Micro-sample preparation device for frozen electron microscope and sample preparation method

A technology of cryo-electron microscopy and sample preparation, applied in measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve problems such as large sample consumption, carbon film rupture, and poor volume controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

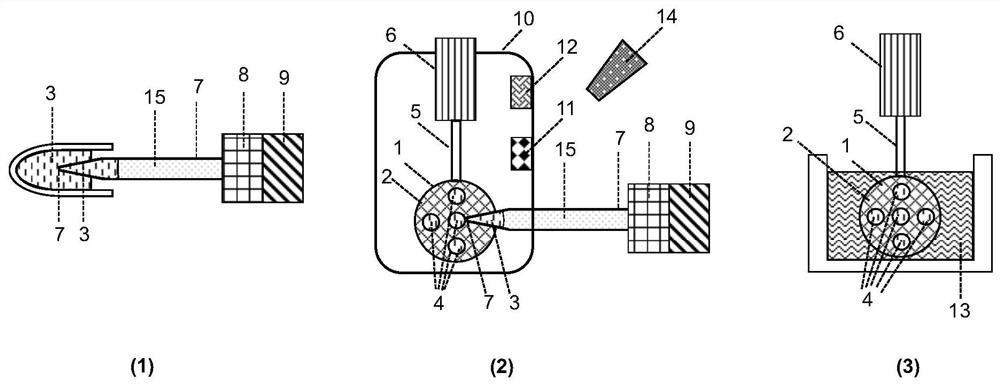

[0067] figure 1 It is a schematic diagram of the structure and sample preparation operation of the device for micro-sample preparation for cryo-electron microscopy in Example 1.

[0068] Sample solution 3 is a ferritin solution, and the sample solution is added to a small centrifuge tube. Using a glass capillary as the sample preparation probe 7, first draw the sample preparation probe 7 in a butane flame to obtain a sample preparation probe 7 with a pointed tip, and then treat the cleaned sample preparation probe 7 with a surface treatment reagent , to obtain the sample preparation probe 7 whose inner and outer surfaces are both hydrophobic. The sample preparation probe 7 uses paraffin oil 15 as a carrier liquid. The sample preparation probe 7 is connected to the liquid driving device 8 composed of a 10 microliter syringe and a precision syringe pump, and then installed on the three-dimensional translation platform 9 to form a liquid droplet manipulation robot. Tweezers ar...

Embodiment 2

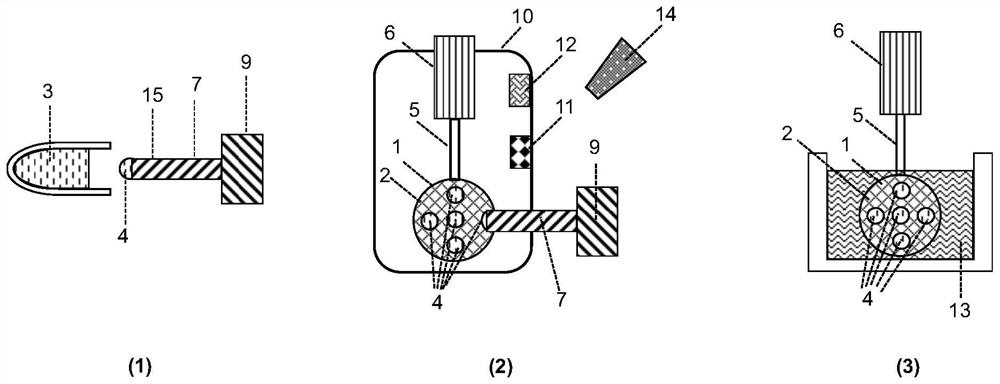

[0073] figure 2 It is a schematic diagram of the structure and sample preparation operation of the device for micro-sample preparation for cryo-electron microscopy in Example 2.

[0074] Add sample solution 3 (transferrin solution) to a microcentrifuge tube. A solid metal needle is used as the sample preparation probe 7, the tip of the sample preparation probe 7 is flat, slotted or other shaped structure that is conducive to carrying the sample solution 3, and the region other than the tip of the sample preparation probe 7 is treated with a hydrophobic reagent to obtain A sample preparation probe with a hydrophilic tip7. The sample preparation probe 7 is installed on the three-dimensional translation platform 9 to form a liquid droplet manipulation robot. Tweezers are used as the copper mesh clamping device 5 for fixing the copper mesh 2, and a motor-driven synchronous belt slide table is used as the copper mesh quick transfer device 6. A transparent acrylic plate is used ...

Embodiment 3

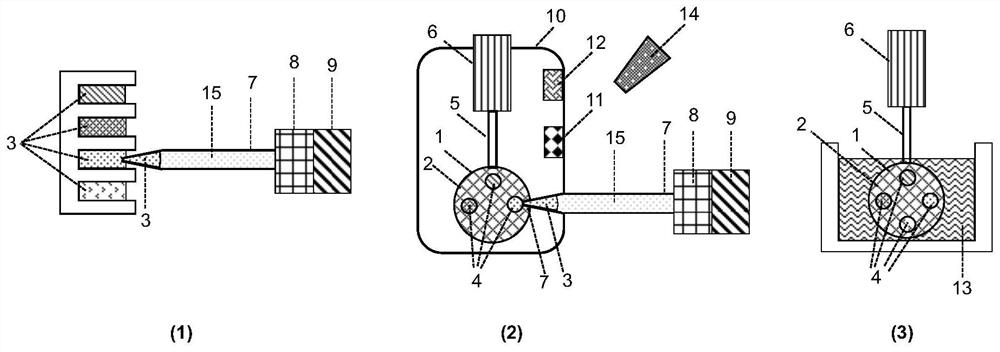

[0078] image 3 Schematic diagram of the structure and sample preparation operation of the device for micro-sample preparation for cryo-electron microscopy in Example 3

[0079] Four kinds of different sample solutions 3 to be tested are installed in four holes of a 384-well plate respectively, and ultrapure water is loaded in another hole ( image 3not shown in ). Using a glass capillary as the sample preparation probe 7, first draw the sample preparation probe 7 in a butane flame to obtain a sample preparation probe 7 with a pointed tip, and then treat the cleaned sample preparation probe 7 with a surface treatment reagent , to obtain the sample preparation probe 7 whose inner and outer surfaces are both hydrophobic. The sample preparation probe 7 uses paraffin oil as the carrier liquid. The sample preparation probe 7 is connected to the liquid driving device 8 composed of a 10 microliter syringe and a precision syringe pump, and then installed on the three-dimensional tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com