Preparation method of ZSM-5 mesoporous and microporous composite molecular sieve

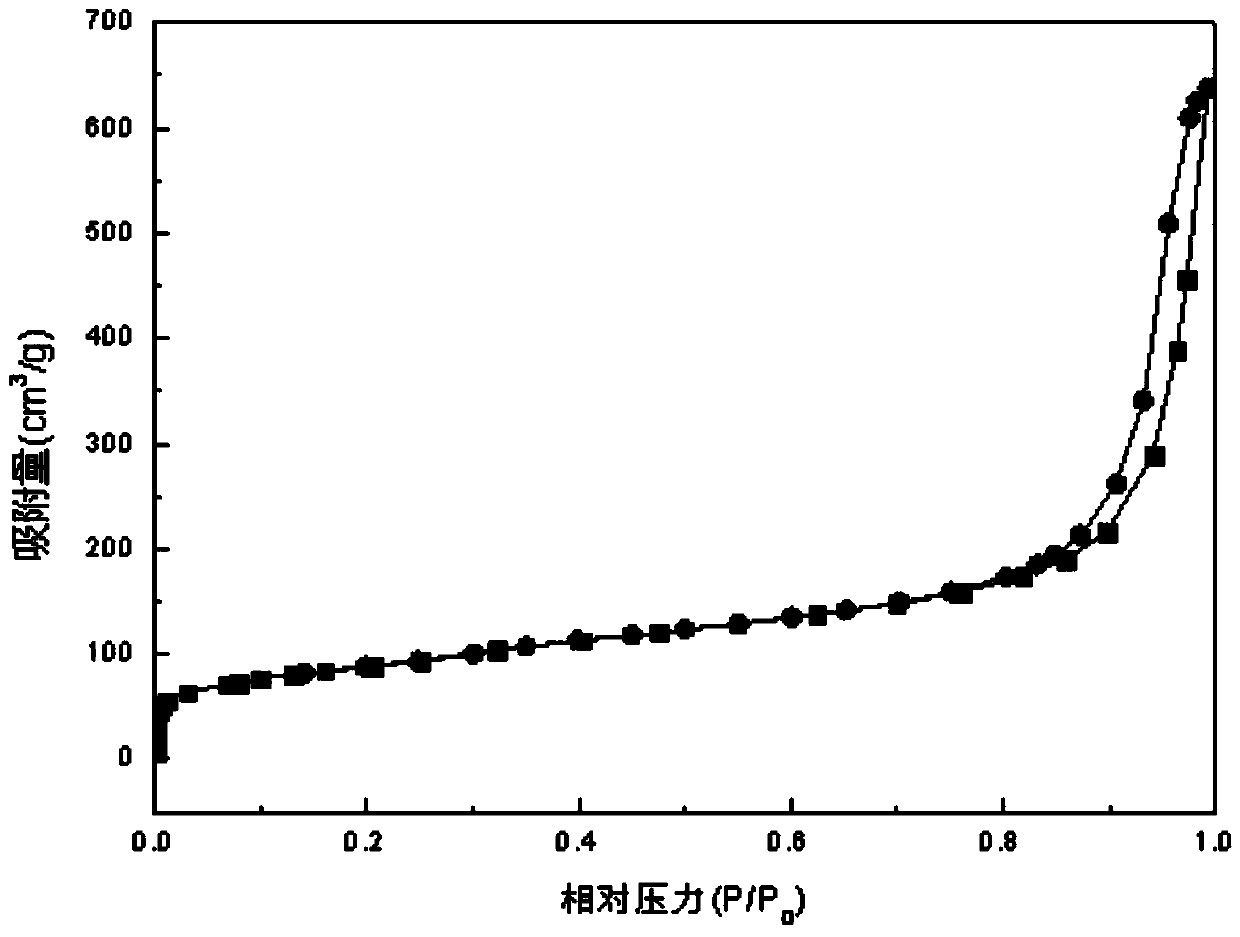

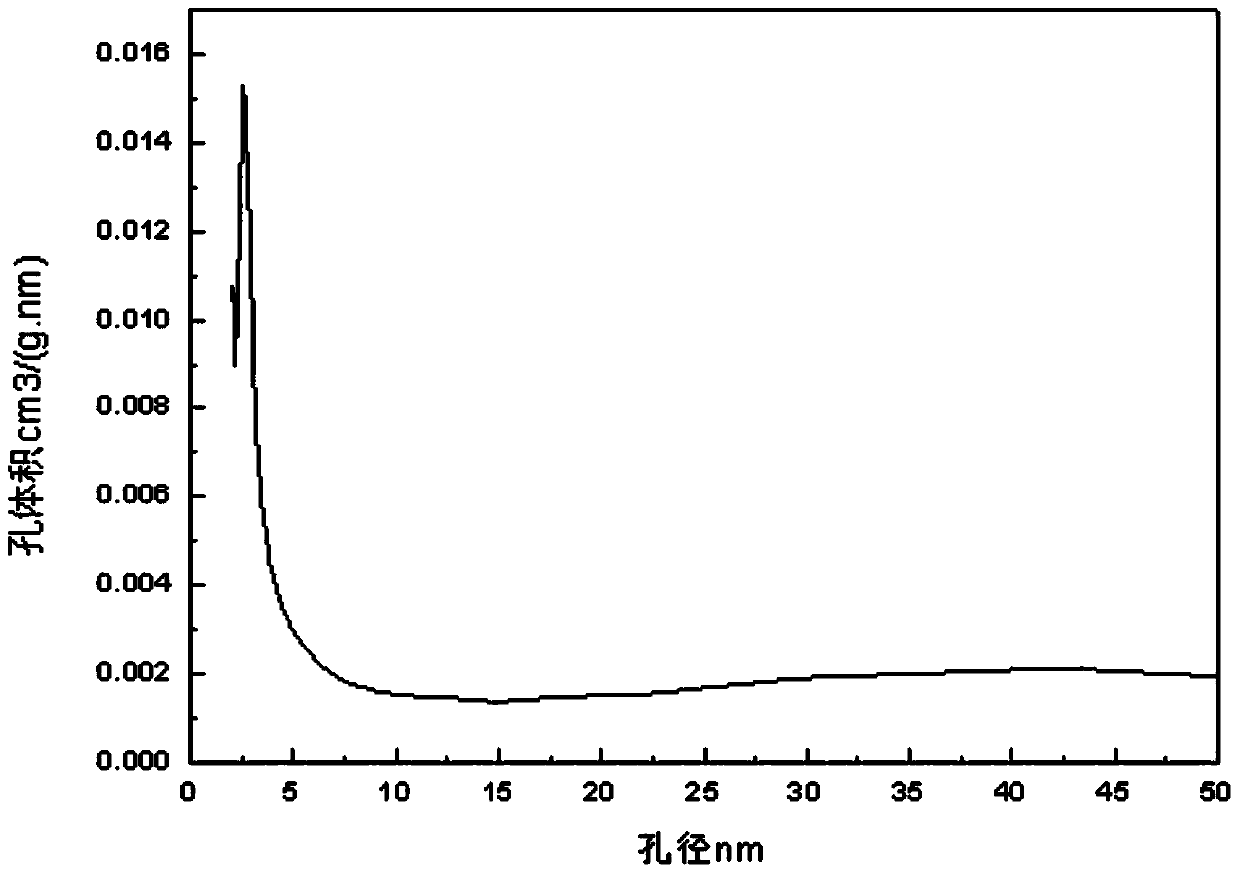

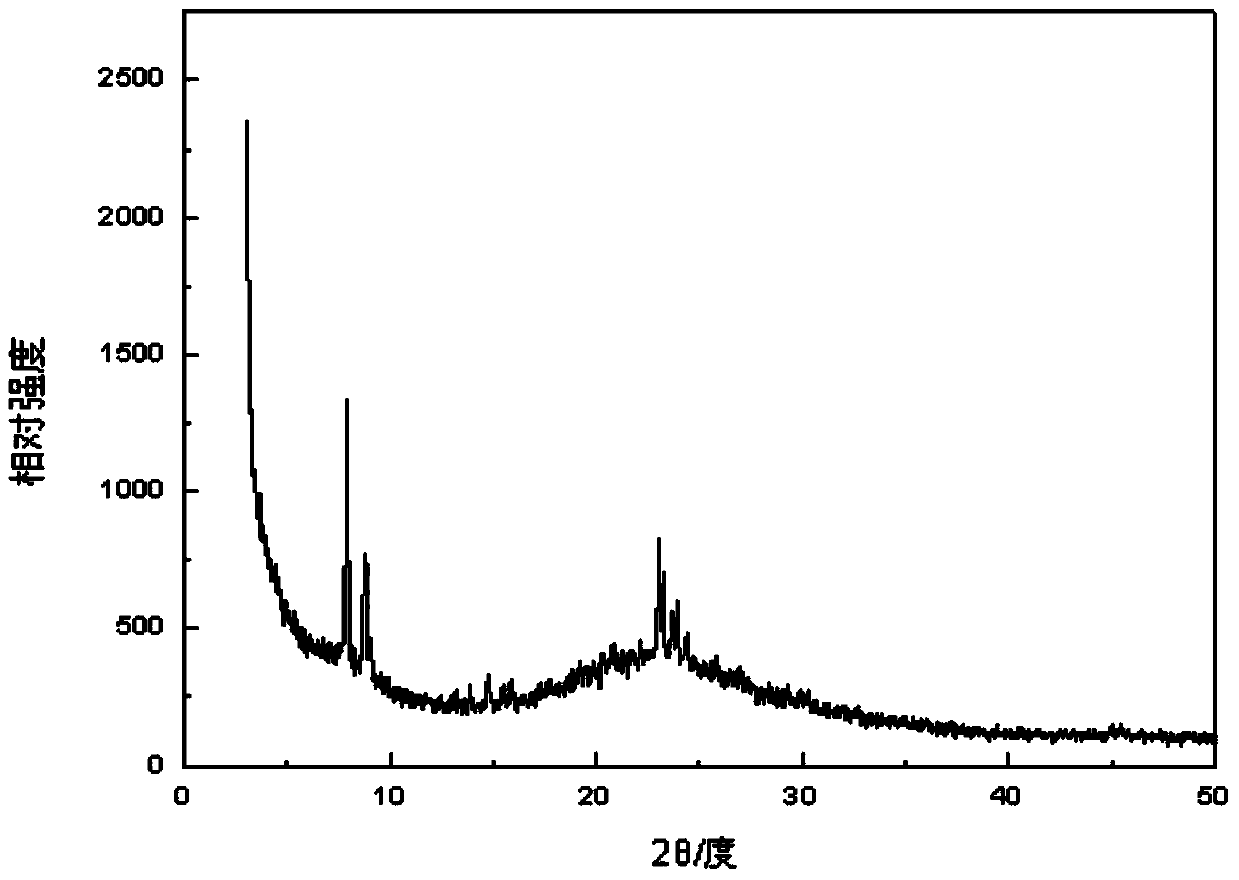

A technology of ZSM-5 and composite molecular sieve, which is applied in the field of molecular sieves, can solve the problems of difficult industrialization, cumbersome technical steps, and small specific surface area, and achieve the effects of simplified synthesis steps, simple process, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 0.328gNaAlO 2 and 15.589gTEOS (98%wt in H 2 O) Dissolve in 31.3g of water at 20°C and stir for 1h; gradually add 3.927g of TEAOH (25%wt in H 2 O) and stirred for 2h; put the mixed solution into a stainless steel high-pressure reactor, and react under homogeneous conditions at 90°C and 30r / min, and the reaction time is 1d; cool the reactor to room temperature, and drop it into the product at 60°C Add 0.486gCTAB and 96.7gH 2The mixed solution of O was stirred for 1 h; 12.593 g of EtOH was added dropwise to the mixture and stirred for 2 h; the mixed solution was put into a stainless steel autoclave, and crystallized at 140 ° C for 5 d; Extract the product by centrifugal filtration, put it in a vacuum drying oven and dry it at 40°C, put the dried product into a muffle furnace, set the ramp temperature rise to 2°C / min, calcinate at 500°C for 6h, and dry The final product can be directly put into the muffle furnace, and the initial temperature is in the room temperature ra...

Embodiment 2

[0030] 0.328gNaAlO 2 and 17.007gTEOS (98%wt in H 2 O) Dissolve in 19.3g of water at 20°C and stir for 1h; gradually add 4.712g of TEAOH (25%wt in H 2 O) and stirred for 2h; put the mixed solution into a stainless steel high-pressure reactor, and react under homogeneous conditions at 90°C and 30r / min, and the reaction time is 1d; cool the reactor to room temperature, and drop it into the product at 60°C Add 0.729gCTAB and 120.7gH 2 The mixed solution of O was stirred for 1h; 12.900g of EtOH was added dropwise to the mixture and stirred for 2h; the mixed solution was put into a stainless steel autoclave, and crystallized at 140°C for 5d; Extract the product by centrifugal filtration, put it into a vacuum drying oven and dry it at 40°C, put the dried product into a muffle furnace, set the ramp temperature rise to 2°C / min, and calcinate at 500°C for 6h to obtain a sample B2.

Embodiment 3

[0032] 0.328gNaAlO 2 and 15.589gTEOS (98%wt in H 2 O) Dissolve in 31.3g of water at 30°C and stir for 2h; gradually add 3.927g of TEAOH (25%wt in H 2 O) and stirred for 3h; the mixed solution was put into a stainless steel autoclave, and reacted under homogeneous conditions at 110°C and 40r / min, and the reaction time was 2d; the reactor was cooled to room temperature, and dripped into the product at 80°C Add 0.486gCTAB and 96.7gH 2 The mixed solution of O was stirred for 2h; 12.593g of EtOH was added dropwise to the mixture and stirred for 4h; the mixed solution was put into a stainless steel autoclave and crystallized at 160°C for 7d; Extract the product by centrifugal filtration, put it in a vacuum drying oven and dry it at 60°C, put the dried product into a muffle furnace, set the ramp temperature rise to 3°C / min, and calcinate it at 550°C for 7h to obtain a sample B3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com