Purification method of polyethylene glycol recombinant human granulocyte colony-stimulating factor

A technology of PEGylation and stimulatory factors, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problem of low purity of PEG-G-CSF, which can only reach 95% or 90%. and other problems, to achieve the effect of short purification cycle, easy operation and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Step 1, PEG-G-CSF modified product buffer replacement

[0044] The PEG-G-CSF modified product was clarified and filtered through a 0.45 μm filter element (CVHL71TP3) to obtain a clarified reaction solution;

[0045] 20mmol / L acetic acid-sodium acetate, pH4.0 buffer balance hollow fiber column UFP-10-E-55 and hollow fiber system FlexStand;

[0046] Pump the clarified reaction solution into the storage tank of the FlexStand hollow fiber system, start the system, adjust the return valve, and control the transmembrane pressure (TMP) at 20-30PSI;

[0047] Use 20mmol / L acetic acid-sodium acetate, pH4.0 buffer as the replacement solution, and replace with a constant volume, so that the rate of the replacement solution added is the same as that of the permeate, and the volume of the sample is kept constant in the hollow fiber system storage tank. The replacement ends when the dosage is about 5 times the volume of the sample;

[0048] Samples were collected from the bottom val...

Embodiment 2

[0060] Step 1, PEG-G-CSF modified product buffer replacement

[0061] Same as Example 1: Step 1

[0062] Step 2, SP Sepharose HP column chromatography purification of PEG-G-CSF crude product

[0063] Equilibrate the SP Sepharose HP chromatography column with 20mmol / L acetic acid-sodium acetate, pH4.0 buffer solution, flow rate 60cm / h, equilibrate 5 times the column volume, until the UV and conductivity are stable;

[0064] Load the PEG-G-CSF crude product at a flow rate of 40cm / h;

[0065] After loading the sample, wash the chromatography column with 20mmol / L disodium hydrogen phosphate-citric acid, pH4.5 buffer solution for 5 times the column volume, and the flow rate is 70cm / h;

[0066] Use 20mmol / L disodium hydrogen phosphate-citric acid, pH4.5 solution as solution A, take 20mmol / L disodium hydrogen phosphate-citric acid, pH8.0 solution as solution B, use from 0% to 100% B solution The sample was eluted with a linear gradient at a flow rate of 70 cm / h, the gradient volum...

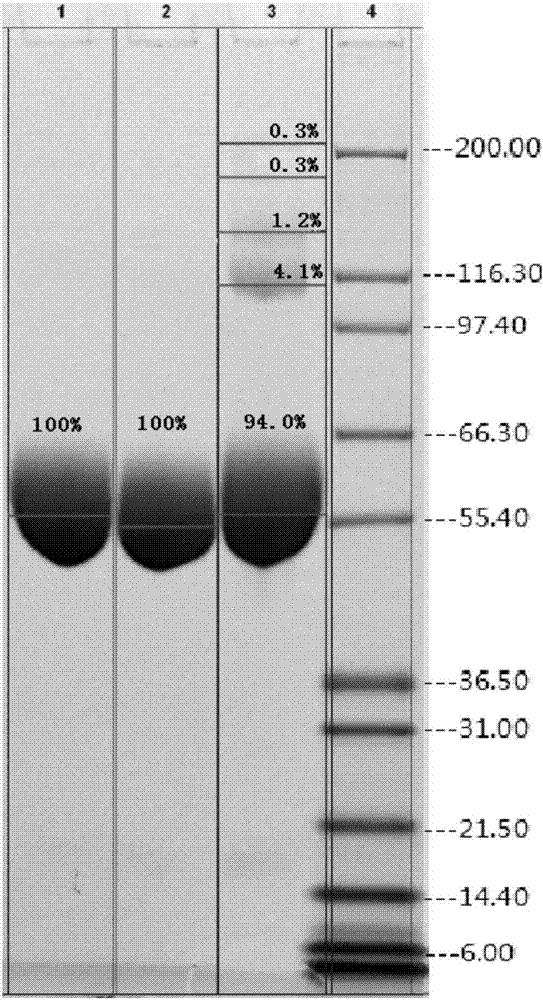

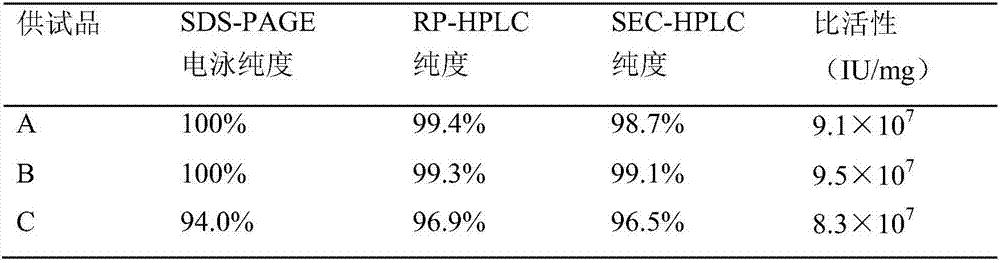

Embodiment 3

[0070] Step 1, PEG-G-CSF modified product buffer replacement

[0071] Same as Example 1: Step 1

[0072] Step 2, SP Sepharose HP column chromatography purification of PEG-G-CSF crude product

[0073] Operate according to the purification conditions in CN101172161B embodiment three, first wash 5 times the volume with 0.5M NaOH solution, then wash with purified water to neutrality, then balance the SP Sepharose HP layer with 20mmol / L acetic acid-sodium acetate, pH4.0 buffer solution Analysis column, flow rate 120cm / h, equilibrate 5 times the column volume, until the UV and conductivity are stable;

[0074] Load the crude PEG-G-CSF at a flow rate of 120cm / h;

[0075] After the sample loading is completed, wash the chromatography column with 20mmol / L acetic acid-sodium acetate, pH4.0 buffer solution for 10 times the column volume, and the flow rate is 120cm / h;

[0076] Use 20mmol / L acetic acid-sodium acetate, pH4.0 solution as solution A, and 20mmol / L acetic acid-sodium acetate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com