Method for reducing content of Cu, Cd, Ni, Co and Sb in zinc hydrometallurgy zinc sulfate solution

The technology of zinc sulfate solution and zinc hydrometallurgy is applied in the fields of reducing Cu, Co, Cd, Sb content and Ni content in zinc sulfate solution of hydrometallurgical zinc, and can solve the problem of long impurity removal cycle, complicated procedure and poor product quality. and other problems, to achieve significant economic benefits and environmental protection value, short purification cycle, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

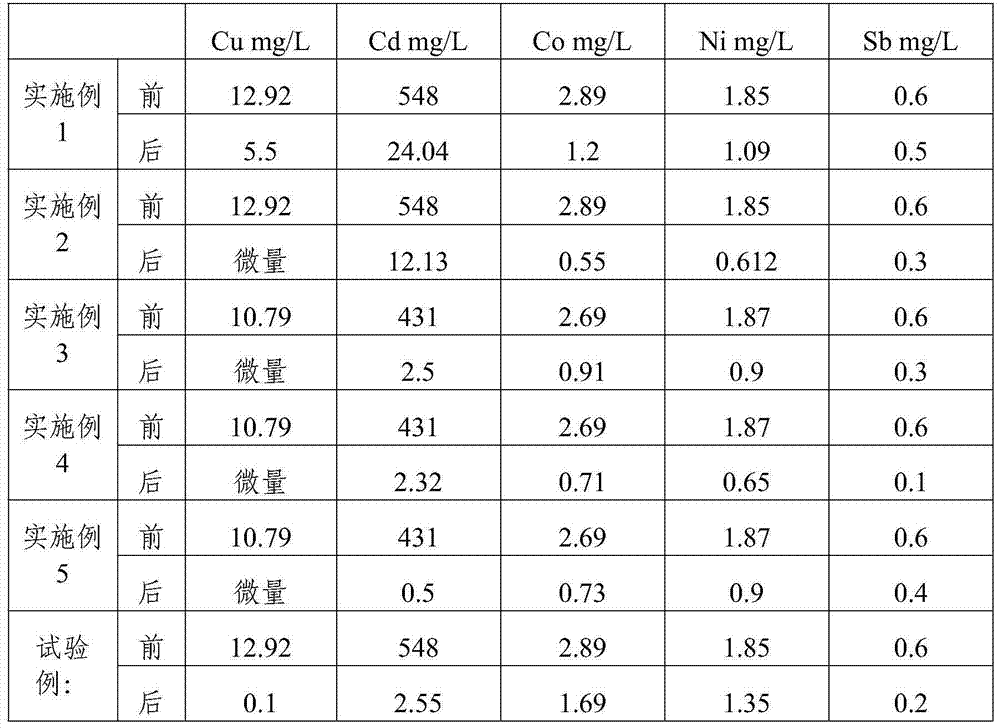

Embodiment 1

[0021] A method for reducing the content of Cu, Cd, Ni, Co, and Sb in the zinc sulfate solution of zinc hydrometallurgy, detecting the contents of Cu, Cd, Ni, Co, and Sb in the zinc sulfate solution of zinc hydrometallurgy, and recording the The measured contents of Cu, Cd, Ni, Co, and Sb are specifically 548mg / L of Cd, 0.6mg / L of Sb, 2.89mg / L of Co, 1.85mg / L of Ni, and 12.92mg / L of Cu; The pH value of the zinc sulfate solution in zinc hydrometallurgy is 3.5, and then it is heated up to a solution temperature of 55°C, and then a cobalt removal agent with a content of 1.35 times the sum of Ni and Co is added to it, and it is stirred for 1.5 hours , and then add zinc powder which is 3 times the sum of Cu, Cd, Ni, and Co content to it, then carry out stirring treatment for 1 hour, and then carry out filtering treatment.

[0022] The acidity of the sulfuric acid is PH=2.5.

[0023] For the stirring of adding the cobalt removal agent, the stirring speed is 50r / min.

[0024] For t...

Embodiment 2

[0029] A method for reducing the content of Cu, Cd, Ni, Co, and Sb in the zinc sulfate solution of zinc hydrometallurgy, detecting the contents of Cu, Cd, Ni, Co, and Sb in the zinc sulfate solution of zinc hydrometallurgy, and recording the The measured contents of Cu, Cd, Ni, Co, and Sb are specifically 548mg / L of Cd, 0.6mg / L of Sb, 2.89mg / L of Co, 1.85mg / L of Ni, and 12.92mg / L of Cu; The pH value of the zinc sulfate solution in zinc hydrometallurgy is 2.5, and then it is heated up to a solution temperature of 50°C, and then a cobalt removal agent with a content of 1.35 times the sum of Ni and Co is added to it, and it is stirred for 2 hours, Then add zinc powder which is 3.5 times the sum of Cu, Cd, Ni, and Co content to it, then carry out stirring treatment for 0.5h, and then carry out filtering treatment.

[0030] The acidity of the sulfuric acid is PH=3.

[0031] For the stirring of adding the cobalt removal agent, the stirring speed is 60r / min.

[0032] For the stirri...

Embodiment 3

[0037] A method for reducing the contents of Cu, Cd, Ni, Co and Sb in the zinc sulfate solution of zinc hydrometallurgy, detecting the contents of Cu, Cd, Ni, Co and Sb in the zinc sulfate solution of zinc hydrometallurgy, and recording the The measured content of Cu, Cd, Ni, Co, and Sb contains 431mg / L of Cd, 0.6mg / L of Sb, 2.69mg / L of Co, 1.87mg / L of Ni, and 10.79mg / L of Cu, and the wet method is adjusted by sulfuric acid The pH value of the zinc sulfate solution for zinc smelting is 3, and then it is heated to a solution temperature of 60°C, and then a cobalt removal agent with a content of 1.65 times the sum of Ni and Co is added to it, and it is stirred for 1.8 hours, and then Add zinc powder with a content of 3.3 times the sum of Cu, Cd, Ni, and Co to it, then stir it for 0.7h, and then filter it.

[0038] The acidity of the sulfuric acid is PH=3.5.

[0039] For the stirring of adding the cobalt removal agent, the stirring speed is 55 r / min.

[0040] For the stirring o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com