Patents

Literature

39results about How to "Meet high purity requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for directly producing high-purity electronic level cobaltous sulfate by using cobalt-containing waste

ActiveCN102061390AMeet high purity requirementsImprove overall recoveryProcess efficiency improvementTotal recoveryGoethite

The invention provides a method for directly producing high-purity electronic level cobaltous sulfate by using cobalt-containing waste, in particular a process for producing cobaltous sulfate by using cobalt-containing waste. The method comprises the steps of: checking and classifying raw materials, wet-milling and size-mixing, acid-decomposing, filtering, washing, separating, and extracting copper sponge. The method is characterized by also comprising the steps of: removing iron with a goethite process, extracting P2O4 and removing impurities, separating nickel from cobalt, extracting N235, purifying, concentrating and crystallizing. The high purity electron level cobaltous sulfate is directly regenerated by using various kinds of cobalt wastes, the requirement of the modern high-technology industry on high purity of the cobaltous sulfate is met; the total recovery of the cobalt is higher than or equal to 98 percent; various usable elements can be comprehensively recycled, and coppersponge, tungsten carbide, iron hydroxide and nickel carbonate can be regenerated while the electronic level cobaltous sulfate as a main product is regenerated. The invention has the advantages of comprehensively utilizing waste cobalt resources, recycling the wastes, improving the enterprise benefit, and being beneficial to the development of energy conservation, emission reduction, environment protection and circular economy.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

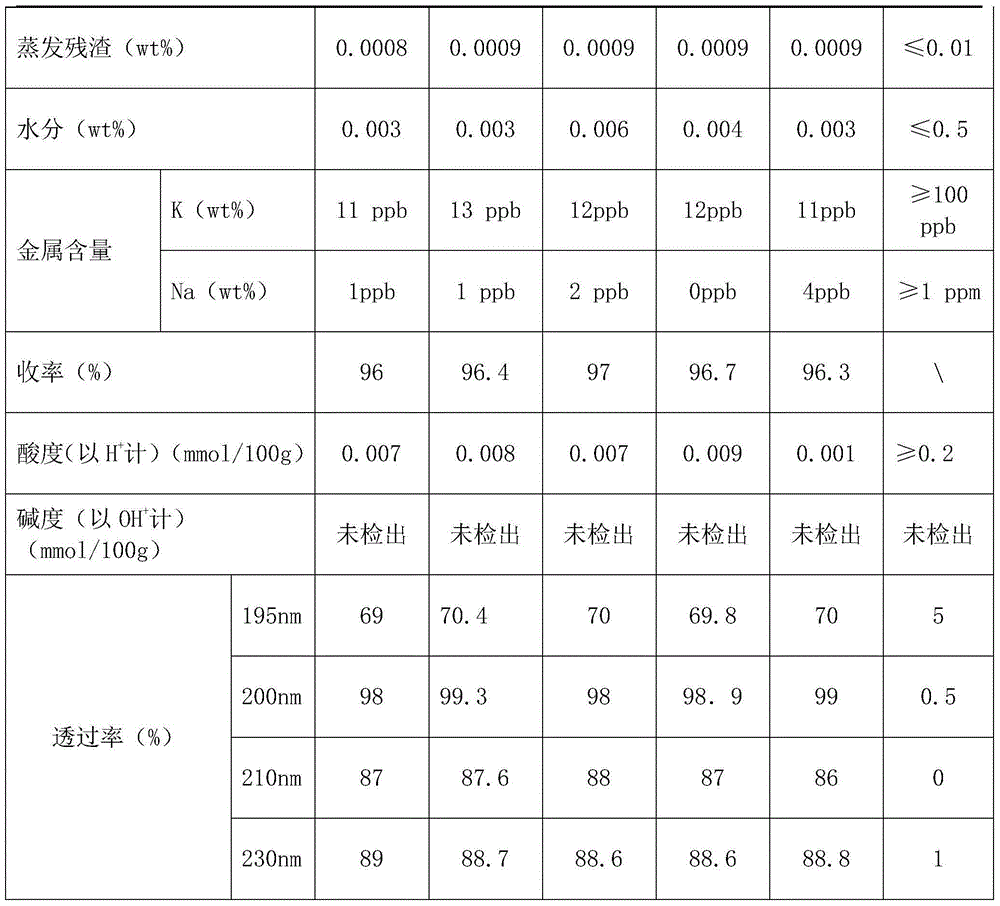

Method for purifying acetonitrile for liquid chromatogram-mass spectrometer

InactiveCN104744300AExpand the scope of applicationReduce the cost of importsCarboxylic acid nitrile purification/separationChemistryActivated carbon

The invention discloses a method for purifying acetonitrile for a liquid chromatogram-mass spectrometer. The method is characterized in that impurities in a raw material acetonitrile are removed through procedures such as modified activated carbon adsorption, and thus acetonitrile for the liquid chromatogram-mass spectrometer can be obtained. By adopting the method for purifying acetonitrile for the liquid chromatogram-mass spectrometer, acetonitrile of which the purity is greater than or equal to 99.99% (wt) can be obtained, the requirements of the liquid chromatogram-mass spectrometer on high purity can be met, the purified acetonitrile can be applied to the field of liquid chromatogram-mass spectrometers, and the application range is widened.

Owner:上海星可高纯溶剂有限公司

After-absorbing technique for electric cable material

ActiveCN101182377AAdd filter systemImprove cleanlinessPlastic/resin/waxes insulatorsHigh pressureTwin screw extruder

The invention relates to a production process of medium-pressure and high-pressure power cable insulation material. The invention aims at solving the technical problem that the process has the characteristics of the effective filtration of impurities in the material, the good compounding uniformity of finished products and the good performances of the finished products. The invention has a technical proposal of post absorption process of the cable material, orderly comprising the following steps: 1) filtration and purification: polyethylene, antioxidant and additive are mixed, extruded out ofa twin-screw extruder and treated through filtration and purification; the temperature for extrusion and filtration is 160 DEG C to 200 DEG C; then a pelletizer is used for preparing granules; 2) homogenizing and absorption: the prepared granules are put into an absorption kettle; cross-linker is added according to the proportion for homogenizing and absorption; the homogenizing temperature is 50DEG C to 90 DEG C; the homogenizing time is 10 hours to 30 hours; then the products are cooled and packaged. The item number of meshes of the used filter screen for filtration is 200 items to 800 items. The underwater cutting material is used in the pelletizer when preparing the granules.

Owner:ZHEJIANG WANMA MACROMOLECULE MATERIAL

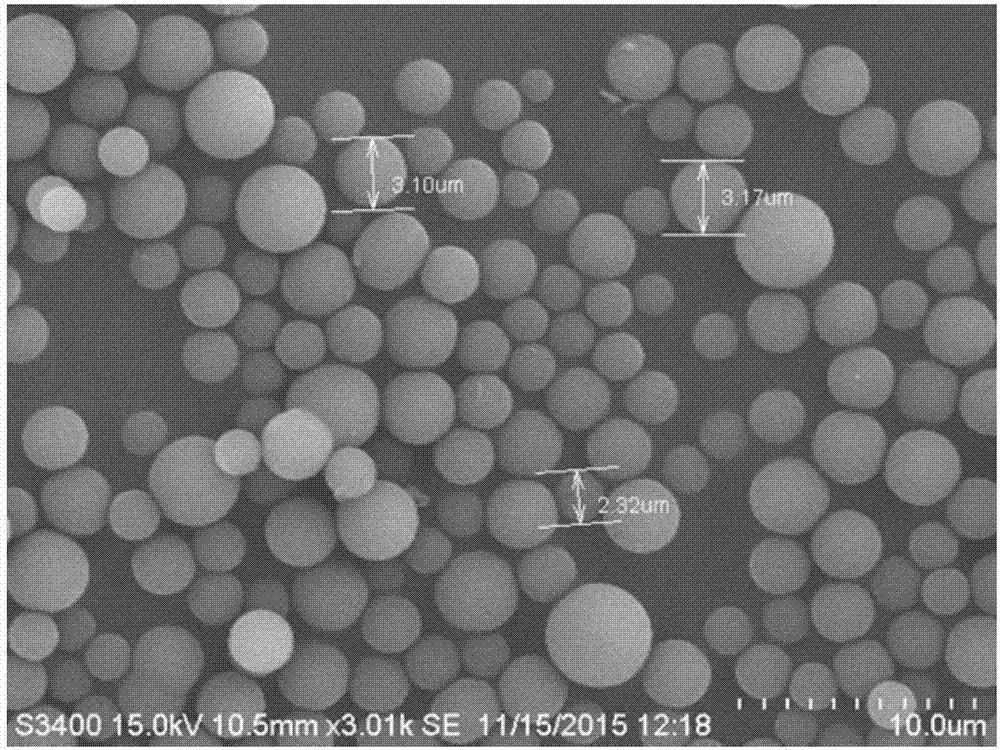

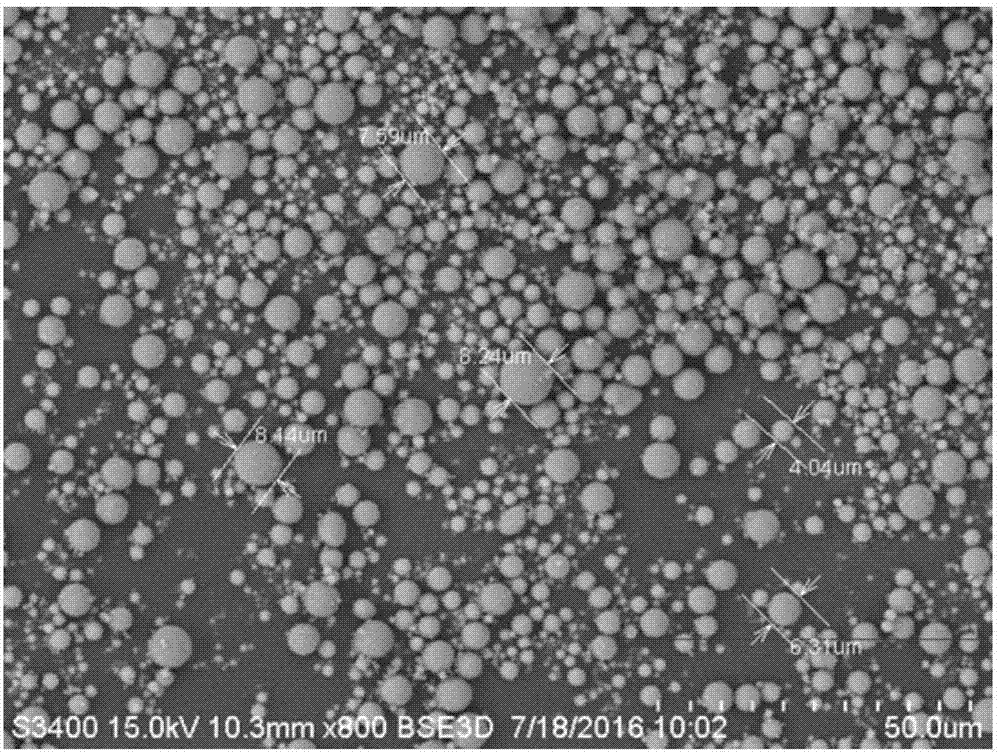

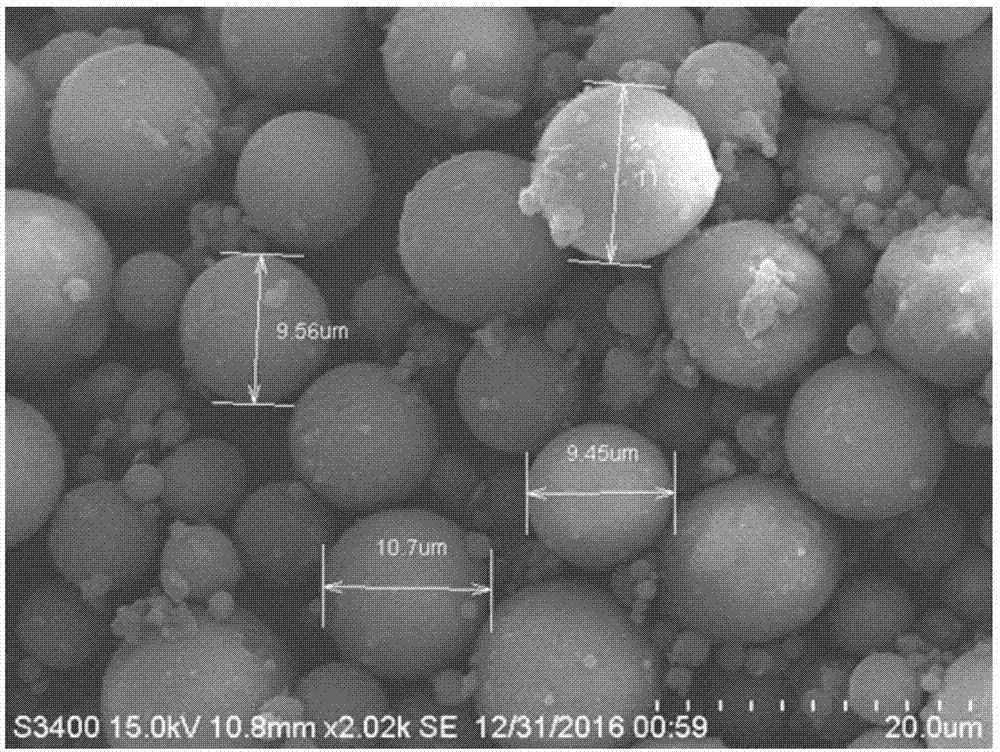

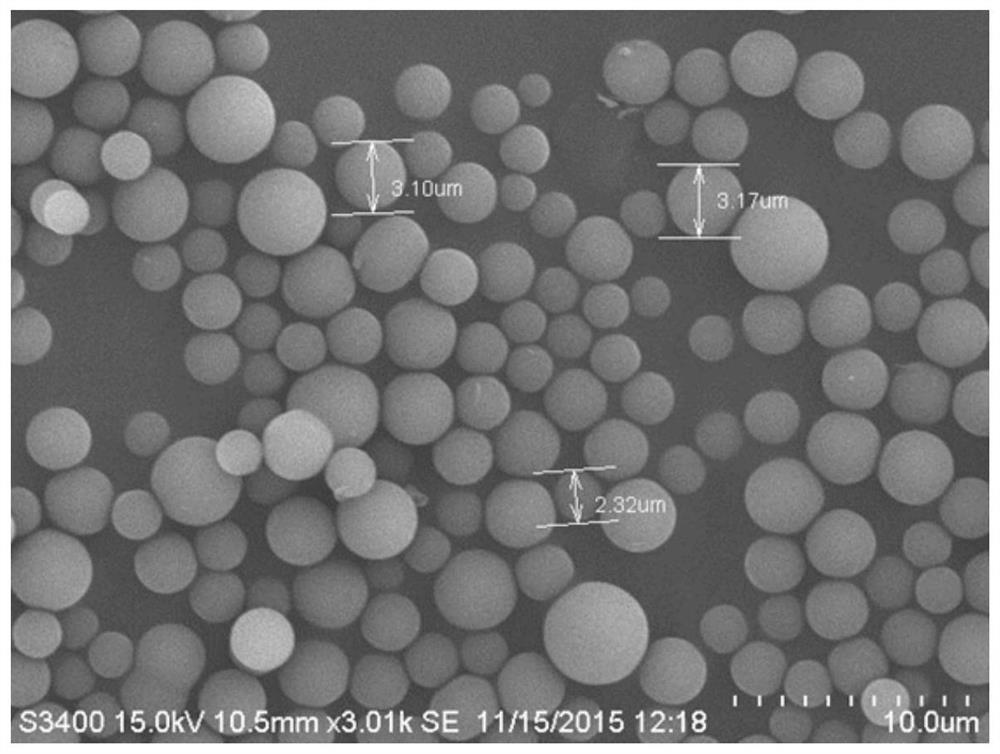

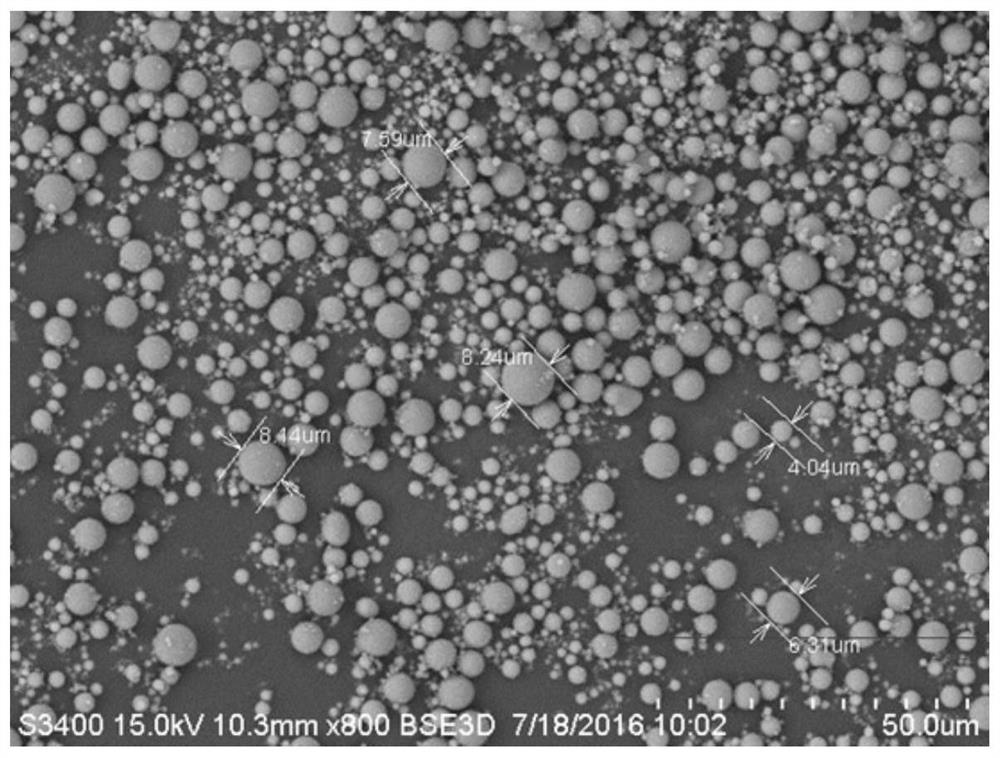

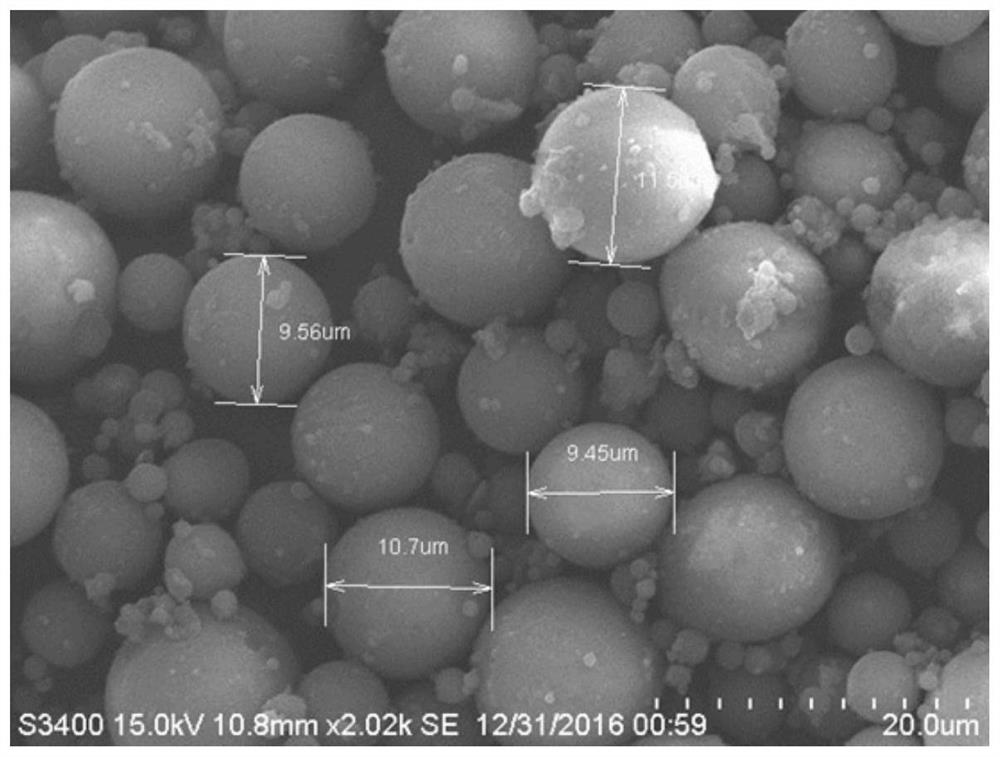

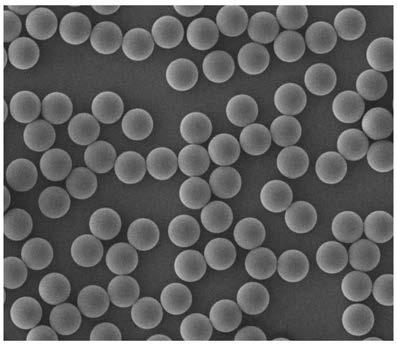

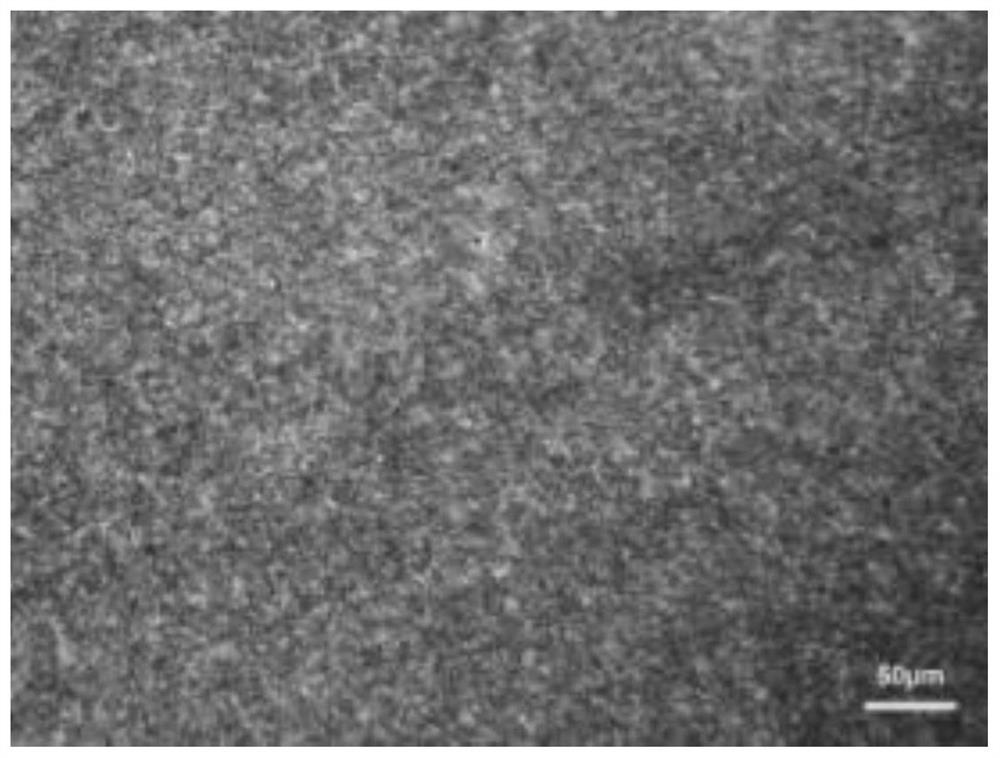

Preparation method of high-purity micron-sized spherical silica micropowder

The invention discloses a preparation method of high-purity micron-sized spherical silica micropowder. The preparation method comprises the following steps: firstly, providing a precursor solution containing silicon; secondly, adding the precursor solution into an oil phase containing an emulsifier and then stirring to obtain a mixed solution; thirdly, adding a basic catalyst into the mixed solution, standing and ageing, washing precipitate with a mixture of a solvent and water, and then drying to obtain silica microspheres, wherein the precursor solution containing the silicon is one or a mixture of two or more of Si(OR)4, ethyl silicate 40, ethyl silicate 32 and SiR2(OR1)3, and R, R1 and R2 are C1-3 alkyl groups which are independent of one another. The silica microspheres disclosed by the invention have the advantages that the purity is excessively-high and the contents of all metal impurities are below 0.2 ppm; in addition, the preparation method disclosed by the invention is easy to operate and products in the preparation process are easy to treat; and particle sizes of the finally-obtained silica microspheres are 0.3 to 0.4 [mu]m.

Owner:ETERNAL SPECIALTY MATERIALS ZHUHAI CO LTD

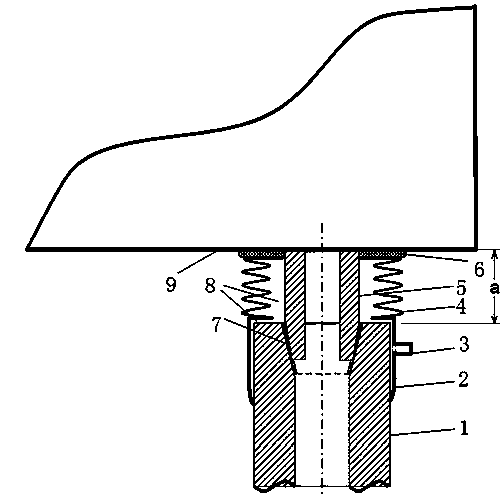

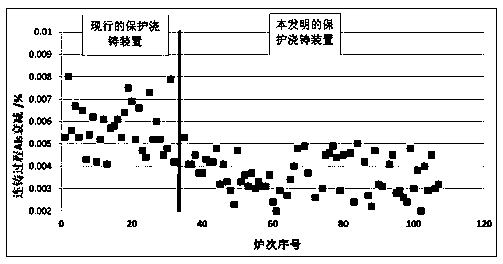

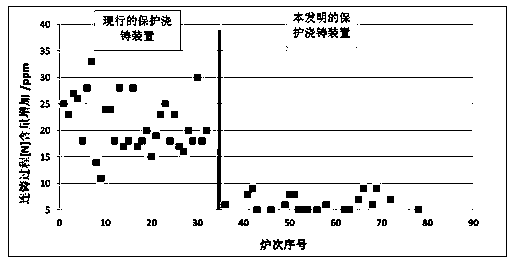

Continuous casting protection casting device of high-quality steel

The invention relates to a continuous casting protection casting device of high-quality steel, which belongs to molten steel casting equipment, and particularly relates to a continuous casting protection casting device for the high-quality steel. The continuous casting protection casting device is characterized in that an elastic corrugated pipe is arranged on an iron casing, a water outlet is surrounded by the corrugated pipe, and an annular asbestos sealing gasket is arranged on the upper end of the corrugated pipe, is abutted below a steel ladle and is opposite to a steel outlet; a conical asbestos sealing ring is arranged in the contact position of the water outlet and a long water opening, and the long water opening, the elastic corrugated pipe, the asbestos sealing gasket, the water outlet and the asbestos sealing ring form an elastic argon gas sealing chamber. The continuous casting protection casting device has the advantages that the elastic argon gas sealing chamber which is provided with an argon gas inlet and is formed by the elastic corrugated pipe, the asbestos sealing gasket and the asbestos sealing ring is arranged between the water outlet and the long water opening, so that molten steel is effectively prevented from being contacted with air, the argon sealing effect is enhanced, secondary oxidation of the molten steel is avoided, smooth continuous casting production is guaranteed, inclusions in steel are reduced, the quality of the molten steel is improved and improved, and the requirement of high purity of the high-quality steel is satisfied.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

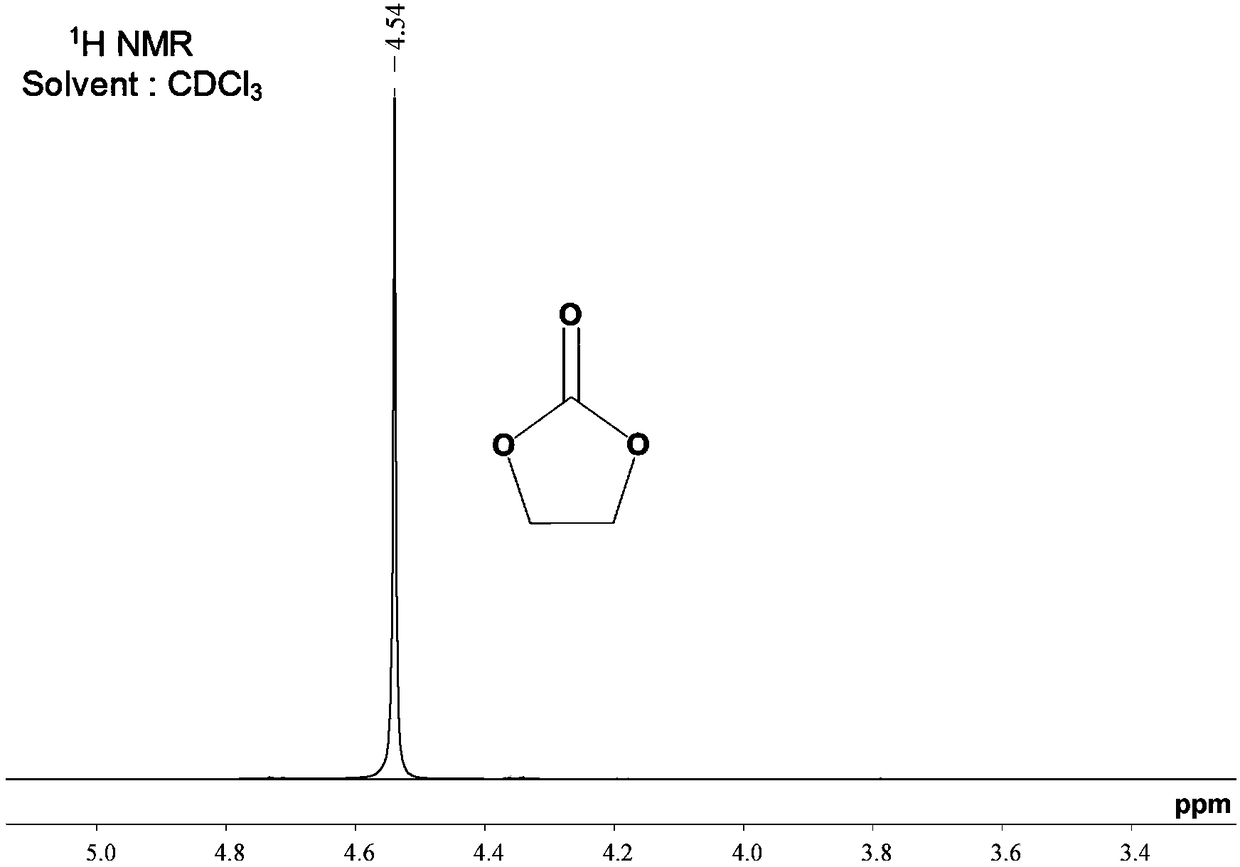

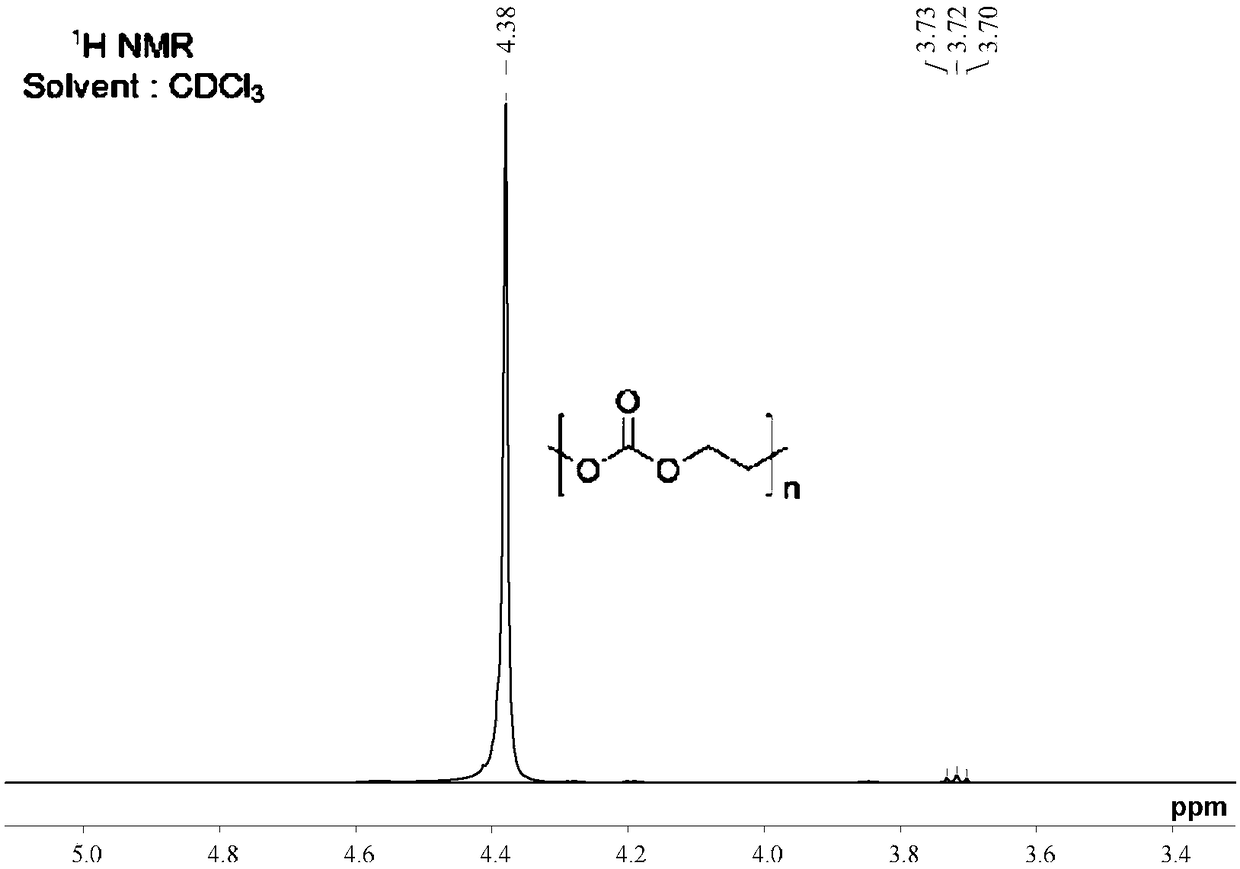

Polycarbonate preparation method

The invention discloses a polycarbonate preparation method, wherein triphosgene and a dihydroxy-based compound are used as raw materials and are subjected to a normal pressure condensation polymerization reaction in the presence of an appropriate amount of a catalyst and an acid binding agent to obtain polycarbonate. According to the present invention, the method has advantages of mild reaction condition, easy operation, high product purity and controllable molecular weight, can avoid the decarboxylation reaction induced ether chain introduction in the product, and can meet the high-purity requirements of the lithium battery industry.

Owner:HUAZHONG UNIV OF SCI & TECH

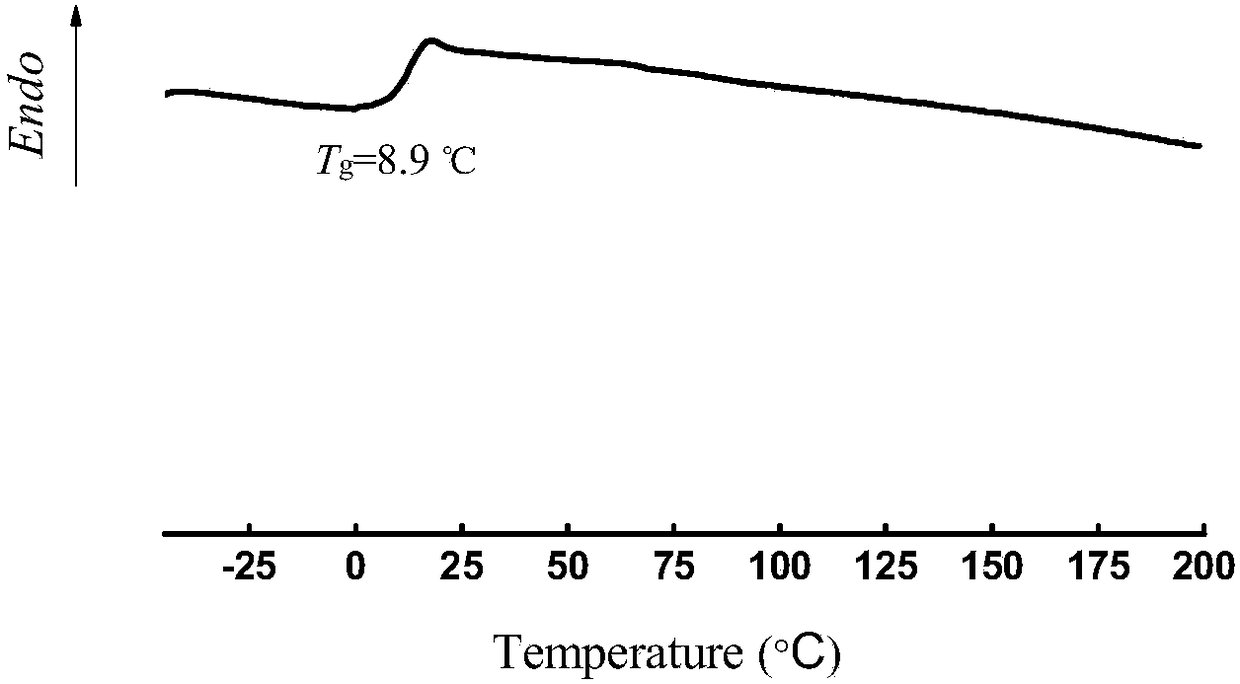

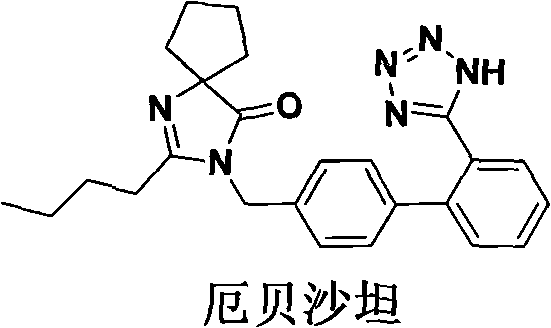

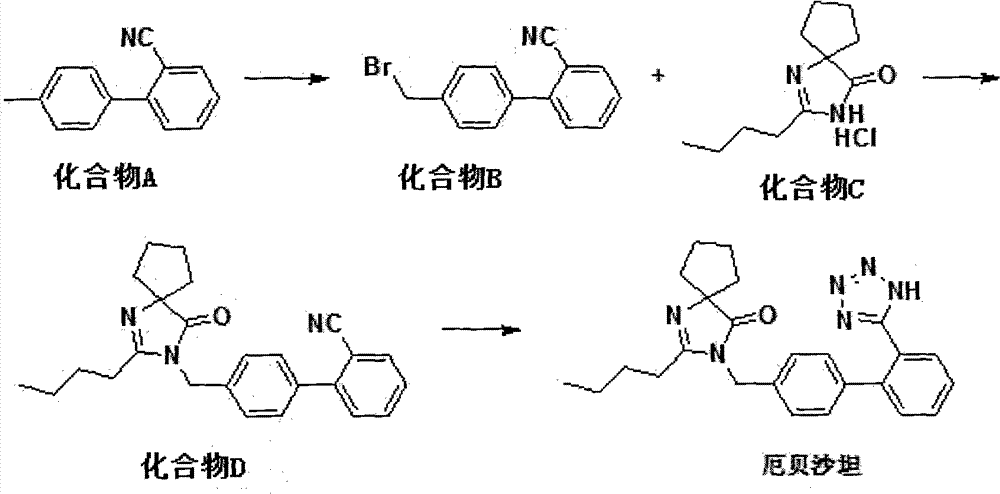

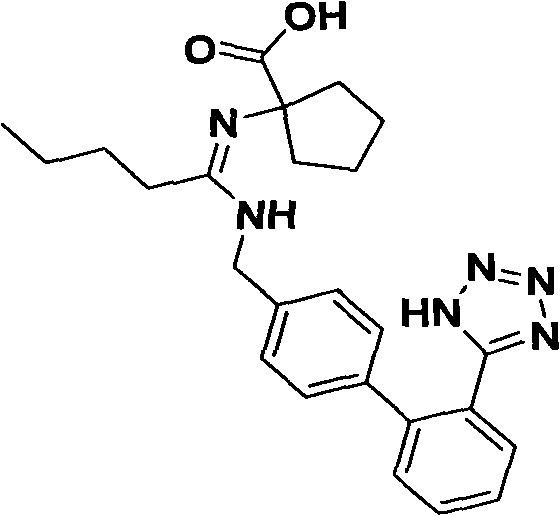

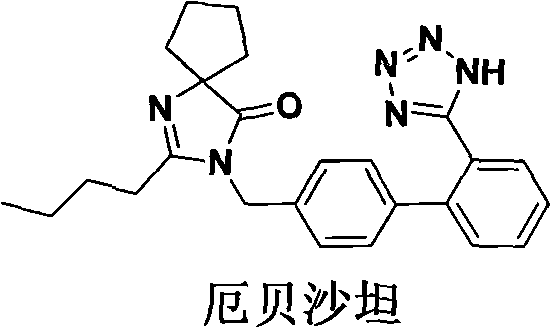

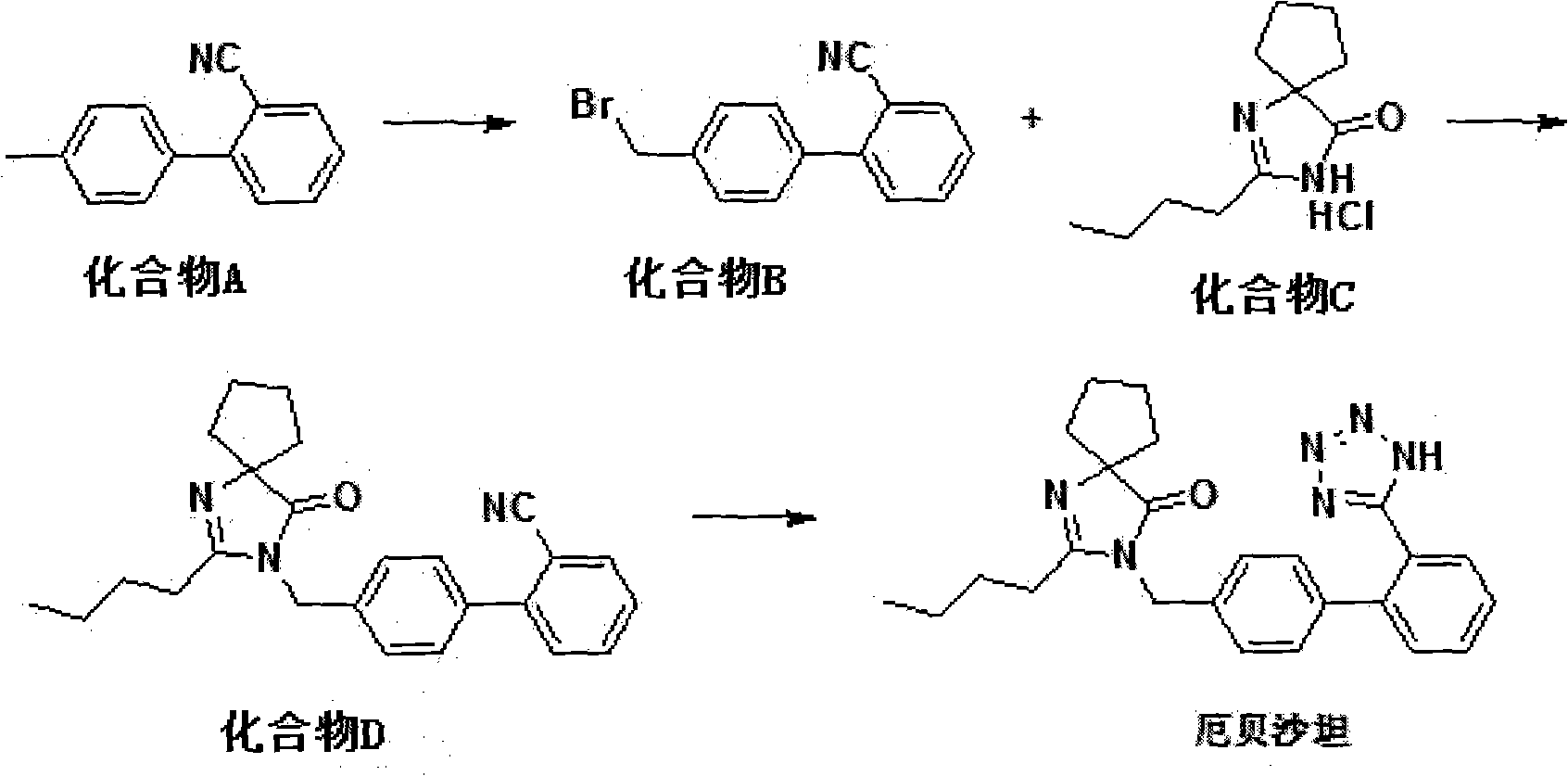

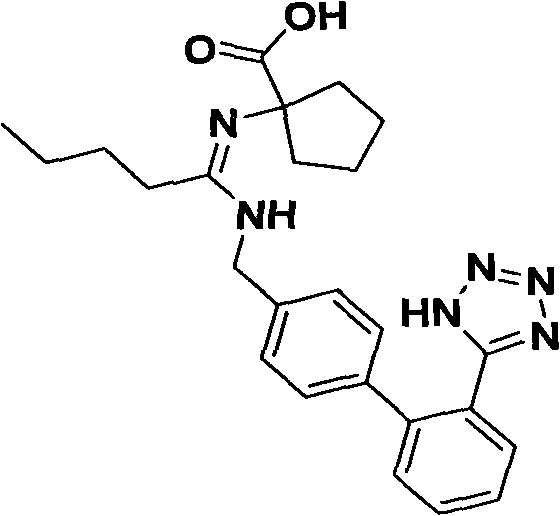

Synthetic route and preparation method of irbesartan

The invention relates to a synthetic route and a preparation method of irbesartan. The method comprises three steps: (1) reacting a compound I (2-cyano-4'-methyl diphenyl), an inorganic salt oxidant, and an inorganic salt reductant in dichloromethane and water to form a compound IRB-02 (2-cyano-4'-bromomethylbiphenyl); (2) reacting a compound IRB-02, a compound IRB-01 (2-butyl-1, 3-diaza spiro [4.4] nonane-1-vinyl-4-ketone hydrochloride), tetrabutylammonium bromide and inorganic alkali in dichloromethane and water to obtain a compound IRB-03 (2-butyl-3-[(2-cyano biphenyl-4-base)methyl]-1,3-diaza spiro [4.4] nonane-1-vinyl-4-ketone); and (3) reacting a compound IRB-03, tetrabutylammonium bromide, zinc chloride and sodium azide in toluene to obtain the irbesartan.

Owner:珠海保税区丽珠合成制药有限公司

Natural high-purity nano hydroxylapatite leaching technology

InactiveCN101462707ASolve the recrystallization problemMeet high purity requirementsPhosphorus compoundsCrystal propertiesSolvent

The invention relates to a process for leaching a natural high-purity nanometer hydroxyapatite biomaterial. The hydroxyapatite keeps the basic crystal structure not damaged, and is a base biomaterial, the performance of the base biomaterial is closer to the biological performance of a bone, and the crystal structure is more suitable for the growth of bone cells and osteoclasts. The leaching process adopts a physical leaching method and a chemical leaching method which are alternately applied; and by the pure solute dissolution flow and chemical reactions under specific conditions and in specific solvents, organic compositions in the bone are dissolved, and the used solvents include water, ethanol, ketone or other organic solvents such as amine and the like. In the leaching process, the control temperature is adjusted, and the boiling water is repeatedly washed so as to ensure the purity and the nanometer crystal property of the natural hydroxyapatite.

Owner:孙炜

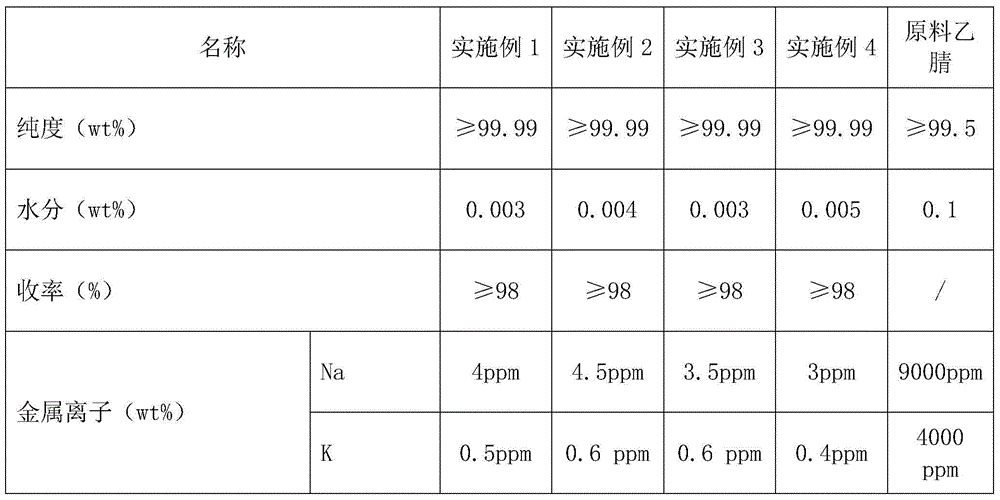

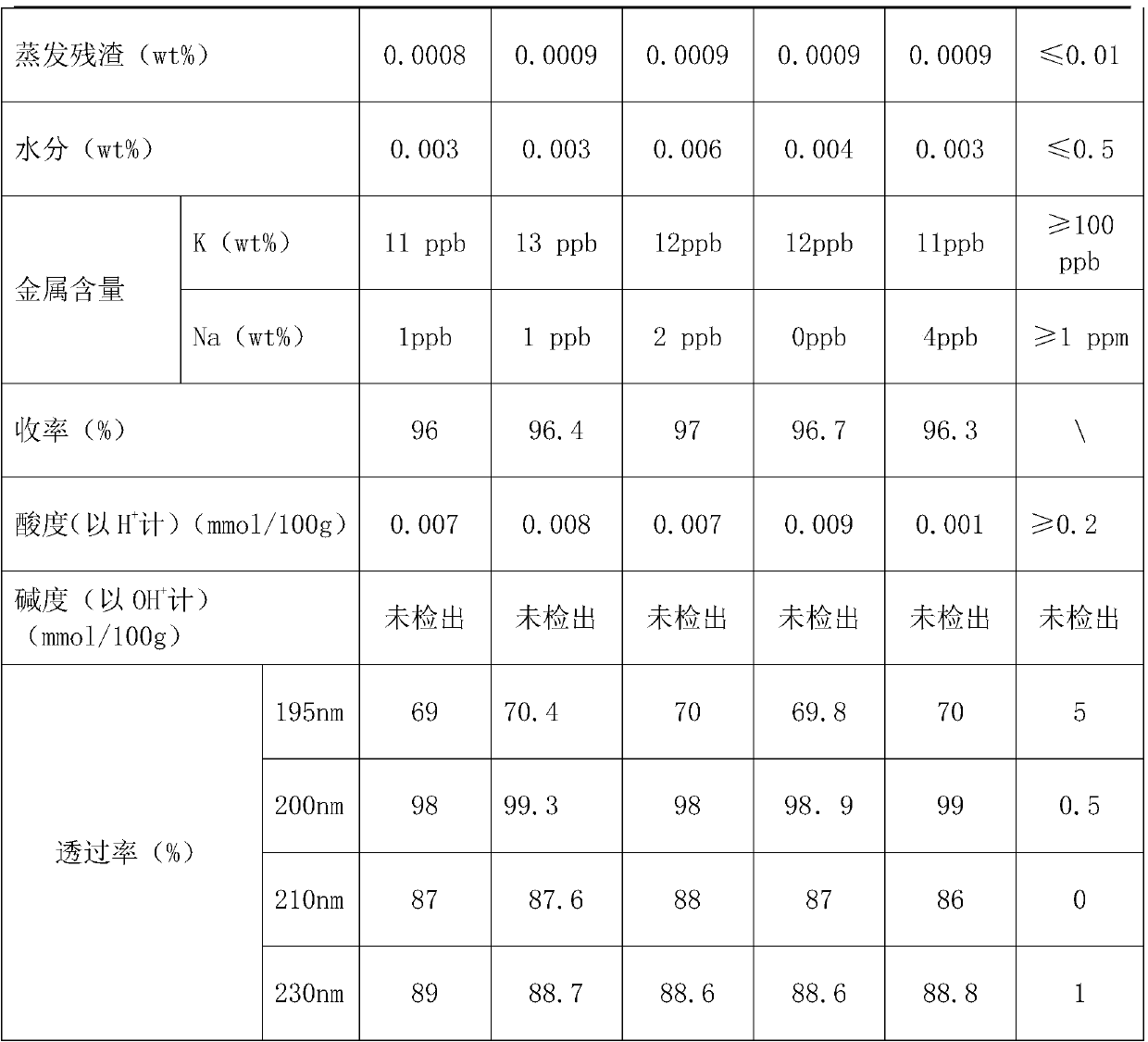

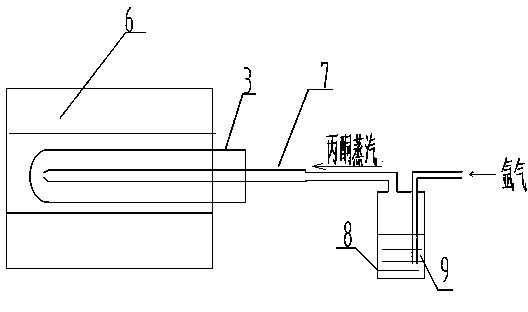

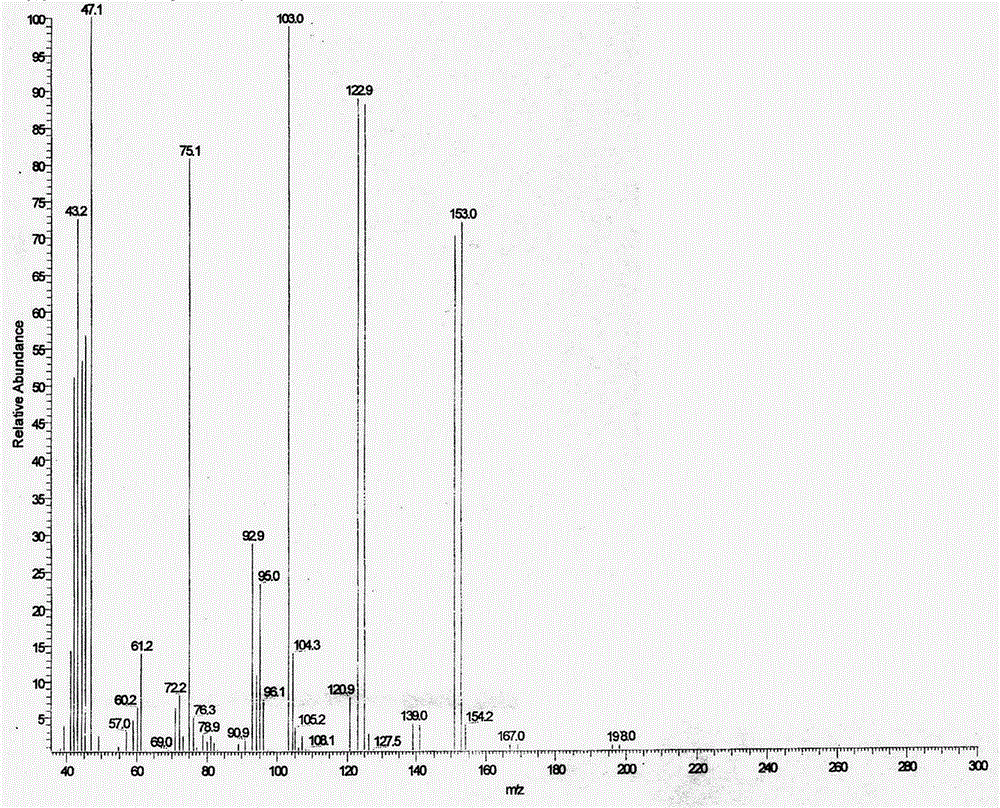

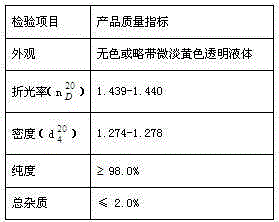

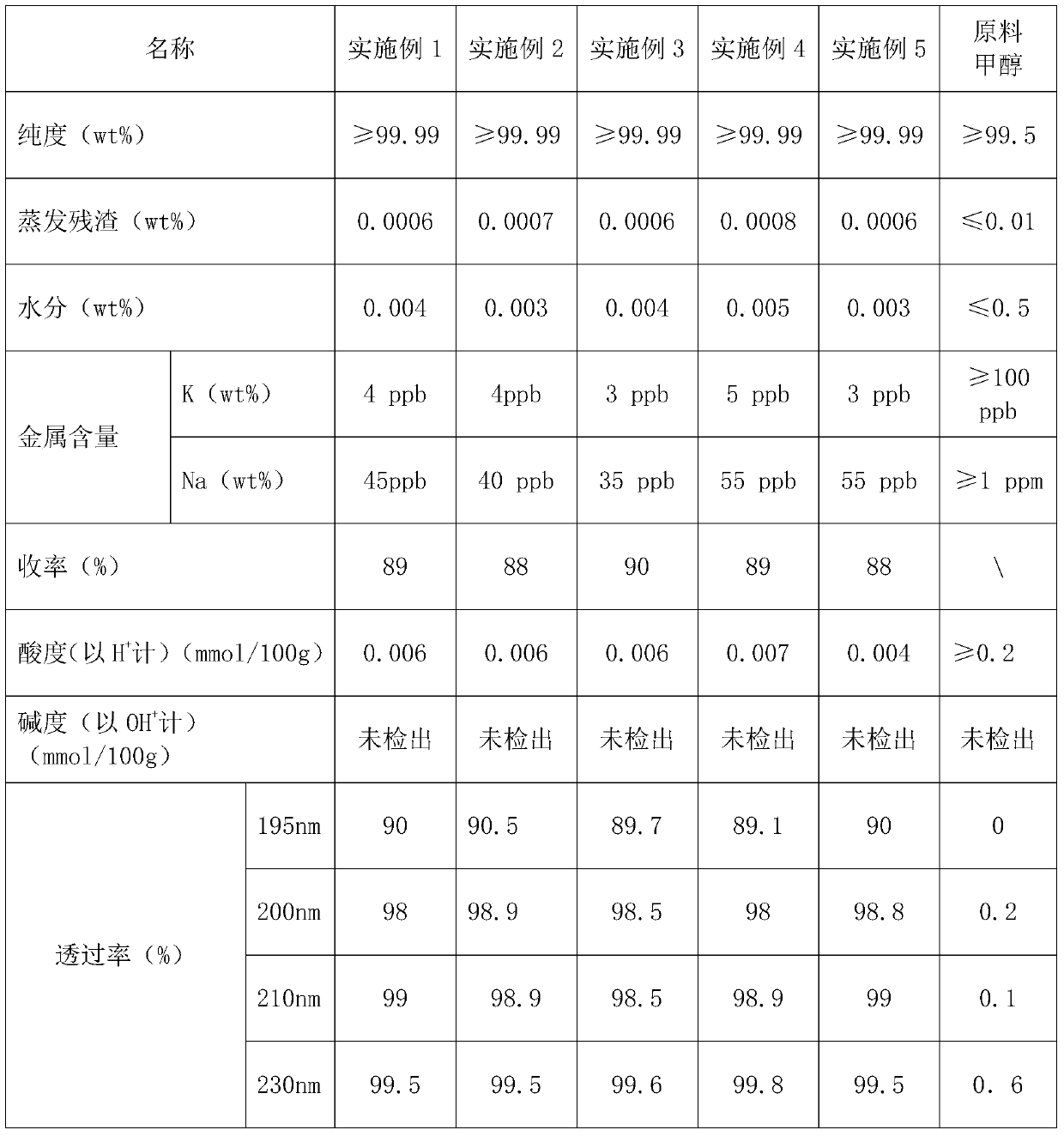

Purification method of gradient elution solvent acetonitrile

InactiveCN105085319AMeet high purity requirementsExpand the scope of applicationCarboxylic acid nitrile purification/separationSolventActive carbon

The invention discloses a purification method of a gradient elution solvent acetonitrile. The method is characterized in that impurities in a raw material acetonitrile are removed through processes such as modified active carbon, ion exchange resin adsorption and the like so as to obtain the gradient elution solvent acetonitrile with its purity being greater than or equal to 99.99 wt%. By the purification method of the gradient elution solvent acetonitrile, a gradient elution solvent acetonitrile which can be applied in the field of gradient elution can be obtained.

Owner:上海星可高纯溶剂有限公司

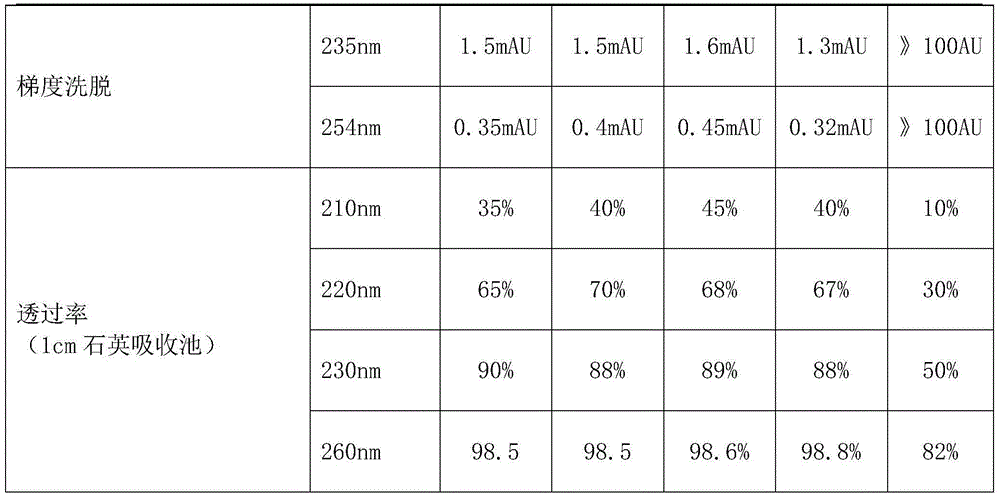

Purification method of acetonitrile for liquid chromatography-mass spectrometer

InactiveCN105085317AMeet high purity requirementsLow costCarboxylic acid nitrile purification/separationActivated carbonChemistry

The invention discloses a purification method of acetonitrile for a liquid chromatography-mass spectrometer. The method is characterized in that impurities in a raw material acetonitrile are removed through processes such as modified activated carbon adsorption and the like so as to obtain acetonitrile for a liquid chromatography-mass spectrometer. By the purification method of acetonitrile for a liquid chromatography-mass spectrometer, acetonitrile with its purity being greater than or equal to 99.99 wt% can be obtained, thus meeting the high-purity requirement of a liquid chromatography-mass spectrometer. The acetonitrile obtained after purification can be applied in the field of liquid chromatography-mass spectrometers, and the application range of acetonitrile is broadened.

Owner:上海星可高纯溶剂有限公司

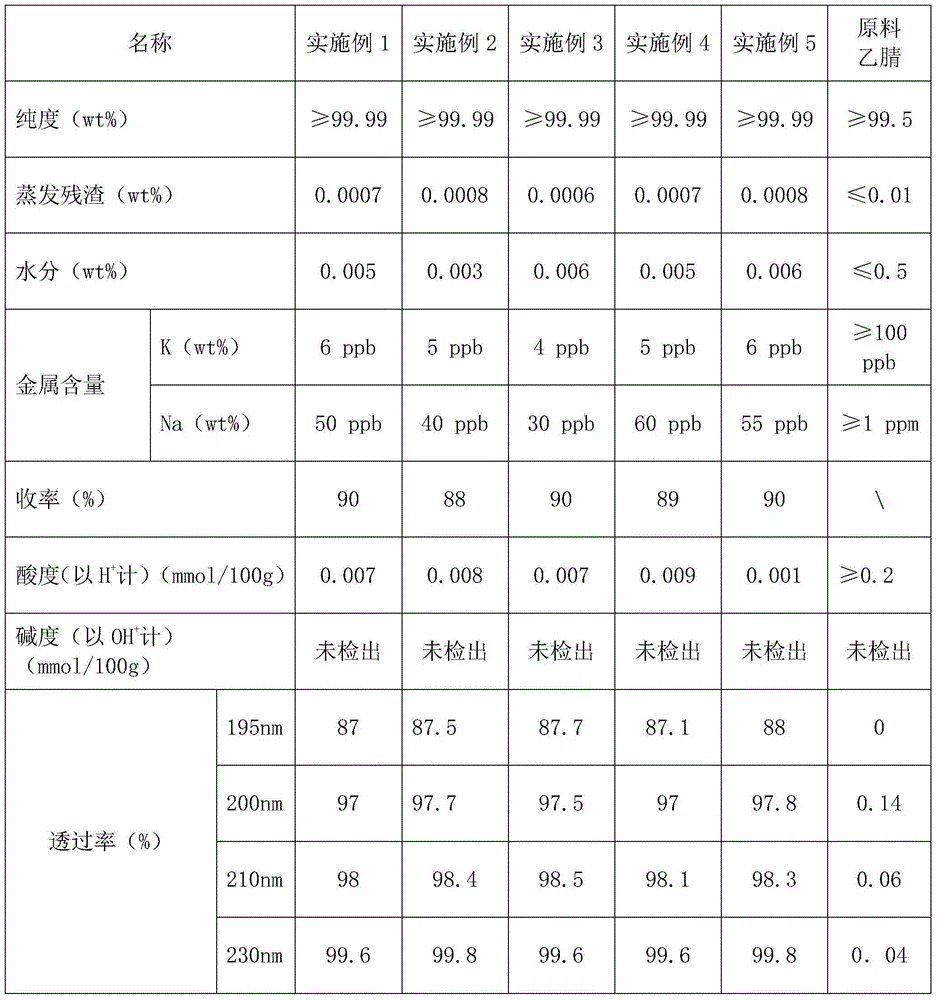

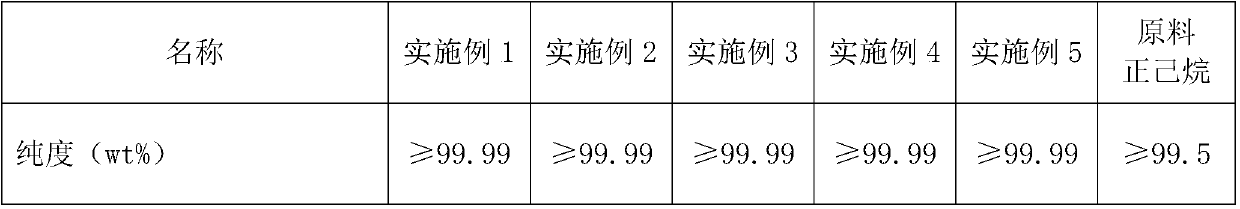

Purification method of n-hexane for liquid chromatography-mass spectrometer

ActiveCN105085140AFill the production gapLow costHydrocarbonsAdsorption purification/separationPurification methodsImpurity

The invention discloses a purification method of n-hexane for a liquid chromatography-mass spectrometer. The method is characterized in that impurities in a raw material n-hexane are removed through processes such as modified active carbon adsorption and the like so as to obtain n-hexane for a liquid chromatography-mass spectrometer. By the purification method of n-hexane for a liquid chromatography-mass spectrometer, n-hexane with purity being greater than or equal to 99.99 wt% can be obtained. The method meets high-purity requirement of a liquid chromatography-mass spectrometer. Therefore, n-hexane obtained after purification can be applied in the field of liquid chromatography-mass spectrometers, and the application range of n-hexane is broadened.

Owner:上海星可高纯溶剂有限公司

Purification auxiliary material of microcrystalline graphite and production method thereof

InactiveCN104495818ASimple recipeSolve the defect that the scope of application is limitedPhosphoric acidRoom temperature

The invention discloses a purification auxiliary material of microcrystalline graphite and a production method thereof. The purification auxiliary material of microcrystalline graphite is composed of the following materials in percentage by weight: 40-50% of microcrystalline graphite, 15-25% of hydrochloric acid, 12-18% of phosphoric acid and 15-30% of ammonium fluoride. The production method of the purification auxiliary material of microcrystalline graphite comprises the following steps: (1) selecting microcrystalline graphite, hydrochloric acid, phosphoric acid and ammonium fluoride according to the percentage by weight; (2) sequentially mixing microcrystalline graphite with hydrochloric acid, phosphoric acid and ammonium fluoride; and (3) placing the uniformly-mixed mixture in an environment at a temperature of 60-100 DEG C, drying the mixture, and cooling to a room temperature, thereby obtaining the purification auxiliary material of microcrystalline graphite. The purification auxiliary material of microcrystalline graphite and the production method thereof disclosed by the invention are simple in formula, achieve the requirement of high purity, and are wide in application range.

Owner:林前锋

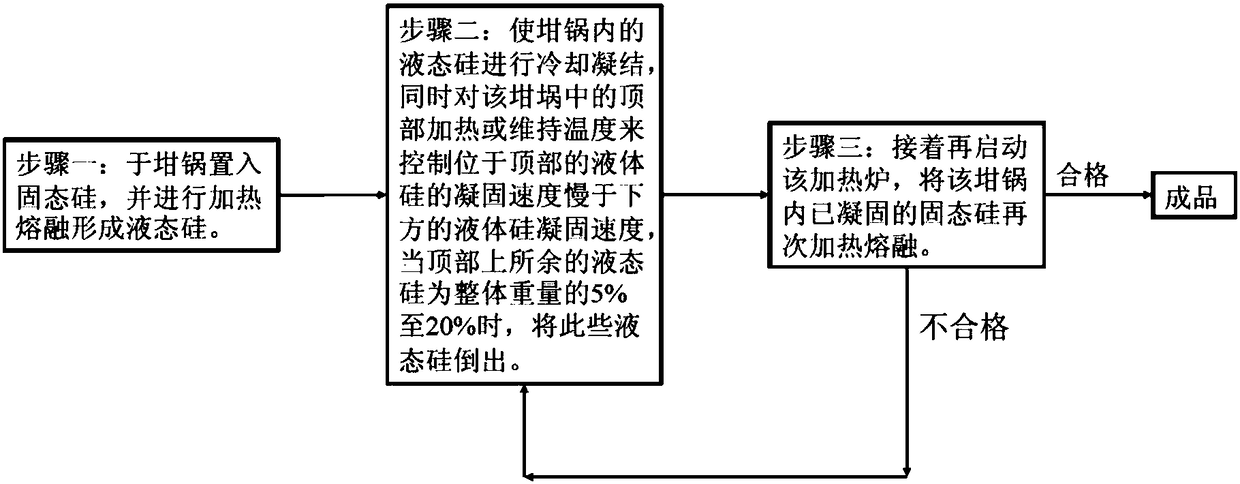

Method for segregating and purifying high-purity silicon

The invention provides a method for segregating and purifying high-purity silicon, which is an efficient, low-cost and simple operation method for removing impurities, can eliminate the complicated procedures required for cutting, and is a metallurgical polysilicon dephosphorization purification method especially suitable for large-scale industrial production. The method can make the purity of polycrystalline silicon achieve the high purity requirement of solar grade polycrystalline silicon faster than the conventional technology. The method performs segregation solidification purification ina crucible of a heating furnace, which heats or maintains the temperature in the top of the crucible of the heating furnace to control the solidification speed of the liquid silicon at the top being slower than the solidification speed of the liquid silicon below, and when the remaining liquid silicon on the top is 5% to 20% of the whole, the liquid metal silicon is poured out. After repeating this step, the purity of the fixed silicon after solidification reaches the target value.

Owner:孙文彬 +2

After-absorbing technique for electric cable material

ActiveCN101182377BEfficient removalMeet high purity requirementsPlastic/resin/waxes insulatorsPower cableFiltration

The invention relates to a production process of medium-pressure and high-pressure power cable insulation material. The invention aims at solving the technical problem that the process has the characteristics of the effective filtration of impurities in the material, the good compounding uniformity of finished products and the good performances of the finished products. The invention has a technical proposal of post absorption process of the cable material, orderly comprising the following steps: 1) filtration and purification: polyethylene, antioxidant and additive are mixed, extruded out ofa twin-screw extruder and treated through filtration and purification; the temperature for extrusion and filtration is 160 DEG C to 200 DEG C; then a pelletizer is used for preparing granules; 2) homogenizing and absorption: the prepared granules are put into an absorption kettle; cross-linker is added according to the proportion for homogenizing and absorption; the homogenizing temperature is 50DEG C to 90 DEG C; the homogenizing time is 10 hours to 30 hours; then the products are cooled and packaged. The item number of meshes of the used filter screen for filtration is 200 items to 800 items. The underwater cutting material is used in the pelletizer when preparing the granules.

Owner:ZHEJIANG WANMA MACROMOLECULE MATERIAL

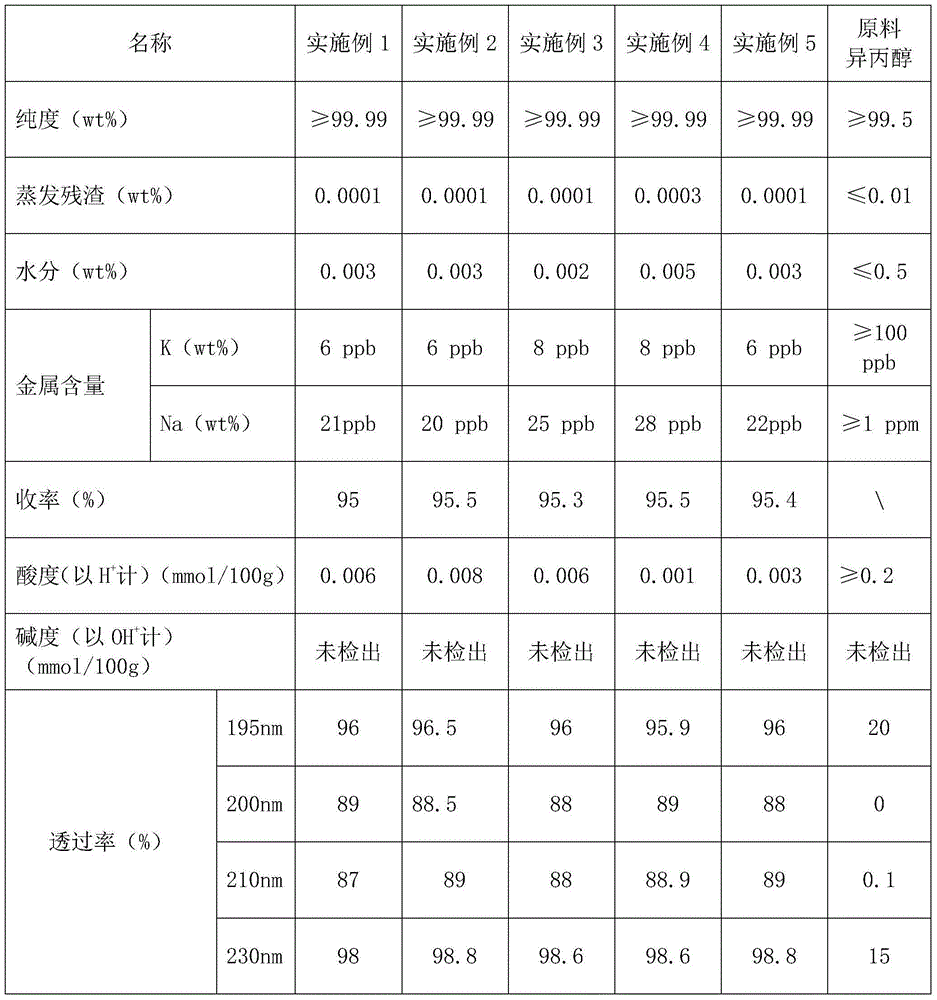

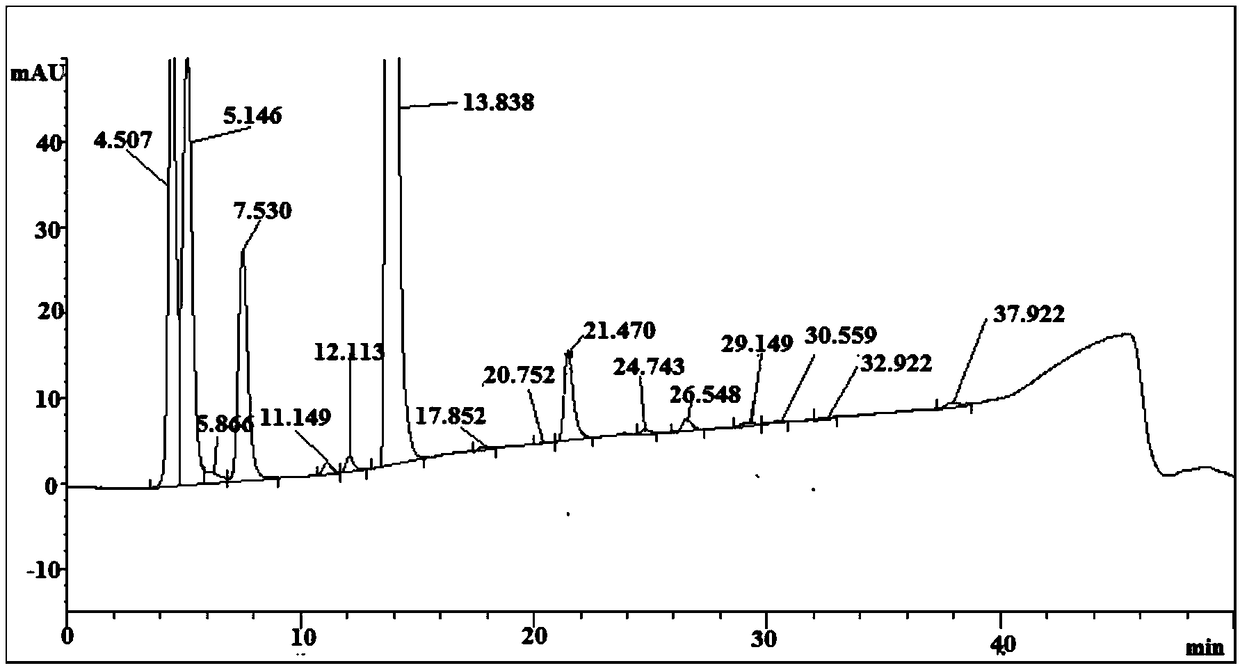

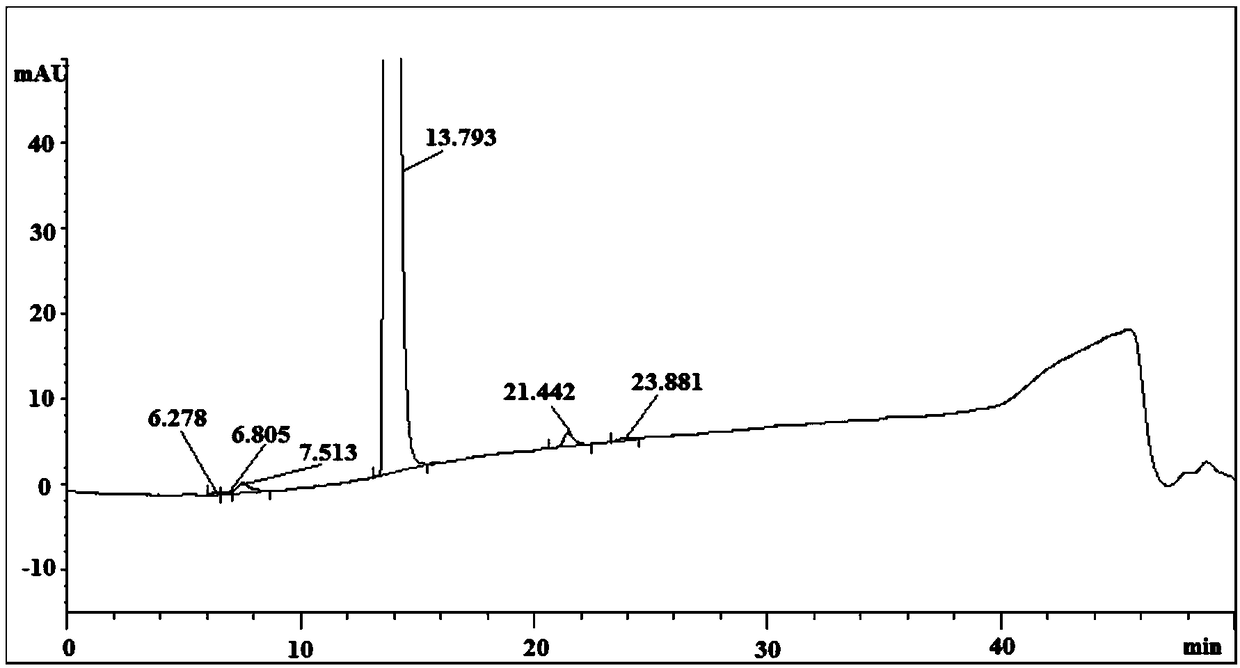

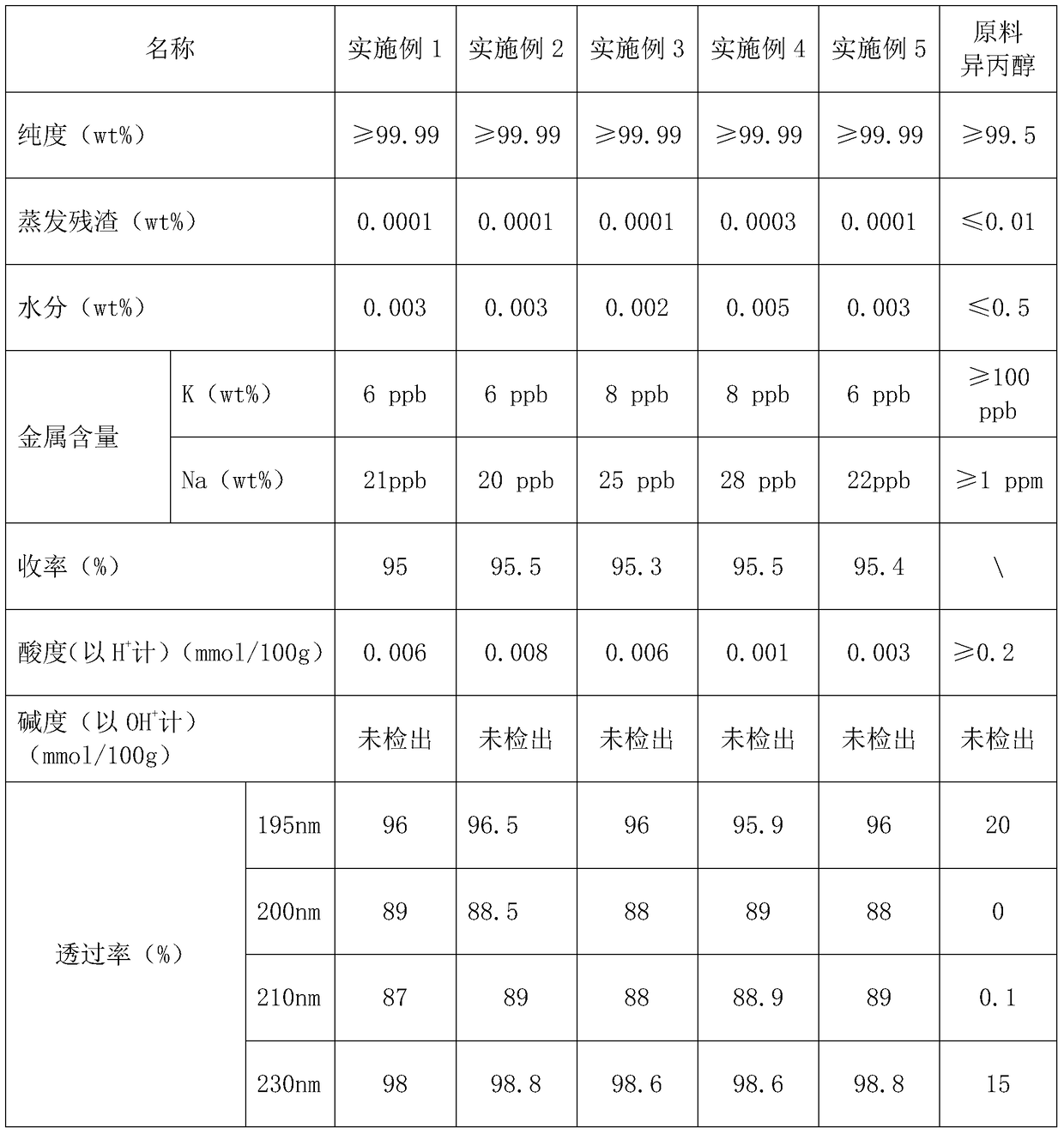

Purification method of isopropyl alcohol for liquid chromatography-mass spectrometer

ActiveCN105085184AMeet high purity requirementsFill the production gapHydroxy compound separation/purificationChemistryActive carbon

The invention discloses a purification method of isopropyl alcohol for a liquid chromatography-mass spectrometer. The method is characterized in that impurities in a raw material isopropyl alcohol are removed through processes such as modified active carbon adsorption and the like so as to obtain isopropyl alcohol for a liquid chromatography-mass spectrometer. By the purification method of isopropyl alcohol for a liquid chromatography-mass spectrometer, isopropyl alcohol with purity being greater than or equal to 99.99 wt% can be obtained. The method meets high-purity requirement of a liquid chromatography-mass spectrometer. Therefore, isopropyl alcohol obtained after purification can be applied in the field of liquid chromatography-mass spectrometers, and the application range of isopropyl alcohol is broadened.

Owner:上海星可高纯溶剂有限公司

Cotton pulp for electrolytic capacitor paper and its production process

ActiveCN105926334BMeet high purity requirementsGuaranteed purityPretreatment with acid reacting compoundsPulp bleachingElectrolysisWater soluble

The invention discloses cotton pulp for electrolytic capacitor paper. The cotton pulp has the following indexes: the degree of polymerization is 900-950; the electrolyte absorbability is guaranteed while the necessary mechanical strength is guaranteed, and the electric conductivity is smaller than or equal to 1.5 ms / m; the content of water-soluble chloride is smaller than or equal to 10 ppm; the ash content is smaller than 0.08%; the content of iron is smaller than or equal to 10 ppm; the requirement for high purity of an electrolytic capacitor is met, influence of impurities on performance of an electrolyte and electrode foil is eliminated, and the high purity is the main mark for differing the electrolytic capacitor paper from other paper. The invention further discloses a technology of the cotton pulp. The technology comprises a step of early processing of cotton linter and a step of late processing.

Owner:山东银鹰化纤有限公司

Purification method of n-hexane for liquid chromatography-mass spectrometry

ActiveCN105085140BFill the production gapLow costHydrocarbonsAdsorption purification/separationActivated carbonMass Spectrometry-Mass Spectrometry

The invention discloses a method for purifying n-hexane used in liquid chromatography-mass spectrometry, which is characterized in that impurities in the raw material n-hexane are removed through processes such as modified activated carbon adsorption to obtain liquid chromatography-mass spectrometry Use n-hexane. The method for purifying n-hexane used in liquid chromatography-mass spectrometry provided by the invention can obtain n-hexane with a purity ≥ 99.99% (wt), which meets the high-purity requirements of liquid chromatography-mass spectrometry and makes the purified n-Hexane can be applied to the field of liquid chromatography-mass spectrometry, expanding the scope of application.

Owner:上海星可高纯溶剂有限公司

Preparation method of high-purity zinc phosphide

The invention discloses a preparation method of high-purity zinc phosphide, comprising the following steps: 1) quartz tube pretreatment, 2) batching, 3) tube sealing, 4) high-temperature synthesis, 5) product treatment, the invention uses high-purity phosphorus and high-purity Zinc direct conversion and production of high-purity zinc phosphide, the main reaction process occurs after the temperature reaches the melting point of zinc, actually belongs to the reaction between steam, belongs to the direct synthesis of elements, the requirements for the form of raw materials are not very strict, and the raw materials have not been processed , to meet the requirements of high purity, the present invention controls the internal pressure of the tube through temperature control operations such as slow temperature rise, constant temperature, and slow temperature drop, and distributes the length of the heating area and condensation area of the synthetic quartz tube to successfully control the phosphorus vapor pressure in the quartz tube to achieve a large amount of The safe synthesis of zinc phosphide; through the control of the length of the condensation area and the heating area, a higher yield of the product is achieved. The product is used in the application fields of optoelectronic device production, diffusion source, and nanomaterials.

Owner:峨嵋半导体材料研究所

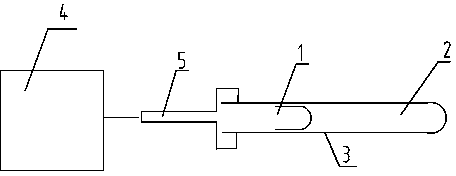

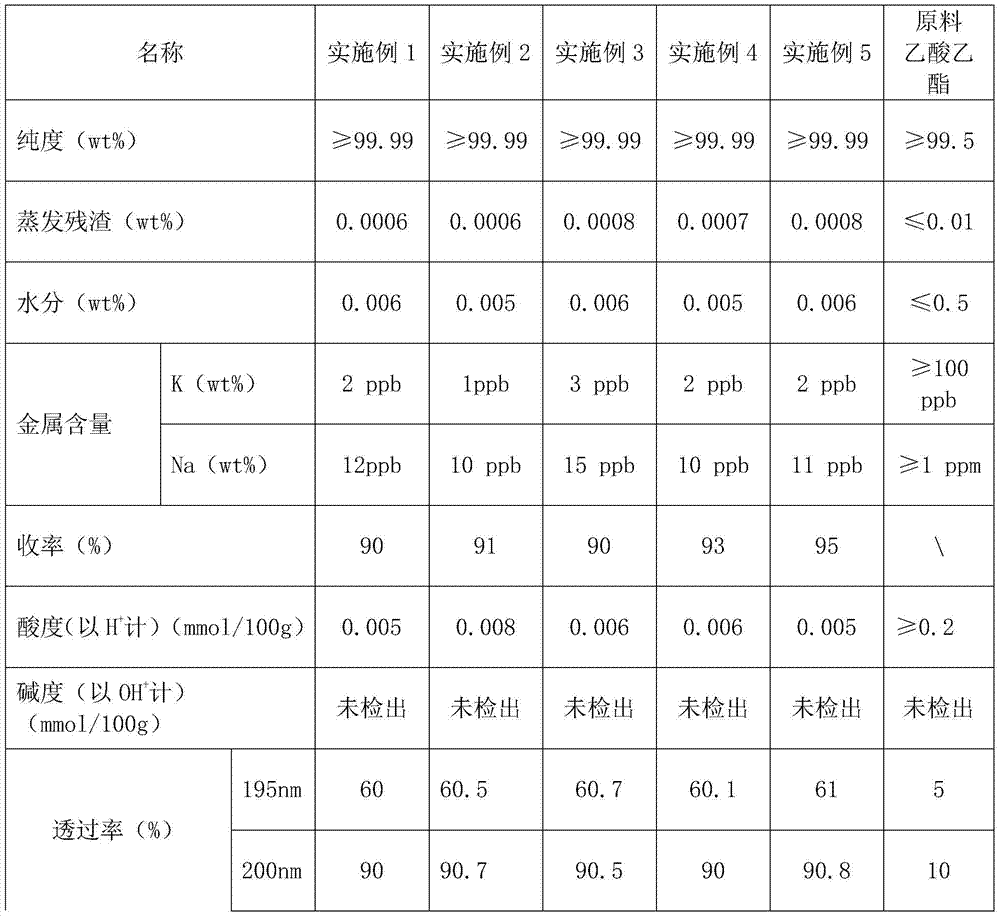

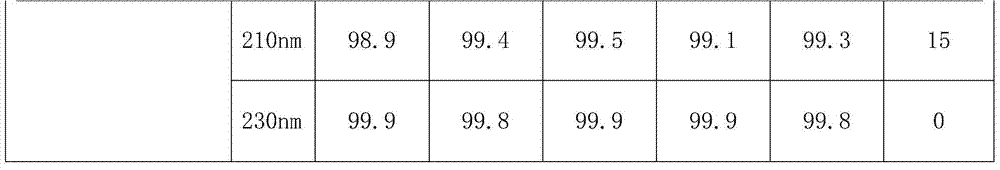

Purification method of ethyl acetate for liquid chromatography-mass spectrometer

ActiveCN105085260AMeet high purity requirementsFill the production gapOrganic compound preparationCarboxylic acid esters separation/purificationAcetic acidPurification methods

The invention discloses a purification method of ethyl acetate for a liquid chromatography-mass spectrometer. The method is characterized in that impurities in a raw material ethyl acetate are removed through processes such as modified active carbon adsorption and the like so as to obtain ethyl acetate for a liquid chromatography-mass spectrometer. By the purification method of ethyl acetate for a liquid chromatography-mass spectrometer, ethyl acetate with purity being greater than or equal to 99.99 wt% can be obtained. The method meets high-purity requirement of a liquid chromatography-mass spectrometer. Therefore, ethyl acetate obtained after purification can be applied in the field of liquid chromatography-mass spectrometers, and the application range of ethyl acetate is broadened.

Owner:上海星可高纯溶剂有限公司

Mulberry anthocyanin powder preparation process

InactiveCN107056741AEasy to operateOvercoming low extraction ratesOrganic chemistryChemical industrySolventChemistry

The invention discloses a mulberry anthocyanin powder preparation process. The process is characterized by comprising the steps that 1, ultrasonic-assisted enzyme method extraction; 2, flocculation filtration; 3, super filtration; 4, resin adsorption; 5, tubular nanofiltration membrane module system is adopted, and penetrating liquid and interception liquid are obtained, the separation of material liquids and elution solvents is achieved, and the material liquids are concentrated, and a concentrated liquid is obtained; 6, spray drying. By the mulberry anthocyanin powder preparation process, the various problems of low extraction ratio, undesirable purification effect, high membrane fouling, high organic solvent energy consumption and the like in mulberry anthocyanins in the available anthocyanin preparation process are effectively solved, the green, safe and efficient extraction of mulberry anthocyanins and mulberry anthocyanins powder is achieved, energy resources are saved and work hours are saved.

Owner:HUZHOU ZHIWEI TECHNICAL SERVICE CO LTD

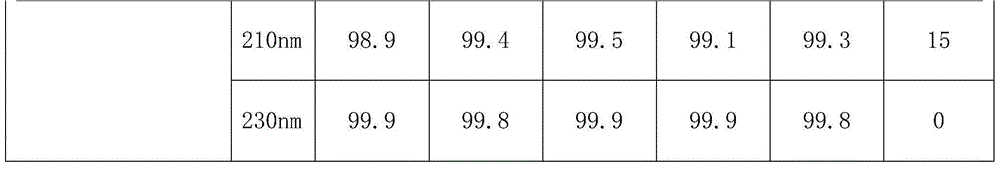

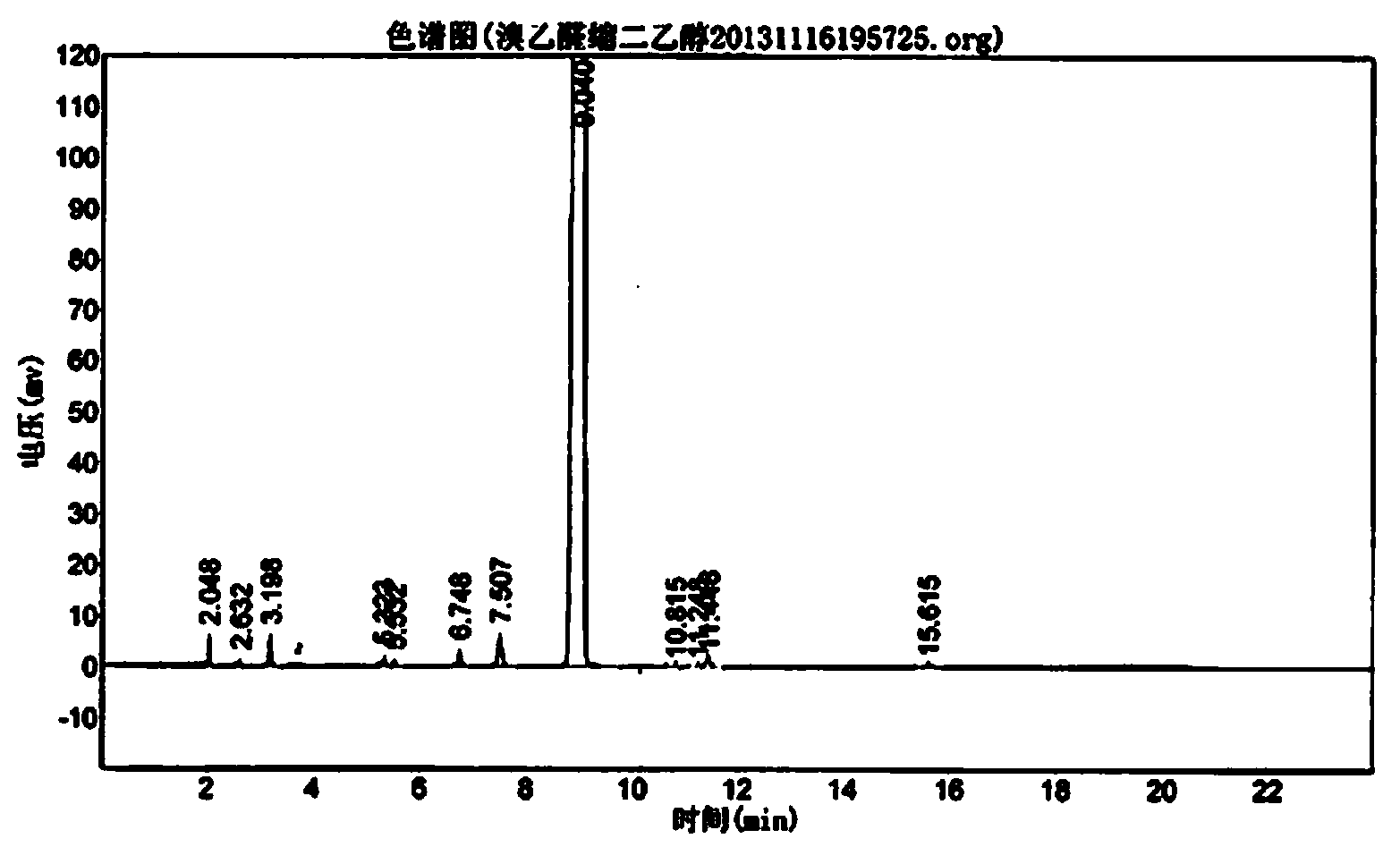

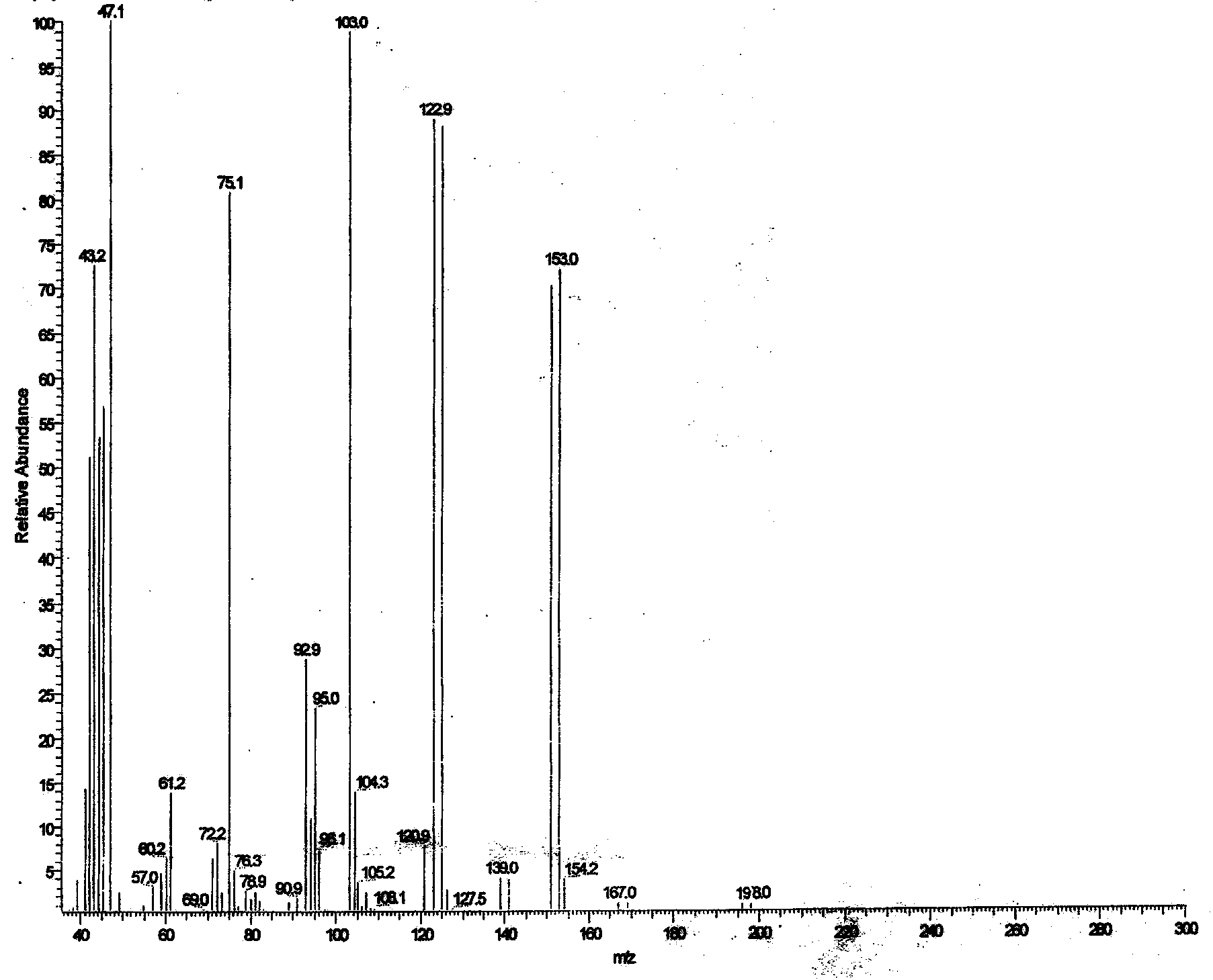

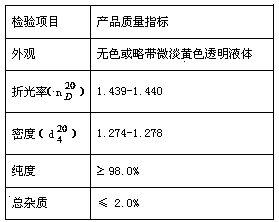

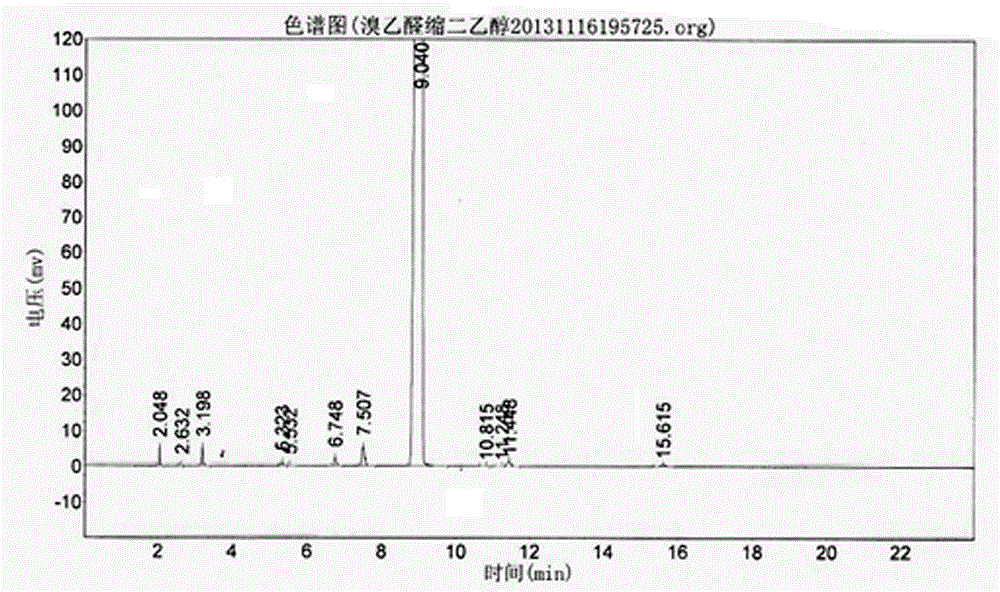

Synthesis method for bromoacetaldehyde diethyl acetal

ActiveCN104230677AReduce pollutionReduce manufacturing costOrganic compound preparationCarbonyl compound preparationIce waterDistillation

The invention discloses a synthesis method for bromoacetaldehyde diethyl acetal. The synthesis method for bromoacetaldehyde diethyl acetal is composed of the following process steps: (1) catalytic bromination reaction: stirring and dissolving raw materials, namely paracetaldehyde, a copper catalyst, concentrated sulphuric acid and absolute ethyl alcohol, cooling by an ice-salt bath, then slowly dropwise adding elementary-substance bromine in a reaction kettle, and reacting for 1-1.5 hours at minus 5-0 DEG C to obtain the ethanol solution of bromoacetaldehyde; (2) acetalation reaction: pouring an inorganic dehydrant in the ethanol solution of bromoacetaldehyde, which is obtained in the last step, heating to 35-40 DEG C, reacting for 5-6 hours while preserving heat, then adding ice water, reacting for 15-20 minutes, adding sodium carbonate to neutralize the reaction solution, stirring, standing to layer, separating out an organic layer, extracting a water layer by dichloroethane twice, mixing organic phases, carrying out reduced pressure distillation to recover a solvent, then carrying out reduced pressure distillation, and collecting fractions at 65-68 DEG C to obtain high-purity bromoacetaldehyde diethyl acetal. The synthesis method for bromoacetaldehyde diethyl acetal disclosed by the invention is available in raw materials, few in reaction steps, low in cost, high in product purity, and stable in quality.

Owner:HUANGGANG MEIFENG CHEM TECH +1

A kind of synthetic route and preparation method of irbesartan

The invention relates to a synthetic route and a preparation method of irbesartan. The method comprises three steps: (1) reacting a compound I (2-cyano-4'-methyl diphenyl), an inorganic salt oxidant, and an inorganic salt reductant in dichloromethane and water to form a compound IRB-02 (2-cyano-4'-bromomethylbiphenyl); (2) reacting a compound IRB-02, a compound IRB-01 (2-butyl-1, 3-diaza spiro [4.4] nonane-1-vinyl-4-ketone hydrochloride), tetrabutylammonium bromide and inorganic alkali in dichloromethane and water to obtain a compound IRB-03 (2-butyl-3-[(2-cyano biphenyl-4-base)methyl]-1,3-diaza spiro [4.4] nonane-1-vinyl-4-ketone); and (3) reacting a compound IRB-03, tetrabutylammonium bromide, zinc chloride and sodium azide in toluene to obtain the irbesartan.

Owner:珠海保税区丽珠合成制药有限公司

A nitrogen control method for carburized gear steel

The invention discloses a nitrogen control method for carburizing gear steel. The nitrogen control method comprises the steps of converter smelting, LF ladle refining, VD vacuum refining and continuous casting. In the present invention, the molten steel in the ladle is softly blown after the converter is tapped, the manganese nitride alloy is added to the molten steel during the soft blowing process, and nitrogen is blown into the molten steel during the refining process of the LF ladle, so as to effectively improve the content of the molten steel in the molten steel. Nitrogen content; degassing and de-inclusion during VD vacuum refining. The nitrogen control method of the carburized gear steel of the present invention can realize precise control of the nitrogen content in the carburized gear steel, so as to have a better effect of refining grains. The high cleanliness of the carburized gear steel is realized, and the cleanliness requirements are met; the nitrogen control method of the present invention can be realized by simply improving the preparation process of the existing carburized gear steel, and has the advantages of low cost of process improvement and easy popularization. Advantage.

Owner:SHIJIAZHUANG IRON & STEEL

A kind of preparation method of high-purity micron spherical silica powder

Owner:ETERNAL SPECIALTY MATERIALS ZHUHAI CO LTD

Purification method of ethyl acetate for liquid chromatography-mass spectrometry

ActiveCN105085260BMeet high purity requirementsFill the production gapOrganic compound preparationCarboxylic acid esters separation/purificationPurification methodsEthyl acetate

The invention discloses a method for purifying ethyl acetate for liquid chromatography-mass spectrometry, which is characterized in that impurities in raw ethyl acetate are removed through procedures such as modified activated carbon adsorption to obtain liquid chromatography-mass spectrometry. Use ethyl acetate. The liquid chromatography-mass spectrometry purification method provided by the invention uses ethyl acetate, which can obtain ethyl acetate with a purity ≥ 99.99% (wt), which meets the high purity requirements of the liquid chromatography-mass spectrometry and makes the purification The obtained ethyl acetate can be applied to the field of liquid chromatography-mass spectrometry, which expands the scope of application.

Owner:上海星可高纯溶剂有限公司

Separation and purification method for uridine triphosphate

ActiveCN109503687AHigh purification yieldPurification yield and stableSugar derivativesSugar derivatives preparationChromatography columnChemistry

The invention provides a separation and purification method for uridine triphosphate. The separation and purification method comprises the following steps: 1) loading a sample: filtering a crude product of uridine triphosphate and then loading into a chromatographic column, wherein chromatographic column filler is made of monodisperse microspheres taking polyacrylate as substrate; 2) eluting: using an eluant for eluting UTP absorbed in the chromatographic column; 3) collecting and gathering: fractionally collecting eluted uridine triphosphate solution and gathering the component liquid meetingthe requirement for target peak. The separation and purification method for uridine triphosphate provided by the invention is simple and convenient and is short in purification period; the requirement for high purity of uridine triphosphate can be met by only one-step chromatographic purification; purity can reach up to 99% or above; purification yield is high and stable.

Owner:SUZHOU NANOMICRO TECH CO LTD

Purification method of isopropanol for liquid chromatography-mass spectrometry

ActiveCN105085184BMeet high purity requirementsFill the production gapHydroxy compound separation/purificationPurification methodsIsopropyl alcohol

Owner:上海星可高纯溶剂有限公司

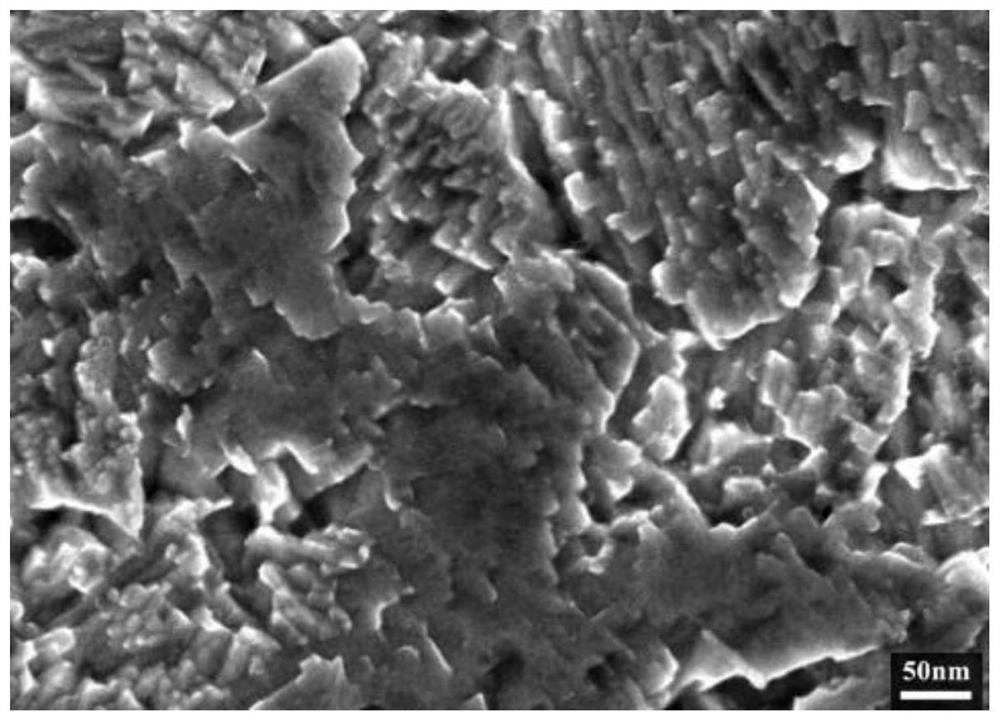

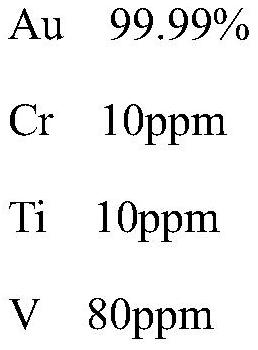

A kind of low thermal conductivity gold material and preparation method thereof, gold ware

ActiveCN112210686BLow thermal conductivityImprove mechanical propertiesHeat-exchange elementsPlatesMetallurgyMaterials science

Owner:GUOJIN GOLD CO LTD

A kind of synthetic method of bromoacetaldehyde diethyl acetal

ActiveCN104230677BReduce pollutionReduce manufacturing costOrganic compound preparationCarbonyl compound preparationIce waterDistillation

The invention discloses a synthesis method for bromoacetaldehyde diethyl acetal. The synthesis method for bromoacetaldehyde diethyl acetal is composed of the following process steps: (1) catalytic bromination reaction: stirring and dissolving raw materials, namely paracetaldehyde, a copper catalyst, concentrated sulphuric acid and absolute ethyl alcohol, cooling by an ice-salt bath, then slowly dropwise adding elementary-substance bromine in a reaction kettle, and reacting for 1-1.5 hours at minus 5-0 DEG C to obtain the ethanol solution of bromoacetaldehyde; (2) acetalation reaction: pouring an inorganic dehydrant in the ethanol solution of bromoacetaldehyde, which is obtained in the last step, heating to 35-40 DEG C, reacting for 5-6 hours while preserving heat, then adding ice water, reacting for 15-20 minutes, adding sodium carbonate to neutralize the reaction solution, stirring, standing to layer, separating out an organic layer, extracting a water layer by dichloroethane twice, mixing organic phases, carrying out reduced pressure distillation to recover a solvent, then carrying out reduced pressure distillation, and collecting fractions at 65-68 DEG C to obtain high-purity bromoacetaldehyde diethyl acetal. The synthesis method for bromoacetaldehyde diethyl acetal disclosed by the invention is available in raw materials, few in reaction steps, low in cost, high in product purity, and stable in quality.

Owner:HUANGGANG MEIFENG CHEM TECH +1

Purification method of methanol for liquid chromatography-mass spectrometry

ActiveCN105085179BMeet high purity requirementsFill the production gapOrganic compound preparationHydroxy compound separation/purificationActivated carbonPurification methods

The invention discloses a method for purifying methanol for liquid chromatography-mass spectrometry, which is characterized in that impurities in raw methanol are removed through processes such as modified activated carbon adsorption to obtain methanol for liquid chromatography-mass spectrometry . The method for purifying methanol used in liquid chromatography-mass spectrometry provided by the invention can obtain methanol with a purity ≥ 99.99% (wt), which meets the high-purity requirements of liquid chromatography-mass spectrometry, so that the purified methanol can It is applied to the field of liquid chromatography-mass spectrometry, expanding the scope of application.

Owner:上海星可高纯溶剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com