Method for preparing and concentrating tetraethylammonium hydroxide with membrane integration technique

A technology of tetraethylammonium hydroxide and membrane integration, which is applied in the purification/separation of amino compounds, electrolysis process, electrolysis components, etc., can solve the problems of environmental hazards, ion leakage, waste liquid discharge, etc., and achieve no pollutant discharge , Increase product concentration and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

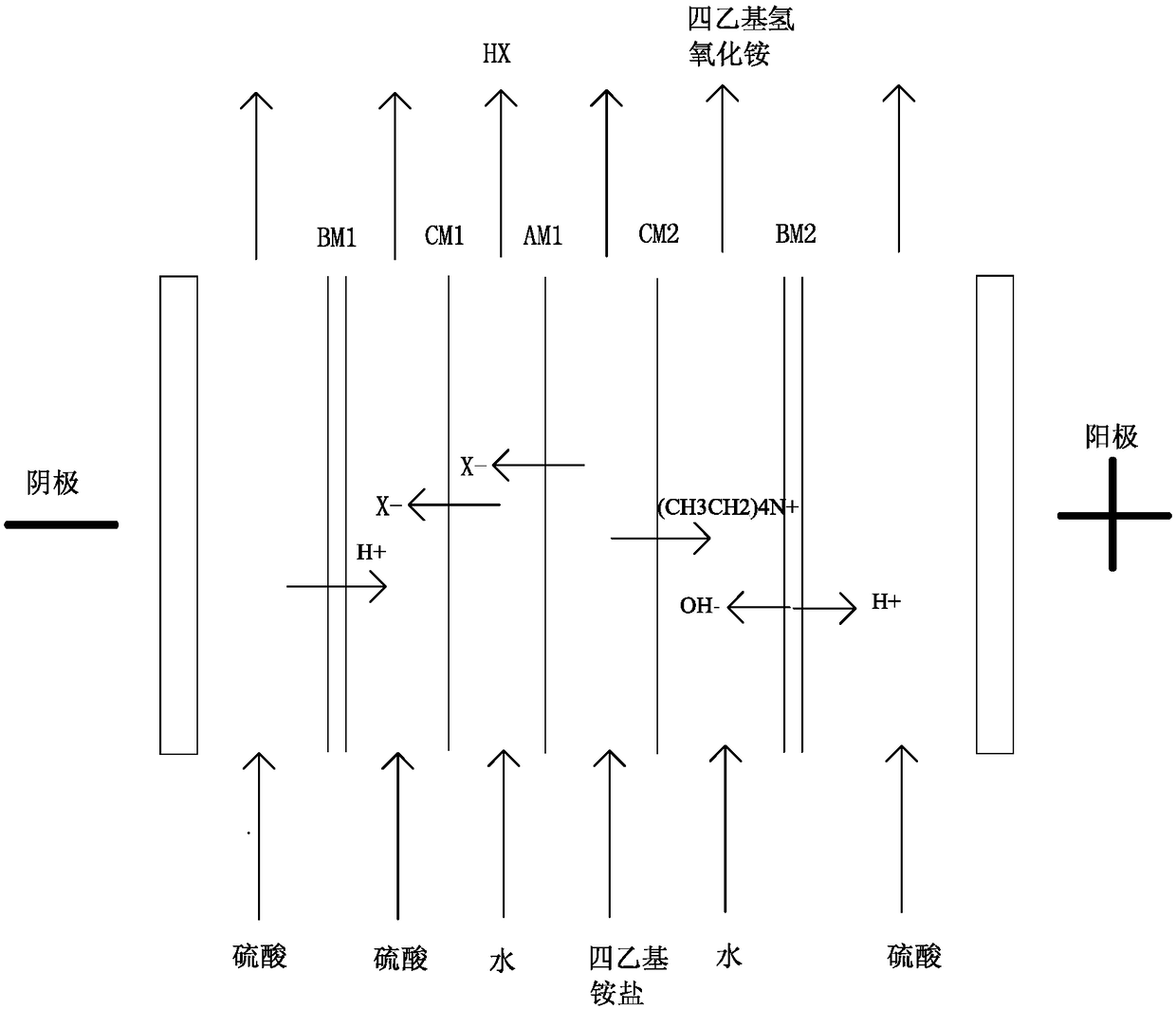

[0028] The bipolar membrane electrodialysis system used in this example is a bipolar membrane electrodialysis device, which is composed of anolyte chambers on both sides and an electrodialysis compartment sandwiched between the anolyte chambers on both sides. The cathode chamber and the anode chamber, the electrodialysis compartment is composed of 10 sets of membrane units arranged in series, and the membrane unit is a four-compartment structure consisting of a bipolar membrane BM1, a cation exchange membrane CM1, an anion exchange membrane AM1, A cation exchange membrane CM2 and a bipolar membrane BM2 are arranged at intervals to form a buffer solution room, an acid solution room, a raw material solution room and an alkali solution room. The bipolar membrane, cation exchange membrane, and anion exchange membrane used therein are homogeneous membranes purchased from Zhejiang Scitech Membrane Technology Co., Ltd., and the cathode and anode all use titanium-coated ruthenium elect...

Embodiment 2

[0033] The bipolar membrane electrodialysis system used in this example is a bipolar membrane electrodialysis device, which is composed of anolyte chambers on both sides and an electrodialysis compartment sandwiched between the anolyte chambers on both sides. The cathode chamber, the anode chamber, and the electrodialysis chamber are composed of 30 sets of membrane units arranged in series. The membrane unit is a four-compartment structure consisting of a bipolar membrane BM1, a cation exchange membrane CM1, an anion exchange membrane AM1, A cation exchange membrane CM2 and a bipolar membrane BM2 are arranged at intervals to form a buffer solution room, an acid solution room, a raw material solution room and an alkali solution room. The bipolar membrane, cation exchange membrane, and anion exchange membrane used therein are homogeneous membranes purchased from ASTOM Corporation of Japan, and the cathode and anode all use titanium-coated ruthenium electrodes.

[0034] In additi...

Embodiment 3

[0038] The bipolar membrane electrodialysis system used in this example is a bipolar membrane electrodialysis device, which is composed of anolyte chambers on both sides and an electrodialysis compartment sandwiched between the anolyte chambers on both sides. The cathode chamber, the anode chamber, and the electrodialysis compartment are composed of 25 sets of membrane units arranged in series. The membrane unit is a four-compartment structure consisting of a bipolar membrane BM1, a cation exchange membrane CM1, an anion exchange membrane AM1, A cation exchange membrane CM2 and a bipolar membrane BM2 are arranged at intervals to form a buffer solution room, an acid solution room, a raw material solution room and an alkali solution room. The bipolar membrane, cation exchange membrane, and anion exchange membrane used therein are homogeneous membranes purchased from Fuma-tech Company in Germany, and the cathode and anode all use titanium-coated ruthenium electrodes.

[0039] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com