A kind of preparation method of high-purity micron spherical silica powder

A silicon dioxide and microsphere technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of affecting industrialization and production capacity, easy to exceed the metal content, difficult to control the reaction, etc., to improve elasticity, shrinkage rate improvement, curing time quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of silicon dioxide microsphere provided by the invention, it comprises the steps:

[0039] i) providing a silicon-containing precursor solution;

[0040] ii) adding the silicon-containing precursor solution into the oil phase containing an emulsifier and stirring to obtain a mixed solution;

[0041] iii) adding the basic catalyst into the mixed solution, and after standing for aging, washing the precipitate with a mixture of solvent and water, and drying to obtain the silica microspheres.

[0042] Step i) the silicon-containing precursor is Si(OR) 4 , ethyl silicate 40, ethyl silicate 32 and SiR 2 (OR 1 ) 3 One or a mixture of two or more, wherein, R, R 1 , R 2 each independently as C 1-3Alkyl; preferably tetramethyl orthosilicate (TMOS), tetraethyl orthosilicate (TEOS), methyltrimethoxysilane (methyltrimethoxysilane) or ethyltrimethoxysilane (Ethyltrimethoxysilane) A mixture of one or more than two, more preferably tetraethyl silicate (TE...

Embodiment 1

[0062] Ethyl orthosilicate (TEOS) and ethyl acetate were distilled under reduced pressure for use.

[0063] Step i) Take 200g of deionized water, add acid to PH=1.50, mix with 90g of tetraethyl orthosilicate (TEOS), and react for 0.5h to form a clear and transparent silicon-containing precursor solution. Based on the total weight of silicon precursors, the SiO 2 Content is 15 parts by weight;

[0064] Step ii) Take 2.63g Span-80, 0.36g Tween-80, 85g kinematic viscosity (40°C)=5mm 2 / s white oil, rotating speed 200rpm, time 15min; take 40g of silica sol and add to mixed white oil, rotating speed 20000rpm, time 15min, get white emulsion;

[0065] Step iii) adding ammonia water to react for 2 hours, standing and aging for 2 hours, taking white precipitate; washing with water and ethyl acetate several times in sequence, and drying to obtain high-purity micron-sized spherical silica microspheres 1 .

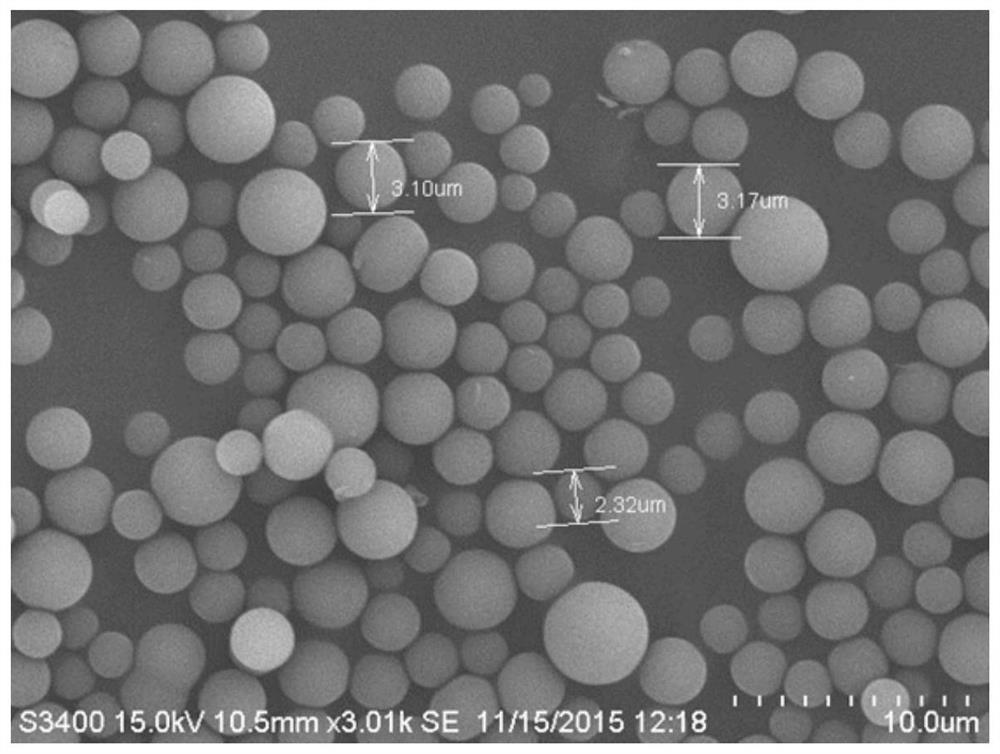

[0066] The SEM image of the obtained high-purity micron-sized spherical silica...

Embodiment 2

[0068] Ethyl orthosilicate (TEOS) and ethyl acetate were distilled under reduced pressure for use.

[0069] Step i) Take 90g of deionized water, add acid to PH = 2.5, mix with 180g of tetraethyl orthosilicate (TEOS), and react for 1.5h to form a clear and transparent silicon-containing precursor solution. Based on the total weight of silicon precursors, the SiO 2 Content is 30 parts by weight;

[0070] Step ii) Take 8.76g Span-80, 1.24g Tween-80, 85g kinematic viscosity (40°C)=10mm 2 / s oil phase, rotation speed 200rpm, time 25min; take 85g of silica sol and add it to the mixed white oil, rotation speed 10000rpm, time 10min, to obtain white emulsion;

[0071] Step iii) adding diethylamine to react for 2 hours, standing and aging for 2 hours, take the white precipitate; successively wash with water and ethyl acetate several times, and dry to obtain high-purity micron-sized spherical silica microspheres 2 .

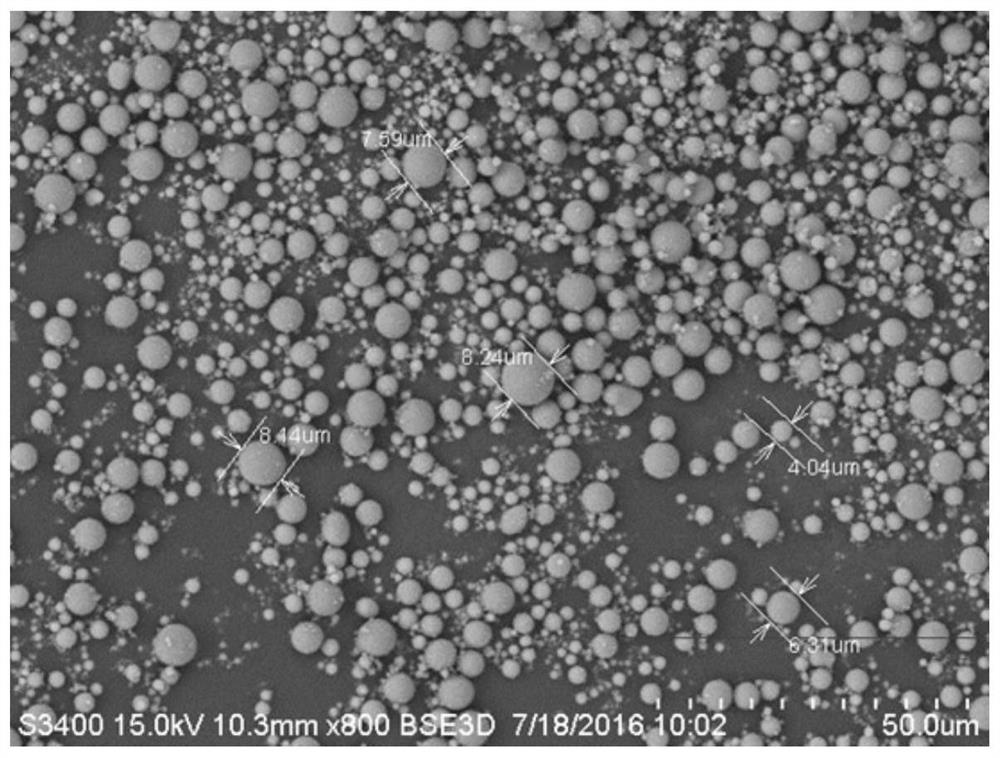

[0072] The SEM image of the obtained high-purity micron-sized spher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com