectivity and a high throughput of separations of CO2 / CH4 and CO2 / H2.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

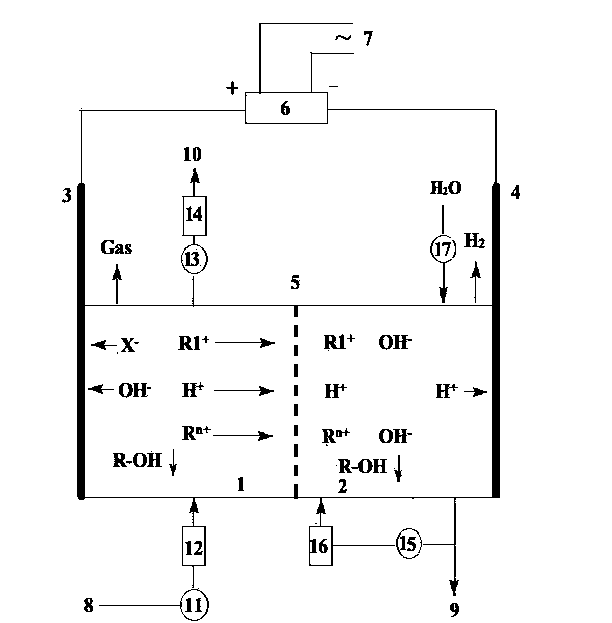

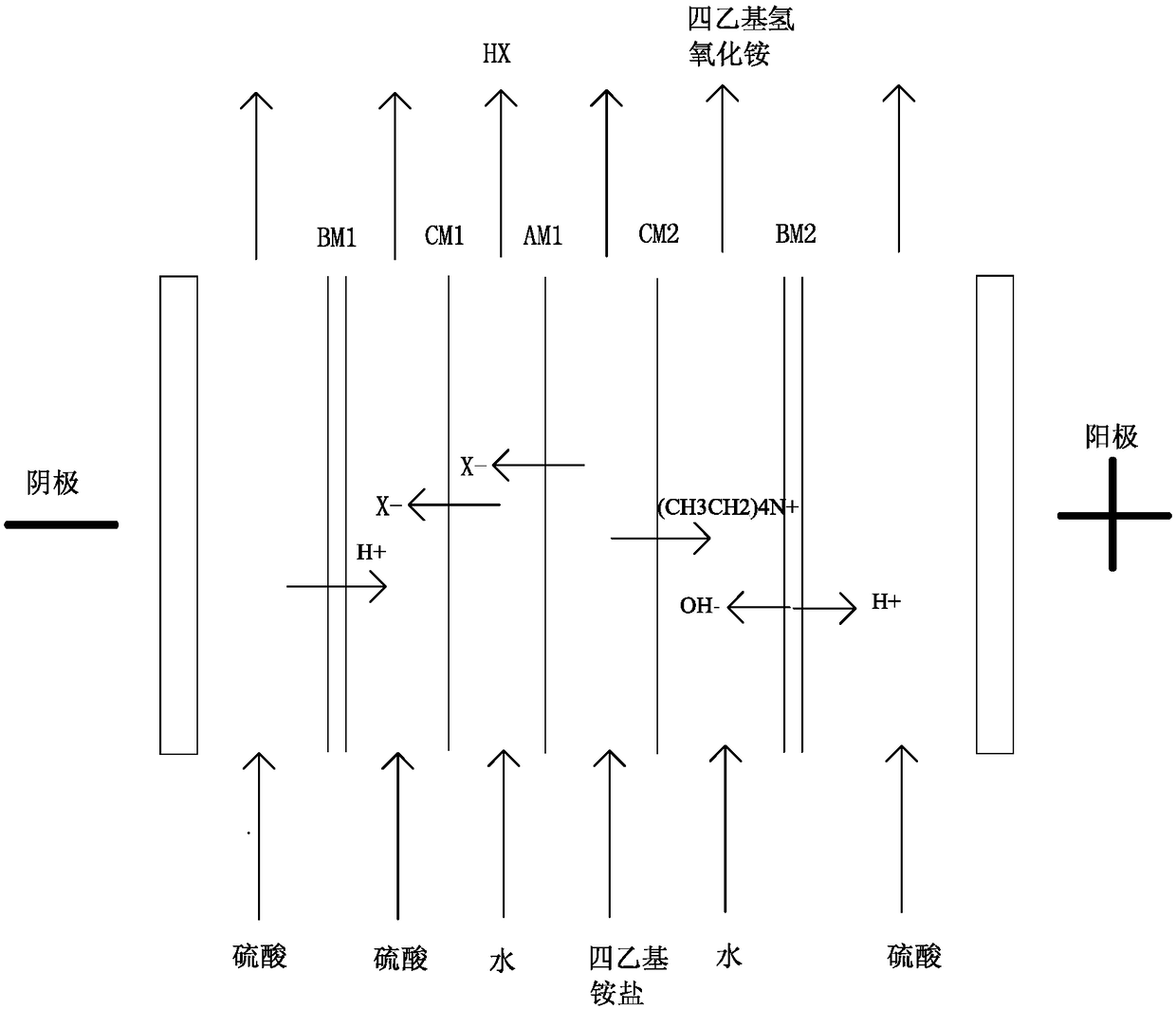

Method for preparing high-purity tetraethylammonium hydroxide by continuous electrolysis

ActiveCN103526224ANot prone to lifeNot prone to performance drawbacksOrganic chemistryElectrolysis componentsElectrolysisAmmonium hydroxide

The invention discloses a method for preparing high-purity tetraethylammonium hydroxide by continuous electrolysis. The method comprises the following steps: placing tetraethylammonium salt aqueous liquor with the raw material concentration of 30-50% in an anode chamber of a two-chamber one-membrane ionic membrane electrolysis device, adding tetraethylammonium hydroxide with the concentration of 2-5% into a cathode chamber of the device, and communicating current between an anode plate and a cathode plate, wherein in the anode chamber, tetraethylammonium salt is hydrolyzed to generate cation (CH3CH2)4N<+> and anion X<->, the cations (CH3CH2)4N<+> and H<+> and a metal cation Rn<+> in the liquor enter the cathode chamber through a cation exchange membrane, and the anions X<-> and OH<-> reach the anode plate to generate a gas; in the cathode chamber, tetraethylammonium hydroxide is produced from the cation (CH3CH2)4N<+> and OH<-> obtained by water hydrolysis, H<+> reaches the cathode plate to obtain electrons to generate H2, and tetraethylammonium hydroxide with the concentration of 5-30% is obtained. According to the method disclosed by the invention, feed and discharge are continuously carried out, and the concentrations of the materials in the anode and cathode chambers are relatively constant, so that the current efficiency and the product conversion ratio are improved, and the energy consumption is lowered.

Owner:镇江润晶高纯化工科技股份有限公司

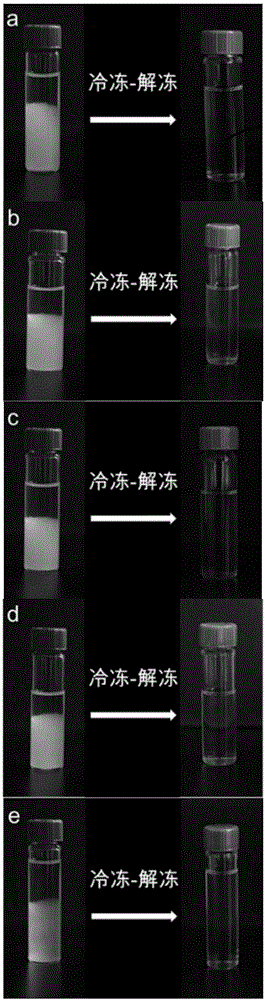

Cellulose solution and dissolving method and application thereof

The invention discloses a cellulose solution and a dissolving method and application thereof. The cellulose solution is prepared by dispersing cellulose in alkyl ammonium hydroxide solution with concentration of 0.5-2.5 M; settling the solution at -10 to -30 DEG C until the dispersing fluid is completely frozen; continuing to freeze for 0-12 hours and then unfreezing the solution at room temperature to obtain uniform and transparent cellulose solution. The alkyl ammonium hydroxide is one or several of tetramethylammonium hydroxide, triethyl methyl hydroxide, tetraethylammonium hydroxide, benzyltrimethylammonium hydroxide, and benzyltriethylammonium hydroxide. The cellulose solution is applicable to natural cellulose of which molecular weight is 7.0x104-3.0x105; the cellulose solution is simple and convenient to operate, strong in dissolving ability, strong in cellulose solution stability, and free from environmental pollution; the dissolution is a physical process and free from chemical reaction; the solvent system is one-component solvent, the prepared cellulose solution can regenerate cellulose through water coagulating bath; alkyl ammonium hydroxide in the waste fluid is easy to recycle and reuse, and has very wide application prospect.

Owner:WUHAN UNIV

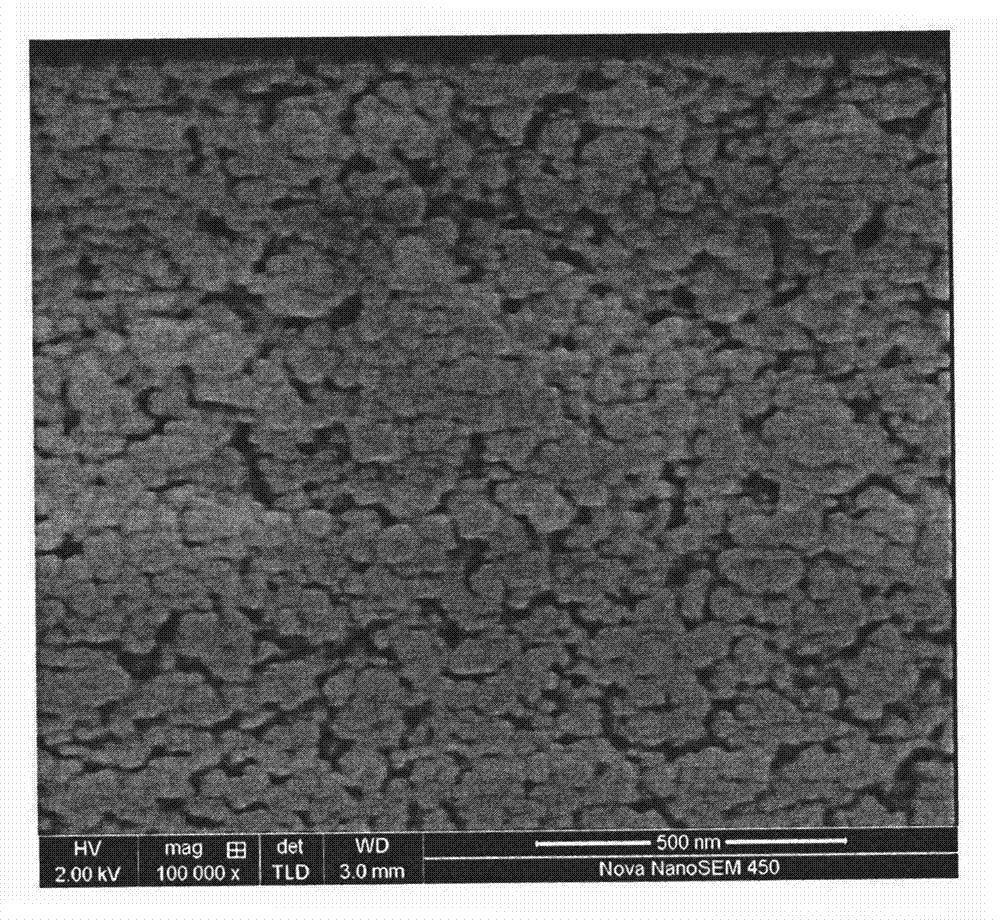

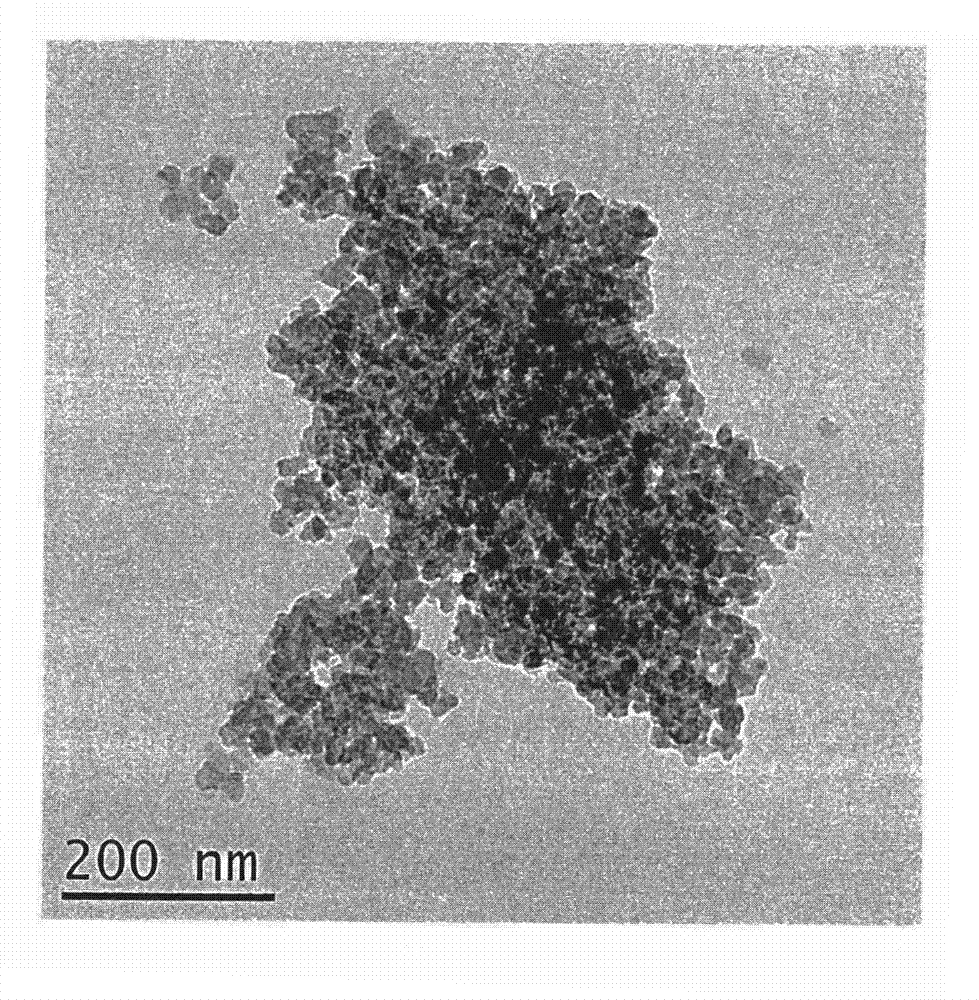

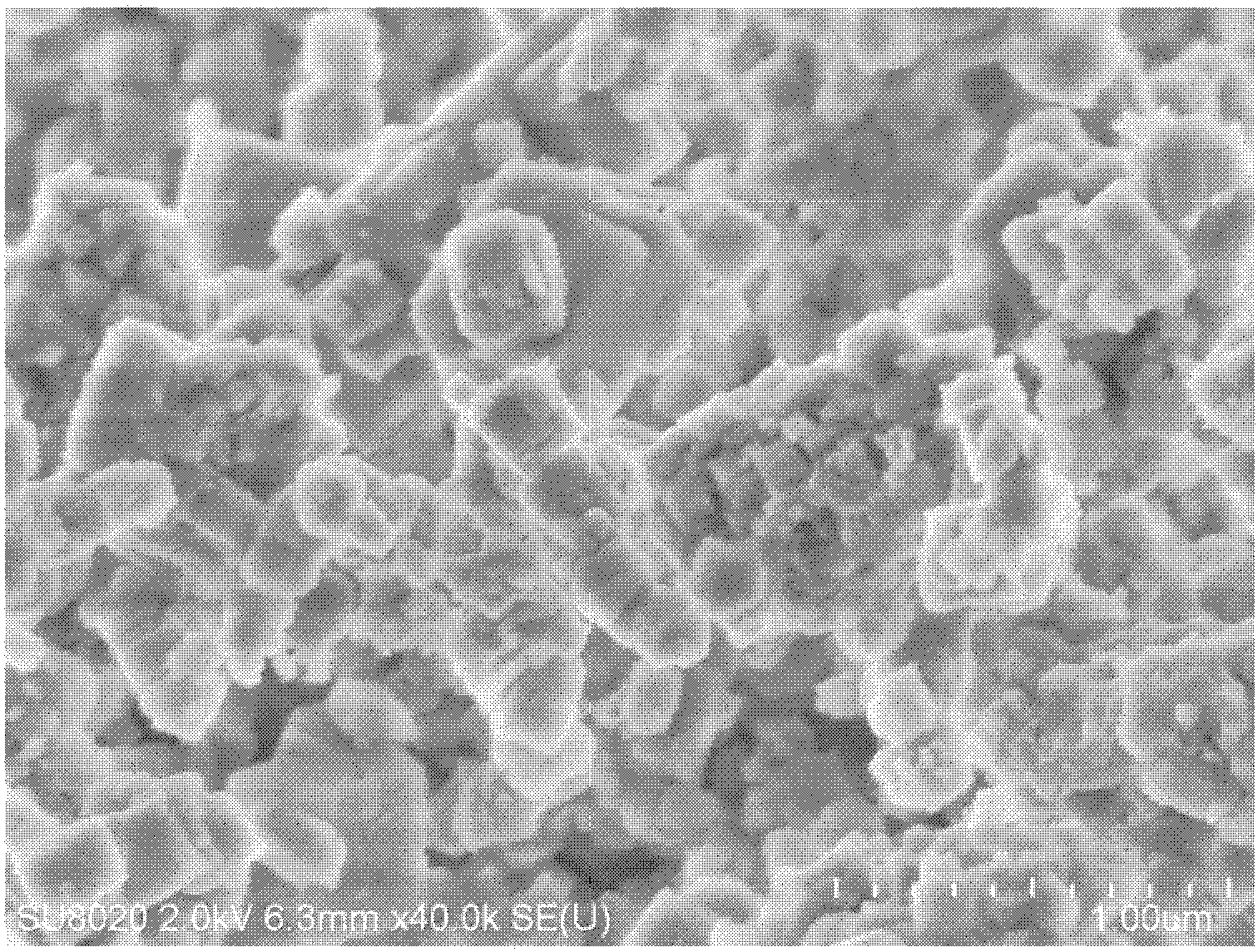

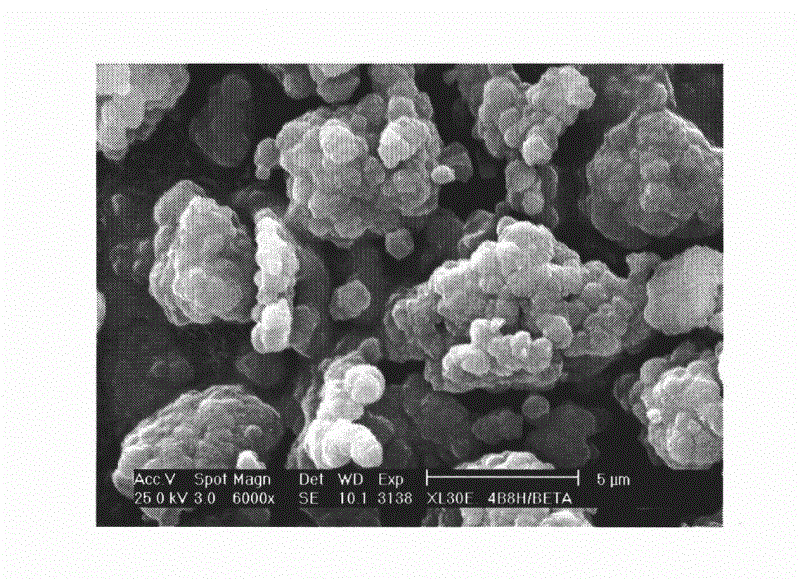

SAPO-34 (Silicoaluminophosphate-34) molecular sieve catalyst and application thereof to preparation of low-carbon olefin from methanol

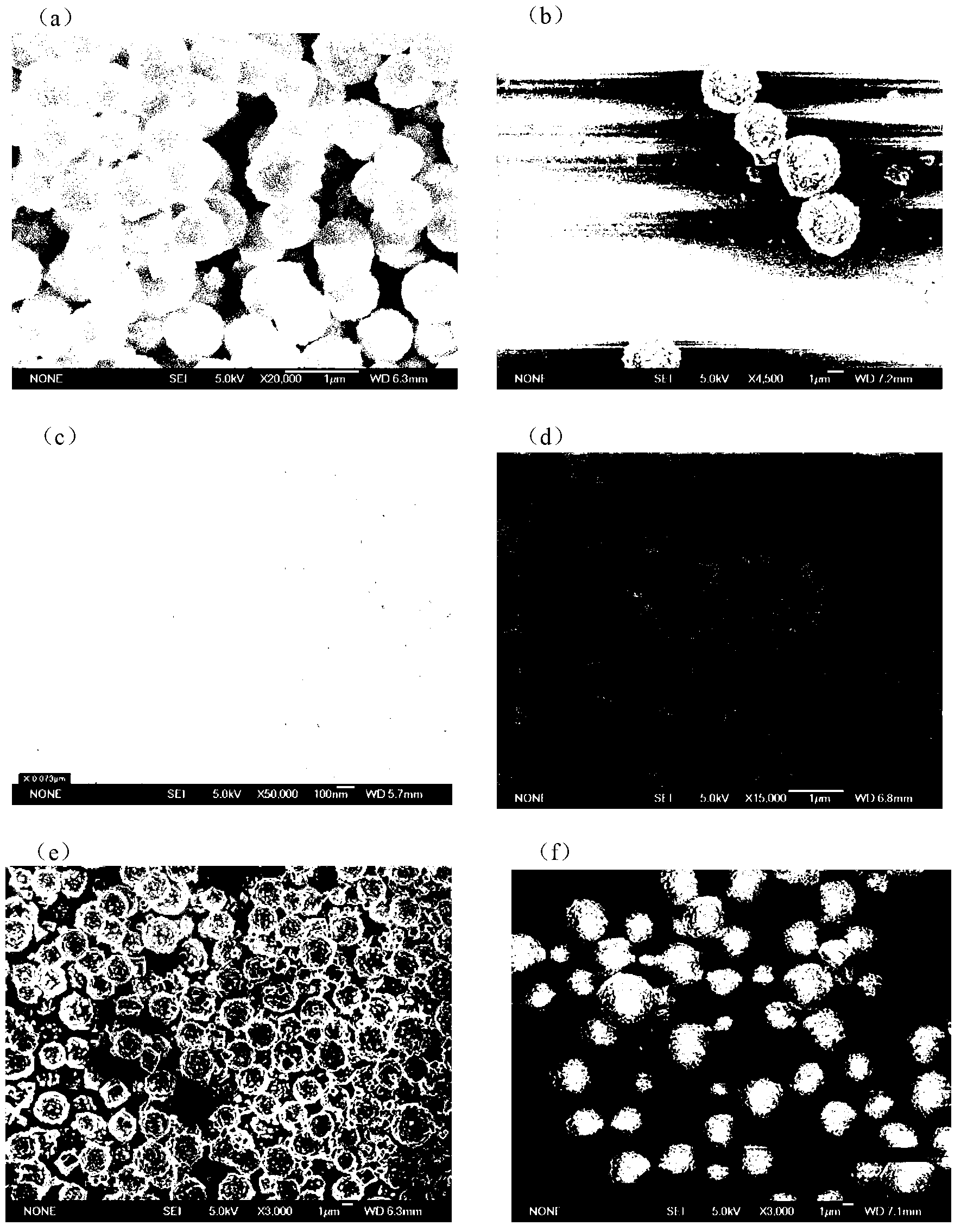

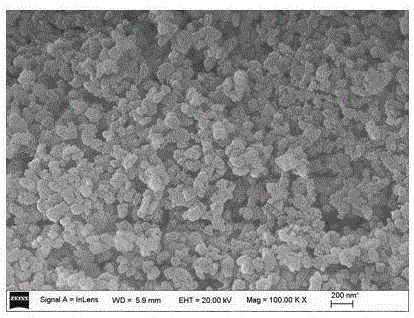

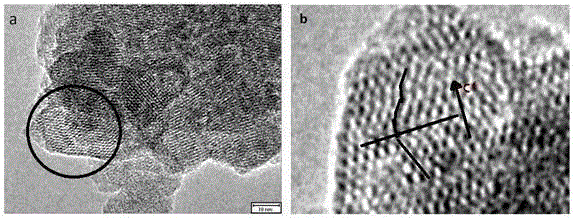

InactiveCN102836741AMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMicron scaleMicrosphere

The invention belongs to the technical field of molecular sieve, and particularly relates to an SAPO-34 (Silicoaluminophosphate-34) molecular sieve catalyst and application thereof to preparation of low-carbon olefin from methanol. The spherical SAPO-34 molecular sieve agglomerated by nanoparticles is synthesized by modulating reaction initial gel concentration, and the size range is within a range of 0.5 micron to 10 microns. Tetraethylammonium hydroxide is used as a template and is mixed with an aluminum source, a silicon source and a phosphorus source; the gel concentration is controlled by adding a specific amount of solvent; and the catalyst is quickly prepared by the conventional hydrothermal or microwave heating mode. The spherical SAPO-34 molecular sieve provided by the invention has the characteristics of quickness in production, low cost in gel synthesis raw materials, low reaction energy consumption, high molecular sieve yield and the like. The characteristic of microspheres agglomerated by the nanoparticles enables long life of catalytic application of the nanoparticles, the characteristic of a catalytic effect of the molecular sieve in catalytic reaction can be obviously improved, and meanwhile, the molecular sieve catalyst also has the advantage of easiness in separation and extraction after synthesis of a micron scale catalyst.

Owner:JILIN UNIV

Synthetic method of high silica ZSM-5 zeolite

InactiveCN101898767AReduce dosageShape is easy to controlPentasil aluminosilicate zeoliteTetramethylammonium bromideAdhesive

The invention discloses a synthetic method of high-silica ZSM-5 zeolite, the method comprises the steps of adopting water glass as a silica source, adopting aluminum salts of aluminum sulfate, aluminum nitrate, aluminum chloride and the like, as well as organic aluminum compounds of sodium metaaluminate, isopropanol and the like as aluminum sources, using sulfuric acid or hydrochloric acid to regulate alkalinity, adding an organic template, simultaneously adding a guide adhesive, carrying out high-temperature crystallization at 120-200 DEG C, and then synthesizing the high-silica ZSM-5 zeolite with the SiO2 / Al2O3 ratio which is greater than 100; and the molar ratio of raw materials is as follows: SiO2 / Al2O3 is equal to 100-infinity, Na2O / SiO2 is equal to 0.05-0.20, and H2O / SiO2 is equal to 10-100. The organic template comprises tetrapropylammonium bromide, tetrapropylammonium hydroxide, tetraethylammonium bromide, tetraethylammonium hydroxide, n-butylamine, ethylamine, hexamethylene diamine and any other organic matters which can synthesize the ZSM-5 zeolite or the mixture thereof, wherein the using amount of the organic template is that R / SiO2 is equal to 0.005-0.50; and the amount of silicon dioxide in the guide adhesive is 0-5% of the total weight of the silicon dioxide in a synthetic system. The synthetic method can synthesize the high-silica ZSM-5 zeolite with the SiO2 / Al2O3 ratio which is greater than 100 and has the advantages of cheap raw materials, a small using amount of the organic template, and capability of realizing the control of product appearance and particle size by changing the relative using amount of the template and the guide adhesive.

Owner:EAST CHINA NORMAL UNIV

Beta molecular sieve of high-content Fe in framework and preparing method of beta molecular sieve

ActiveCN105253895AIncrease contentGood thermal and hydrothermal stabilityCrystalline aluminosilicate zeolitesTETRAETHYLAMMONIUM HYDROXIDEChemistry

The invention relates to a beta molecular sieve of high-content Fe in a framework and a preparing method of the beta molecular sieve. Tetraethylammonium hydroxide serves as a template agent, a Fe- complex serves as a Fe source, and the Fe-beta zeolite molecular sieve of high-content Fe in the framework is synthesized through a one-step method. The synthesizing method is simple, the silica-alumina ratio can be adjusted, the mass fraction of Fe in the framework can reach 3-8%, and the synthesized Fe-beta zeolite molecular sieve is neat in structure, high in crystallinity and good in application prospect.

Owner:BEIJING UNIV OF CHEM TECH

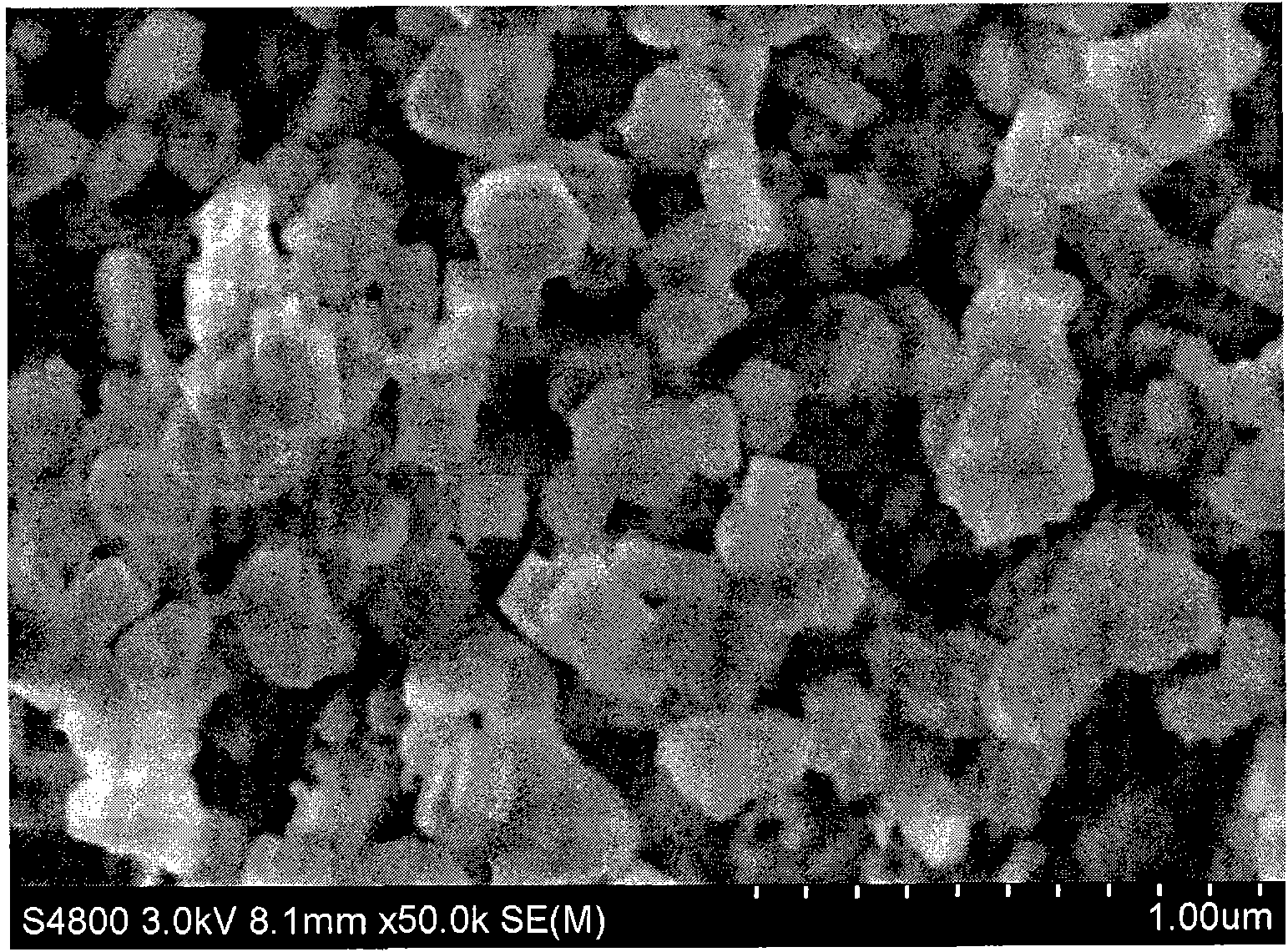

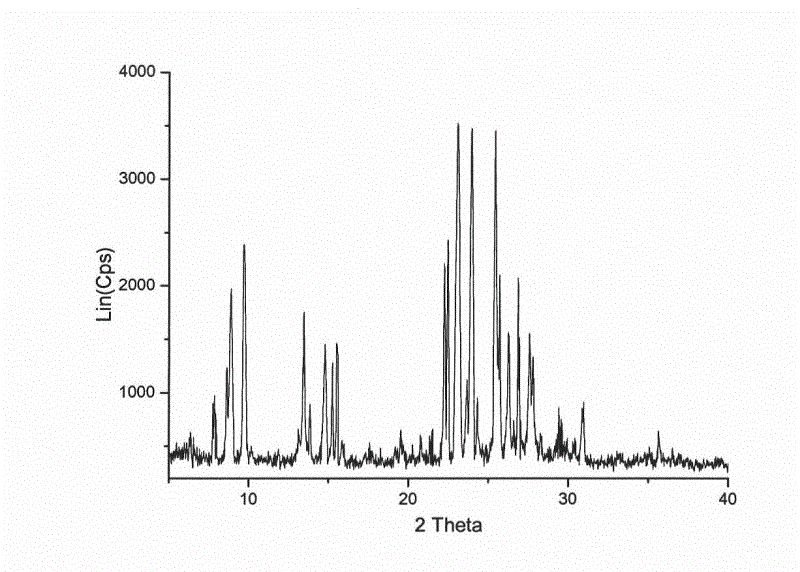

Synthesis method for nanometer Beta zeolite

ActiveCN102464330ASolving Recycling ProblemsAvoid lossCrystalline aluminosilicate zeolitesSynthesis methodsTriethylamine

The invention relates to a synthesis method for nanometer Beta zeolite, which mainly solves the problems in the prior art that the synthesized Beta zeolite has big crystal particle, and the efficiency is low when the nanometer zeolite is recovered with a common filtering or centrifugal separation method. The synthesis method for the nanometer Beta zeolite comprises the following steps: a) mixing a silicon source, an aluminum source, alkali MOH and compound template agent RN with water, wherein reaction mixture is calculated at the following molar ratio: SiO2 / Al2O3 is equal to 5-100, MOH / SiO2 is equal to 0.1-2.0, H2O / SiO2 is equal to 5-80, RN / SiO2 is equal to 0.01-1.0; crystallizing the mixture at the temperature of 110-200DEG C for 5-100hours to obtain crystallization liquid, wherein the compound template agent RN is the mixture of R1 and R2, R1 is selected from at least one of tetraethylammonium hydroxide and triethylamine or diethylamine, R2 is selected from tetraethyl ammonium halide, and the molar ratio of R1 to R2 is 0.05-2.0; and b) adding acid compound into the crystallization liquid, regulating the pH value of the crystallization liquid to be less than 11, and separating, washing and drying to obtain the nanometer Beta zeolite, wherein the acid compound is selected from at least one of inorganic acid, organic acid or ammonium chloride. According to the technical scheme, the problem is better solved. The synthesis method for the nanometer Beta zeolite can be used for the industrial production of the Beta zeolite.

Owner:CHINA PETROLEUM & CHEM CORP +1

High strength sapo-34 microsphere catalyst, method for preparing same, and method for preparing light olefins using same

ActiveUS20120203046A1Improve catalytic performanceImprove efficiencyCatalytic crackingMolecular sieve catalystsMicrosphereFluidized bed

The present invention relates to a high-strength silicoaluminophasphate-34 (SAPO-34) microsphere catalyst, a method for preparing the same, and a method for preparing light olefins by using the same, and when described in more detail, the present invention relates to a method for preparing a SAPO-34 microsphere catalyst, including: spray drying a mixed slurry including a matrix, a binder, an additive, and the like to a SAPO-34 slurry prepared by a hydrothermal synthesizing method using various organic templates such as tetraethylammonium hydroxide (TEAOH), and the like alone or in mixtures to prepare microspheres, and firing the microspheres, and to a SAPO-34 microsphere catalyst for a circulating-fluidized bed reactor, prepared by the preparation method. The SAPO-34 microsphere catalyst of the present invention has excellent reaction activity while having high strength, and thus is appropriate for use in a circulating-fluidized bed reactor requiring high strength of the catalyst. Further, the SAPO-34 microsphere catalyst has a long life-span and excellent conversion rate of C1 to C4 oxygen-including compounds (oxygenates), and thus is appropriate for use in the preparation of light olefins such as ethylene, propylene, butene, and the like.

Owner:KOREA RES INST OF CHEM TECH

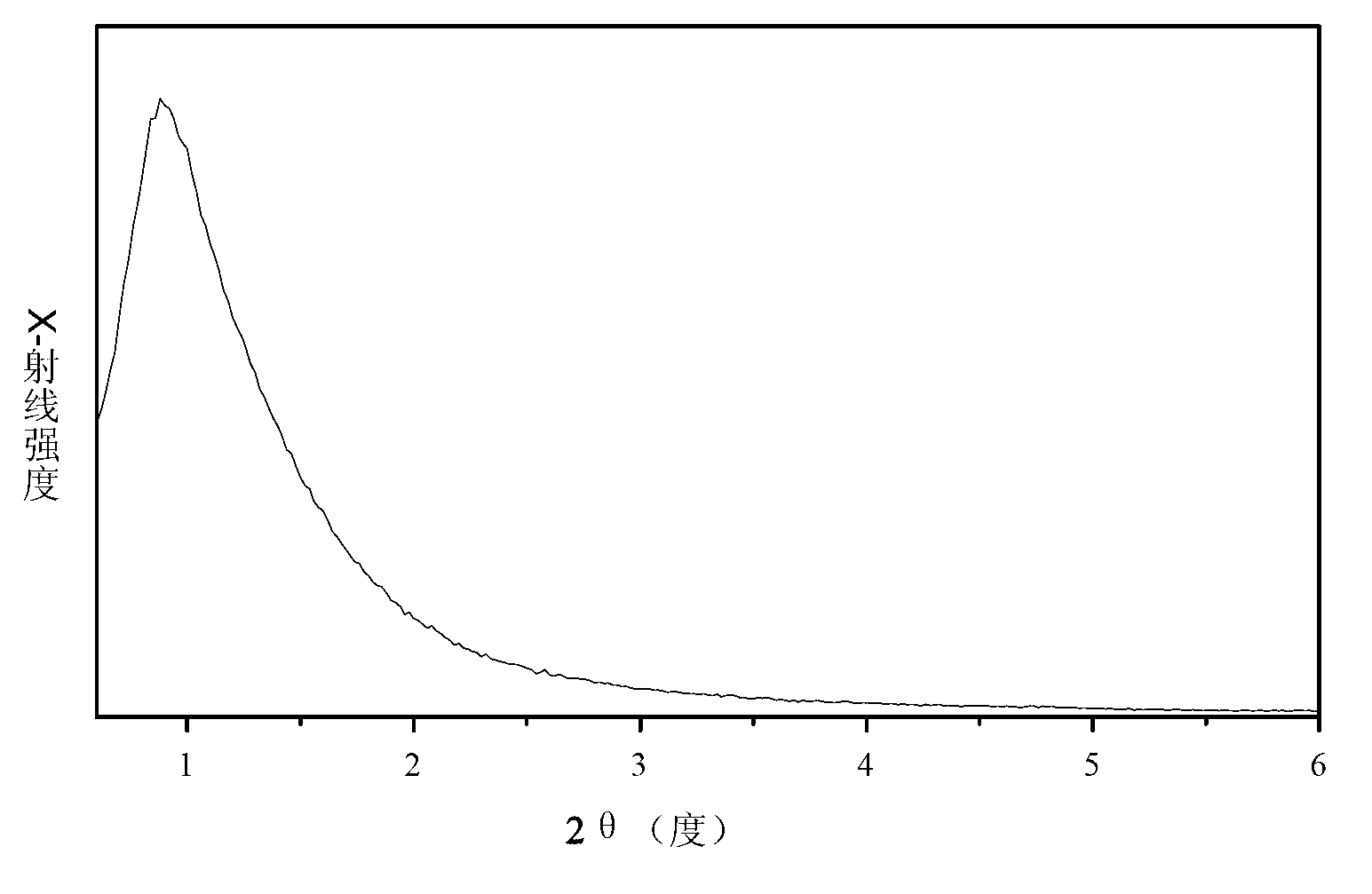

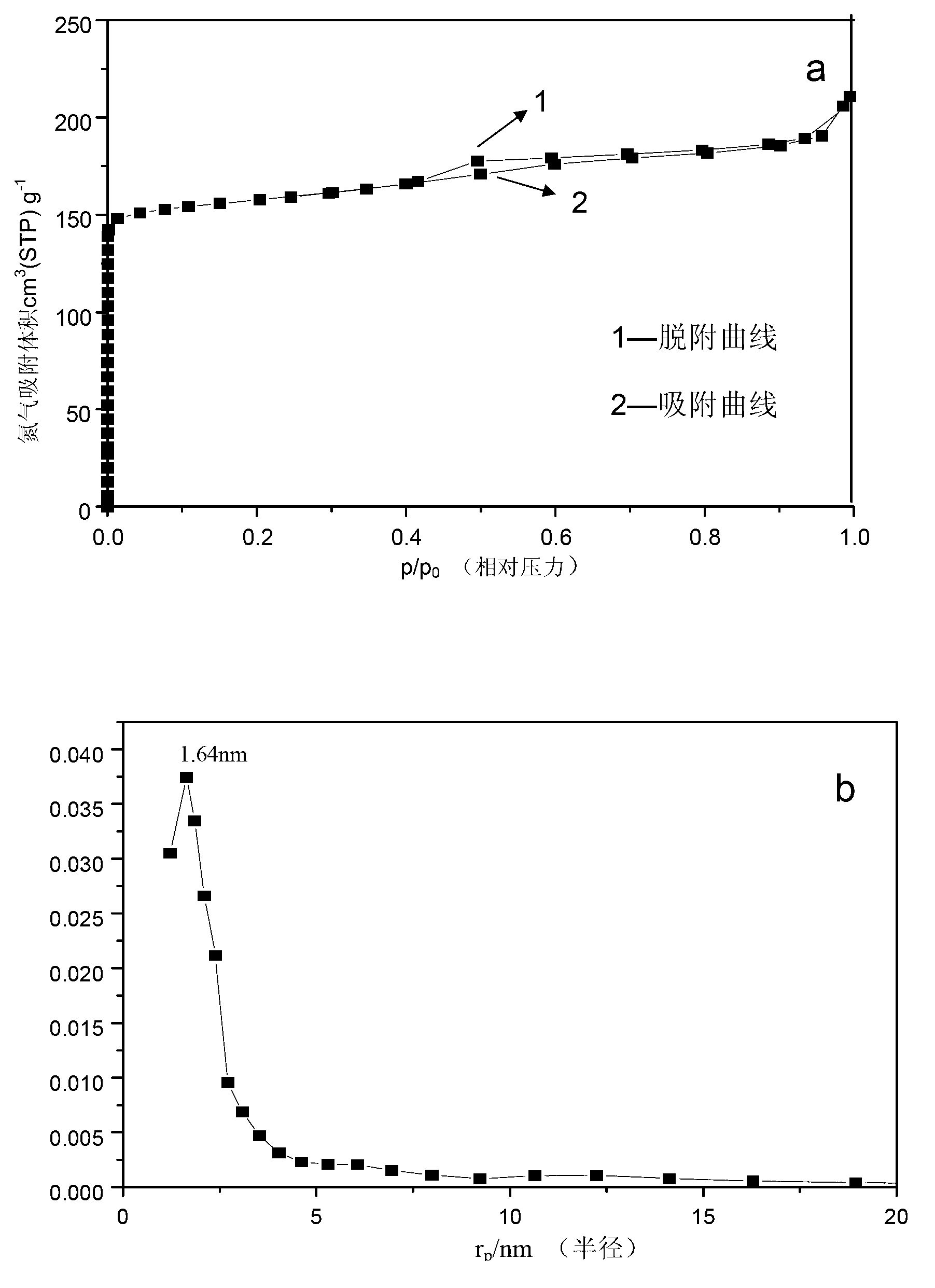

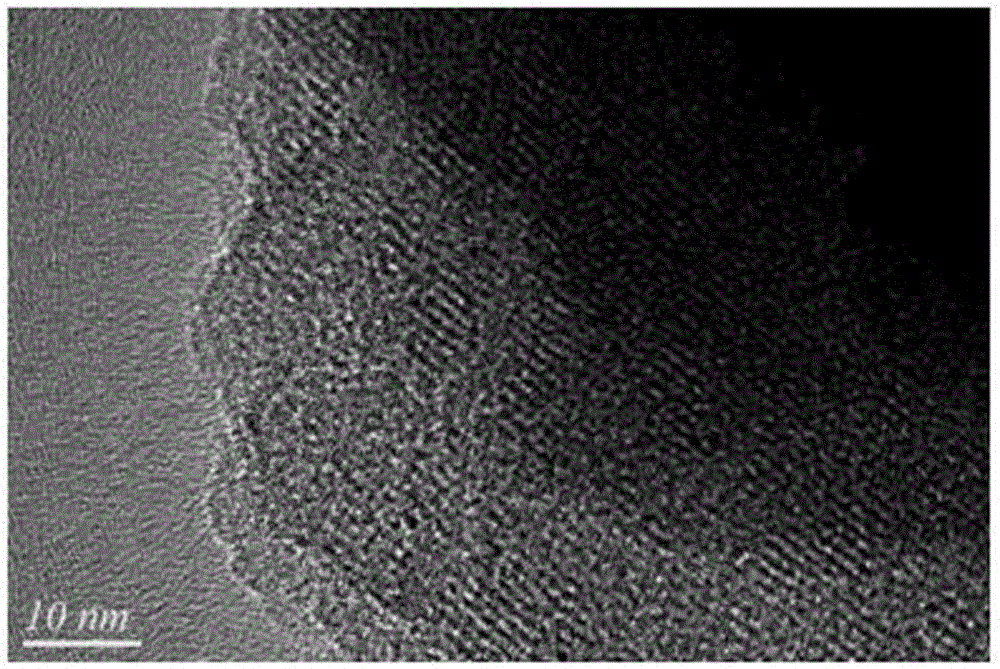

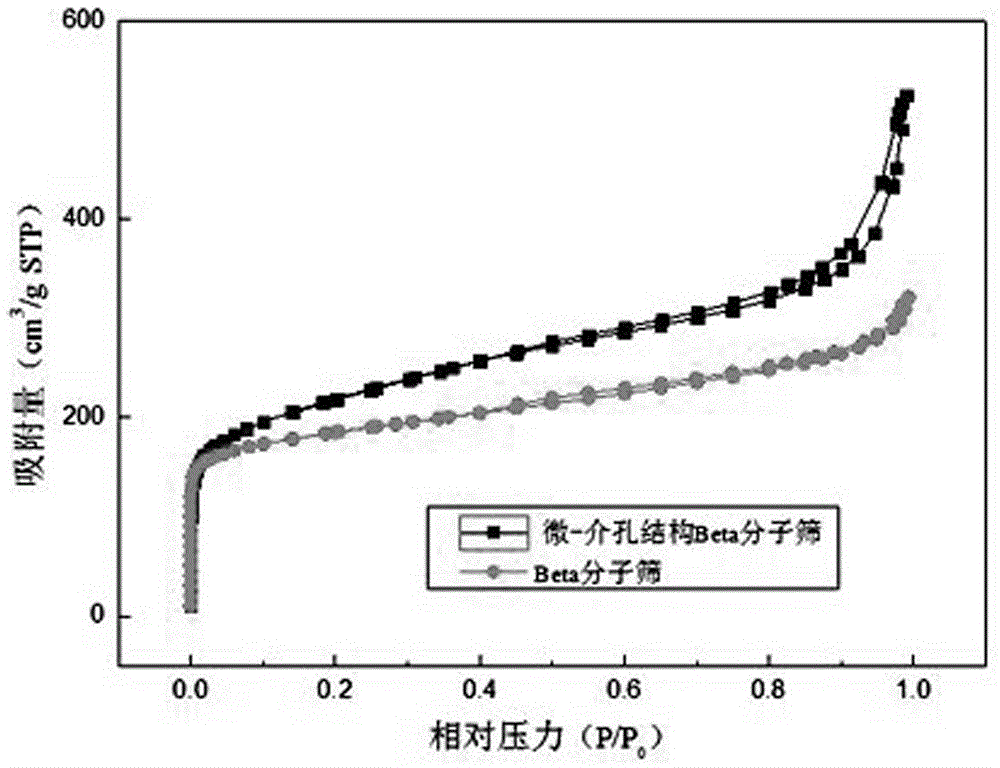

Preparation method of micro-mesoporous structure Beta molecular sieve

InactiveCN106185972AEasy to manufactureStrong production practicabilityCrystalline aluminosilicate zeolitesGas phaseColloid

The invention discloses a preparation method of a micro-mesoporous structure Beta molecular sieve. The method comprises the steps that tetraethylammonium hydroxide, deionized water and sodium hydroxide are stirred, dimeric surfactant and sodium metaaluminate are dissolved in the mixture to continue to be stirred, finally, gas-phase silicon dioxide is dissolved in the mixture to continue to be stirred, and white silica-alumina colloid is obtained; the white silica-alumina colloid is paced in a reaction kettle to be heated for a reaction, the product is washed, produced and calcined after the reaction is finished, and the micro-mesoporous structure Beta molecular sieve is obtained. The gas-phase silicon dioxide, the sodium metaaluminate, the dimeric hyamine surfactant and the like are used as the raw materials to synthesize the micro-mesoporous structure Beta molecular sieve with the high degree of crystallinity and high specific area. The mesoporous content in the synthesized micro-mesoporous structure Beta molecular sieve is 53.20%, and the micro-mesoporous connectedness is high.

Owner:TAIYUAN UNIV OF TECH

Method for preparing and concentrating tetraethylammonium hydroxide with membrane integration technique

InactiveCN108299209AImprove qualityLow costAmino compound purification/separationElectrolysis componentsMembrane distillationImpurity

The invention provides a method for preparing and concentrating tetraethylammonium hydroxide with a membrane integration technique. The method comprises steps as follows: an aqueous tetraethylammoniumsalt solution is introduced into a feed liquid chamber of a bipolar-membrane electrodialysis device, pure water is introduced into an acid liquor chamber and an alkali liquor chamber respectively, and a sulfuric acid solution is introduced into electrode liquor chambers and a buffer solution chamber respectively; a direct-current electric field is applied to an anode plate and a cathode plate, cations (CH3CH2)4N<+> in the feed liquid chamber enter the alkali liquor chamber through a cation exchange membrane, and anions X<-> in the feed liquid chamber enter the buffer solution chamber throughan anion exchange membrane; the cations (CH3CH2)4N<+> and hydroxyl ions produced by bipolar-membrane hydrolytic dissociation are bound to generate tetraethylammonium hydroxide in the alkali liquor chamber, the tetraethylammonium hydroxide is collected and subjected to membrane distillation, and an aqueous tetraethylammonium hydroxide solution with mass concentration being 15%-20% is obtained. According to the method, bipolar-membrane electrodialysis and membrane distillation technologies are integrated, and the prepared aqueous tetraethylammonium hydroxide solution is high in concentration, low in impurity content and low in production cost.

Owner:盐城泛安化学有限公司

Hydrothermal synthesis method of nano Sn-Beta molecular sieve aggregate

ActiveCN111285381AAvoid incompatibility problemsImprove catalytic performanceCrystalline aluminosilicate zeolitesSilanesEthyl group

The invention belongs to the technical field of petrochemical engineering, and provides a hydrothermal synthesis method of a nano Sn-Beta molecular sieve aggregate. Hydrophilic organosilane is directly doped into tin-silicon oxide by using an aerosol technology, and is used as a precursor to be mixed with tetraethylammonium hydroxide and hydrofluoric acid for crystallization. The organosilane is trimethoxy[3-(phenylamino)propyl]silane. According to the synthesis method disclosed by the invention, organosilane is pre-dispersed in tin-silicon oxide in advance, so that the problem that organosilane is insoluble in a synthesis system is avoided. Compared with a traditional Sn-Beta molecular sieve, the obtained nano Sn-Beta aggregate in the Baeyer-Villiger oxidation reaction of ketones and hydrogen peroxide has the catalytic performance obviously improved.

Owner:DALIAN UNIV OF TECH

Oxygen carrier, and preparation method and application thereof

ActiveCN106669685AHigh oxygen loading rateHigh activityHydrogenFuel additivesCeriumReaction temperature

The invention discloses an oxygen carrier, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, mixing NaAlO2, NaOH, silica gel, cetyltrimethylammonium bromide (CTAB), isohexadecylami (CA), tetraethylammonium hydroxide (TEAOH) and water according to a certain ratio to form gel, carrying out hydrothermal crystallization on the above obtained gel system, drying obtained crystals, and roasting the dried crystals to prepare a material A containing structural defects; 2, dispersing the material A prepared in step 1 in distilled water to prepare a suspension, adding titanium dioxide sol to the suspension, filtering the obtained material, drying the filtered material, and roasting the dried material to prepare a carrier; and 3, loading lanthanum and / or cerium and nickel and / or cobalt to the carrier prepared in step 2 in order to obtain the oxygen carrier. The oxygen carrier bears a high reaction temperature, and has the advantages of high dispersion of metal oxides in the oxygen carrier, high oxygen carrying rate, high oxygen cycle ability, high hydrogen production efficiency and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of silicon aluminum phosphate molecular sieve of multilevel porous structure, prepared molecular sieve and application of molecular sieve

InactiveCN108264058AImprove reaction stabilityHigh yieldMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesSodium acetateALUMINUM PHOSPHATE

The invention relates to a preparation method of a silicon aluminum phosphate molecular sieve of a multilevel porous structure, the prepared molecular sieve and application of the molecular sieve. Thepreparation method and the prepared molecular sieve are mainly used for solving the problems that the operation process is complicated and the cost is high since mesoporous template agents are adopted for synthesis in the prior art. The method includes the step of adopting the silicon aluminum phosphate molecular sieve of the porous structure for being in contact with a solution containing a modifier, wherein at least one of ammonium hydroxide, oxalic acid, acetic acid, ethanedioic acid, citric acid, sodium carbonate, sodium acetate trihydrate, sodium acetate, sodium hypochlorite, tetraethylammonium hydroxide, tetrapropylammonium hydroxide and tetrabutyl ammonium hydroxide is adopted as the modifier. By means of the technical scheme, the problems above are well solved, and the preparationmethod can be applied to industrial production of silicon aluminum phosphate molecular sieves of multilevel porous structures.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of ZSM-5 mesoporous and microporous composite molecular sieve

InactiveCN103466654ALarge specific surface areaThe synthesis steps are simplePentasil aluminosilicate zeoliteAlcoholRoom temperature

The invention discloses a preparation method of a ZSM-5 mesoporous and microporous composite molecular sieve. The method comprises the steps of dissolving NaAlO2 and TEOS (tetraethyl orthosili) in water, stirring to form a settled solution, dropwise adding TEAOH (tetraethylammonium hydroxide) into the settled solution, putting obtained mixed liquid in a high-pressure stainless steel reaction kettle for reaction under a homogeneous phase condition, cooling the reaction kettle to the room temperature, dropwise adding a mixed solution of CTAB (cetyltrimethyl ammonium bromide) and H2O into a product and stirring, dropwise adding EtOH (ethyl alcohol) and stirring, putting a product in the high-pressure stainless steel reaction kettle for hydrothermal synthesis reaction, repeatedly washing a product with water, centrifugally extracting, drying, placing a dried product in a muffle furnace for roasting, and obtaining the ZSM-5 mesoporous and microporous composite molecular sieve. The process of preparing the molecular sieve is simple; the method is good in repeatability; a synthesized material is provided with an excellent mesoporous and microporous composite duct structure; the mass transfer efficiency is improved during the reaction; therebfore, the method has better application prospects in macromolecular catalysis, adsorption, separated from and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of SAPO-56 molecular sieve

ActiveCN103058208AReduce dosageLow costMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesHexamethylenediaminePropylamine

The invention relates to a preparation method of an SAPO-56 molecular sieve which solves the problems that the SAPO-56 molecular sieve synthesized by the existing technology is low in relative crystallinity, large in molecular sieve crystal grain and high in synthesizing cost. A compound template consisting of N, N, N', N'-tetramethyl-1, 6-hexamethylenediamine and at least one of di-n-propylamine, tetraethylammonium hydroxide, cyclohexylamine and triethylamine is added in the process of preparing a colloid mixture, wherein the dose of the N,N,N',N'-tetramethyl-1,6-hexamethylenediamine solves the problem according to the technological project that the N,N,N',N'-tetramethyl-1,6-hexamethylenediamine takes up to 10-90% of the dose of the compound template, so that the preparation method can be applicable to the industrial production of preparing a low-carbon olefin catalyst through methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing metal modified SAPO-34 molecular sieve

ActiveCN104495870AShort synthesis timeRaise the ratioMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMorpholineIon exchange

The invention discloses a metal modified SAPO-34 molecular sieve. The preparation method comprises the following steps: adopting a mixed template agent of tetraethylammonium hydroxide and morpholine, adding a proper silicon source, an aluminum source and a phosphorus source, controlling the pre-crystallization and crystallization conditions, and adding sodium carboxymethyl cellulose in a proper ratio, thereby obtaining the SAPO-34 molecular sieve filter cake and a mother solution; mixing a metal salt and the mother solution to generate a metal complex, finally, adding dextrin into the metal complex and the SAPO-34 molecular sieve filter cake, performing centrifugal separation to obtain a filter cake, performing ion exchange between the filter cake and ammonium chloride to obtain metal modified SAPO-34 molecular sieve raw powder, and roasting, thereby obtaining the metal modified SAPO-34 molecular sieve. According to the process disclosed by the invention, the regular pore structure and large specific surface area of the SAPO-34 molecular sieve can be effectively maintained, the ratio of the pores can be improved to be about 90 percent by effectively regulating the acidity and pore size, and the ethylene / propylene selectivity of the reaction for producing olefins from methanol is improved to be 94 percent. According to the process disclosed by the invention, metals can be uniformly distributed in the SAPO-34 molecular sieve, and the mother solution treatment difficulty can be reduced.

Owner:SHANDONG QILU HUAXIN HIGH TECH

Preferred orientation growth method of MFI type zeolite

ActiveCN102874832AConducive to environmentally friendly industrial productionWide variety of sourcesCrystalline aluminosilicate zeolitesTetramethylammonium hydroxideDiketone

The invention relates to a preferred orientation growth method of MFI type zeolite, and mainly solves the problem of high toxicity in conventional templates. The method comprises the following steps of mixing a silicon source, an aluminium source, a template R1, a template R2 and water; adjusting a pH value of the reaction mixture to 8-14 with an inorganic base; wherein the molar ratio in the reaction mixture is as follows: Al2O3 / SiO2=0-0.05, R1 / SiO2=0.1-2, H2O / / SiO2=10-100 and R2 / SiO2=0.05-2; and crystallizing the above mixture for 1-10 days at a temperature of 100-250 DEG C, separating, washing and drying the crystallized mixture, and thus the preferred orientation growth MFI type zeolite is obtained, wherein the template R1 is selected at least one from tetramethylammonium hydroxide pentahydrate, tetraethylammonium hydroxide, tetrapropylammonium hydroxide or tetrabutylammonium hydroxide; and R2 is selected at least one from beta-diketone, a beta-diketone salt, oxalic acid, oxalate, pyrocatechol or 8-hydroxyquinoline. The preferred orientation growth method solves the problem well, and can be used in industrial production of the MFI type zeolite.

Owner:CHINA PETROLEUM & CHEM CORP +1

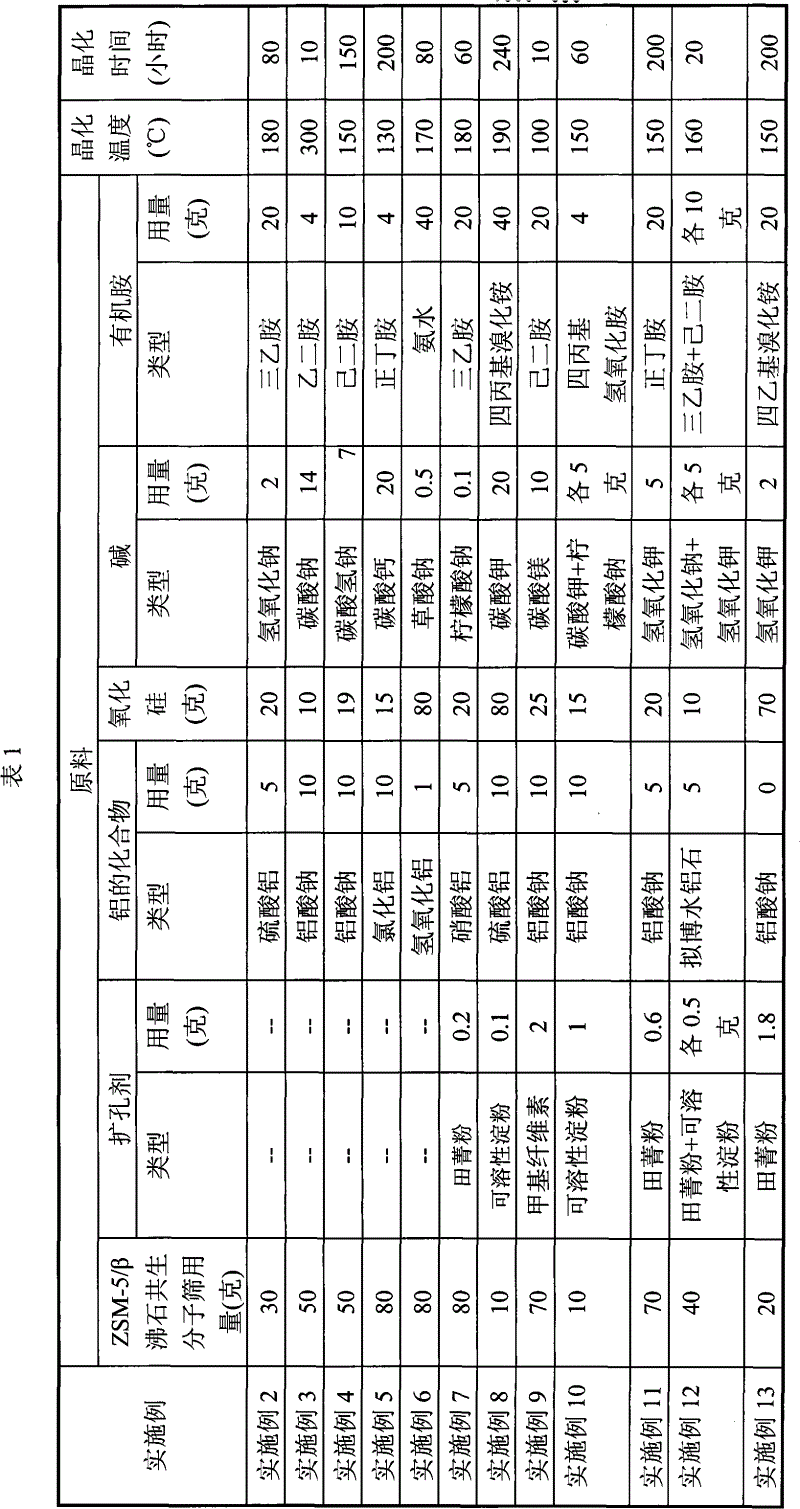

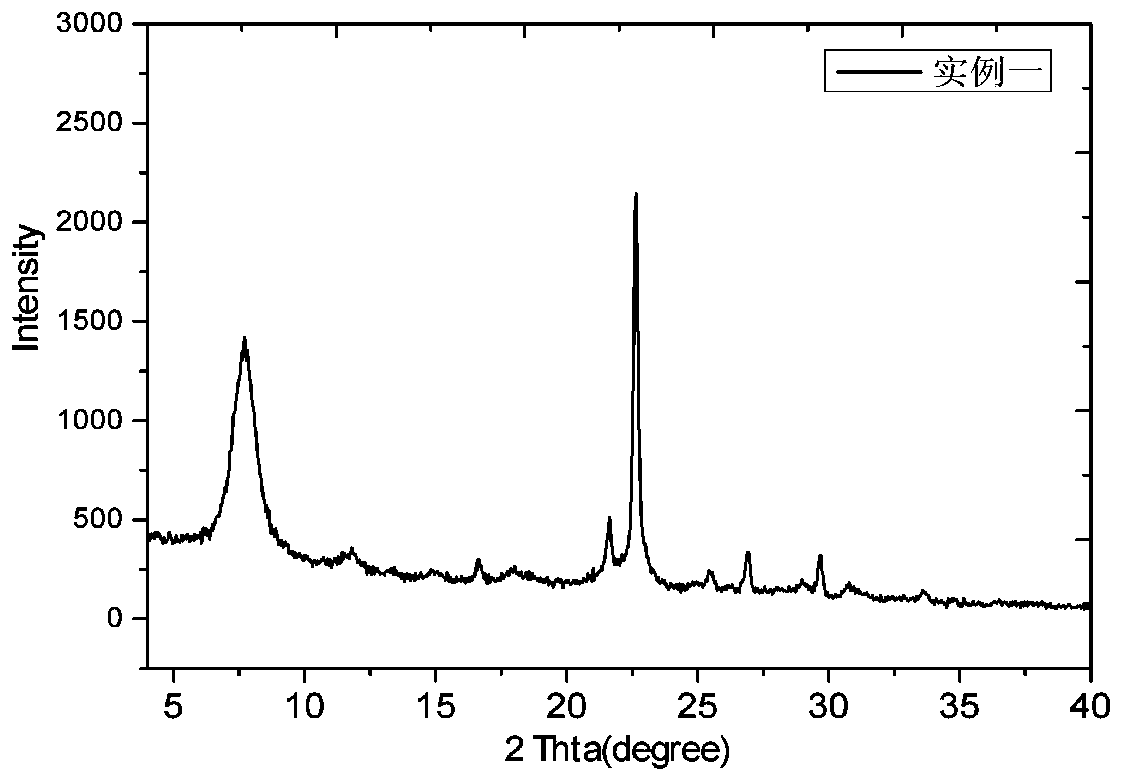

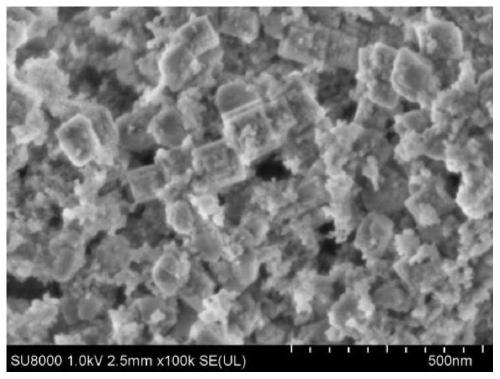

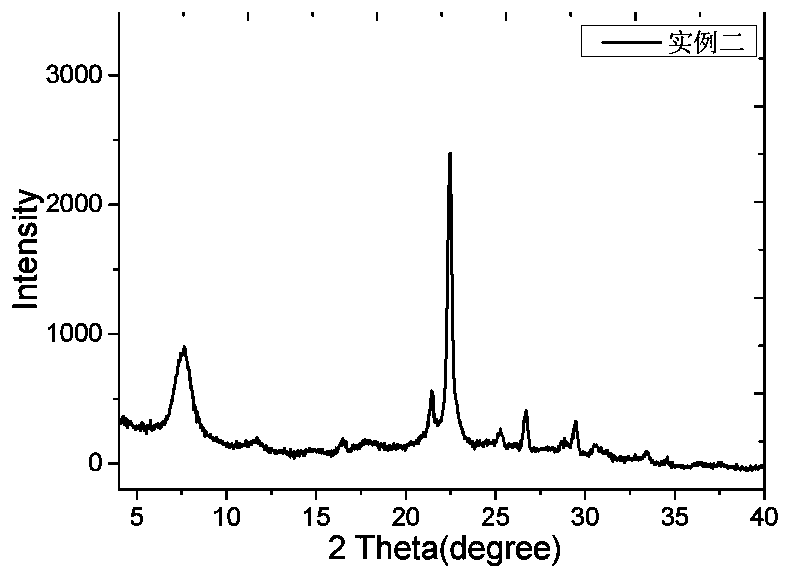

Preparation method of non-binder ZSM-5/zeolite beta coexisting molecular sieve catalyst

ActiveCN102039171BIncrease contentHigh activityMolecular sieve catalystsCatalyst activation/preparationEthylenediamineTetramethylammonium bromide

The invention relates to a preparation method of a non-binder ZSM-5 / zeolite beta coexisting molecular sieve catalyst. In the invention, the problems that when a hydrothermal synthesis method is adopted to prepare the existing ZSM-5 / zeolite beta coexisting molecular sieve, the preparation process is complicated, the cost is higher, the ZSM-5 / zeolite beta coexisting molecular sieve catalyst with the binder has lower activity, the non-binder ZSM-5 / zeolite beta coexisting molecular sieve has lower strength and the mechanical mixture of ZSM-5 with the binder and zeolite beta has lower activity, are mainly solved. The technical scheme in the invention comprises the following steps: mixing ZSM-5 / zeolite beta coexisting molecular sieve, alkaline substance, aluminum compound and silicon oxide, forming, drying, placing the dried mixture in template agent vapor containing at least one of ammonia water, ethylenediamine, triethylamine, n-butylamine, hexanediamine, tetrapropylammonium bromide or tetrapropylammonium hydroxide, and tetraethylammonium hydroxide or tetraethylammonium bromide to perform crystallization treatment at 100-200 DEG C for 10-300 hours and obtain the non-binder ZSM-5 / zeolite beta coexisting molecular sieve catalyst, wherein the weight contents of ZSM-5 / Magadiite coexisting molecular sieve, alkaline substance, aluminum compound and silicon oxide calculated according to the weight of the formed and roasted catalyst are 10-80%, 0.1-10%, 0.5-20%, and 20-80% respectively. The problems can be better solved and the prepared non-binder ZSM-5 / zeolite beta coexisting molecular sieve catalyst can be used in the naphtha catalytic cracking reaction for preparing propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of Sn-beta molecular sieve nanocrystal

ActiveCN110422857AGood dispersionUniform particle size distributionMaterial nanotechnologyCrystalline aluminosilicate zeolitesDispersityWater use

The invention discloses a preparation method of a Sn-beta molecular sieve nanocrystal. The preparation method comprises the following steps: mixing 0.006g-0.042g of tin tetrachloride with a solution of 4.21g-20g of tetraethylammonium hydroxide with a mass fraction of 35%, and conducting drying at 40-90 DEG C for 30-720 minutes, so as to obtain a mixed solution; uniformly mixing the mixed solutionwith 1g-5g of white carbon black, so as to obtain a mixture; carrying out crystallization on the mixture under a steam-assisted condition, so as to obtain a crystallization product; and sequentially cooling, washing, drying and calcining the crystallization product, so as to obtain the high-crystallinity Sn-beta molecular sieve nanocrystal. The synthetic steps of the preparation method are simple,seed crystals are not used, F ions are not introduced, the complete crystallization can be realized in a short time, the prepared Sn-beta molecular sieve nanocrystal is good in dispersity and uniformin particle size distribution, and meanwhile, the use amounts of a template agent and water used in the synthetic process are low, so that the method further has the advantages of being low in cost and environmental pollution, beneficial to industrial production and the like.

Owner:NORTHEASTERN UNIV

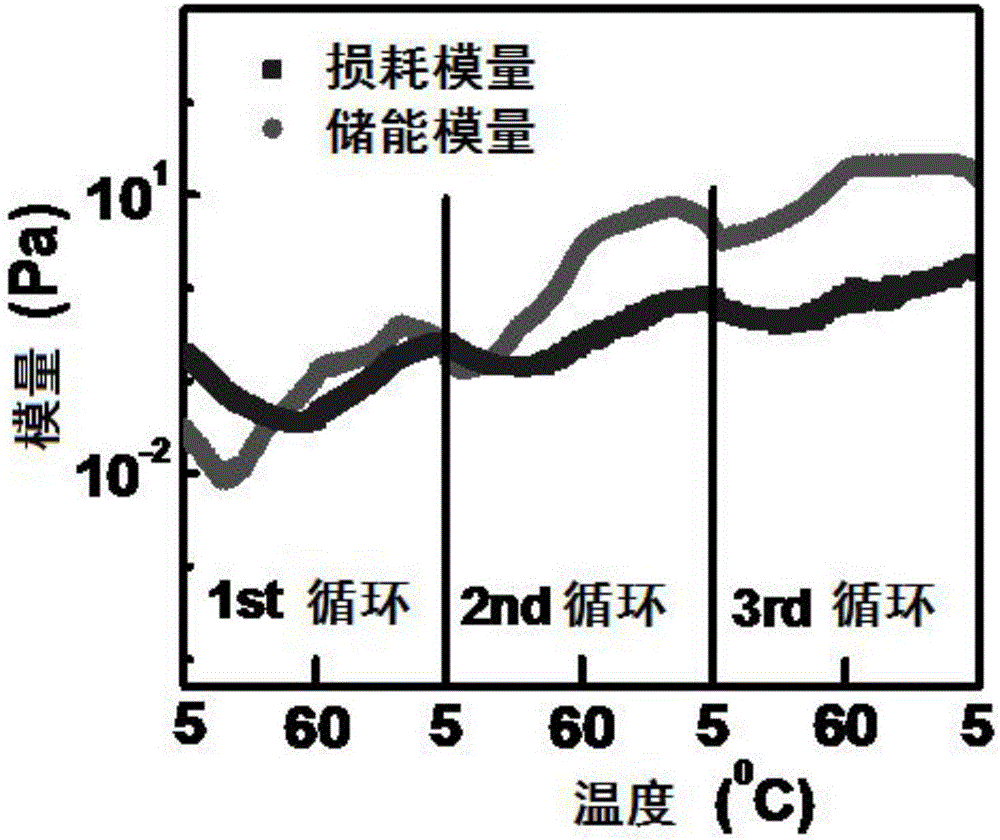

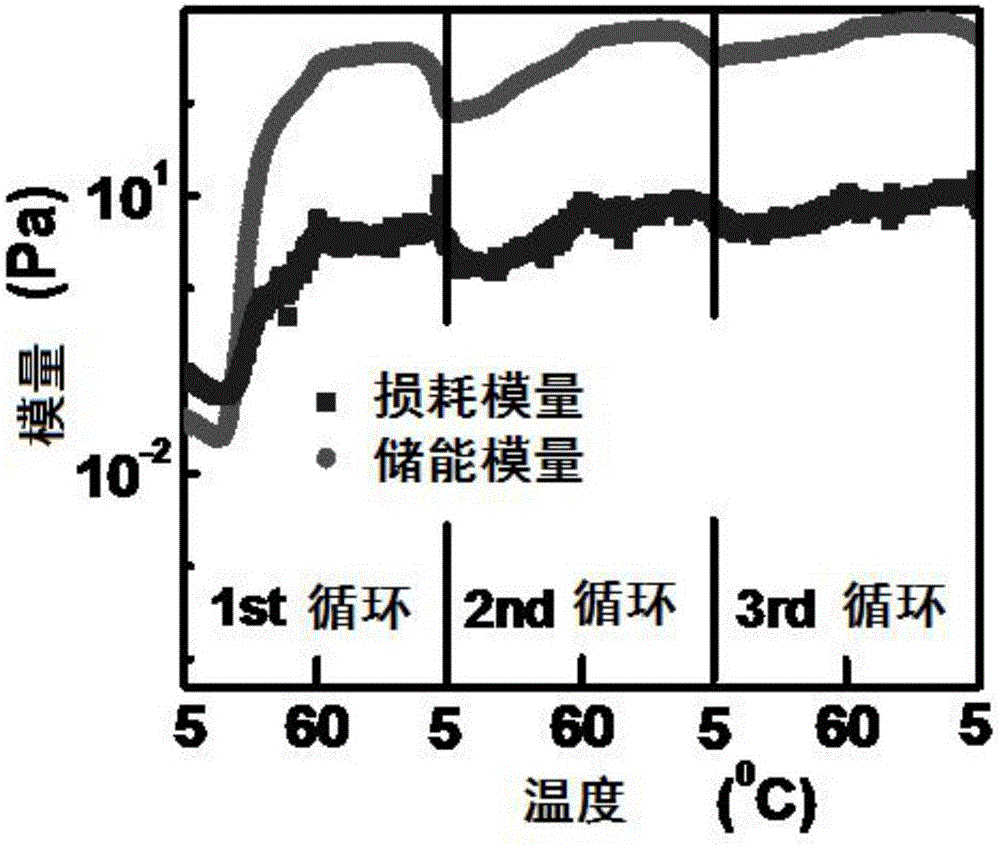

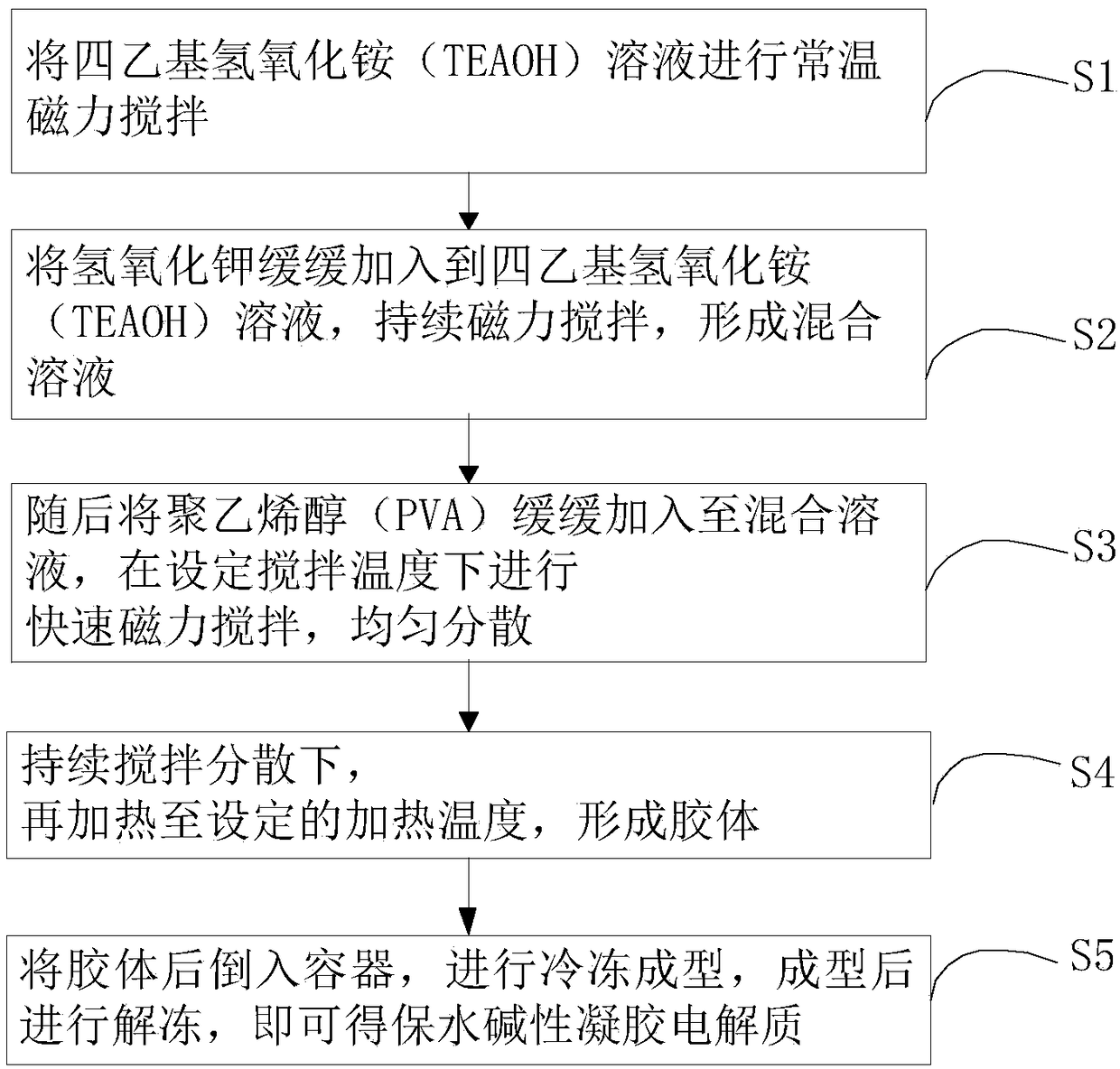

Preparation method of water-retentive alkaline gel electrolyte

InactiveCN109301360AGood moisturizing effectImprove stabilityAlkaline accumulatorsAlkaline electrolytesPolyvinyl alcoholPotassium hydroxide

The invention discloses a preparation method of water-retentive alkaline gel electrolyte, comprising the steps of subjecting TEAOH (tetraethylammonium hydroxide) solution to normal-temperature magnetic stirring; adding potassium hydroxide slowly into the TEAOH solution, and magnetically stirring continuously to form a mixed solution; adding PVA (polyvinyl alcohol) slowly into the mixed solution, and stirring and dispersing at a set stirring temperature; heating under continuous stirring and dispersing to a set heating temperature to from gel; pouring the gel into a container, freezing to shape, and thawing after shaping to obtain water-retentive alkaline gel electrolyte. The water-retentive alkaline gel electrolyte prepared herein has good moisturizing function and stability in air and hashi8gh ion migration rate and high conductivity, the preparation method is simple, and the service life of a flexible cell can be extended.

Owner:SHANGHAI SHANGDE EXPERIMENTAL SCHOOL

Preparation method of CuCeSAPO-34 molecular sieve, product obtained therethrough, and use of product

InactiveCN108905603AWeaken non-redox reactionsNo wasteMolecular sieve catalystsDispersed particle separationCeriumIon exchange

The invention relates to a preparation method of CuCeSAPO-34 molecular sieve, a product obtained therethrough, and a use of the product. The preparation method comprises the following steps: adding tetraethylammonium hydroxide to deionized water, stirring the tetraethylammonium hydroxide and deionized water to obtain a uniform solution, adding aluminum isopropoxide, adding orthophosphoric acid andethyl orthosilicate after the aluminum isopropoxide is completely dissolved, uniformly mixing the obtained solution, adding a cerium salt, fully stirring the solution and the cerium salt, adding a copper salt, adding the obtained completely stirred sol into a hydrothermal reactor, crystallizing the sol, carrying out room temperature cooling, separating the obtained solid crystallization product with the obtained mother liquor, washing the solid crystallization product until the solid crystallization product is neutral, drying the washed solid crystallization product, and calcining the dried solid crystallization product in air to obtain the CuCeSAPO-34 molecular sieve catalyst. Copper and cerium are introduced, a subsequent ion exchange step is avoided, the molecular sieve catalyst with different catalysis activities is obtained by using the cooperative effect of copper and cerium, controlling the addition amount of the cerium salt and adjusting the load capacity of cerium, and the preparation method has the advantages of good crystallinity and simple synthesis steps.

Owner:YANCHENG ENVIRONMENTAL ENG TECH RES & DEV CENT TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com