Method for preparing enzyme of dissolving staphylococcal bacteria, its derivative, and method for preparing the derivative

A lysostaphinase and bacteria breaking technology, applied in the biological field, can solve the problems of high cost of PEG modification, the yield of lysostaphinase cannot meet large-scale preparation and the like, and achieves simple expression scheme, reduced immunogenicity and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Synthesis, cloning and expression of embodiment 1 lysostaphin gene

[0052] The expression vector is pET-22b (Invitrogen), and the host bacteria is Escherichia coli BL21 (DE3).

[0053] According to the Lysostaphin gene sequence (AX828346) of Staphylococcus simulans published by Genebank and the lysostaphin gene sequence of patent WO03074689, the lysostaphin gene sequence was optimally designed according to the needs of high-efficiency expression in Escherichia coli, see SEQ ID NO.1, gene encoding product See SEQ ID NO.2 for the amino acid sequence. Synthesize 20 complementary oligonucleotides, and introduce enzyme cutting sites Nde I and BamH I at the 5' end and 3' end respectively, according to the conventional method of molecular cloning, first treat with T4 phage polynucleotide kinase at 37°C After 30 minutes, the phosphorylated oligonucleotide fragments were mixed in equimolar ratios, denatured at 94°C for 5 minutes, annealed at 65°C for 10 minutes immediately, th...

Embodiment 2

[0059] Embodiment 2, the impact of different culture conditions on expression

[0060] The influence of different temperature conditions on the expression state of the product was studied by using medium (0.5% Yeast Extract, 1.0% Peptone, 0.5% NaCl, 0.05mg / L Amp, pH7.4). Inoculum size: 5% (the ratio of the volume of the seed liquid to the volume of the culture medium), the culture temperature before induction is 37° C., and the induction is carried out with IPTG, and the dose is 1 mmol / L. Induction was carried out at 4 temperatures after cultivation, and the results are shown in the table below.

[0061] induction temperature

[0062] Summary: After adding the inducer and culturing at 25°C for 4 hours, the expression level can reach 30%, and the target protein is mainly expressed in the supernatant of the broken bacteria. In the subsequent precipitation, the preferred condition is to induce expression at 25°C for 4 hours after culturing at 37°C. The target protein i...

Embodiment 3

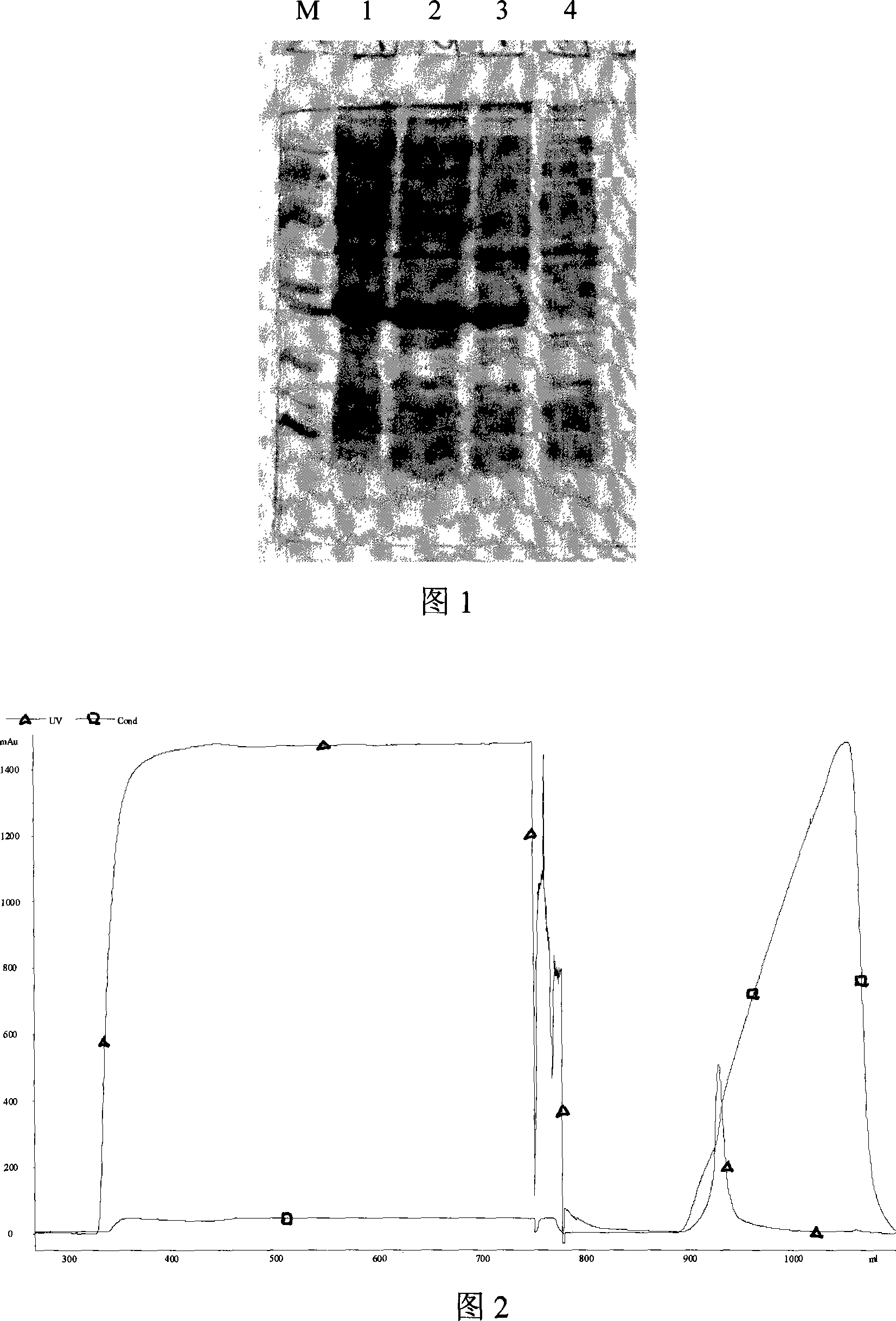

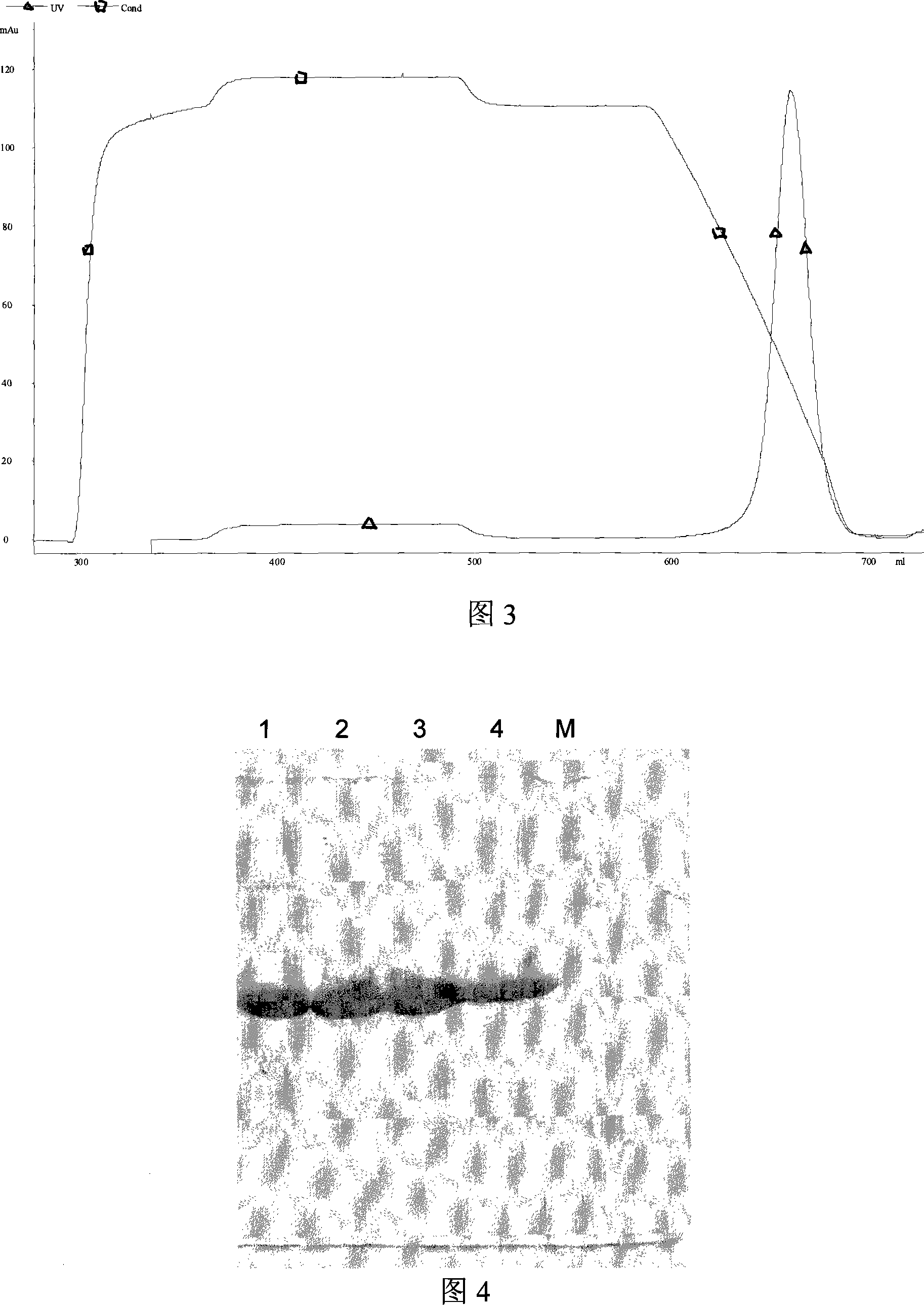

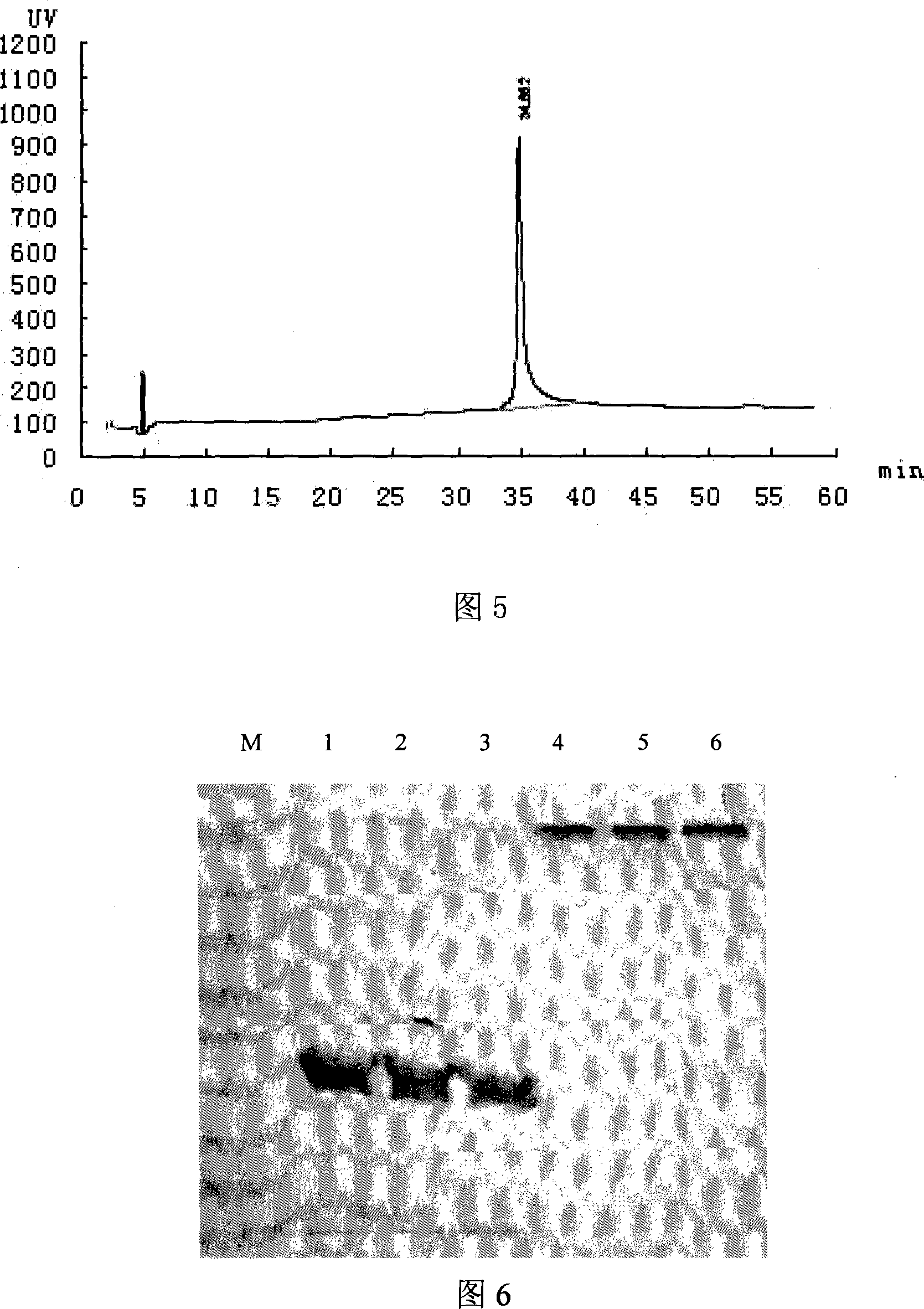

[0063] Example 3 Separation and purification of expression products

[0064] Suspend the wet bacterial cells in a ratio of 20 ml / g with bacterial cell disruption buffer (40 mM Tris-Cl, 02 M NaCl, 0.5 mM EDTA, pH 8.0). Bacteria were disrupted by ultrasonic method (220V, 20khz, 900W, sonicated in an ice-water bath).

[0065] The bacteriostasis solution was centrifuged by high-speed centrifugation (10000g, 30min, 4°C), the precipitate was removed, and the supernatant was collected. The collected bacterial supernatant was separated and purified by ion exchange chromatography, and the process was to dilute with 20mmol / L Tris.CL buffer solution with a pH value of 8.5 to make the conductivity less than 5mS / cm. Use the same buffer solution to equilibrate the chromatographic column (50mm×10cm), and the chromatographic gel can be selected from CM-Sepharose Fast Flow, SP-Sepharose Fast Flow, Mono-S (Amersham Pharmacia). After sample loading, wash with equilibration buffer to the basel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| ionic strength | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com