Patents

Literature

97results about How to "Short purification cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Purification technology for low-grade bentonite

InactiveCN103663481AHigh puritySimple purification processSilicon compoundsLower gradeMontmorillonite

The invention provides a purification technology for low-grade bentonite, belonging to the field of processing and utilization of non-metal ores. The purification technology comprises the following steps of preprocessing the raw materials; stirring to prepare pulp; ultrasonically purifying; standing for precipitating; separating out upper-layer slurry; removing impurities through centrifuging; filtering and drying. The purification technology is supported by ultrasonic waves; in the presence of a dispersing agent, the impurities can be well separated from montmorillonite, so that the purification effect is improved; furthermore, the purification technology is simple, is small in equipment investment, can be used for purifying the product with high content of montmorillonite from the low-grade bentonite rapidly, efficiently, simply and conveniently, has the advantages of low production cost and short purification period, and is easy to popularize.

Owner:广西弘耀祥科技有限公司

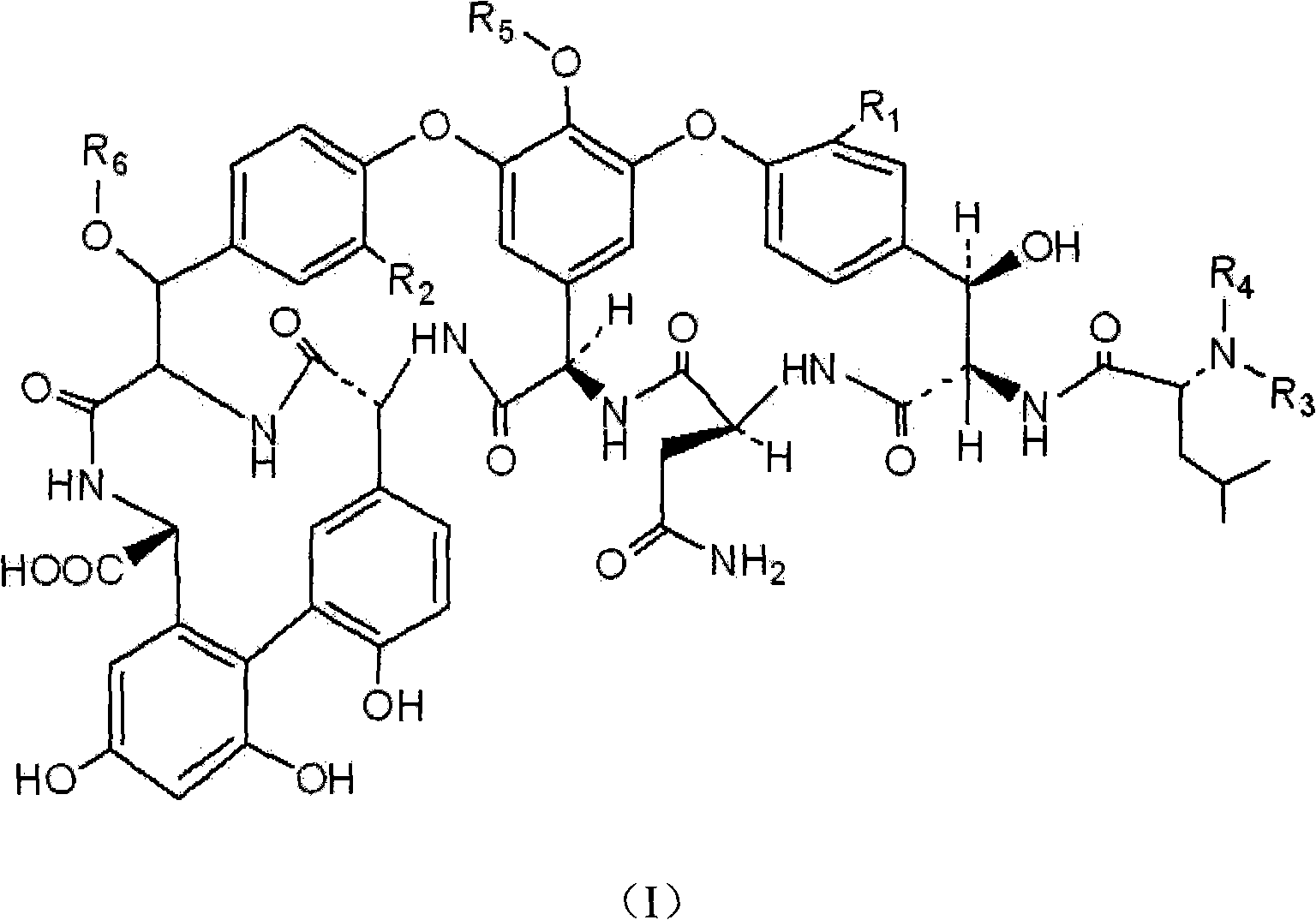

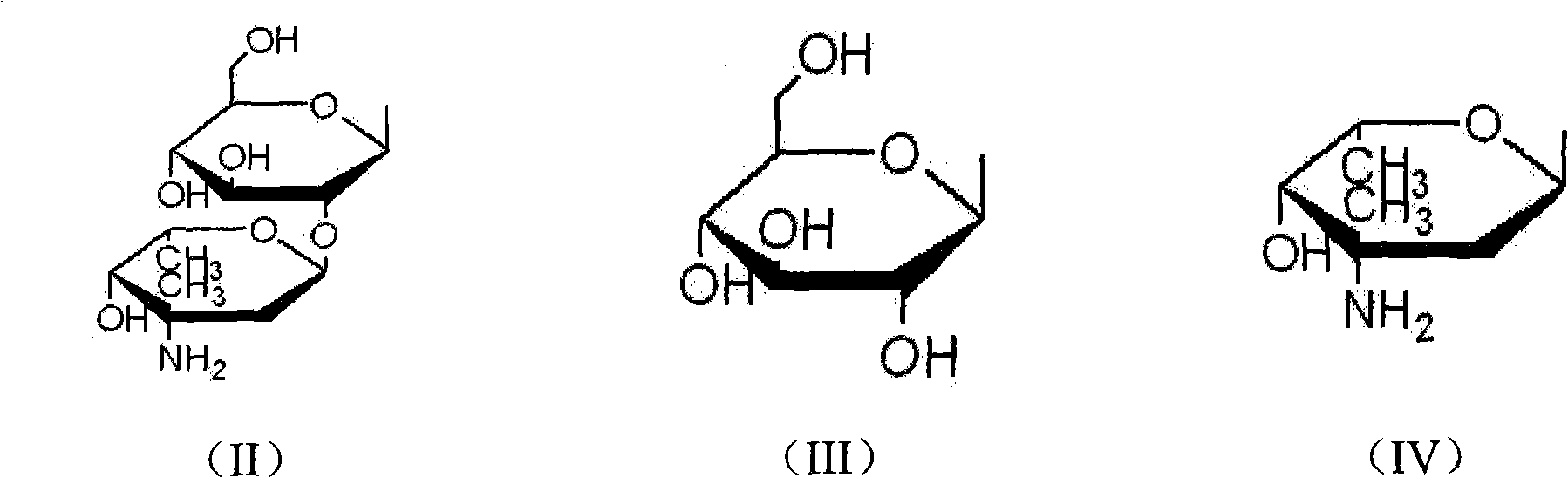

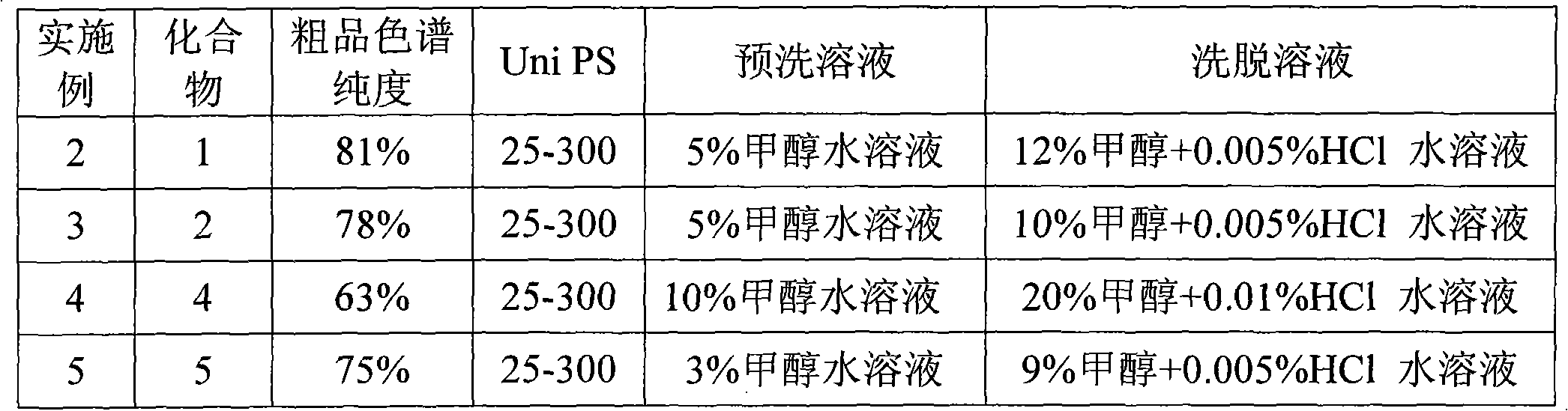

Method for purifying glycopeptide compound

ActiveCN102050866AImprove qualityShort purification cyclePeptide preparation methodsAqueous solutionPolymer

The invention provides a method for purifying a glycopeptide compound, which comprises the following steps: A) loading a sample of aqueous solution of a glycopeptide compound onto an inverse polymer filler Uni PS; B) pre-washing by using pre-washing solution; and C) eluting with eluting solution. When the method provided by the invention is used, the quality of target components of the glycopeptide compound can be improved effectively, the purification period is shortened, and the yield loss is reduced. In addition, the method can be used for preparing a small amount of sample of the glycopeptide compound in a laboratory, and also can be used for industrial production of the glycopeptide compound.

Owner:SHANGHAI LAIYI BIOMEDICAL RES & DEV CENT

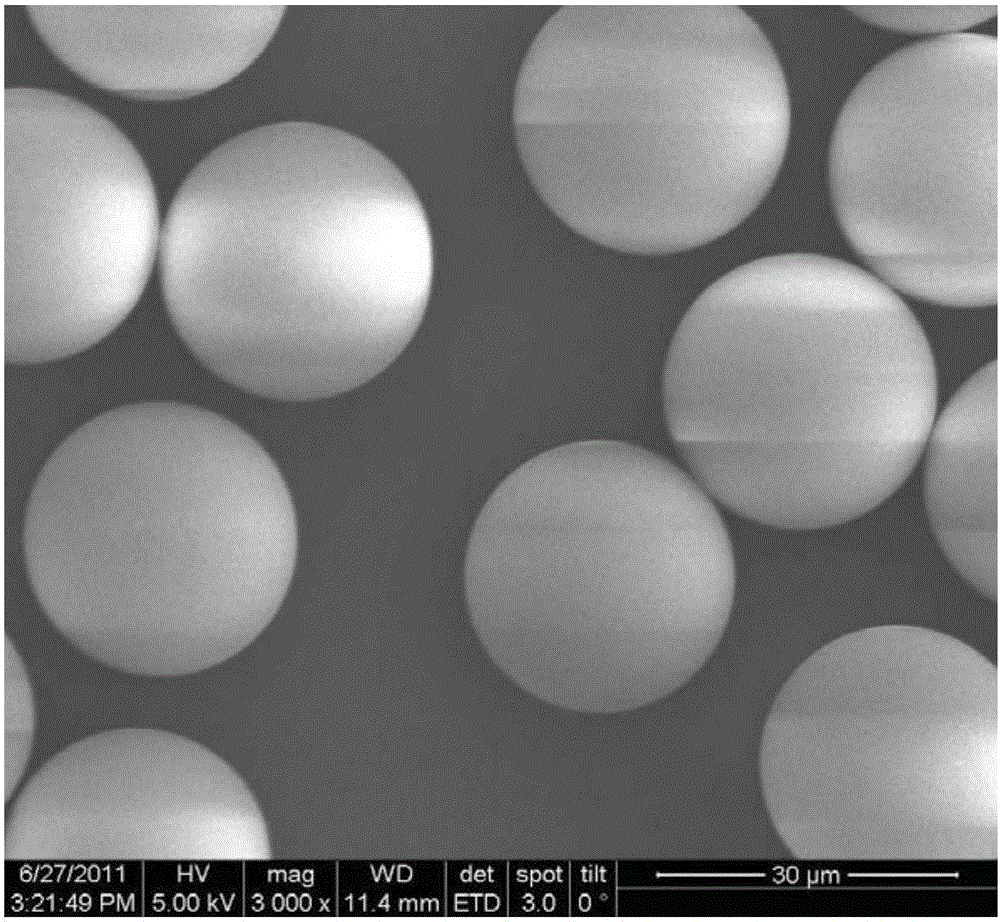

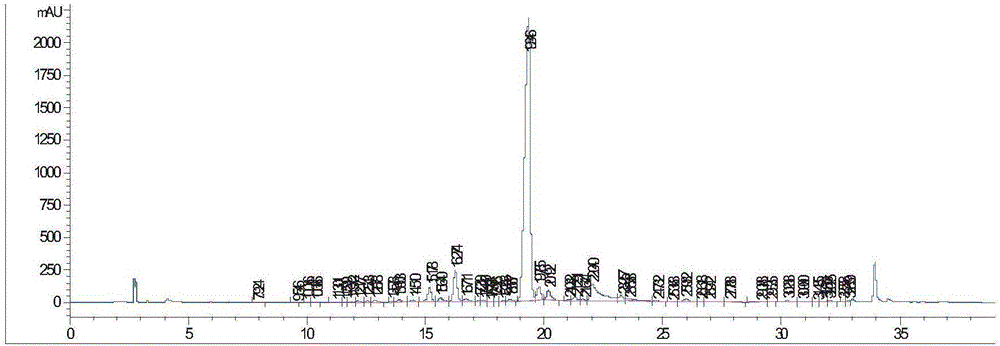

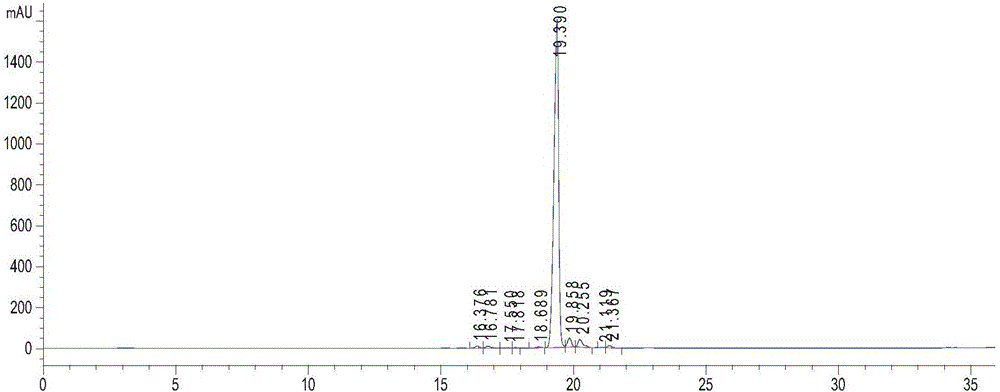

Separation and purification method for dalbavancin

ActiveCN105001309ANo pollution in the processLow costPeptide preparation methodsPurification methodsOrganic solvent

The invention provides a separation and purification method for dalbavancin. The method comprises the following steps: dissolving and filtering a crude dalbavancin extract; loading a sample of a crude solution obtained after filtering into a chromatographic column equipped with polystyrene high-molecular polymer microspheres for chromatography; carrying out gradient elution on a target product with an aqueous phosphoric acid solution and an organic solvent as mobile phases; and collecting solutions with a target peak value in sections and combining constituent solutions meeting requirements. The separation and purification method is simple, can realize large-scale production and has a high and stable recovery rate.

Owner:CHANGSHU NANOMICRO BIOTECHNOLOGY CO LTD

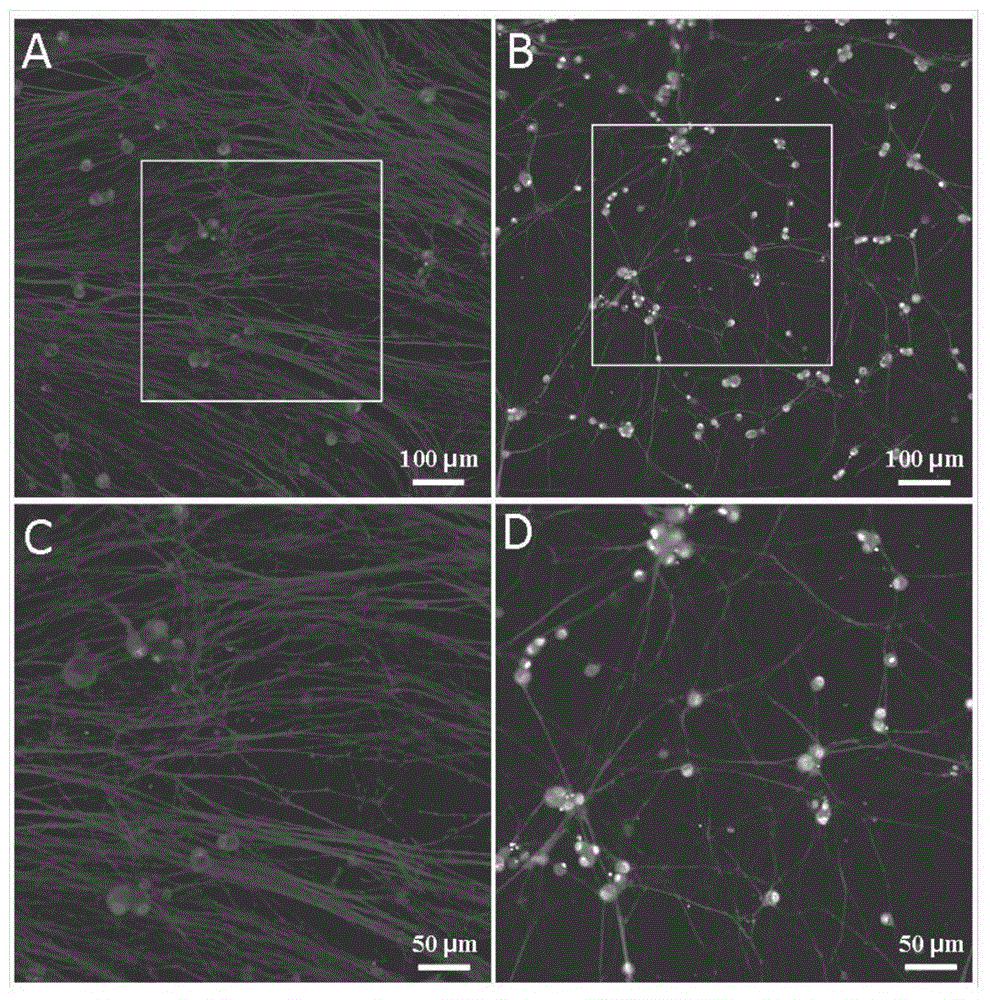

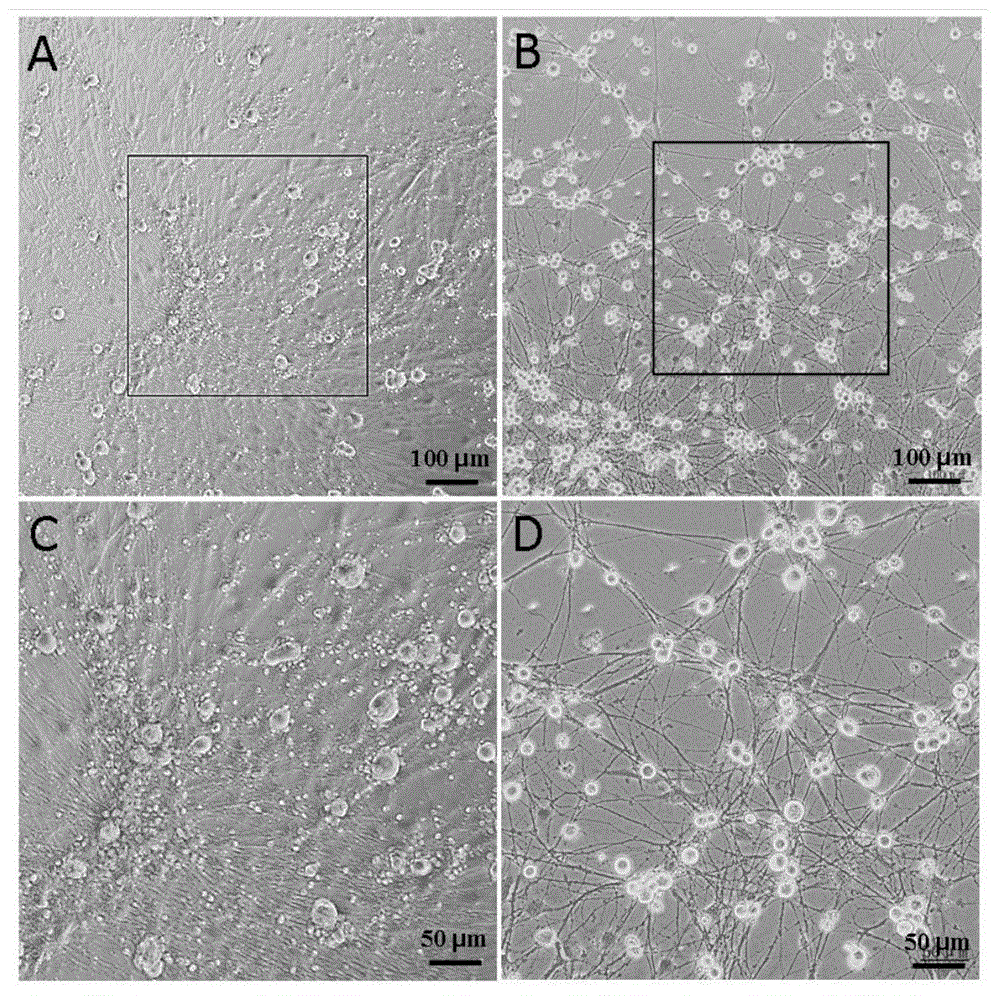

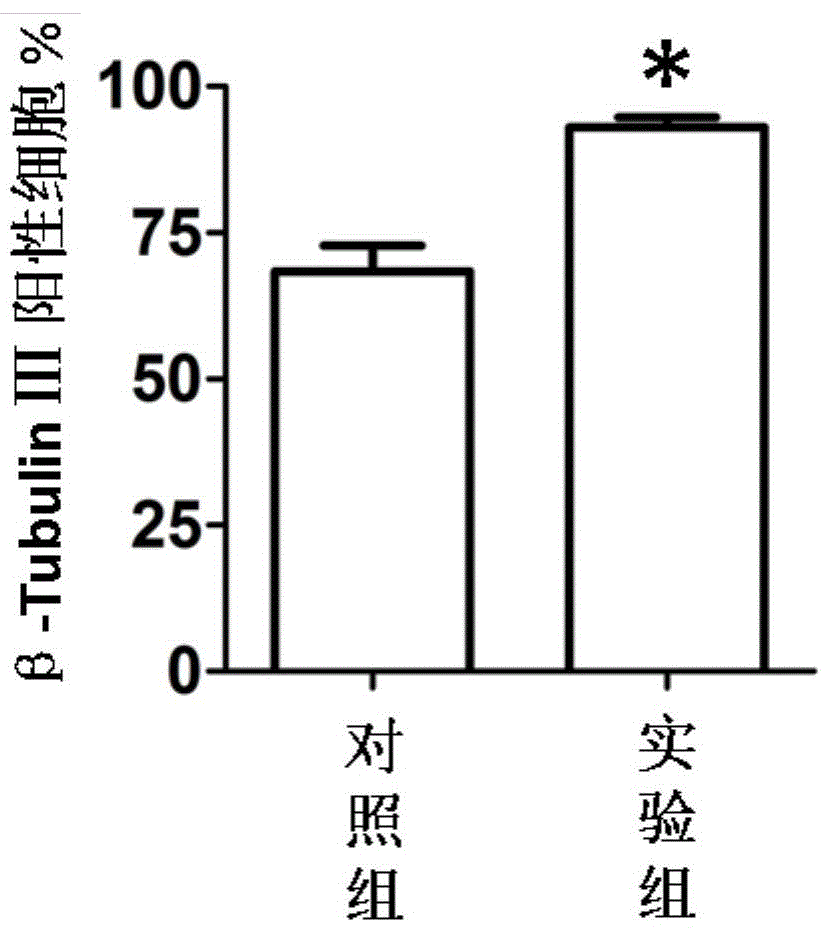

Neuron primary culture purification method

InactiveCN105274055AShort purification cycleHigh purityNervous system cellsNerves tissueEnzymatic hydrolysis

The invention belongs to the technical field of animal cell culture, and specifically relates to a neuron primary culture purification method which comprise the following steps: providing nerve tissues, performing enzymatic hydrolysis and digesting tissues, separating nerve cells with a density gradient centrifugation method, inoculating nerve cells, separating nerve cells by using the differential velocity adhesion characteristic, purifying nerve cell with cytosine arabinoside (Ara-C) to obtain neurons. The neuron primary culture purification method largely shortens primary culture purifying period of DRG neurons, largely promotes the purification of the neurons, guarantees cell activities, facilitates cell culture and growth, and lays a good foundation on the further experiments.

Owner:NANTONG UNIVERSITY

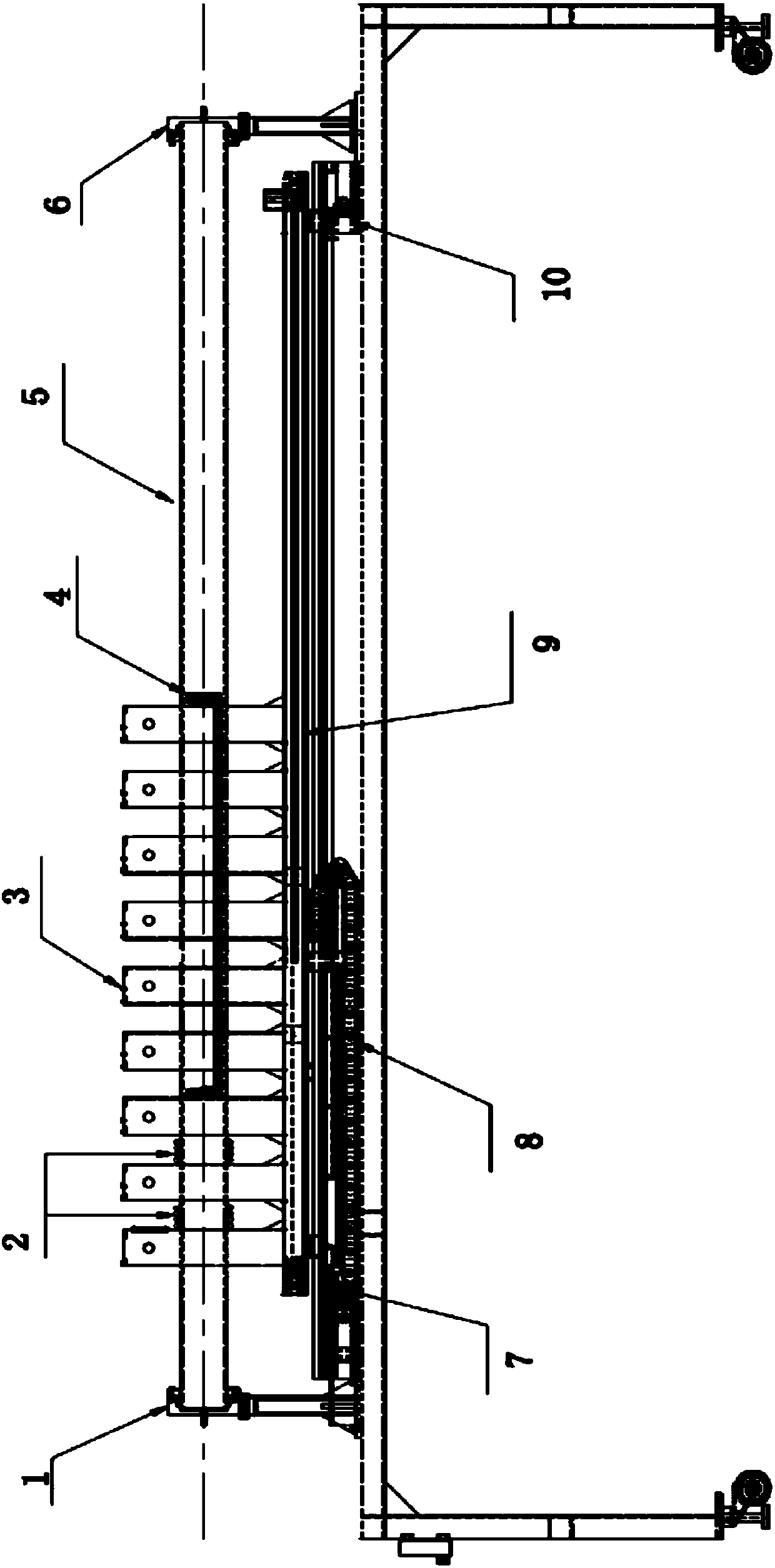

Purification device and purification method for high-purity indium

ActiveCN107858523AIncrease production capacityEasy to controlProcess efficiency improvementElectrical resistance and conductanceIndium

The invention provides a purification device for high-purity indium. The purification device comprises a quartz tube, a plurality of resistance heaters and a guide rail. Two ends of the quartz tube are fixed along the horizontal directions by the aid of a left flange sleeve and a right flange sleeve, and a graphite boat is arranged in the quartz tube; the resistance heaters are arranged on the outer side of the quartz tube and are sequentially arranged along the horizontal directions of the quartz tube, and cooling devices are arranged between the adjacent resistance heaters; the resistance heaters are fixed by the aid of the guide rail, and the guide rail is provided with a left stopper, a slide wire groove and a right stopper. Compared with the prior art, the purification device for thehigh-purity indium has the advantages that the resistance heaters are sequentially arranged on the outer side of the quartz tube along the horizontal directions, and accordingly zone melting and directional solidification can be simultaneously implemented; the temperatures of the resistance heaters are controlled, multistage heating can be implemented, uniform heating temperature gradient distribution and stable temperature fields can be guaranteed, accordingly, integral purification procedures are high in efficiency, and 6N-7N ultrahigh-purity indium production requirements can be met.

Owner:清远先导材料有限公司

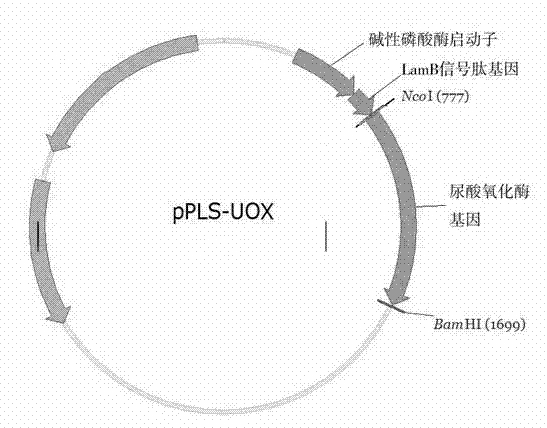

Efficient secretory expression and purification method of recombinant urate oxygen oxidoreductase

InactiveCN103173471AShort purification cycleStable and efficient yieldBacteriaMicroorganism based processesEscherichia coliOperon

The invention discloses an efficient secretory expression and purification method of a recombinant urate oxygen oxidoreductase, and belongs to the field of medical and biological engineering. The technical scheme comprises the following steps of: expressing an escherichia coli operon of the recombinant urate oxygen oxidoreductase using the encoding sequence of a recombinant urate oxygen oxidoreductase which is artificially synthesized from the encoding sequence of an escherichia coli alkaline phosphatase promoter and the encoding sequence of an escherichia coli LamB signal peptide; cloning the operon to a plasmid vector pBR322 carrying the escherichia coli to obtain an expression plasmid; transforming a W3110 escherichia coli empty host using the expression plasmid containing the escherichia coli operon to obtain an engineering strain for the secretory expression of the recombinant urate oxygen oxidoreductase; and carrying out purification technologies of cation-exchange chromatography, hydrophobic chromatography, and anion-exchange chromatography on the recombinant urate oxygen oxidoreductase. The method disclosed by the invention has the beneficial effects that a good secretory expression effect can be achieved through the regulation and control on protein expression by the escherichia coli alkaline phosphatase promoter and induction of the secretory expression of the urate oxygen oxidoreductase by the optimized escherichia coli LamB signal peptide, and the purification method is simple and easy in implementation, short in protein purification period and high in protein yield.

Owner:吉林修正药业新药开发有限公司

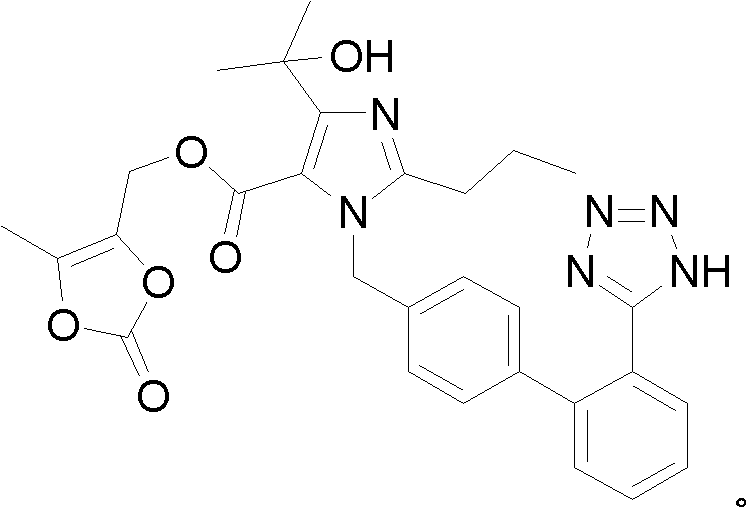

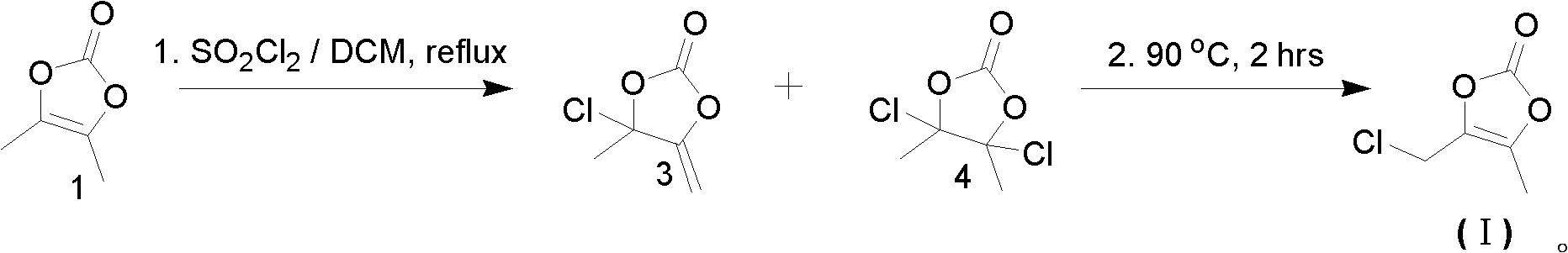

Method for preparing and purifying olmesartan intermediate

The invention relates to a method for preparing and purifying an olmesartan intermediate. The preparation method comprises the following steps of: chlorinating 4,5-dimethyl-1,3-dioxa-cyclopentene-2-ketone, distilling under reduced pressure to obtain 4-chloro-4-methyl-5-methylene-1,3-dioxolane-2-ketone, and performing rearrangement reaction to generate the olmesartan intermediate; reducing the temperature to be below 50 DEG C, concentrating until a solvent is removed completely to obtain a crude product; and recrystallizing and purifying the crude product at the temperature of between -20 and 0 DEG C for 1 to 48 hours, wherein a recrystallization solvent may be one or a mixed solvent of more of an alkane solvent and an ether solvent. The preparation method is low in production cost, mild in reaction condition and easy to operate, raw materials are wide in sources, and high-content 4-chloromethyl-5-methyl-1,3-dioxa-cyclopentene-2-ketone can be obtained directly, so the method is particularly suitable for large-scale industrial production.

Owner:SHANGHAI SYNCORES TECH INC

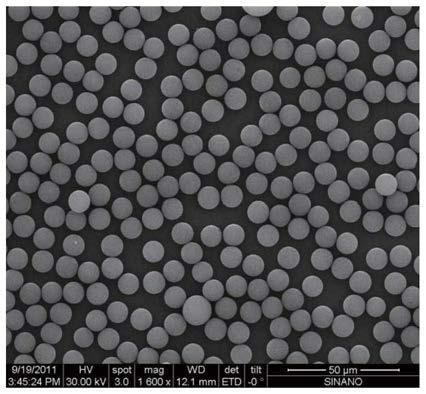

Filler special for purifying semaglutide and purification method of semaglutide

InactiveCN109354622AShort purification cycleIncrease the production batchPeptide preparation methodsGlucagonsIon exchangeIndustrial scale

The invention relates to a filler special for purifying semaglutide and a purification method of semaglutide. The method specifically comprises the steps of dissolving crude semaglutide into an aqueous solution of acetonitrile to obtain a crude peptide solution; conducting filtering, mixing a reverse phase and an ion exchange filler into a fixed phase in a certain proportion, after a filtrate is loaded, conducting HPLC linear gradient elution simultaneously with a moving phase mixed by an organic phase and a salt phase, and collecting distillate containing semaglutide; taking the third distillate, and conducting reduced-pressure rotary evaporation concentration and freeze drying to obtain the filler. Semaglutide with the purity of 30% or so can be purified to 90% or above in one step; meanwhile, the loading quantity is high, industrial scale production is simple, the purification period is short, and the production cost of enterprises is greatly reduced.

Owner:SOOCHOW HIGH TECH CHROMATOGRAPHY

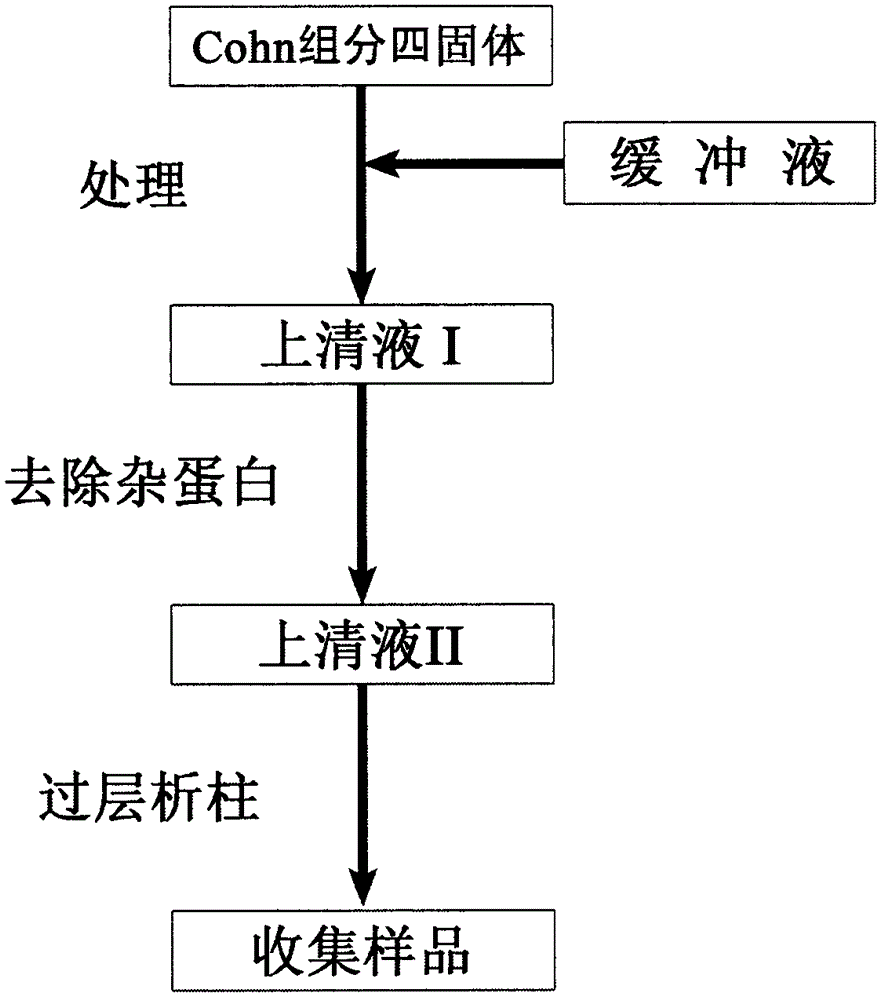

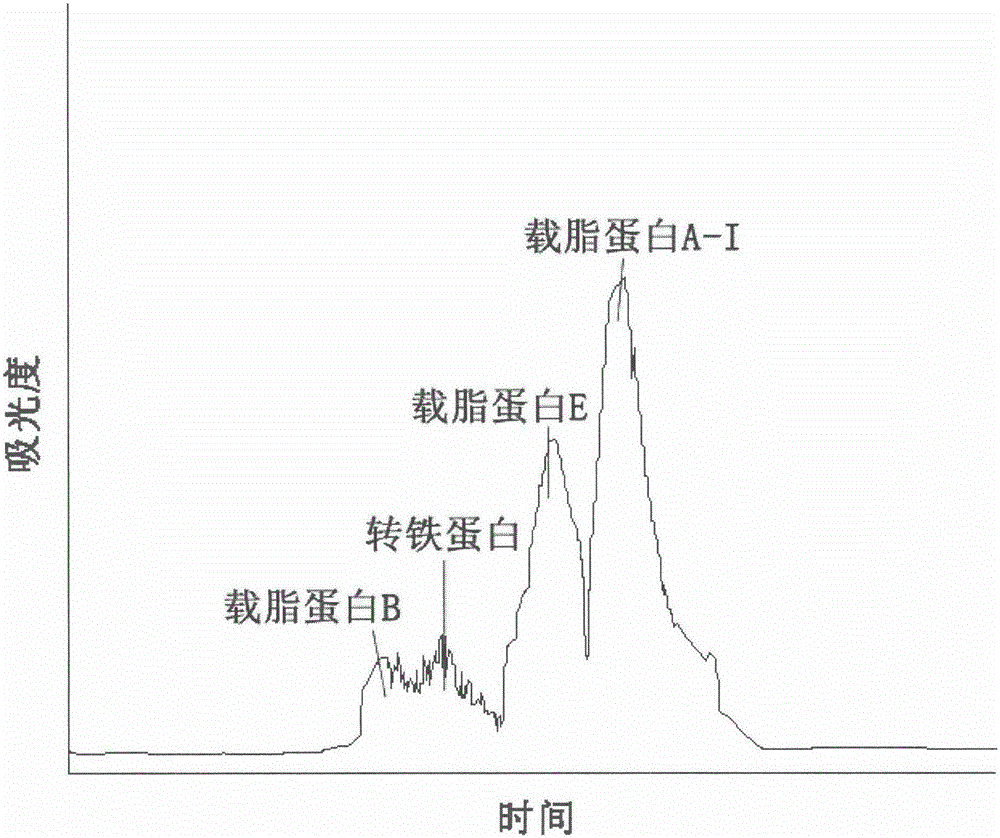

Method for purifying plasma functional proteins from Cohn fraction IV

InactiveCN106279405AHigh purityHigh activityNervous disorderPeptide/protein ingredientsFreeze-dryingPre treatment

The invention discloses a method for purifying plasma functional proteins from a Cohn fraction IV. The method comprises the following steps: carrying out pretreatment and removing a filter aid and other proteins in the raw materials; carrying out gradient separation by chromatography and collecting the plasma functional proteins in sequence; carrying out sterilization and freeze-drying. The method is high in protein yield and low in cost, comprises the purification process with the pipeline characteristic, has high degree of automation, is suitable for industrialization and achieves comprehensive utilization of the byproduct in plasma product production.

Owner:CHINA PHARM UNIV

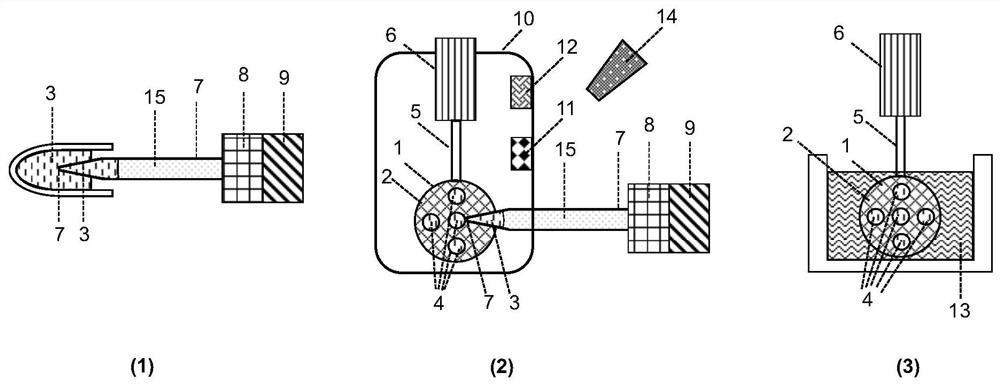

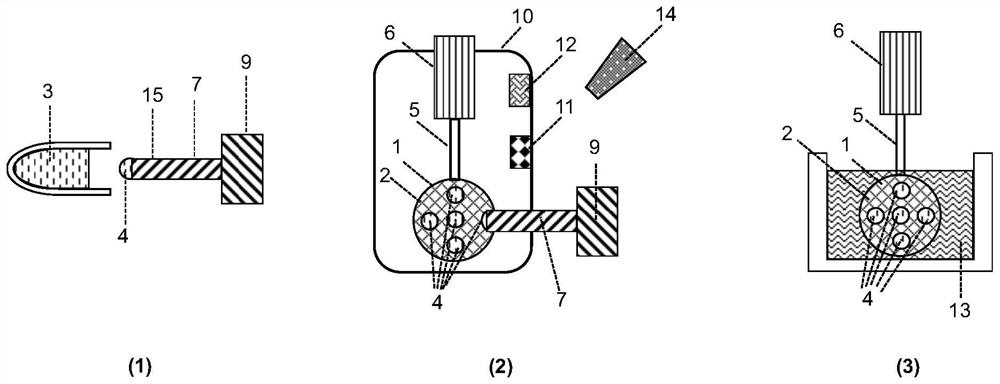

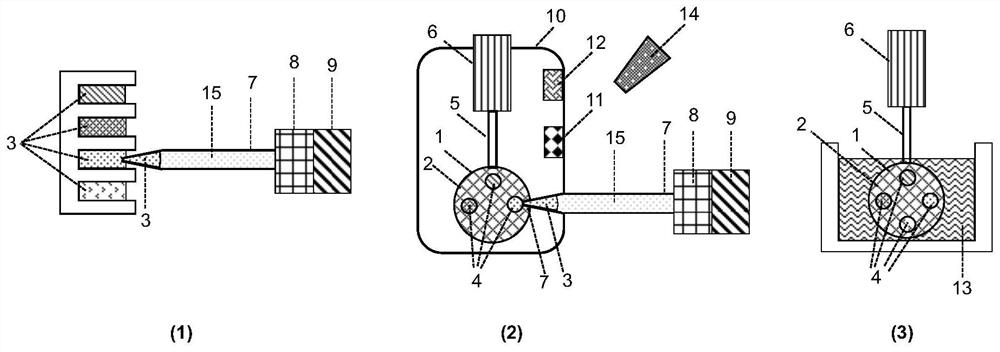

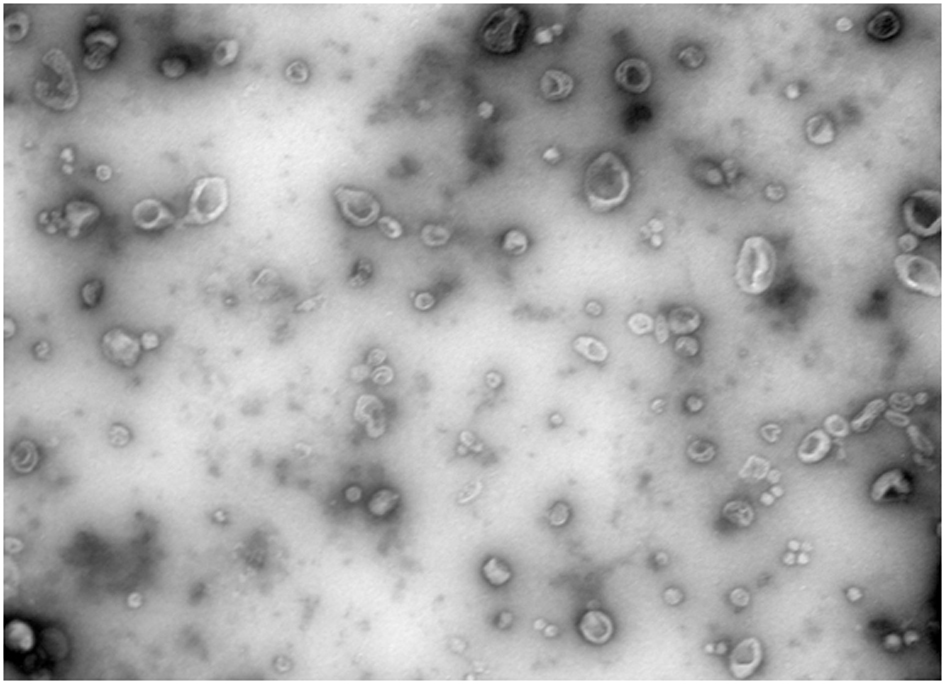

Micro-sample preparation device for frozen electron microscope and sample preparation method

InactiveCN112444530ASample preparationReduce consumptionMaterial analysis using wave/particle radiationPhysical chemistrySample purification

The invention discloses a micro-sample preparation device for a frozen electron microscope and a sample preparation method. The micro-sample preparation device comprises a supporting net assembly witha sample preparation operation state and a freezing operation state, a sample preparation probe used for respectively carrying out sampling operation and completing sample preparation operation on ato-be-detected sample solution on the supporting net assembly, a three-dimensional translation platform used for driving the sample preparation probe to be converted between the sampling operation andthe sample preparation operation, a freezing module used for carrying out freezing operation on the sample solution on the supporting net assembly, and a rapid transfer device used for driving the supporting net assembly to transfer between the sample preparation operation state and the freezing operation state. According to the invention, a frozen electron microscope sample preparation experiment with ultramicro sample consumption can be realized, and the consumption of a single sample liquid drop is in a nano-liter level and below the nano-liter level. Compared with a conventional sample preparation robot, the sample consumption is reduced by 1000 times or above, the experiment cost is remarkably reduced, and the protein sample purification period is shortened. The success rate of frozen electron microscope sample preparation and the reproducibility of experiments are obviously improved.

Owner:ZHEJIANG UNIV

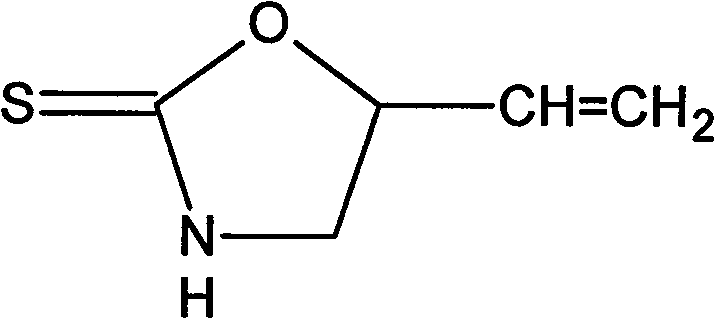

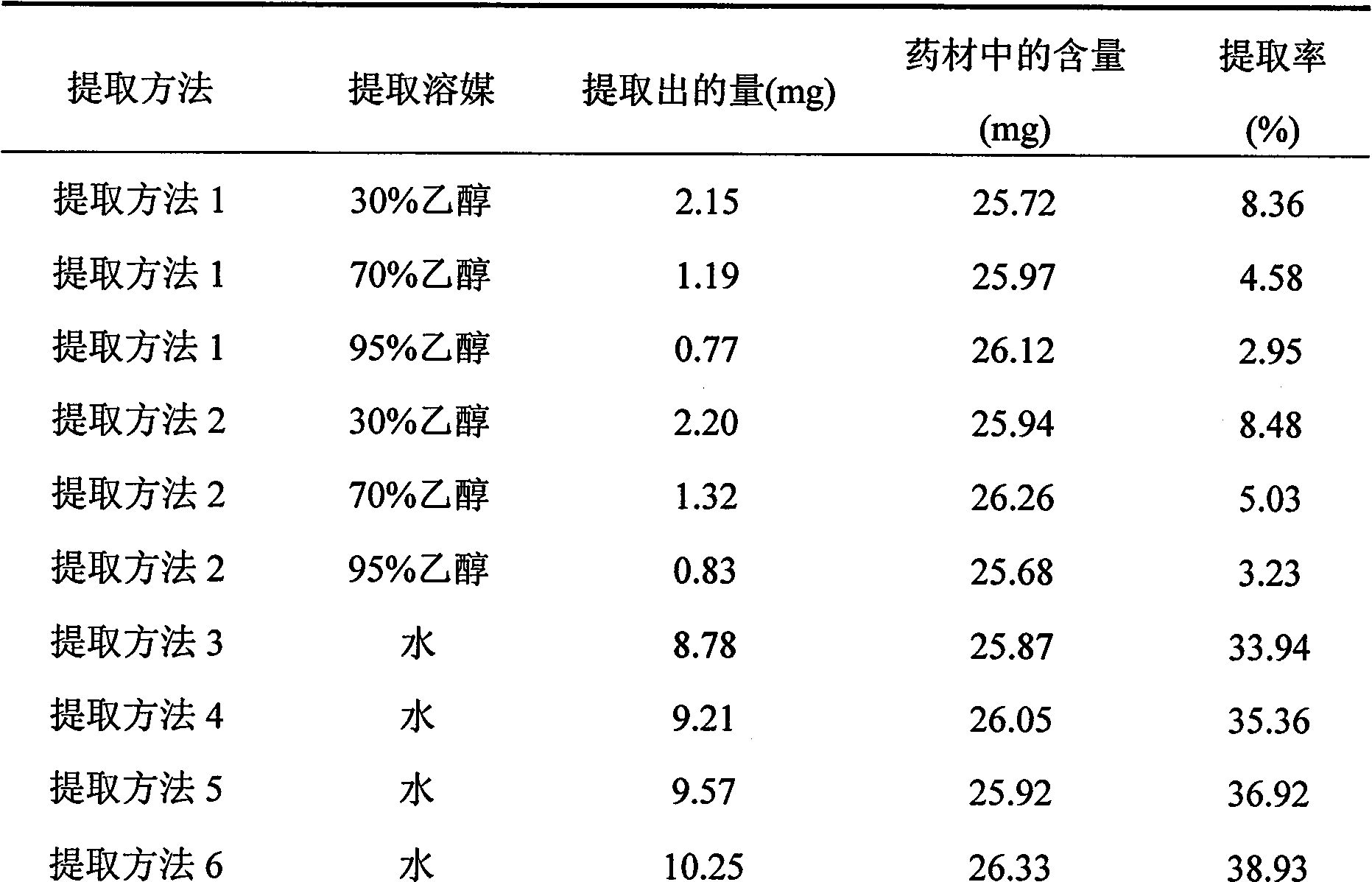

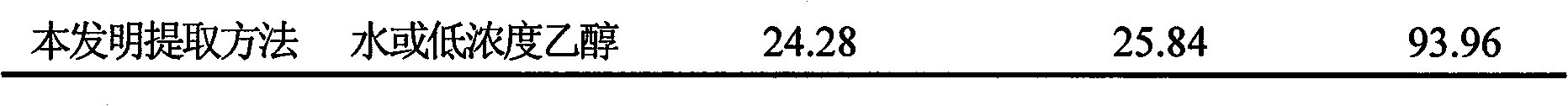

Method for extracting epigoitrin from isatis root with high extraction ratio

InactiveCN101602740AReduce extraction timeSimple processOrganic chemistryAntiviralsAlcoholEconomic benefits

The invention relates to a method for extracting epigoitrin from isatis root with high extraction ratio, comprising the following steps: 1. isatis root medicinal material is crushed into coarse powder, 10-25 times of water or low-concentration ethanol is added in the coarse powder for being extracted at the temperature of 20-70 DEG C; 2. filtrate is decompressed and concentrated at the temperature of 40-70 DEG C for obtaining epigoitrin constituent; 3. concentrated solution passes through processed macroporous resin, and is washed by 5-12 times of column volume of water, and is washed by 2-5 times of column volume of water, and is washed by 30 percent to 50 percent of ethanol by mass concentration and then is collected; 4. ethanol eluent is decompressed and concentrated at the temperature of 40-70 DEG C, thereby obtaining epigoitrin macroporous resin separated constituent; 5. the epigoitrin macroporous resin separated constituent is separated by column chromatography or high-efficiency industrial chromatographic column, thereby preparing into epigoitrin monomer. Compared with the prior art, the extraction efficiency of the epigoitrin is 2.4 times higher than that of the prior art; in addition, the period is short, the impurities are less, the post-processing is convenient, the raw material can be fully utilized, the cost can be shortened and economic benefit is improved.

Owner:贾晓斌

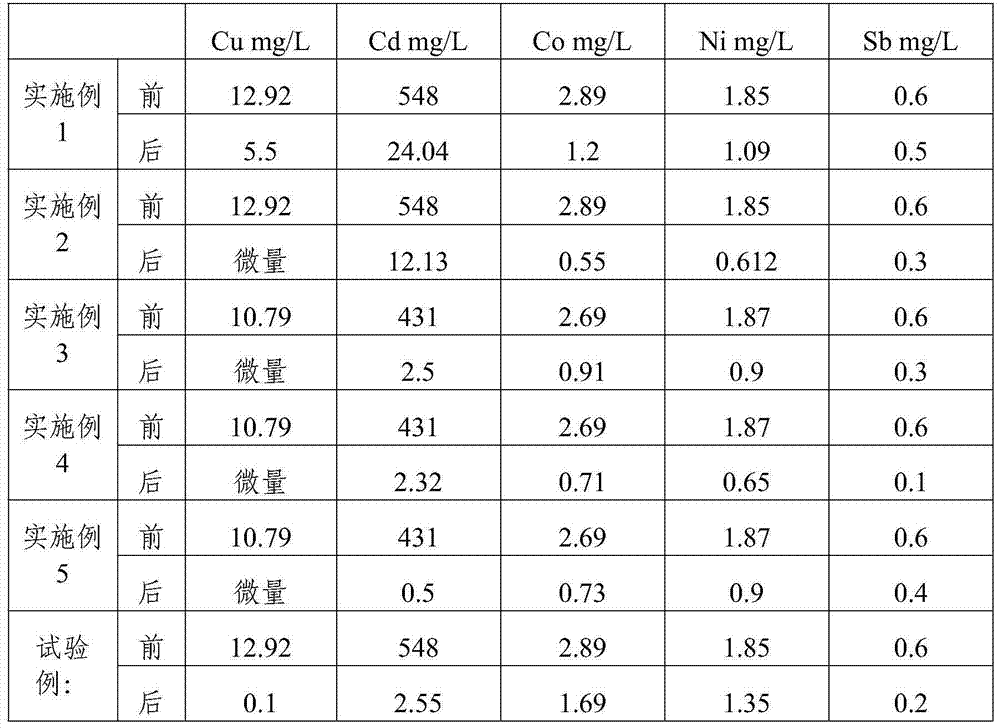

Method for reducing content of Cu, Cd, Ni, Co and Sb in zinc hydrometallurgy zinc sulfate solution

InactiveCN104711423AHigh purityReduce contentProcess efficiency improvementSulfate zincHydrometallurgy

The invention relates to the technical field of hydrometallurgy, and especially relates to a method for reducing the content of Cu, Cd, Ni, Co and Sb in a zinc hydrometallurgy zinc sulfate solution. The method comprises the following steps: detecting and recording the content of components in the zinc sulfate solution, and adjusting the pH value of the zinc sulfate solution to 2.5-3.5 to make zinc sulfate meet condition requirement in subsequent purifying technologies, improves the removal rate of Cu, Cd, Ni, Co and Sb elements in zinc sulfate and improve the purity of the zinc sulfate solution; adding a cobalt removal agent in the treatment process, stirring, adding zinc powder, stirring, and filtering to simultaneously remove Cu, Cd, Ni, Co and Sb elements from zinc sulfate in order to reduce the content of impurity elements in zinc sulfate, improve the purity of zinc sulfate, complete the purification process at 50-60DEG C and reduce the energy consumption in the purification process.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

Lactide combined purification method

ActiveCN102816143AHigh purityTo achieve the effect of purificationOrganic chemistryNon solventPurification methods

The invention discloses a lactide combined purification method and belongs to the field of lactic acid manufacture. The lactide combined purification method comprises the following steps of weighing low-purity lactide, carrying out rectification, collecting fractions, carrying out non-solvent crystallization, and collecting lactide having purity of 99.5%. The lactide combined purification method adopts a high-vacuum rectification and non-solvent crystallization combined technology, solves the problem that only a high-vacuum rectification technology further improves lactide purity difficultly, and further realizes purification effects by a non-solvent crystallization process. Through the lactide combined purification method, lactide purity reaches to above 99.5%. The rest of low-purity lactide can be distilled sequentially. The lactide combined purification method shortens a purification period, avoids use of a large amount of a solvent and is suitable for large-scale production.

Owner:武汉三江航天固德生物科技有限公司

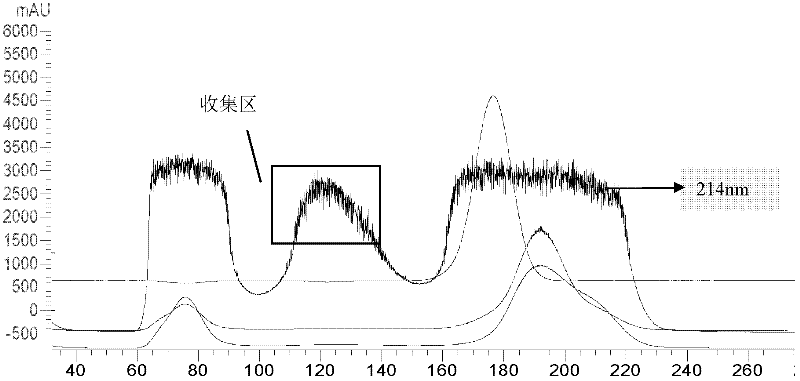

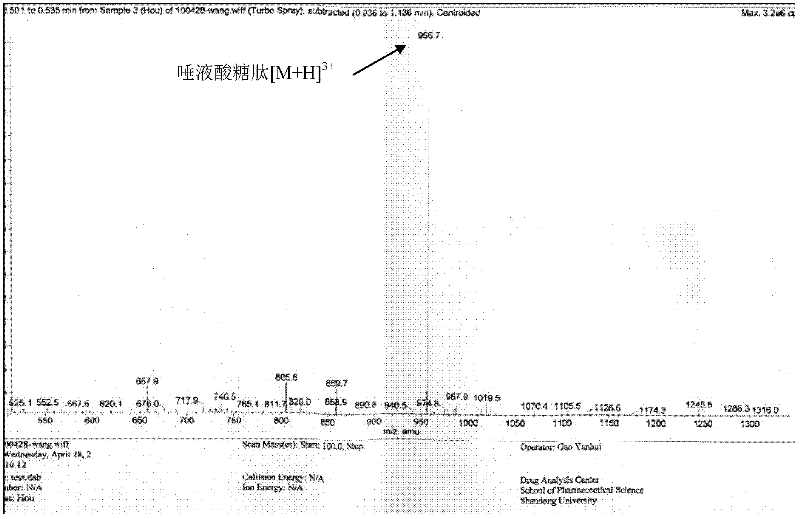

Separation method of sialoglycopeptide

InactiveCN102382178APurification method is stableEfficient purification methodPeptide preparation methodsEvaporationIon exchange

The invention discloses a separation method of sialoglycopeptide, including the following steps: (1) taking a fresh egg yolk, treating the fresh egg yolk with phenol and then conducting rotation evaporation to obtain a sample containing the sialoglycopeptide; (2) separating the sample with sephadex G-50 and collecting eluent; (3) concentrating the eluent, absorbing the concentrated sample with active carbon and then eluting the sample in acetonitrile solution to obtain eluent containing the sialoglycopeptide; and (4) freezing and drying the eluent to obtain pure sialoglycopeptide. In the method, the steps of G-25 desalting, HPLC (High Performance Liquid Chromatography) purification, ion exchange chromatography purification and the like of the existing method are eliminated, therefore the purification period is shortened greatly, the efficiency is improved, the cost is saved and inspected by HPLC, and the purity of the prepared sialoglycopeptide can achieve 99%. The separation method is used for not only laboratories but also small-scale industrial production.

Owner:SHANDONG UNIV

Chicken gallbladder extraction composition and extraction method thereof

InactiveCN103893210AImprove stabilityIncrease contentDigestive systemUnknown materialsCholic acidEvaporation

The present invention relates to a chicken gallbladder extraction composition, which comprises, by mass, 45-55% of taurochenodeoxycholic acid, 10-15% of other cholic acids, 5-15% of amino acids, 23-28% of proteins, and 0.5-2% of fat, wherein the chicken gallbladder extraction composition has the high taurochenodeoxycholic acid content, contains plural kinds of the amino acids, has the high amino acid content, has significant efficacy, and has high stability. The present invention further relates to an extraction method for the chicken gallbladder extraction composition. The extraction method comprises: freezing, chopping, melting and pressing chicken gallbladder, filtering to obtain the bile, adding ethanol to extract, standing, carrying out protein precipitation, filtering to obtain the supernatant, adding petroleum ether to extract, collecting the ethanol layer, and carrying out concentration evaporation dryness to obtain the chicken gallbladder extraction composition. The method has characteristics of simple process, easy operation, low cost and short purification period.

Owner:辽宁省药物研究院

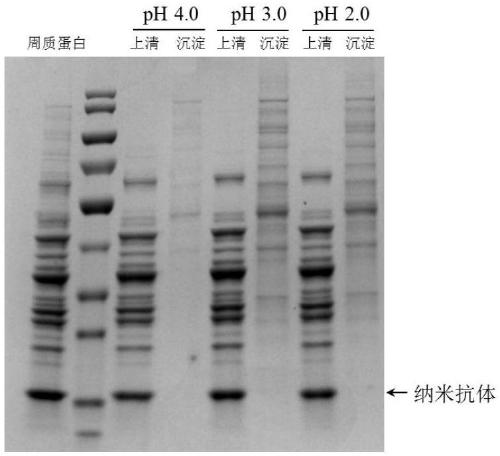

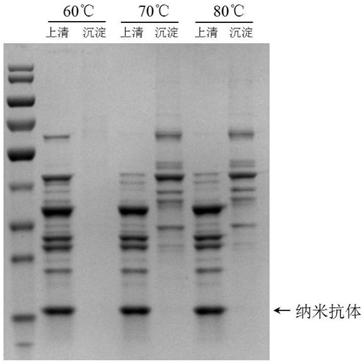

Method for separation and purification of nanobody

PendingCN111378030AHigh purityEasy to operatePeptide preparation methodsImmunoglobulinsBiotechnologyProtein solution

The invention discloses a method for separation and purification of a nanobody, and relates to the technical field of biology. The method comprises the following steps: (1) precipitating impure protein at low pH: regulating pH of a to-be-purified sample to acidity with an acid solution, after standing, performing centrifugation to remove precipitates, and keeping a supernatant solution; (2) precipitating the impure protein at high temperature: heating the supernatant solution obtained in step (1), after heat-preservation standing, performing centrifugation to remove precipitates, and keeping asupernatant solution; and (3) removing the impure protein with an ultrafiltration method: performing ultrafiltration on the supernatant solution obtained in step (2), wherein a protein solution permeating through an ultrafiltration membrane is the high-purity nanobody. The method provided by the invention does not affect the activity of the nanobody, and has simple operation, low cost and a wideapplication range.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Separation and purification method of gold in gold platinum alloy waste

ActiveCN103667706AReduce purification process stepsShort purification cycleProcess efficiency improvementPurification methodsFiltration

The invention relates to a separation and purification method of gold in gold platinum alloy waste. The method comprises steps as follows: 1), gold platinum alloy waste is weighed, aqua regia is heated and dissolved, concentrated HCl is added while concentrated to remove nitric acid, and water is added to obtain a dilution solution; 2), the dilution solution obtained in the step 1) is heated and adjusted to be alkaline, the solution is stirred, and H202 is added until precipitation occurs in the solution; 3), the step 2) is repeated, and excessive H202 is added continuously; 4), the solution obtained in the step 3) is heated to remove H2O2, filtration is performed, and obtained precipitation is cleaned with distilled water; 5), water is added to the precipitation obtained in the step 4) and boiled, filtration is performed, and precipitation is washed with water to remove CI<-1>; and 6), the precipitation obtained in the step 5) is roasted, and solid gold is obtained. With the adoption of the method, the recovery rate of gold is up to 99% or above, the purity of gold is up to 99.9%, no impurity is brought in a gold purification and separation process, a subsequent platinum purification processing step is reduced, the platinum purification period is shortened, and the platinum purification cost is reduced.

Owner:CHONGQING MATERIALS RES INST

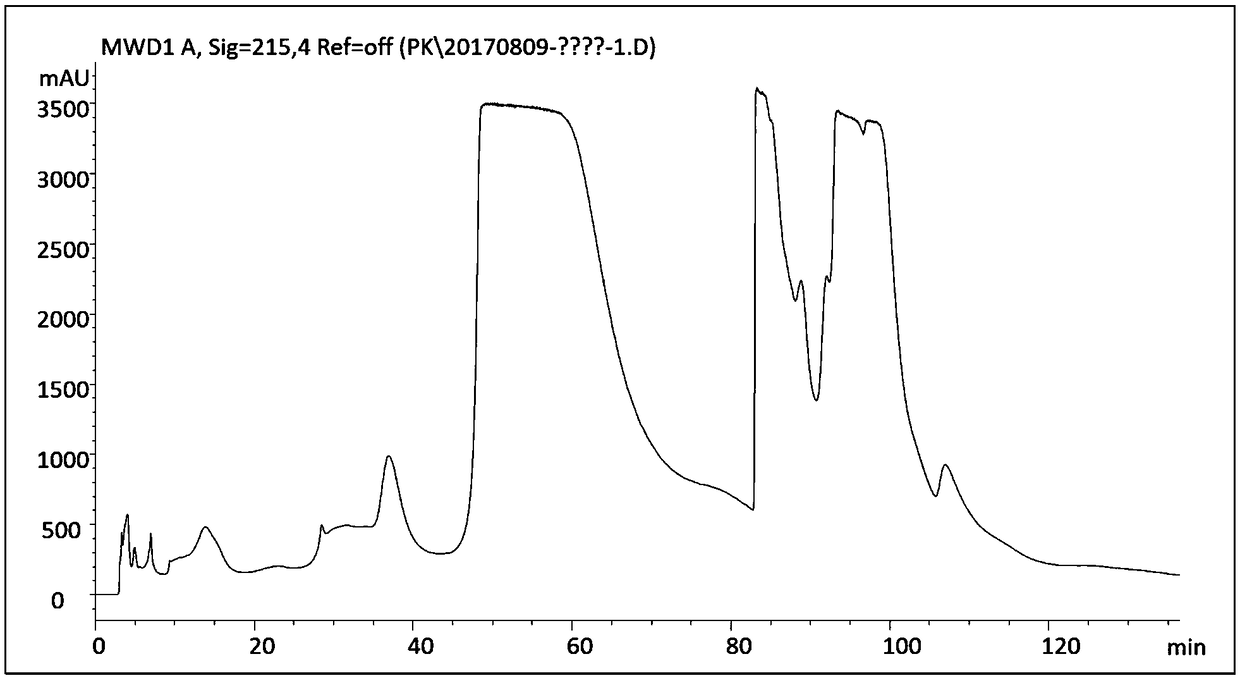

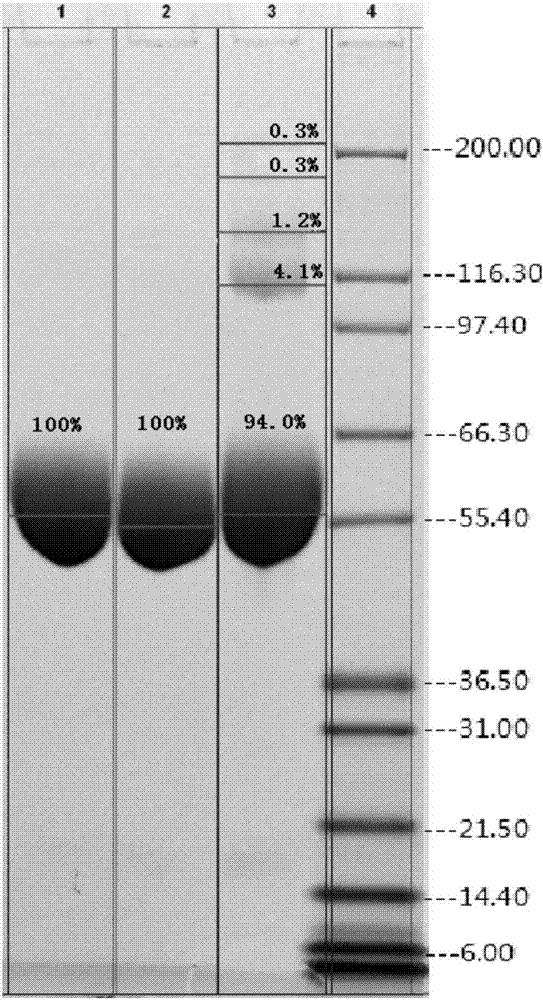

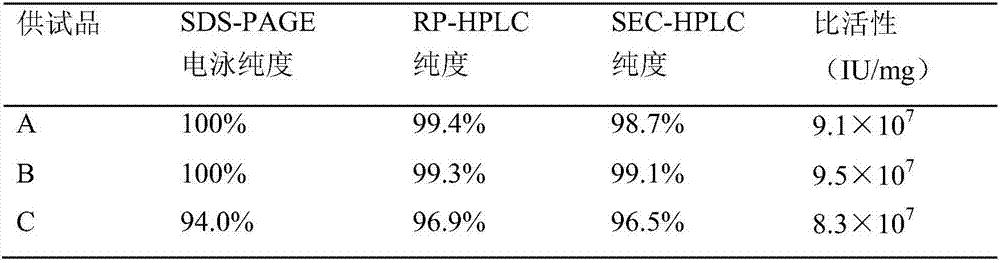

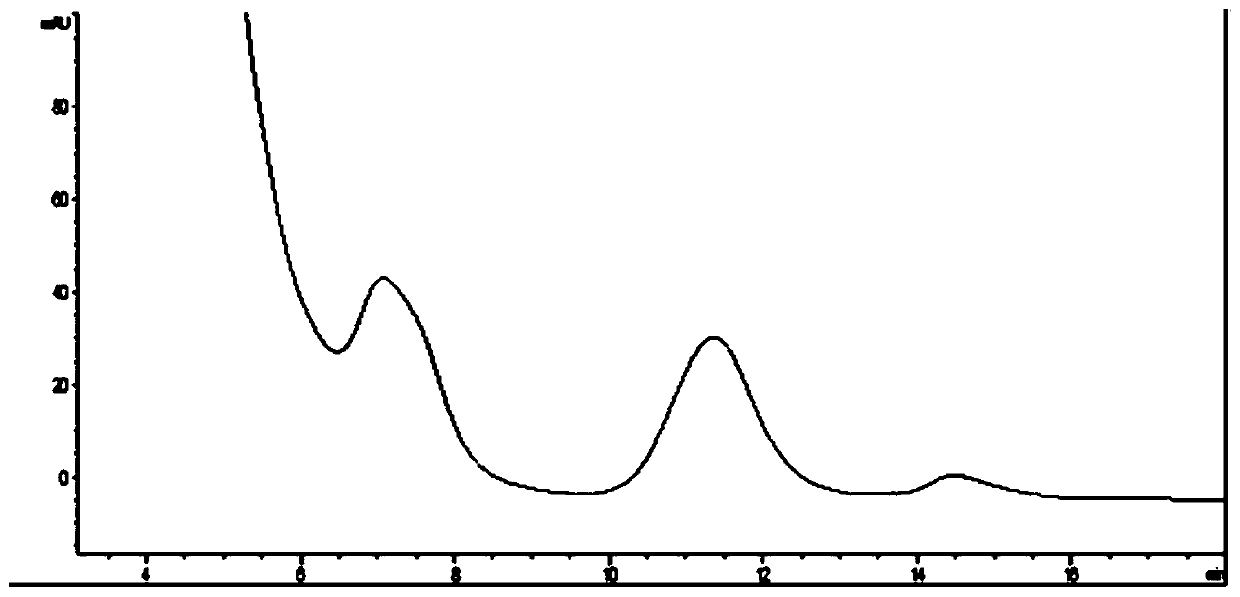

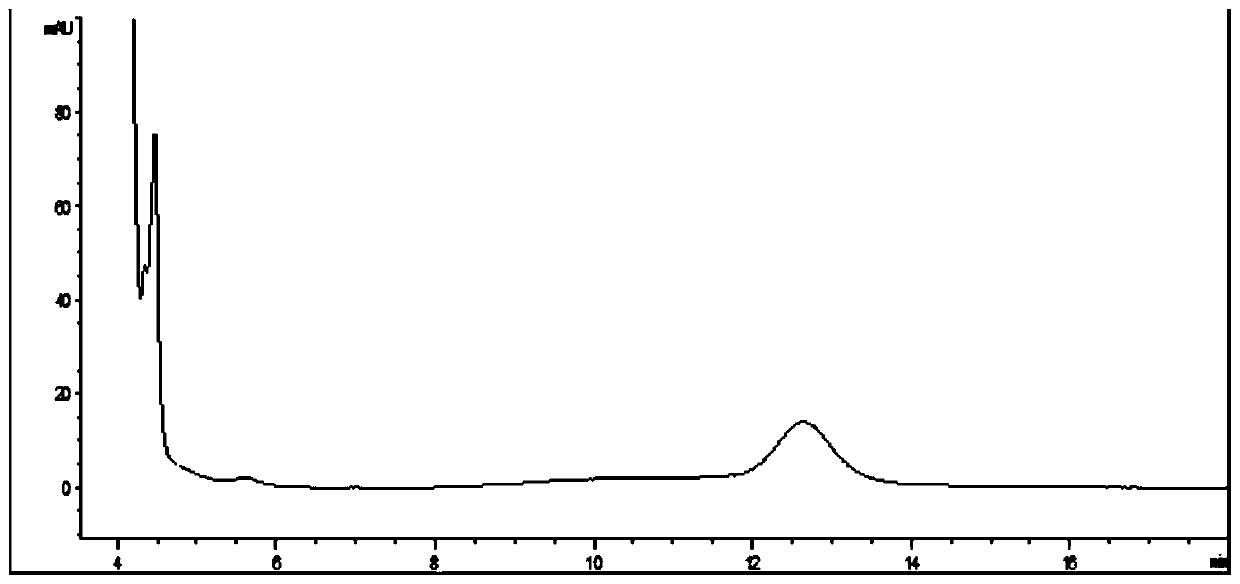

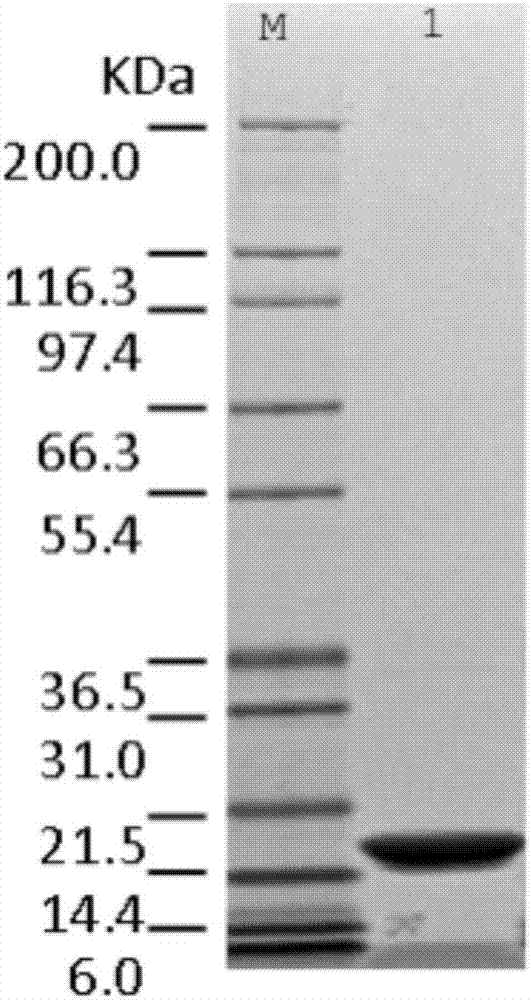

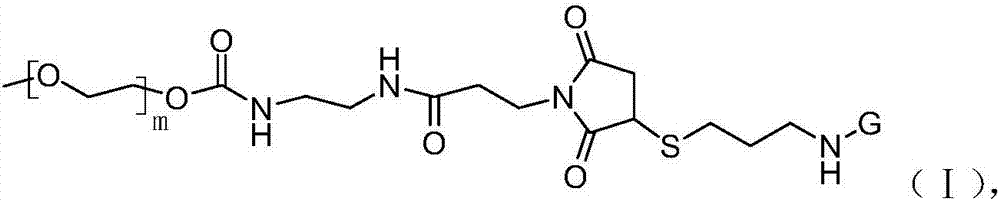

Purification method of polyethylene glycol recombinant human granulocyte colony-stimulating factor

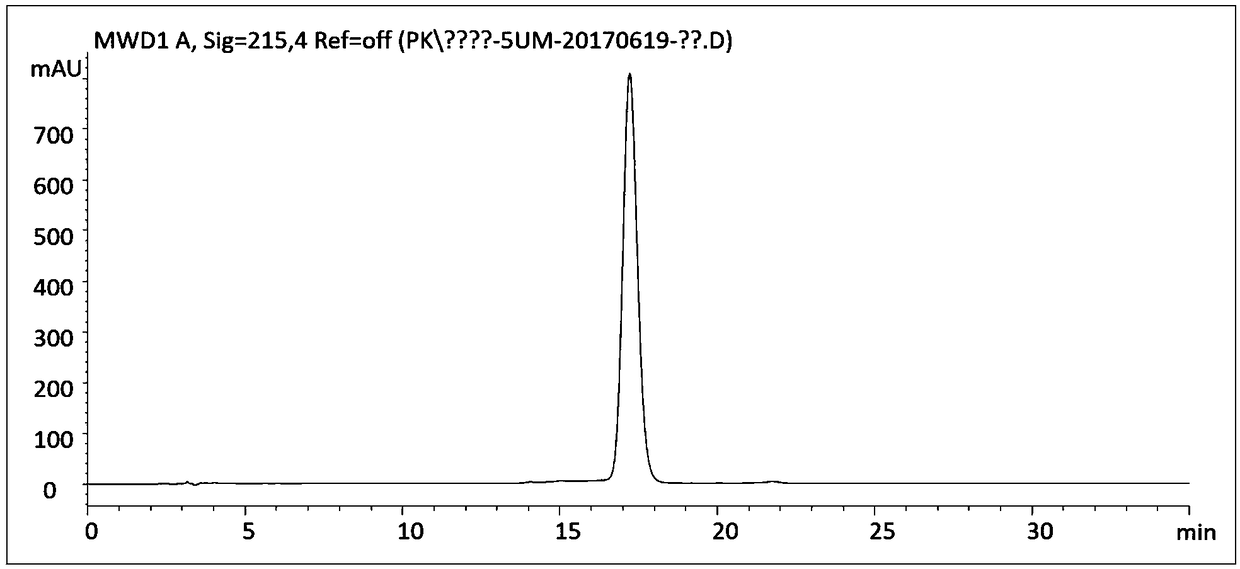

ActiveCN107129531ASimple process routeAchieving Linear AmplificationDepsipeptidesPeptide preparation methodsChromatographic separationPurification methods

The invention relates to a purification method of a polyethylene glycol recombinant human granulocyte colony-stimulating factor. Particularly, the method for performing cation exchange chromatographic separation and purification of the PEG-G-CSF and preparing PEG-G-CSF stock solution by proper buffer solution substitution is optimized, and the PEG-G-CSF with HPLC (high performance liquid chromatography) and electrophoresis purity of 98% or more can be obtained by one-step column chromatographic purification and buffer solution substitution. By the purification process, process routes are simplified, production time is saved, protein recovery rate is high, the obtained protein stock solution is high in purity, proper medical auxiliary materials are added, so that a medicinal preparation can be prepared, and the purification method is quite suitable for large-scale industrial enlarged production.

Owner:JIANGSU HENGRUI MEDICINE CO LTD

Method for separating and purifying pig ganglioside

InactiveCN109705176ALow costLess amount of mobile phaseSugar derivativesSugar derivatives preparationOrganic solventElution

The invention provides a method for efficiently separating and purifying porcine ganglioside, which comprises the steps of: dissolving and filtering a crude extract of the pig ganglioside; applying afiltered solution to a chromatography column filled with a homogenous normal-phase silica gel for chromatography; using ultrapure water and an organic solvent as a flow phase for elution of a target product; collecting the solution of the target peak in stages, and collecting the component liquid meeting the requirements. The method is applied to the deep purifying of the pig ganglioside, and onlyneeds one-step chromatography to satisfy the requirement that the pig ganglioside purity is greater than 99% and the yield is greater than 93.0%. The purification yield is high and stable, and the separation method of the invention is simple and convenient, can be used for large-scale production, and the production cost is greatly reduced.

Owner:SUZHOU NANOMICRO TECH CO LTD

Purification method of recombinant human granulocyte colony-stimulating factor

ActiveCN107188952AEasy to separateSimple stepsDepsipeptidesPeptide preparation methodsPurification methodsG-csf therapy

The invention provides a purification method of a recombinant human granulocyte colony-stimulating factor. The method specifically comprises the steps of selecting a cation chromatographic column to purify renaturation solution of the recombinant human granulocyte colony-stimulating factor (rh-G-CSF), and then performing proper buffer solution replacement to prepare high purity rh-G-CSF stock solution, wherein fillers in the cation chromatographic column is in a cationic type with a mixed mode. According to the purification technology provided by the invention, a technical path is simplified, production time is saved, protein recovery rate is high, the acquired protein stock solution is high in purity, a medicine preparation can be produced by adding proper pharmaceutical adjuvant, and the purification technology is very suitable for large-scale industrial amplification production. Meanwhile, the invention also provides a method for preparing pegylated recombinant human granulocyte colony-stimulating factor.

Owner:JIANGSU HENGRUI MEDICINE CO LTD

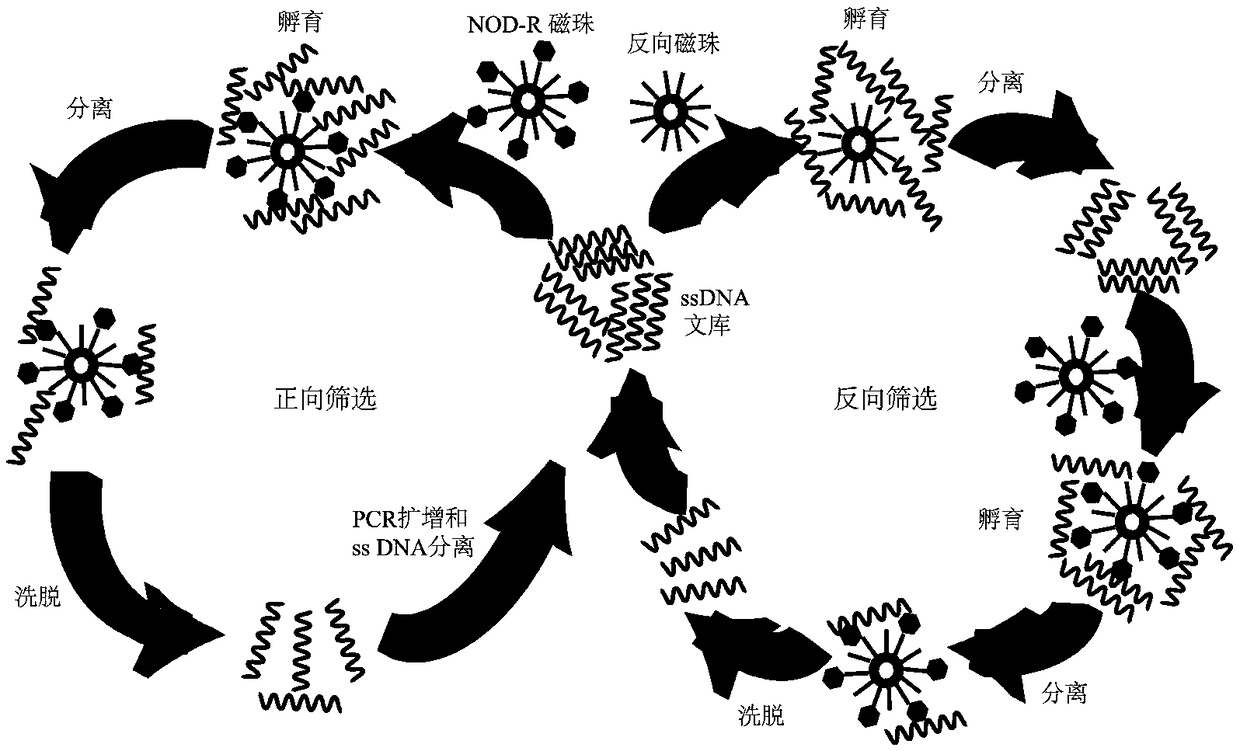

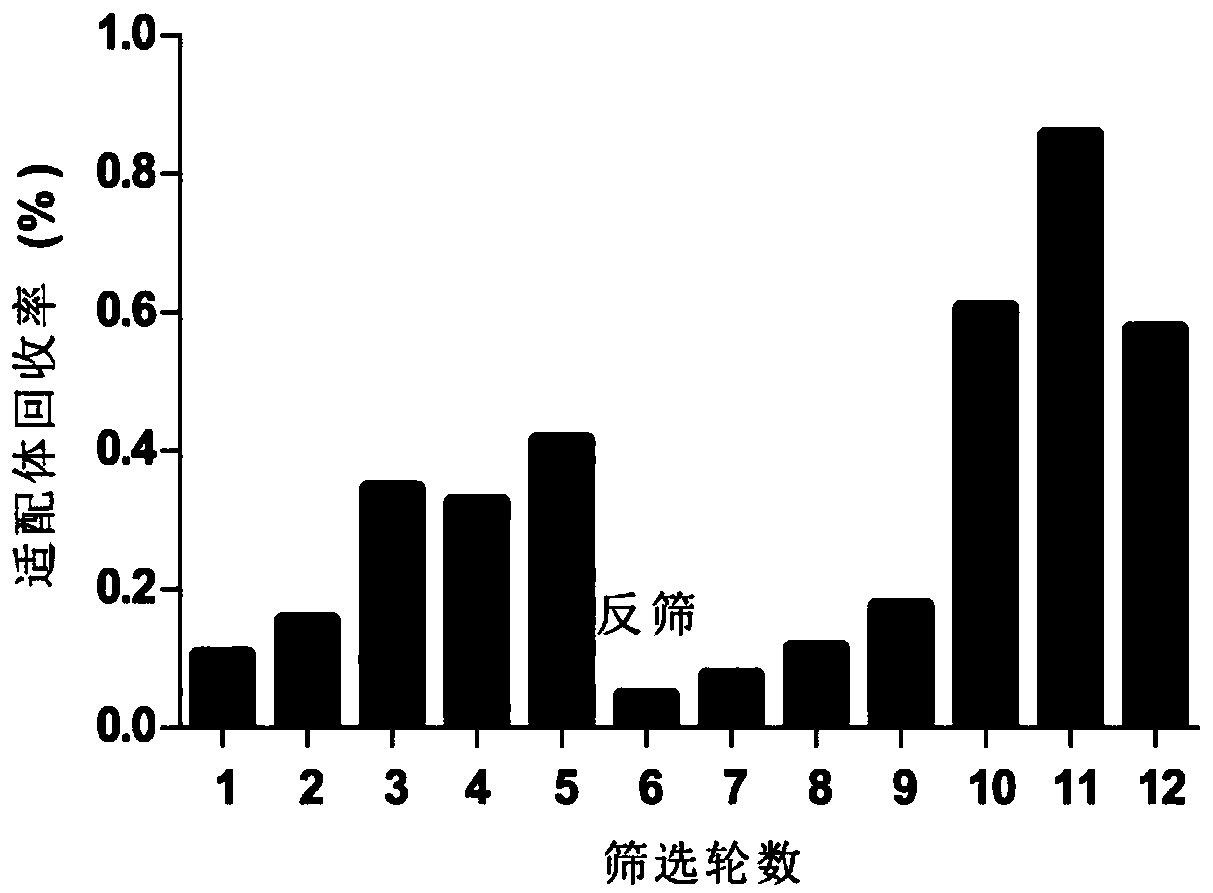

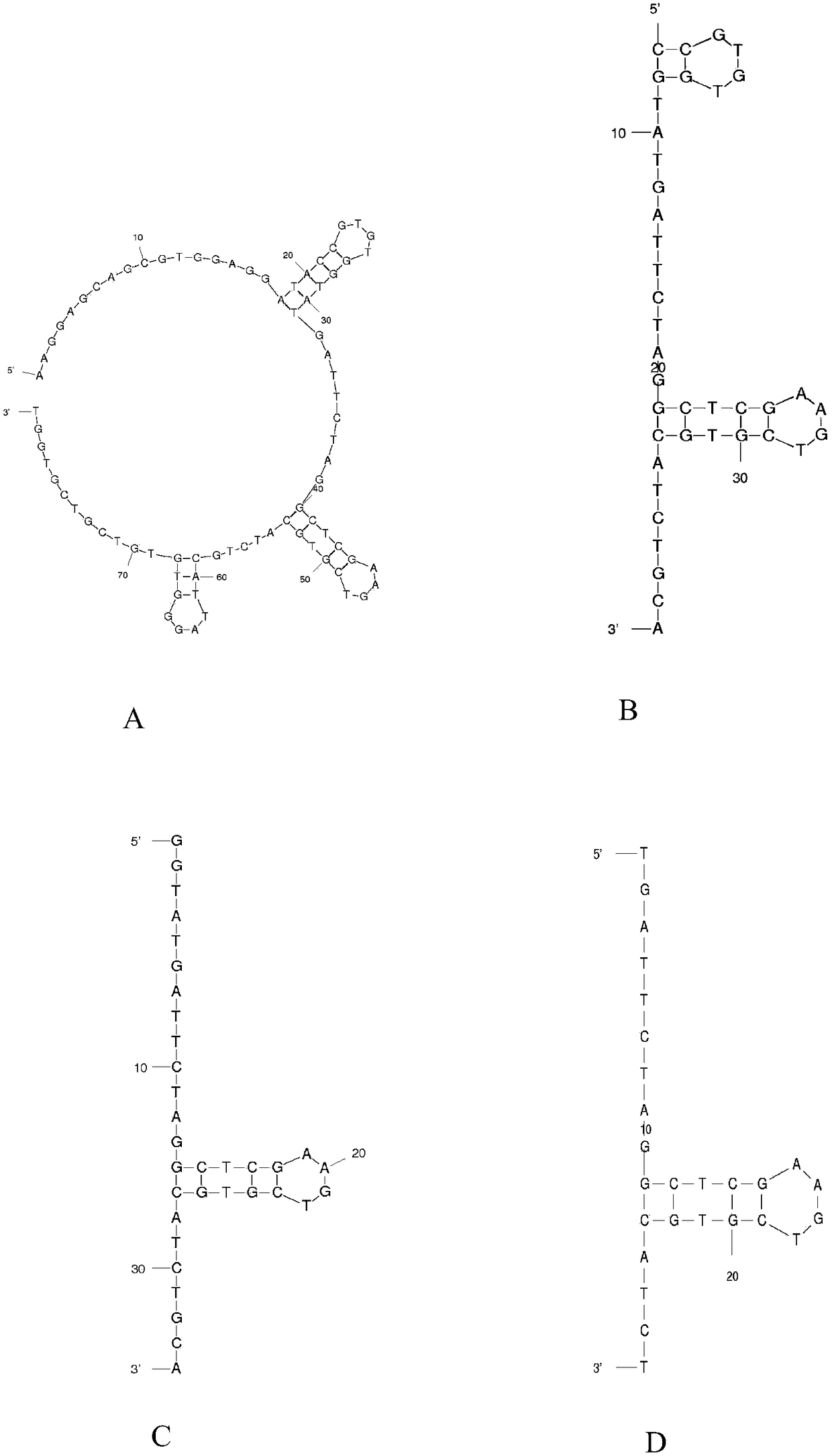

Aptamer capable of being specifically combined with nodularin-R and application of the aptamer

ActiveCN108949765AHigh affinityQuick combinationOrganic active ingredientsWater contaminantsNucleotideAquatic product

The invention relates to the technical field of bio-medicine engineering, and provides an aptamer capable of being specifically combined with nodularin-R and an application of the aptamer. A sequencegeneral formula of the aptamer is 5'-AAGGAGCAGCGTGGAGGATA-N40-TTAGGGTGTGTCGTCGTGGT-3', wherein N is any one of the four deoxyribonucleotide basic groups A, T, G and C, the number 40 refers to the number of random basic groups, preferably a sequence represented as anyone from the SEQ ID No.1 to the SEQ ID No.7, most preferably, anyone from the SEQ ID No.9 to SEQ ID No.11. The aptamer can be used for preparing an aptamer sensor or a detection reagent applied to detection of the NOD-R for a drinking water sample. The products also can be a basis for preparing medicines for preventing or treatingNOD-R poisoning and removing the NOD-R from water body or aquatic products.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

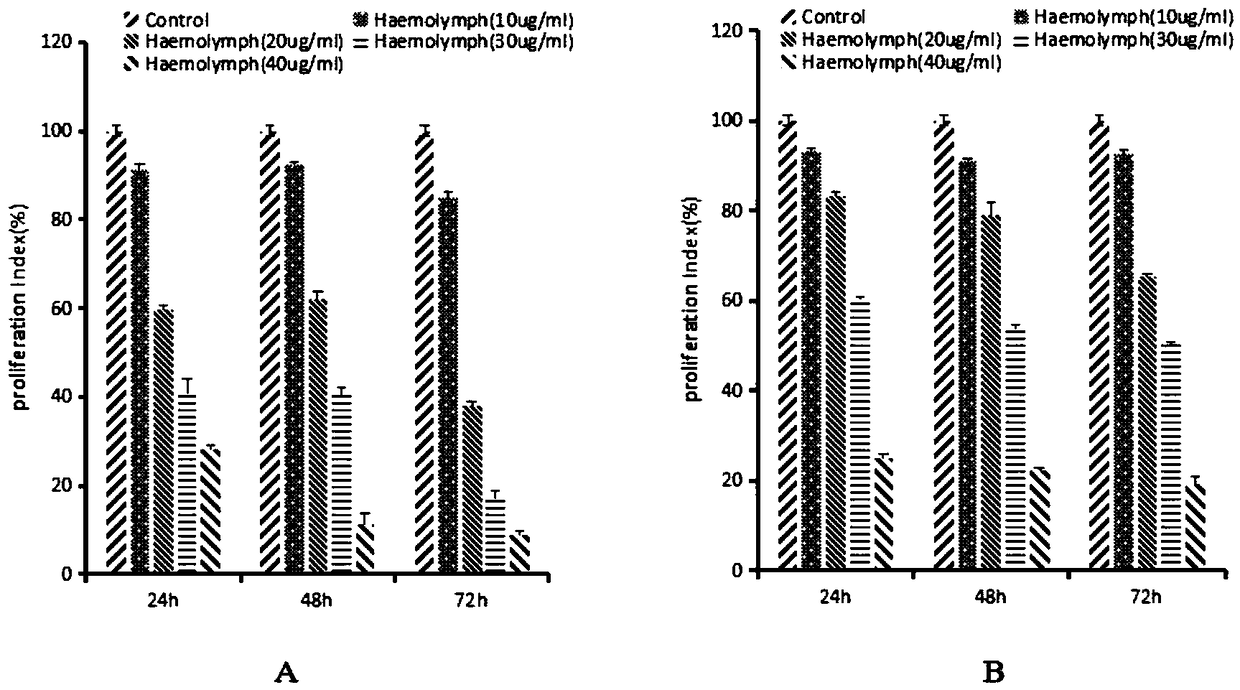

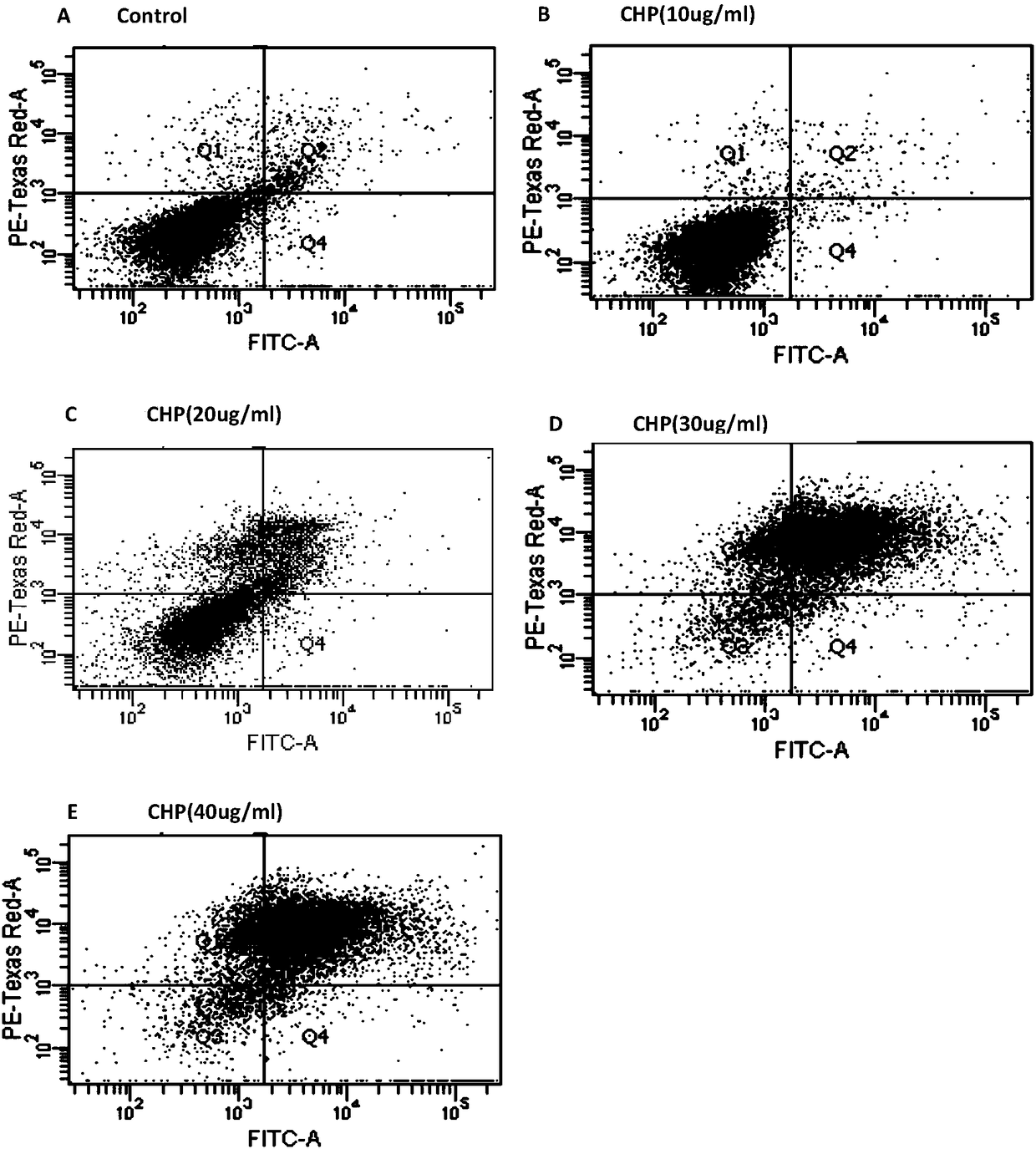

Method for fast separating and purifying aspongopus protein components resistant to tumors

ActiveCN108148110AHigh temperature resistantLow instrument requirementsPeptide preparation methodsAntineoplastic agentsUltrafiltrationChromatographic column

The invention provides a method for fast separating and purifying aspongopus protein components resistant to tumors and belongs to the technical field of biology. Through high-temperature treatment, ammonium sulfate chromatography protein and ultrafiltration, fast separation and purification of the aspongopus protein components resistant to tumors are achieved in order to solve the problems that existing methods are cumbersome in procedure and high in requirement for instruments, the price of related chromatographic columns and fillers is high since high performance liquid chromatographs, nucleic acid protein chromatographs and the like are often required for separation and purification, and the purification period is pretty long.

Owner:GUIZHOU UNIV

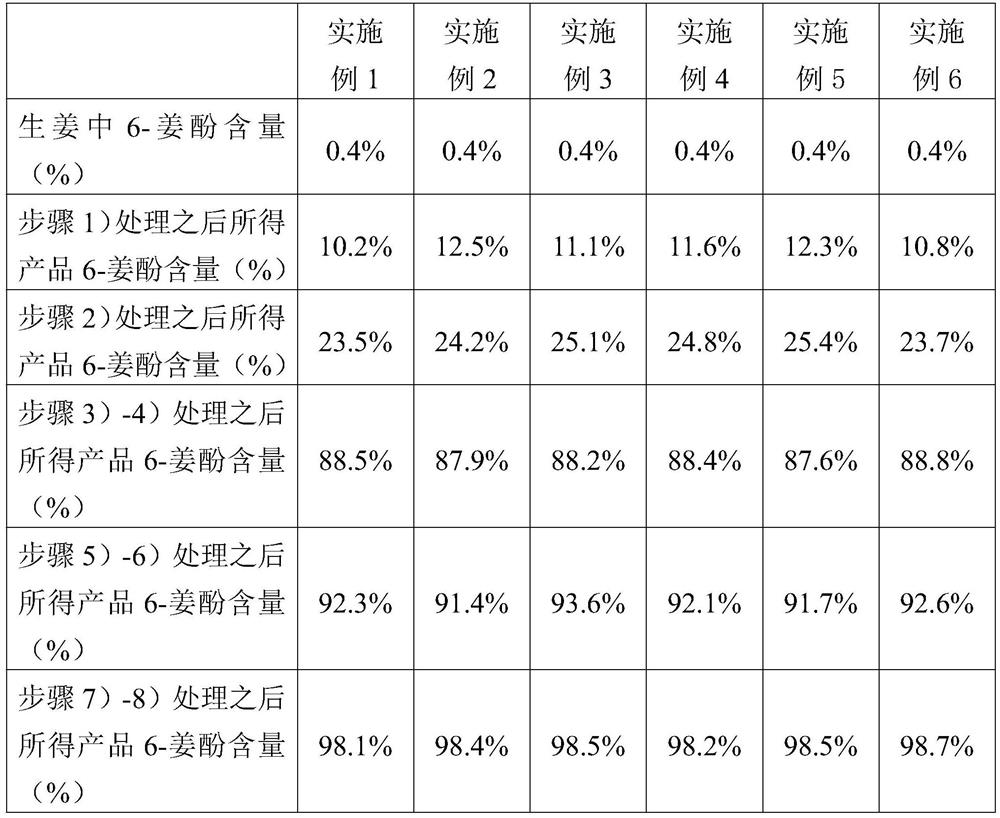

Method for extracting 6-gingerol with content greater than or equal to 98%

ActiveCN112920034AIncrease productivityExtraction method is fast and efficientOrganic compound preparationCarbonyl compound separation/purificationActivated carbonAlcohol ethyl

The invention belongs to the field of 6-gingerol extraction, and particularly relates to a method for extracting 6-gingerol with the content larger than or equal to 98%. The method for extracting 6-gingerol with the content larger than or equal to 98% comprises the following steps: crushing fresh ginger, adding ethyl alcohol for flash extraction, and separating out a filtrate; concentrating the obtained filtrate, carrying out alumina column chromatography, and collecting an alumina column chromatography eluent; adsorbing the alumina column chromatography eluent through a macroporous resin column, eluting with alkali-containing ethanol, acid-containing ethanol and 50-60 vt% ethanol in sequence, collecting 50-60 vt% ethanol eluent, and concentrating to prepare a concentrated solution with the baume degree of 10-15; mixing the obtained concentrated solution with an organic solvent, adjusting the alcohol concentration to 55-60 vt%, adding activated carbon, and filtering with an organic membrane; and performing gradient elution separation on the obtained filtrate by using macroporous resin through 50-60 vt% ethanol and 65-70 vt% ethanol in sequence, respectively collecting each gradient eluent, concentrating and drying to obtain the required 6-gingerol. The original extraction method is replaced by flash extraction, so that the production efficiency is greatly improved, and various data of series macroporous resin purification are optimized to achieve the maximum efficiency.

Owner:GUILIN NATURAL INGREDIENTS CORP

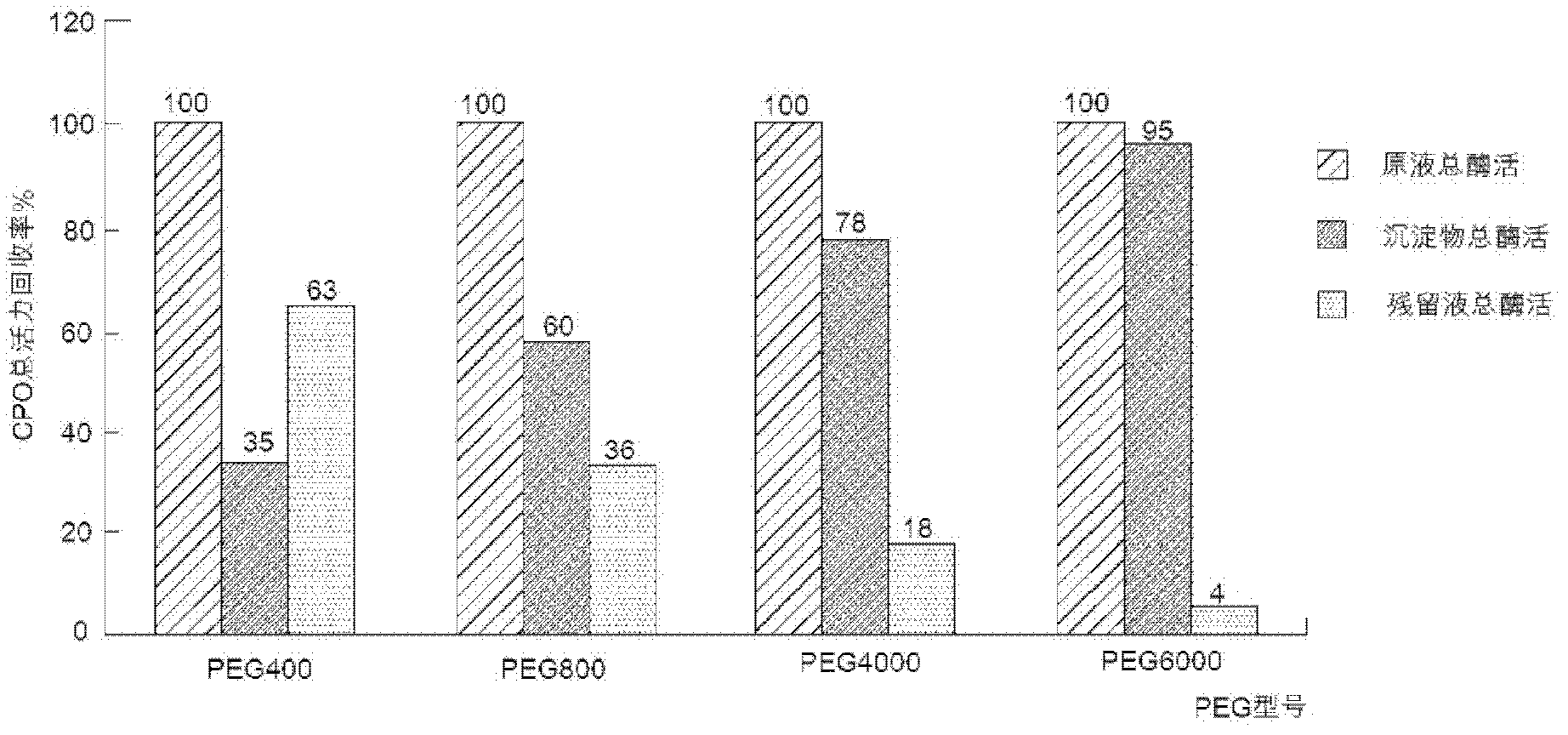

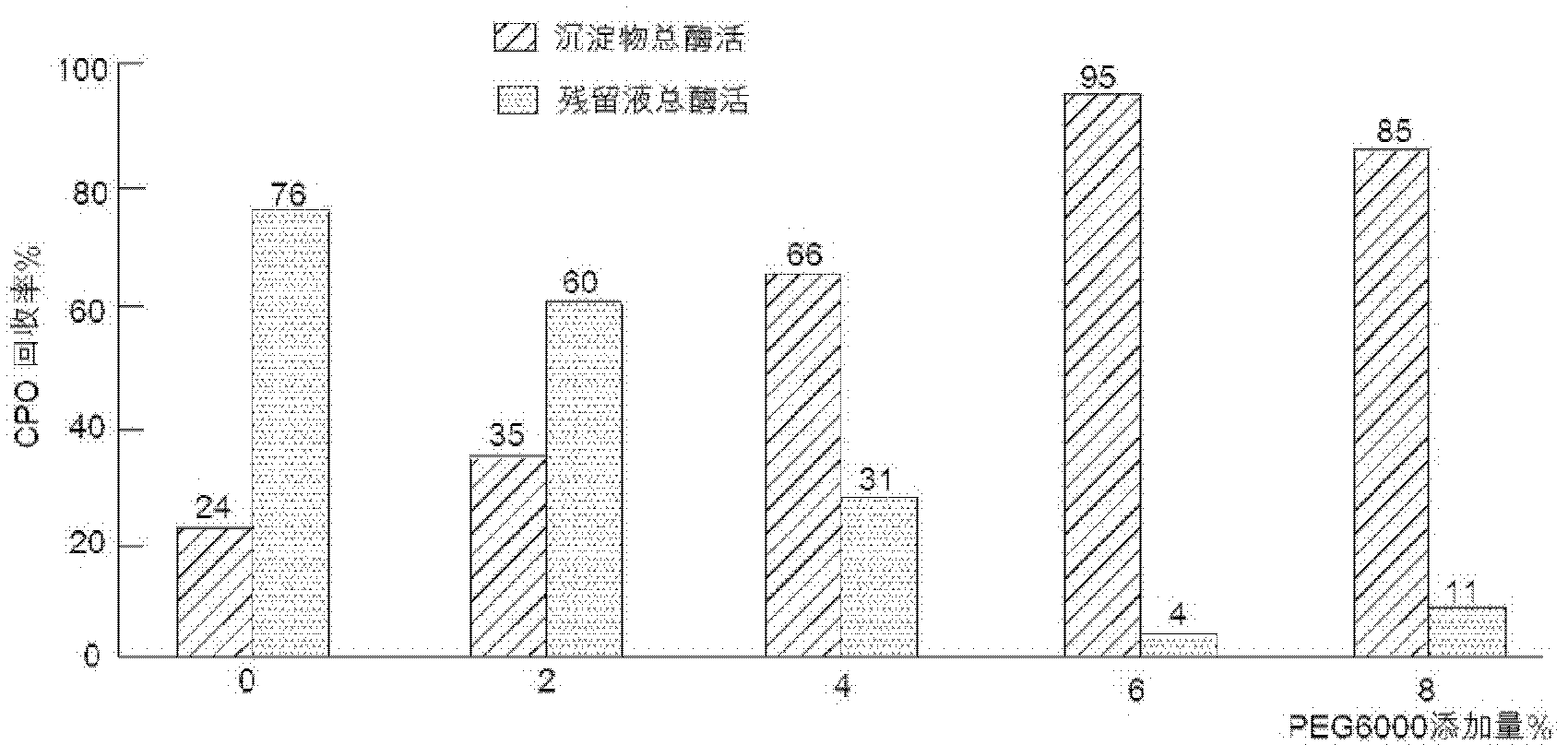

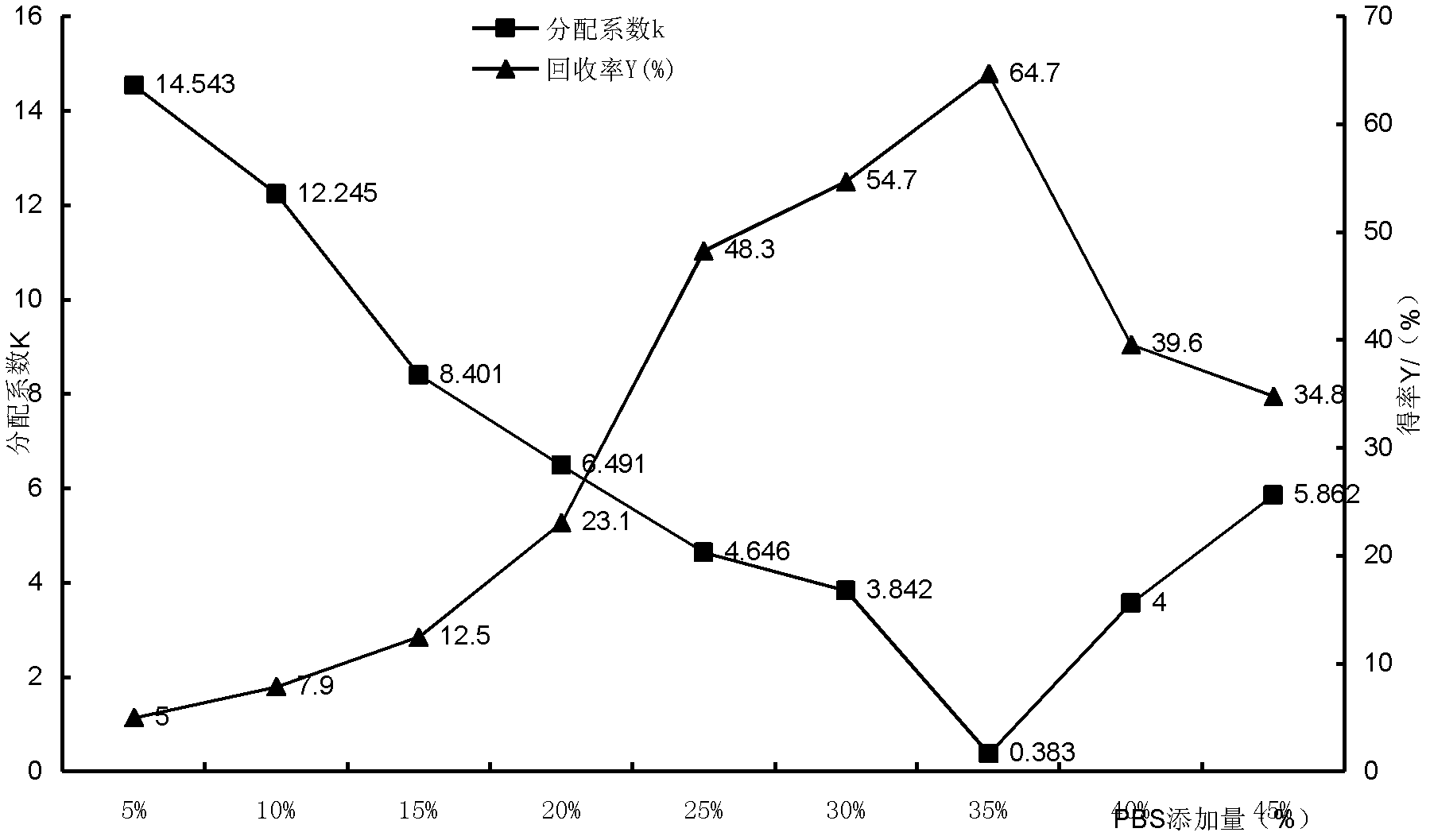

A method for separating and recovering chloroperoxidase

InactiveCN102277339AShort purification cycleSmall volume requirementMicroorganism based processesEnzymesAmount of substanceChemistry

The invention discloses a method for separating and recovering chloroperoxidase (Chloroperoxidase, EC 1.11.1.10, CPO), which utilizes co-precipitation and redissolution method, that is, hydrophilic polymer polyethylene glycol is precipitated and entrained at high salt concentration CPO molecules, so as to enrich the CPO protein concentration, and then use the two-phase extraction technology to efficiently separate and recover high-purity CPO, that is, to separate different proteins by using the different distribution coefficients of the separation target product and impurities in the hydrophilic polymer phase solution. The present invention proposes reasonable and feasible two-phase CPO extraction and purification conditions through research, summarizes the separation technology of micro-content bioactive substances, solves or improves the extraction interference, low recovery rate, high product price, and purification cycle existing in the current CPO production process. Long, can not scale production and other issues.

Owner:SHANGHAI NORMAL UNIVERSITY

Method for efficiently adsorbing arsenic in underground water by using nano iron oxide

ActiveCN109967051AImprove adsorption capacityImprove purification effectOther chemical processesWater contaminantsGroundwaterFerric

The invention discloses a method for efficiently adsorbing arsenic in underground water by using nano iron oxide. The method comprises the following steps of preparation of a mesoporous structure, preparation of the nano iron oxide with a particle diameter of less than 10 nanometers, formation of a resin-based nano iron oxide composite material, precipitation treatment, shaking treatment, adsorption wall adsorption purification, mixed centrifugal treatment and cleaning of the resin-based nano iron oxide composite material. The method for efficiently adsorbing the arsenic in the underground water by using the nano iron oxide has the advantages that the mesoporous structure prepared by adopting a rapid freezing method and the nano iron oxide prepared from powdery ferric trichloride can ensure the effect that the particle diameter of the nano iron oxide is less than 10 nanometers, the resin-based nano iron oxide composite material with the nano iron oxide with small particle diameter hashigh adsorption capacity for arsenic, thereby being capable of improving the purification function for the arsenic in the underground water as an adsorption wall, so that while the drinking safety isensured, economic popularization can also be achieved, and the method is suitable for water improvement in areas with quality-induced water shortage in northwest China, and has the advantages of highefficiency and low cost.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

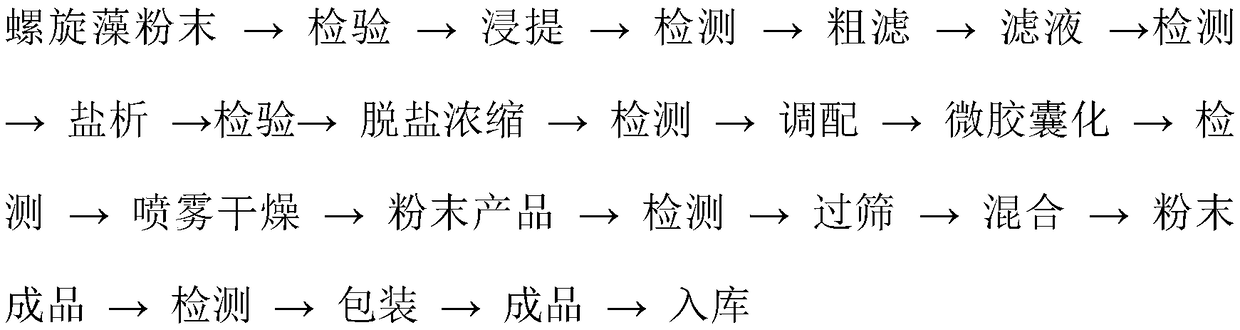

Preparation method of high-purity spirulina blue

ActiveCN108101980AHigh puritySimple preparation processPeptide preparation methodsDepsipeptidesFiltrationAllophycocyanin

The invention discloses a preparation method of high-purity spirulina blue. The preparation method is characterized by adopting spirulina powder as a raw material, and performing continuous productionincluding extraction, filtration, salting out, desalination concentration, micro-encapsulation, spray drying and mixing to obtain spirulina blue, which is blue powder. Phycocyanin is dark blue powder, is separated from spirulina, and looks beautiful. The main component of spirulina blue is phycocyanin, which belongs to porphyrin cyanophycin and is one of infrequent chromoproteins in the nature. The phycocyanin has bright color, is protein itself with abundant nutrients, has complete amino acid composition, and is high in amino acid content. The preparation method is short in production periodand doesn't cause secondary pollution. The obtained spirulina blue is high in purity, contains 71.3% of phycocyanin, has the purity A620 / A280 reach 3.6, and can meet the requirement of food and cosmetic industry.

Owner:JIANGXI DANXIA BIOTECHNOLOGY CO LTD

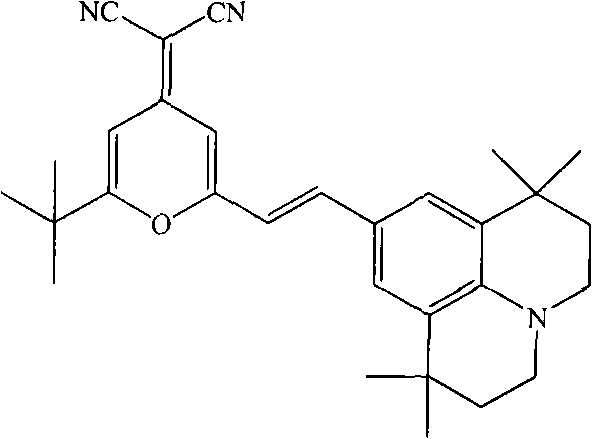

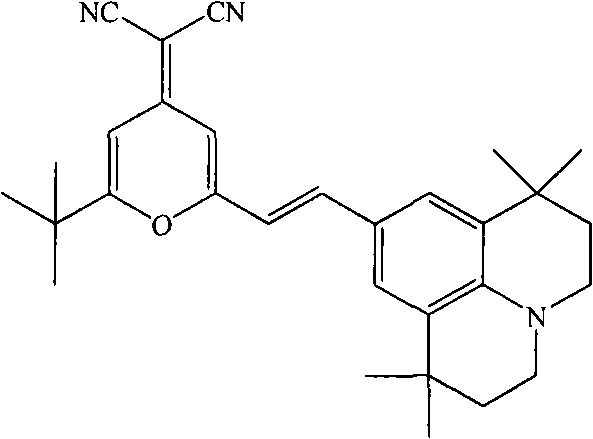

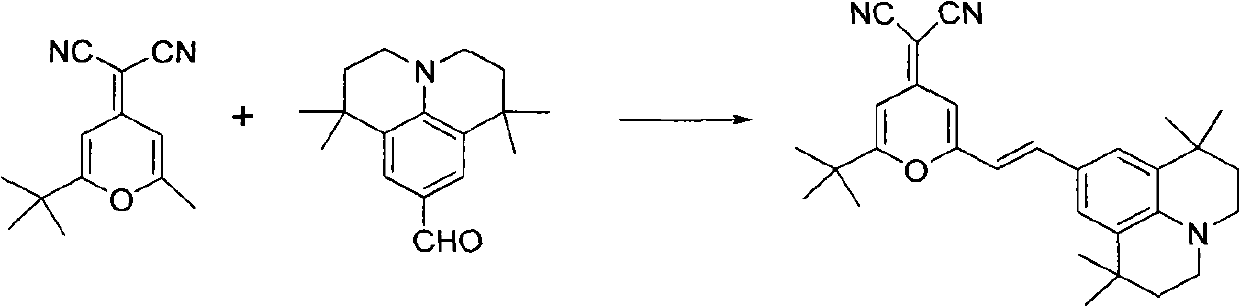

Method for synthesizing 4-(dicyanomethylene)-2-tert-butyl-6-(1,1,7,7-tetramethyljulolidin-4-yl-vinyl)-4H-pyran

The invention discloses a method for synthesizing 4-(dicyanomethylene)-2-tert-butyl-6-(1,1,7,7-tetramethyljulolidin-4-yl-vinyl)-4H-pyran. The structural formula of 4-(dicyanomethylene)-2-tert-butyl-6-(1,1,7,7-tetramethyljulolidin-4-yl-vinyl)-4H-pyran is shown in the specifications. The method comprises the following steps of: uniformly mixing 2-methyl-6-tert-butyl-4-dicyanomethylene-4H-pyran, 9-formyl-1,1,7,7-tetramethyljulolidine, glycerol and piperidine in the molar ratio of (1.5:1:100:3)-(1:1.5:120:5) at room temperature; adding the mixture into a microwave reactor; heating for 2-3 minutestill refluxing; cooling to room temperature; filtering; washing a filter cake with absolute alcohol and drying; and sublimating to obtain 4-(dicyanomethylene)-2-tert-butyl-6-(1,1,7,7-tetramethyljulolidin-4-yl-vinyl)-4H-pyran. The method is used for preparing 4-(dicyanomethylene)-2-tert-butyl-6-(1,1,7,7-tetramethyljulolidin-4-yl-vinyl)-4H-pyran.

Owner:XIAN MODERN CHEM RES INST

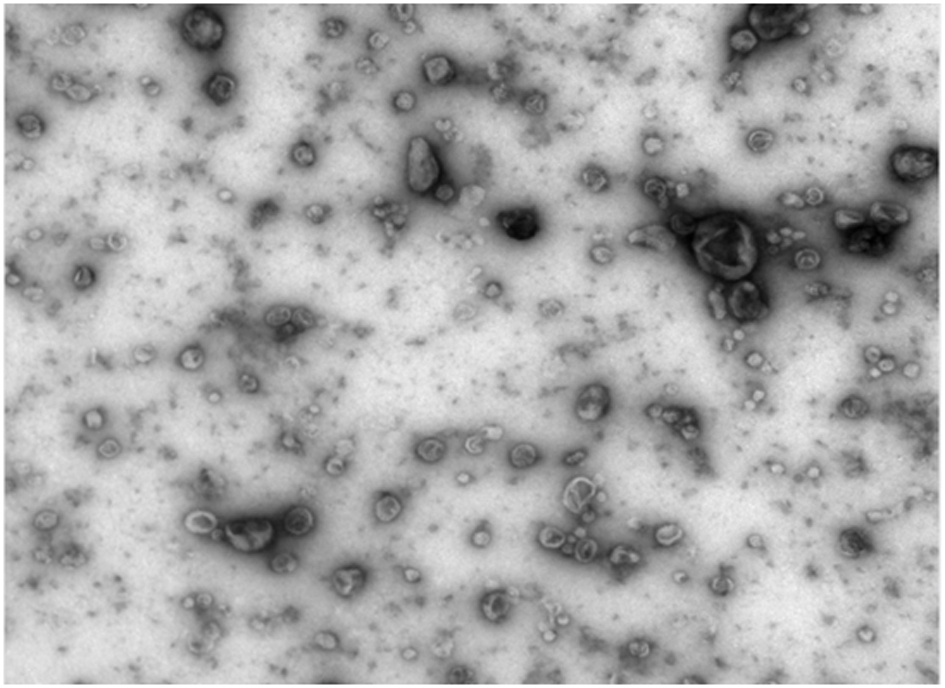

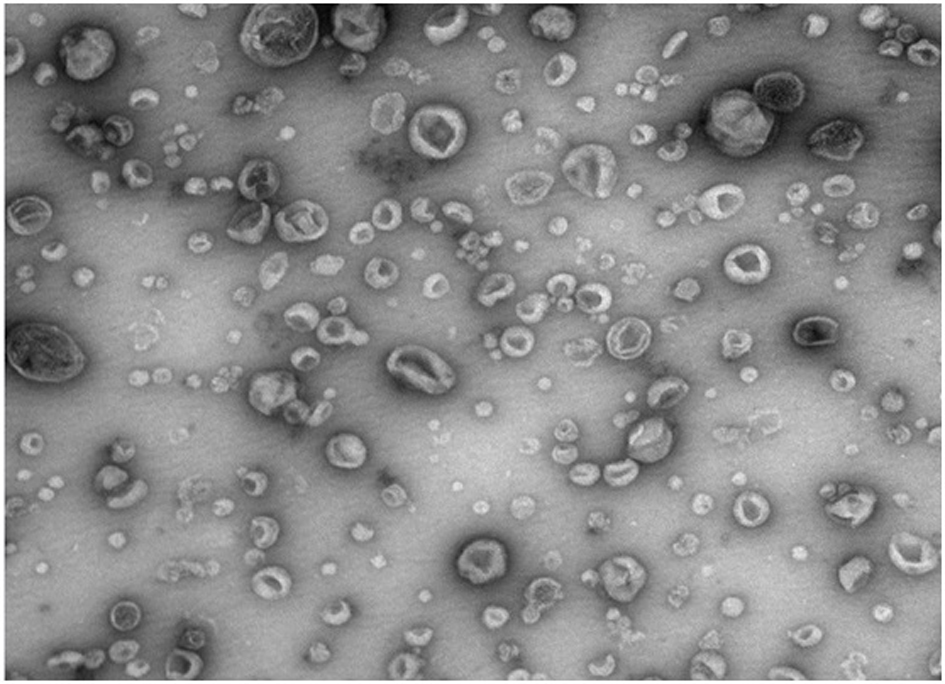

Exosome separation and purification method

PendingCN114591892ALow efficiencyImprove efficiencyCell dissociation methodsArtificial cell constructsMolecular sieveUltrafiltration

The invention relates to an exosome separation and purification method which comprises the following steps: taking a body fluid or a culture solution containing exosome, and carrying out anion exchange chromatography, cation exchange chromatography and molecular sieve chromatography to obtain a purified exosome solution. By means of the purification method, high-purity exosomes can be obtained with low cost and high efficiency even in large-scale exosome requirements; compared with the existing exosome purification methods such as a centrifugation method, a PEG polymer precipitation method, an affinity chromatography method, an ultrafiltration method and a molecular sieve size exclusion chromatography method, the method disclosed by the invention can be used for purifying exosomes with different volumes (100ml to 500L), especially milk-derived products with more impurity proteins, and also can be used for obtaining the milk-derived exosomes with the purity of 99 percent or more; meanwhile, the method has the advantages of low cost and high recovery rate, and can meet the requirements of industrial production.

Owner:九天览月生物科技(天津)有限公司

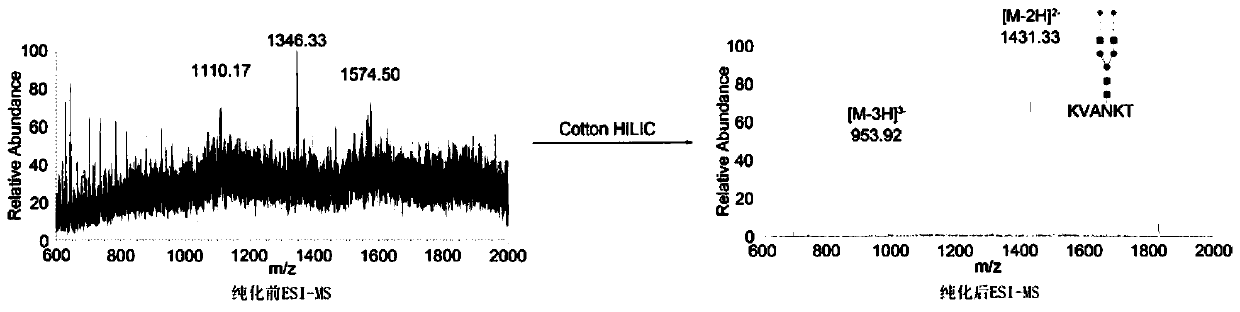

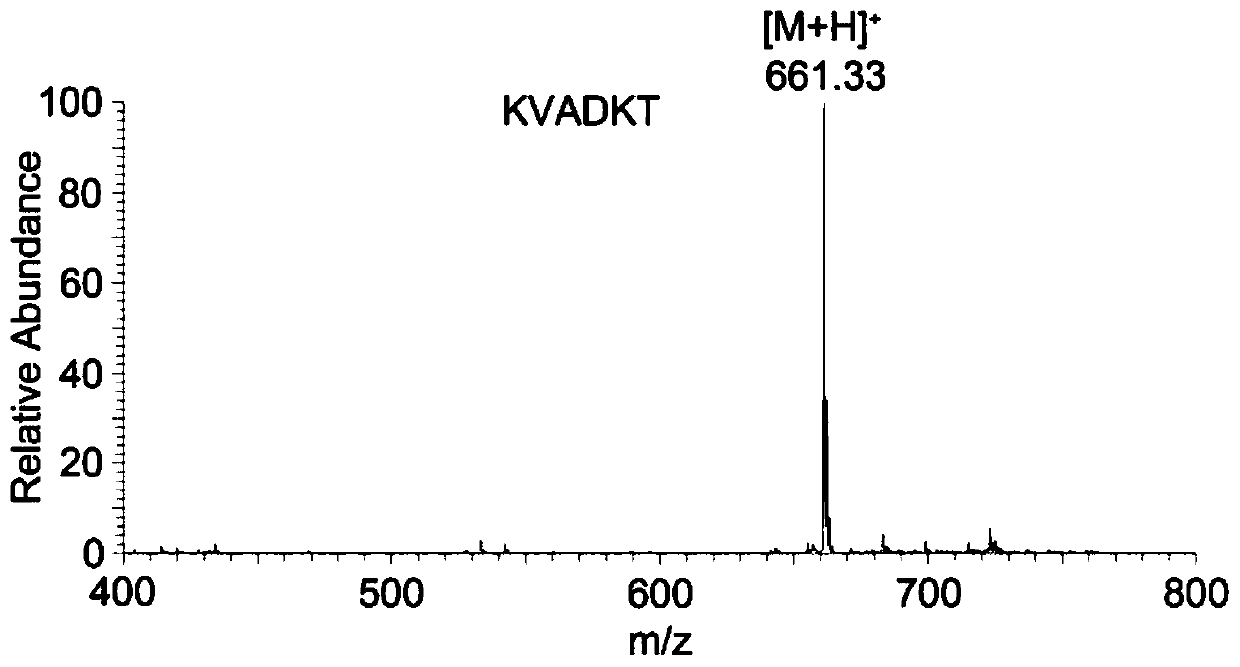

Method for preparing sialoglycopeptide (SGP) by large-scale separation and purification

ActiveCN109824762AImprove hydrophilic abilityHigh yieldPeptide preparation methodsAgainst vector-borne diseasesSialoglycopeptidesIon exchange

The invention discloses a method for preparing sialoglycopeptide (SGP) by large-scale separation and purification. The method comprises (1) taking fresh unfertilized egg yolk, treating with phenol, centrifuging to obtain a supernatant and lyophilizing to obtain coarse sialoglycopeptide; (2) filling a cotton hydrophilic chromatographic column with medical degreasing cotton; (3) adding a solution ofthe crude sialoglycopeptide to the cotton hydrophilic chromatographic column; (4) conducting gradient elution on the cotton hydrophilic chromatographic column with acetonitrile to remove salt and impurities and conducting elution and lyophilization on the glycopeptide with water to obtain pure sialoglycopeptide. According to the method, the cumbersome steps of Sephadex G-50 separation, Sephadex G-25 desalination, ion exchange chromatography purification and the like are omitted, the reaction conditions are mild, the experiment cost is reduced, the purification cycle is shortened, the efficiency is improved, and the purity of the sialoglycopeptide is 95% or above according to the purity detection. The method is not only suitable for enrichment of laboratory glycopeptide but also used for industrial production.

Owner:NORTHWEST UNIV(CN)

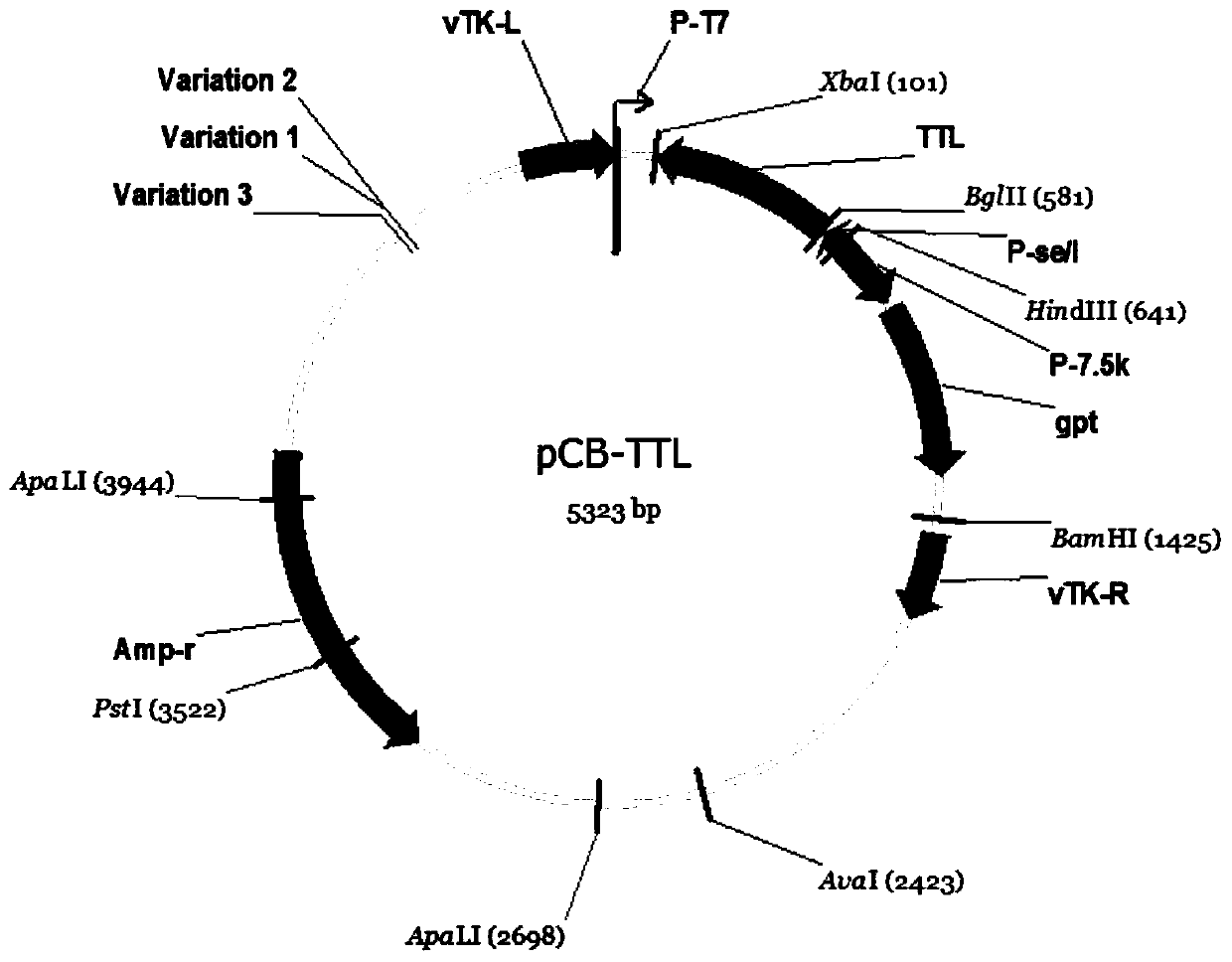

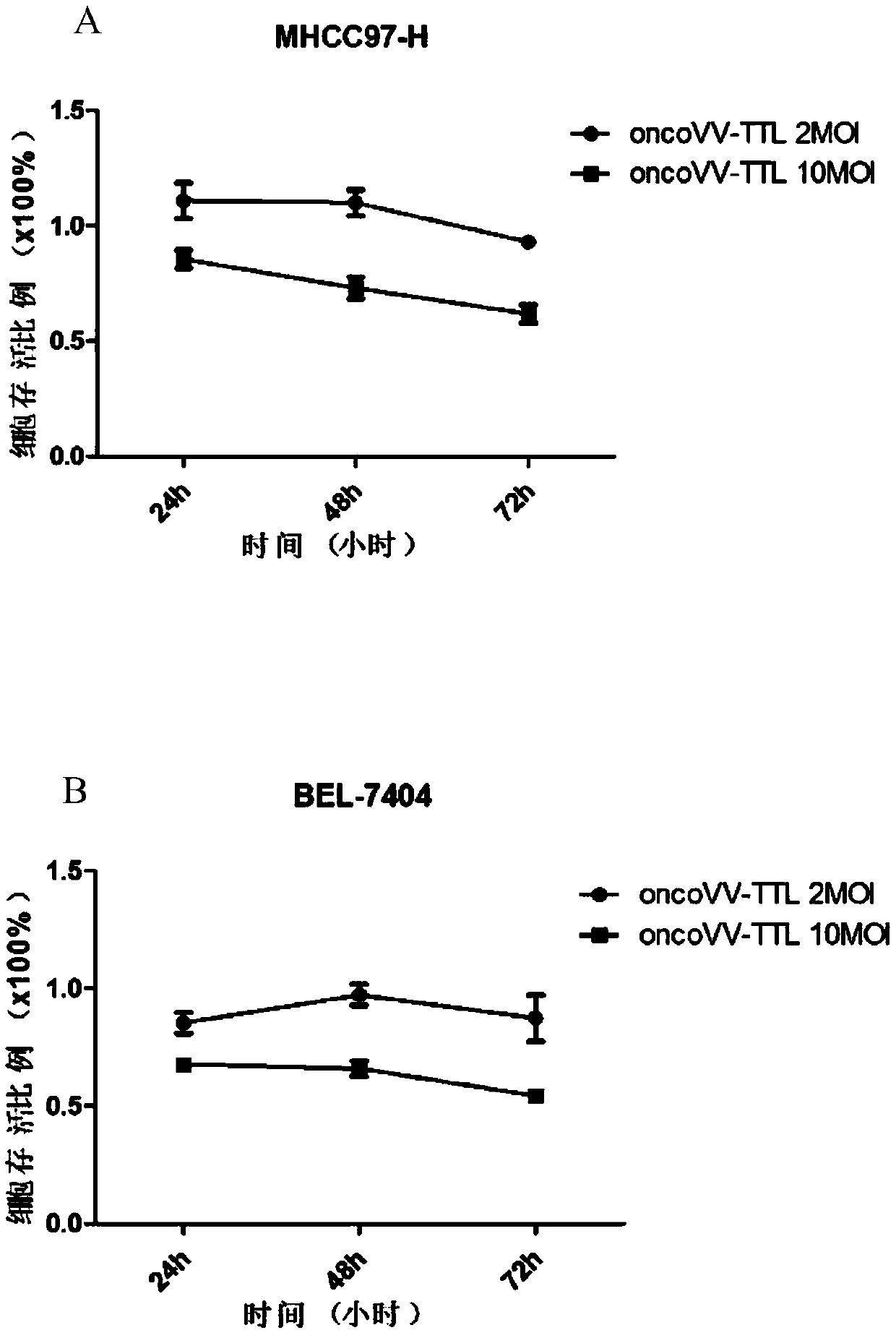

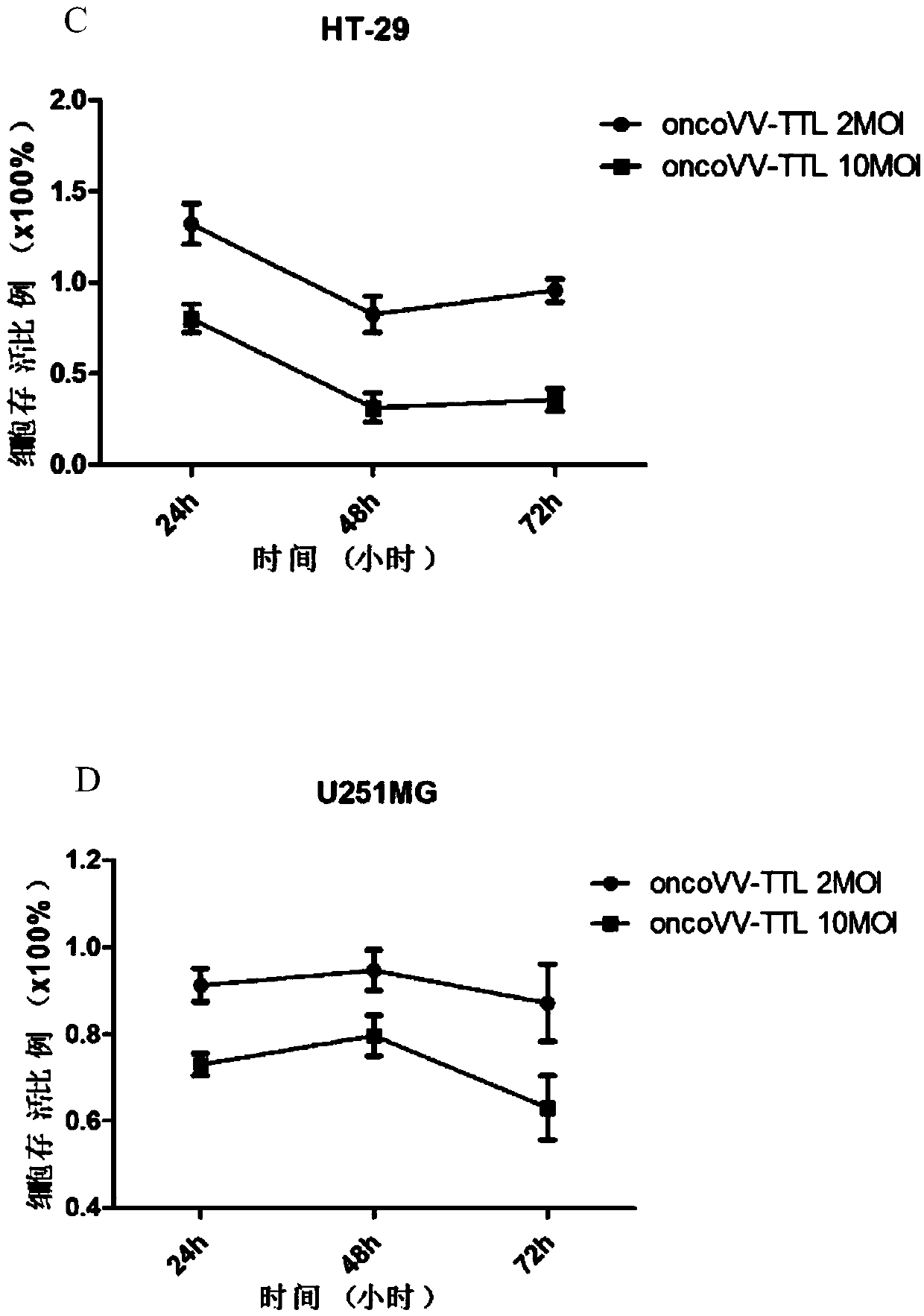

Oncolytic vaccinia virus carrying tachypleus tridentatus lectin gene, and construction method and application thereof

ActiveCN110564700AIncrease the level of replicationEasy to copyPeptide/protein ingredientsPeptidesA-DNATwo step

The invention relates to the technical field of biomedical engineering, and provides an oncolytic vaccinia virus carrying a tachypleus tridentatus lectin gene, and a construction method and an application thereof. The oncolytic vaccinia virus carries the tachypleus tridentatus lectin gene, and a DNA sequence of the tachypleus tridentatus lectin gene is shown as SEQ ID NO: 1; the construction method of the oncolytic vaccinia virus comprises the following two steps: (A) inserting gene sequences of tachypleus tridentatus lectin into pCB plasmids through Xba I and Bgl II loci to obtain pCB-TTL plasmids; and (B) recombining the pCB-TTL plasmid and the vaccinia virus in cells, after screening and identifying, obtaining the oncolytic vaccinia virus carrying the tachypleus tridentatus lectin gene.The oncolytic vaccinia virus disclosed by the invention not only has a remarkable inhibition effect on various tumor cells, but also can remarkably inhibit the antiviral factor level of the tumor cells and remarkably improve the ERK phosphorylation level, and is beneficial to virus replication; and in addition, the replication level of the oncolytic vaccinia virus carrying the TTL gene is also remarkably improved.

Owner:HANGZHOU GONGCHU BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com