Separation method of sialoglycopeptide

A technology for the separation and separation of sialic acid sugars, applied in the field of separation and purification of glycopeptide compounds, which can solve the problems of short cycle, low cost, and many steps, and achieve the effects of stable purification method, shortened purification cycle, and improved purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Egg yolk pretreatment

[0039] First take 100 fresh unfertilized egg yolks (1.9 L), add an equal volume of deionized water to dilute, then add 1 / 5 volume (380 ml) of phenol / water (phenol:water volume ratio 9:1), 4 °C stirring was continued for 3 hours. Add 4.8 L of deionized water to the mixture, mix well and centrifuge (10000 g, 25 minutes), and concentrate the supernatant to 50 ml with a rotary evaporator to obtain a sample containing sialic acid glycopeptide.

[0040] 2. Sephadex G-50 separation

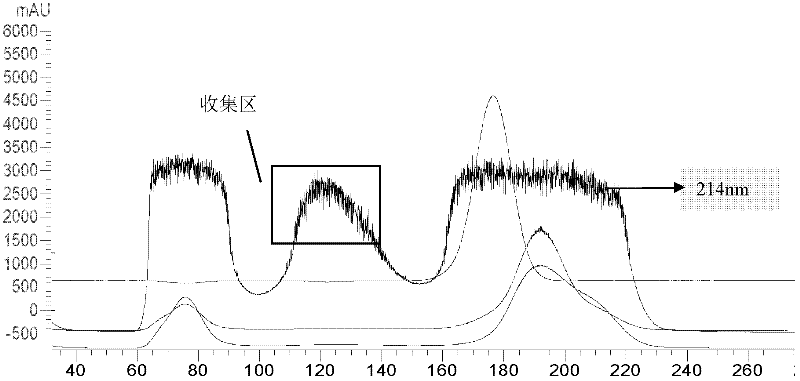

[0041] The Sephadex G-50 column (1.6cm×100cm) was connected with a fast liquid chromatograph, using 0.1M NaCl as the eluent, the flow rate: 1ml / min, and the ultraviolet detection wavelength: 214nm. Place the column in an incubator at a temperature of 25°C. Add 2ml of the sample described in step 1, and collect the 110-140ml sample of the eluent, such as figure 1 As shown, collect the sample marked "Collection Area".

[0042] 3. Concentrate the eluate and desalt and ...

Embodiment 2

[0053] 1. Egg yolk pretreatment

[0054] First take 100 fresh unfertilized egg yolks (1.9L), add an equal volume of deionized water to dilute, then add 1 / 5 volume (380ml) of phenol / water (volume ratio 9:1), and keep stirring at 4°C for 3 Hour. Add 4.8 L of deionized water to the mixture, mix well and centrifuge (10000 g, 25 minutes), and concentrate the supernatant to 50 ml with a rotary evaporator to obtain a sample containing sialic acid glycopeptide.

[0055] 2. Sephadex G-50 separation

[0056] The Sephadex G-50 column (1.6cm×100cm) was connected with a fast liquid chromatograph, using 0.1M NaCl as the eluent, the flow rate: 1ml / min, and the ultraviolet detection wavelength: 214nm. Place the column in an incubator at a temperature of 23°C. Add 2.5ml of the sample described in 1 above, and collect the 110-140ml sample of the eluate.

[0057] 3. Concentrate the eluate and desalt and purify it with an activated carbon column

[0058] Put 50 ml of the eluent into a 100 ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com