Preparation method of beta zeolite with multilevel pore canals

A technology of beta zeolite and channels, which is applied in the field of preparation of multi-stage channel beta zeolite, can solve the problems of complex preparation process, high price, and difficulty in industrial scale application, and achieve easy scale-up production, saving dosage, and adjustable silicon-aluminum ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] 1. Take 32.19 grams of ethyl orthosilicate (28% SiO 2 ), 35.34 grams of tetraethylammonium hydride (25% aqueous solution) and 0.96 grams of sodium hydroxide were stirred at room temperature to obtain a homogeneous solution.

[0026] 2. Take 2 grams of aluminum sulfate octadecahydrate completely dissolved in 20ml of deionized water, add dropwise to the homogeneous solution obtained in 1 while stirring, and stir at a constant temperature of 80°C until a dry gel is obtained.

[0027] 3. Transfer the obtained xerogel into a 100m1 hydrothermal kettle and heat it at 140°C for 48 hours, then cool, dry, add 2.4 grams of silane coupling agent (such as vinyltrimethoxysilane, etc.) In the mixture, stir evenly and transfer to a petri dish to dry.

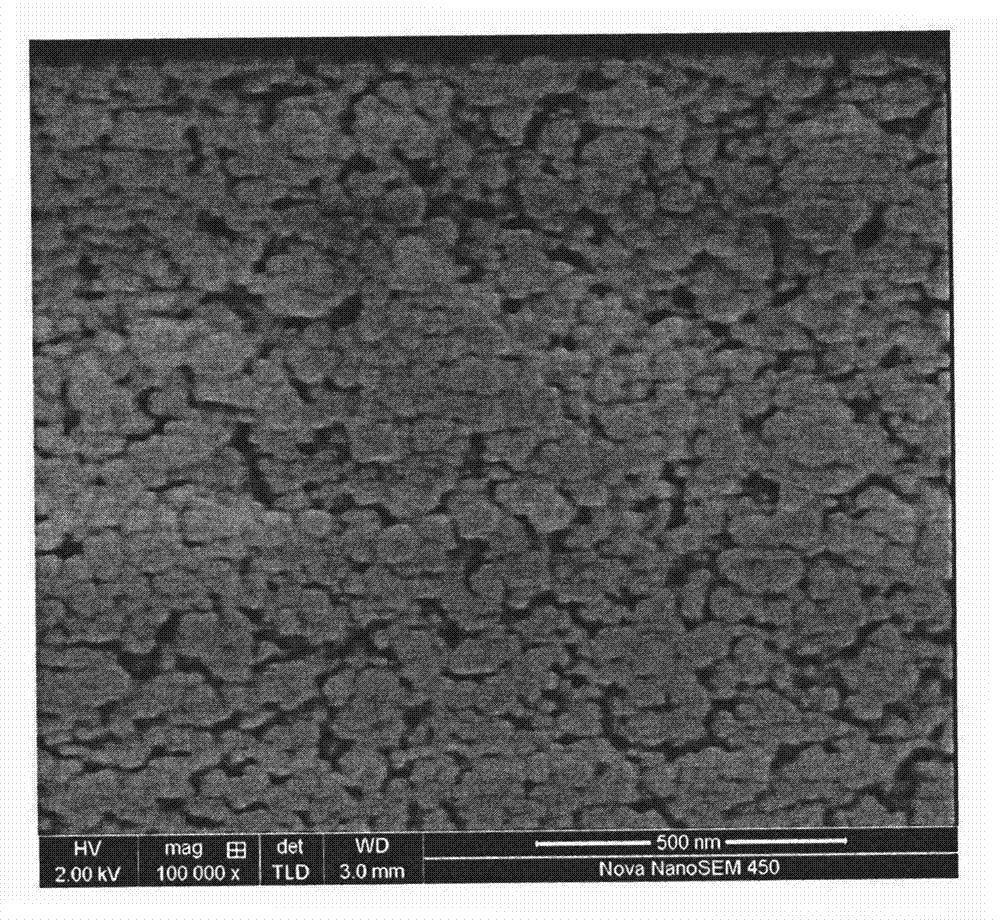

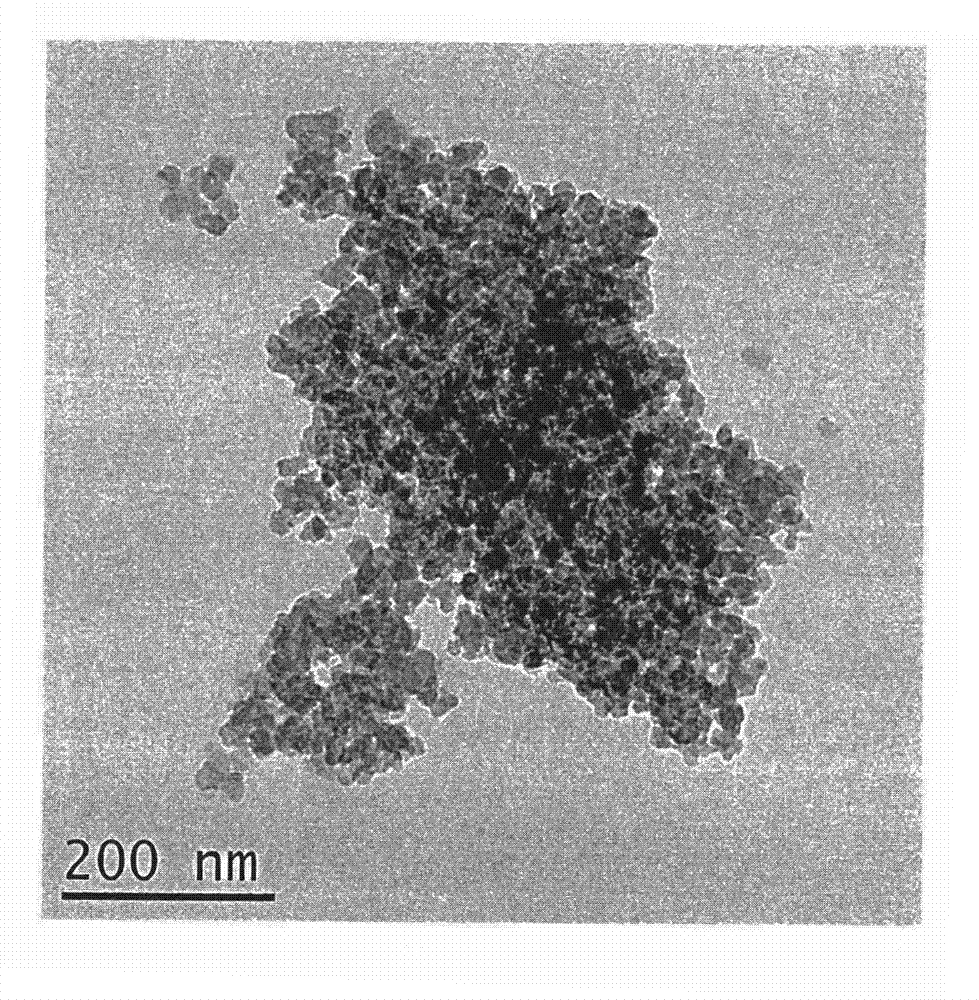

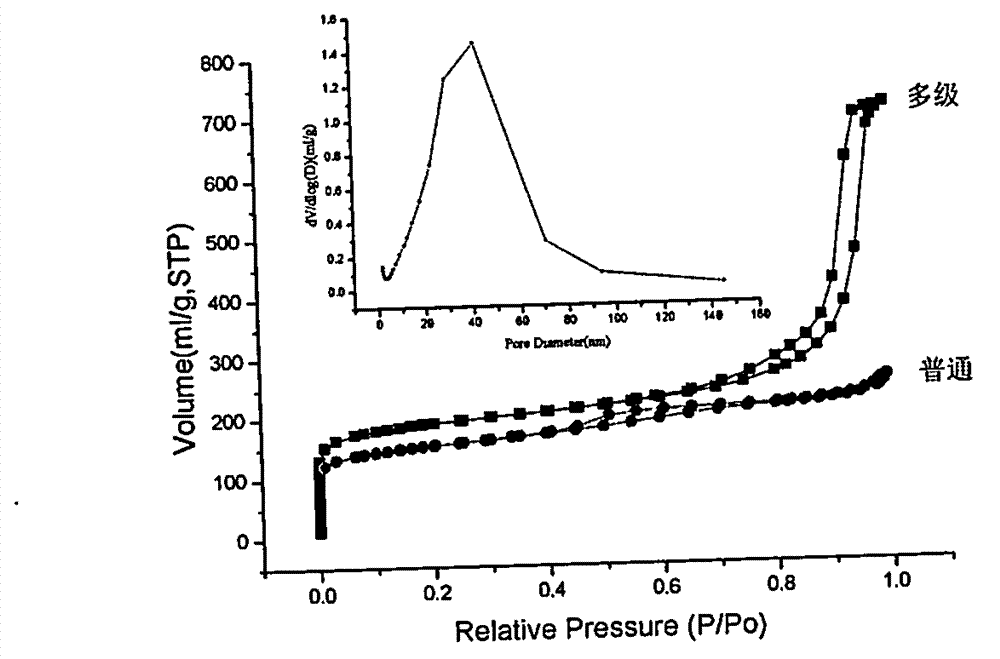

[0028] 4. Move the dried solid into a 100m1 hydrothermal kettle and heat it at 140°C for 72 hours, then cool, filter, wash, dry, and roast to obtain SiO 2 / Al 2 o 3 50 zeolite with hierarchical channels.

example 2

[0030] 1. Take 32.19 grams of ethyl orthosilicate (28% SiO 2 ), 55.2 grams of tetraethylammonium hydroxide (20% aqueous solution) and 0.96 grams of sodium hydroxide were stirred at room temperature to obtain a homogeneous solution.

[0031] 2. Take 0.40 g of aluminum chloride and completely dissolve it in 20 ml of deionized water, add it dropwise into the homogeneous solution obtained in 1 while stirring, and stir at a constant temperature of 80°C until a xerogel is obtained.

[0032] 3. Transfer the obtained xerogel into a 100ml hydrothermal kettle and heat it at 140°C for 48 hours, then cool, dry, and add 2.6 grams of silane coupling agent (such as vinyltrimethoxysilane) and an appropriate amount of ethanol to uniformly In the mixture, stir evenly and transfer to a petri dish to dry.

[0033] 4. Transfer the dried solid into a 100ml hydrothermal kettle and heat it at 140°C for 72 hours, then cool, filter, wash, dry, and roast to obtain SiO 2 / Al 2 0 3 100 zeolite with hi...

example 3

[0035] 1. Get 32.19 grams of silica sol (28% SiO 2 , Shanghai Hengsheng Chemical Industry), 35.34 grams of tetraethylammonium hydroxide (25% aqueous solution) and 0.96 grams of sodium hydroxide, stirred at room temperature to obtain a homogeneous solution.

[0036] 2. Take 0.25 g of aluminum sulfate octadecahydrate and completely dissolve it in 20 ml of deionized water, and add it dropwise to the homogeneous solution obtained in 1 while stirring. After continuing to stir for 2 hours, stir at a constant temperature of 80° C. until a dry gel is obtained.

[0037] 3. Transfer the obtained dry gel into a 100ml hydrothermal kettle and heat it at 140°C for 48 hours, then cool, dry, add 2.6 grams of silane coupling agent (such as vinyltrimethoxysilane) and mix evenly with appropriate amount of ethanol solution, stirred evenly and then transferred to a Petri dish to dry.

[0038] 4. Transfer the dried solid into a 100ml hydrothermal kettle and heat it at 140°C for 72 hours, then coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com