Beta molecular sieve of high-content Fe in framework and preparing method of beta molecular sieve

A molecular sieve, high-content technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of low iron content, difficult Fe, easy loss and coalescence of active substances, etc., achieve good thermal and hydrothermal stability, and strengthen acid volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

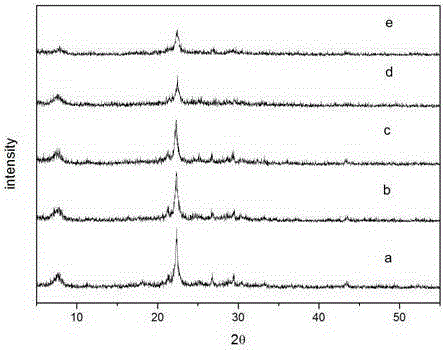

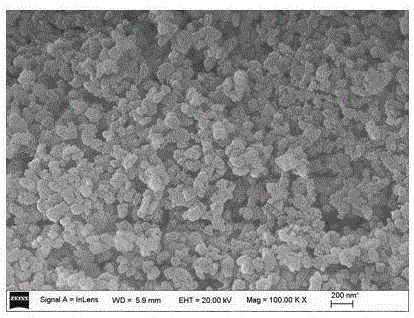

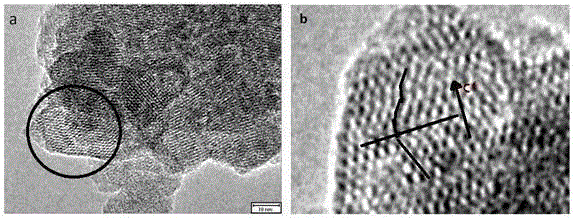

Embodiment 1

[0024] Take 0.93gFeCl 3 ·6H 2 O and 0.54g of tartaric acid were placed in a beaker, and 15mL of deionized water was added, and stirred until dissolved for later use, which was recorded as solution 1. Then take 0.054gNaOH and 0.14gNaAlO 2 In another beaker, add 4 mL of deionized water, stir until dissolved, and record it as solution 2. Take 21.4 mL of tetraethylammonium hydroxide (35%) in a three-necked flask, add 18 mL of tetraethyl silicate dropwise thereto, and stir for 30 minutes to obtain a mixed solution 3. Add the above-prepared solution 1 into the mixed solution 3, continue to stir for 30 minutes to obtain a light yellow sol, and then add the above-mentioned solution 2 into the yellow sol system. The three-necked flask was transferred to a water bath, heated and stirred at 60°C for 15 h, and then the mixture was transferred to a reaction kettle. Under the condition of 130 ℃, hydrothermal reaction 12d. The obtained product was subjected to suction filtration, washed...

Embodiment 2

[0026] Take 1.17gFeCl 3 ·6H 2 O and 0.67g of tartaric acid were placed in a beaker, and 15mL of deionized water was added, and stirred until dissolved for later use, which was recorded as solution 1. Then take 0.054gNaOH and 0.28gNaAlO 2 In another beaker, add 4 mL of deionized water, stir until dissolved, and record it as solution 2. Take 21.8 mL of tetraethylammonium hydroxide (35%) in a three-necked flask, add 18 mL of tetraethyl silicate dropwise thereto, and stir for 30 minutes to obtain a mixed solution 3. Add the above-prepared solution 1 into the mixed solution 3, continue to stir for 30 minutes to obtain a light yellow sol, and then add the above-mentioned solution 2 into the yellow sol system. The three-necked flask was transferred to a water bath, heated and stirred at 60° C. for 12 h, and then the mixture was transferred to a reaction kettle. Under the condition of 130 ℃, hydrothermal reaction 12d. The obtained product was subjected to suction filtration, wash...

Embodiment 3

[0028] Take 1.4gFeCl 3 ·6H 2 O and 0.8g of tartaric acid were placed in a beaker, and 15mL of deionized water was added, and stirred until dissolved for later use, which was recorded as solution 1. Then take 0.054gNaOH and 0.28gNaAlO 2 In another beaker, add 4 mL of deionized water, stir until dissolved, and record it as solution 2. Take 22.2 mL of tetraethylammonium hydroxide (35%) in a three-necked flask, add 18 mL of tetraethyl silicate dropwise thereto, and stir for 30 minutes to obtain a mixed solution 3. Add the above-prepared solution 1 into the mixed solution 3, continue to stir for 30 minutes to obtain a light yellow sol, and then add the above-mentioned solution 2 into the yellow sol system. The three-necked flask was transferred to a water bath, heated and stirred at 60° C. for 24 h, and then the mixture was transferred to a reaction kettle. Under the condition of 130 ℃, hydrothermal reaction 12d. Suction filter the obtained product, wash it with deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com