Method for separation and purification of nanobody

A technology for separation and purification of nanobodies, applied in the biological field, can solve the problems of increasing downstream purification pressure, low purity and high cost of nanobodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Purification of Nanobodies from E. coli periplasmic proteins.

[0031] Obtain the sample to be purified (Escherichia coli intracellular protein): Escherichia coli expression strain in 5L B. Nanobody A was produced in a stirred glass bioreactor, and the nanobody was induced by 1mM IPTG for periplasmic expression. The cell culture medium was centrifuged at 4°C and 8000rpm for 20min to collect the bacteria, resuspend the bacteria, and use ultrasonic The cells were broken, centrifuged at 12000 rpm for 20 min, and the supernatant was collected, filtered and sterilized through a 0.22 μm filter membrane, and then used for subsequent nanobody purification as a sample to be purified.

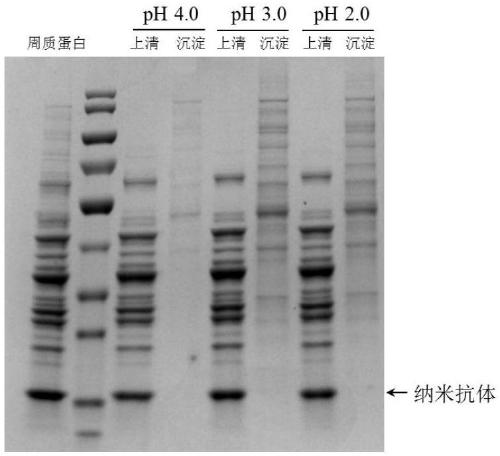

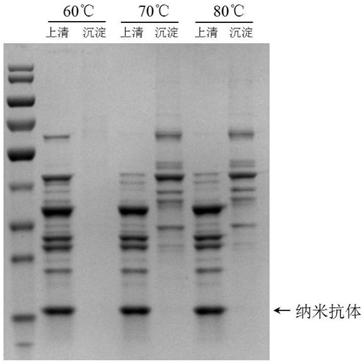

[0032] 1) Precipitation of impurity proteins at low pH: Take 30mL×3 parts of the sample to be purified, and adjust the pH to 2.0, 3.0, and 4.0 with 2mol / L acetic acid solution respectively. As three experiments, the following steps were carried out separately: Set aside for 2h, centrif...

Embodiment 2

[0035] Example 2 Purification of Nanobodies from Escherichia coli periplasmic proteins.

[0036] Repeat Example 1, the difference from Example 1 is that the preparation method for obtaining the sample to be purified (Escherichia coli periplasmic protein) in this example is: the Escherichia coli expression strain is B Produce nanobody B in a stirred glass bioreactor, use 1mM IPTG to induce periplasmic expression of nanobody, centrifuge the cell culture medium at 4°C and 4000×g for 20min, collect the bacteria, and then resuspend and extract the bacteria The periplasmic protein was filtered and sterilized by a 0.22 μm filter membrane and used for subsequent nanobody purification as a sample to be purified. The pH precipitation condition is 3.0, the high temperature precipitation condition is 70 ℃, all the other operations are the same as in Example 1, the results are shown in Figure 4 , the purification effect of Nanobody B is good, and a relatively pure target protein can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com