Separation and purification method for uridine triphosphate

A technology for separation and purification of uridine triphosphate, which is applied in the field of drug purification, can solve problems such as low yield, difficulty in realizing stability and industrialization, and poor purification effect, and achieve stable purification yield, short purification cycle, and high purification efficiency. Yield and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

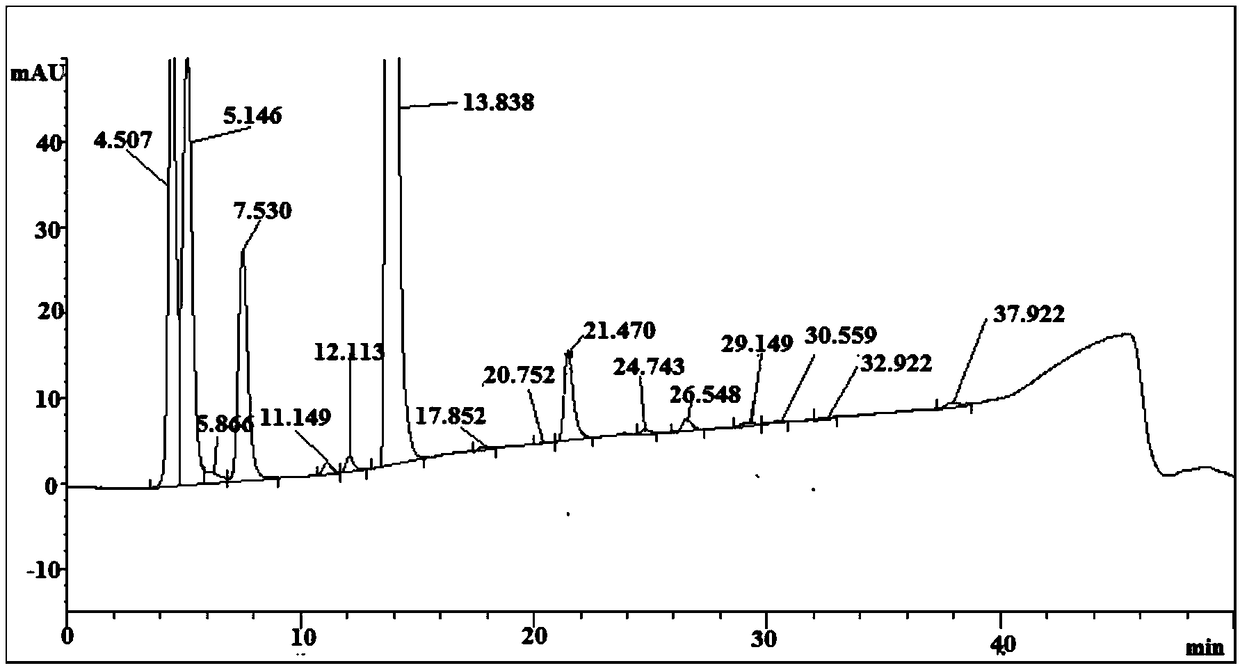

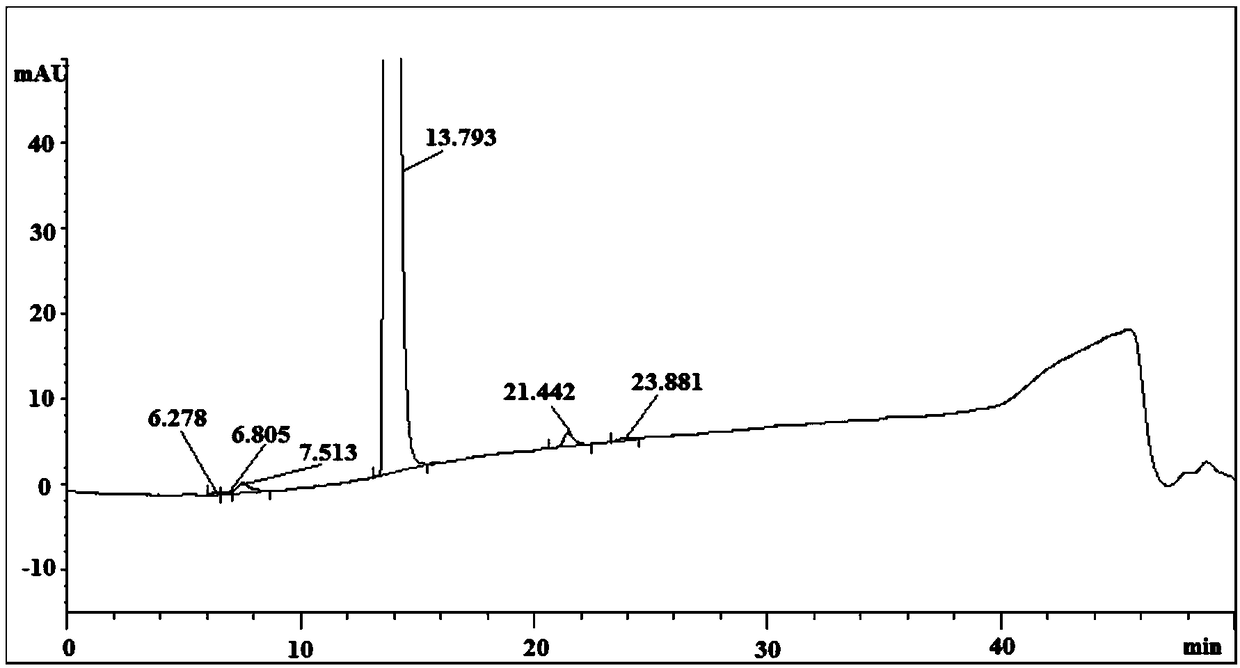

[0045] Take 47.5 mL of crude uridine triphosphate (65.417% purity, the sample was diluted 5 times with mobile phase A), filter it with a filter membrane with a pore size of 0.45 μm, and collect the filtrate for later use. A 7.7×100mm prepacked column was used, and UniQ-50XS strong anion-exchange microspheres (manufactured by Suzhou Nanowell Technology Co., Ltd.) were used as chromatography column fillers. The column volume was 4.65mL, and the loading capacity was 20g / L.

[0046] Equilibrate the chromatographic column before loading the sample, then load the sample, and then use the gradient elution method for elution.

[0047] The solution of the target peak was collected in sections, and the components meeting the requirements were collected. After high-performance liquid chromatography analysis, the purity of uridine triphosphate in the eluent was 99.05%, and the yield was 90.20%.

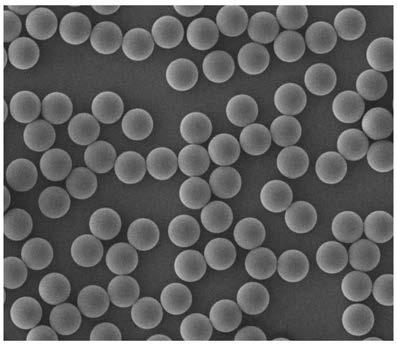

[0048] figure 1 It is the scanning electron micrograph of UniQ-50XS strong anion exchange re...

Embodiment 2

[0052] Take 320 mL of crude uridine triphosphate (65.23% purity, the sample is diluted 5 times with mobile phase A), filter it with a filter membrane with a pore size of 0.45 μm, and collect the filtrate for later use. Tricorn 10-200 chromatographic column and UniQ-50XS strong anion-exchange microspheres (produced by Suzhou Nawei Technology Co., Ltd.) were used as the chromatographic column packing with a packing volume of 15.7 mL and a loading capacity of 20 g / L.

[0053] Equilibrate the chromatographic column before loading the sample, then load the sample, and then use the gradient elution method for elution.

[0054] The solution of the target peak was collected in sections, and the components meeting the requirements were collected. After high-performance liquid chromatography analysis, the purity of uridine triphosphate in the eluent was 99.089%, and the yield was 90.24%.

Embodiment 3

[0056] Take 45 mL of crude uridine triphosphate (63.947% purity, the sample was diluted 5 times with mobile phase A), filter it with a filter membrane with a pore size of 0.45 μm, and collect the filtrate for later use. A 7.7×100mm prepacked column was used, and UniQ-50XS strong anion-exchange microspheres (manufactured by Suzhou Nanowell Technology Co., Ltd.) were used as chromatography column fillers. The column volume was 4.65mL, and the loading capacity was 18g / L.

[0057] Equilibrate the chromatographic column before loading the sample, then load the sample, and then use the gradient elution method for elution.

[0058] The solution of the target peak was collected in sections, and the components meeting the requirements were summarized. After high-performance liquid chromatography analysis, the purity of uridine triphosphate in the eluent was 99.408%, and the yield was 86.54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com