Patents

Literature

81results about How to "High and stable yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

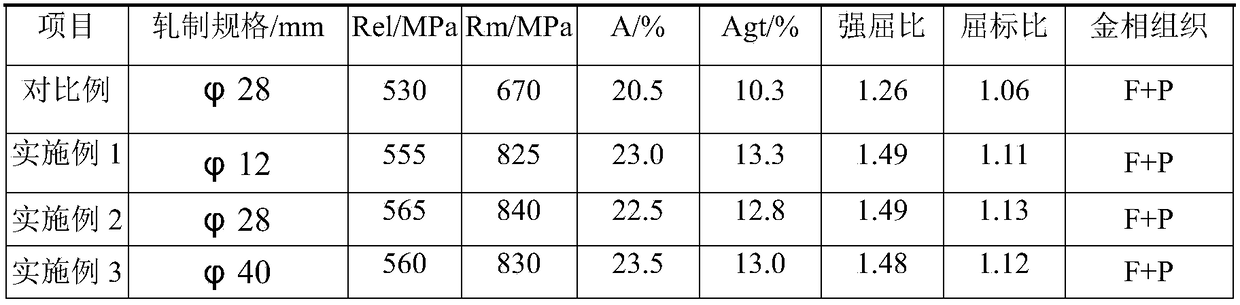

500MPa-grade aseismic microalloy steel bar containing V and Nb and having high strength-yield ratio and production method thereof

The invention belongs to the field of iron and steel metallurgy and steel rolling, particularly relates to a 500MPa-grade aseismic microalloy steel bar containing V and Nb and having a high strength-yield ratio and a production method thereof, and aims to solve the technical problem of low strength-yield ratio of the existing 500MPa-grade aseismic alloy steel bar containing vanadium and nitrogen.The aseismic steel bar containing V and Nb is prepared from the following components: 0.20-0.25% of C, 0.35-0.65% of Si, 1.20-1.60% of Mn, 0.040-0.080% of V, 0.010-0.030% of Nb and 0.0250-0.0350% of N. FeV is added in a steel tapping process and is used for controlling the content of V; cored wires containing Nb and N are fed in a refining process of a ladle furnace (LF), so that the contents of Nb and N can be adjusted; meanwhile, a subsequent rolling process is matched. The produced steel bar is high in lower yield strength surplus and excellent in aseismic performance; the strength-yield ratio of the steel bar reaches 1.40 or above.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for adding rare earth into RH refining furnace

The invention relates to a method for adding rare earth into RH refining furnace. The method is characterized in that rare earth lanthanum ferroalloy is added into a RH refining station vacuum feeding bin; molten steel, which satisfies the condition that total oxygen content T.O is less than or equal to 0.002 wt%, active oxygen content a [O] is less than or equal to 0.0005 wt% and [S] content is less than or equal to 0.005 wt% in steel, undergoes vacuum treatment at the RH refining station for 10 min or more than 10 min; and according to the calculated addition of rare earth, rare earth lanthanum ferroalloy is added into a vacuum chamber from the vacuum feeding bin, wherein the addition of the rare earth is controlled within the range of 0.005-0.015 wt%. The invention has the following advantages: by the adoption of the method, the yielding rate of rare earth is high and stable; continuous casting production is smooth; rare earth in steel is uniformly distributed; by the adoption of the rare earth lanthanum ferroalloy, performance of steel is substantially improved; the method requires low cost and is simple to operate; metallurgical effects of rare earth microalloyed steel are obvious; and the method has an extensive popularization and application prospect.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Chinese medicine composition containing multi glossy ganoderma active constituents and its preparing method

InactiveCN1891240AStrong medicinal effectIncrease contentPowder deliveryDigestive systemSporeTriterpene

The present invention belongs to the field of Chinese medicine technology, in the concrete, it relates to a Chinese medicine composition containing several ganoderma effective components and its preparation method. Said invention uses Chinese medicinal material ganoderma as main raw material, and adopts the processes of dynamic extraction and spray-drying, then detects the contents of several ganoderma effective components and yield of ganoderma extract, and adds the wall-broken ganoderma spore, and uses the contents of 3-50% of ganoderma polysaccharide, 0.2-10% of triterpene and 0.1-15% of polysaccharide peptide as quality standard. The invented Chinese machine composition can be made into powder preparation, capsule preparation, tablet preparation and soft capsule preparation.

Owner:西安道隆实业有限公司 +1

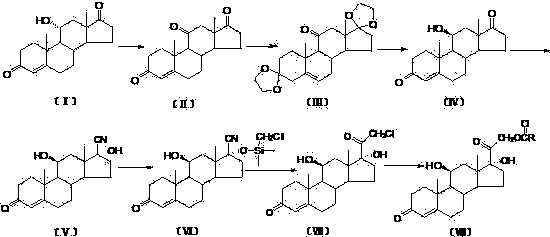

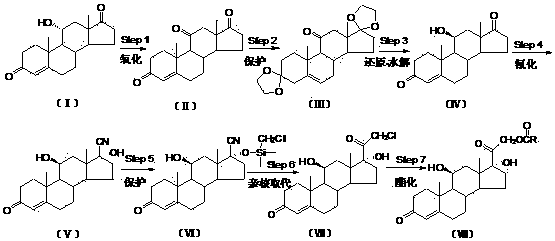

Preparation method of hydrocortisone acetate or analogue thereof

Owner:HUNAN NORCHEM PHARMACEUTICAL CO LTD

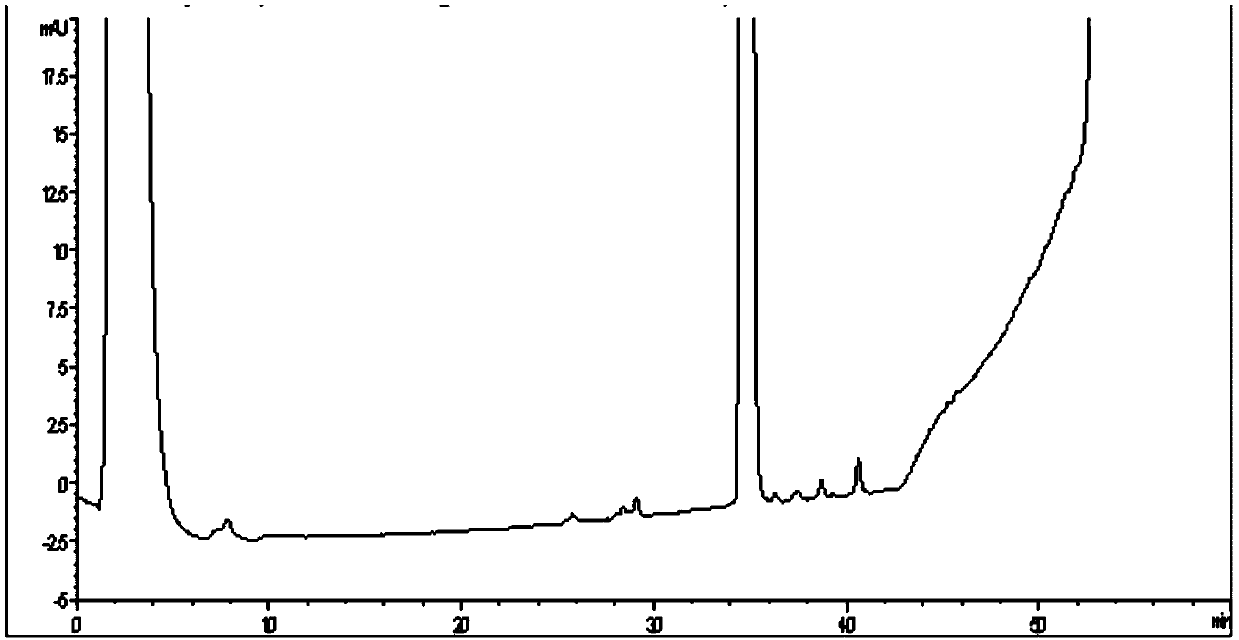

Separation and purification method for dalbavancin

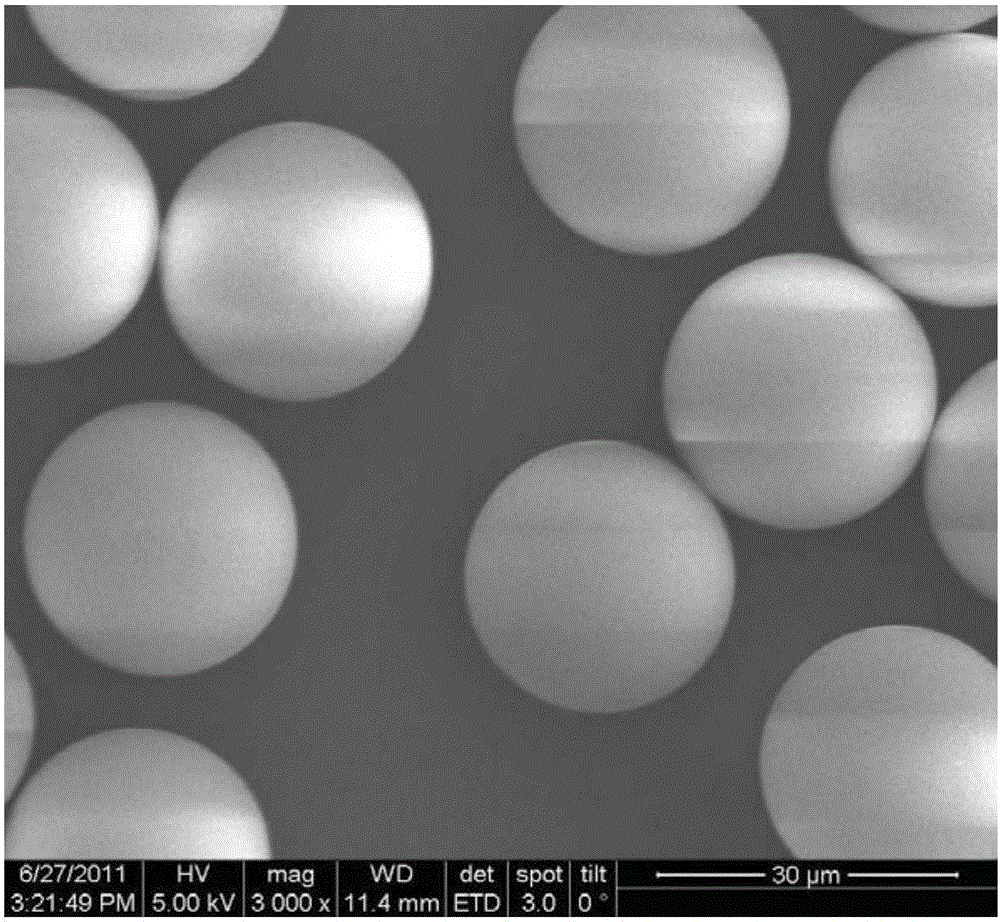

ActiveCN105001309ANo pollution in the processLow costPeptide preparation methodsPurification methodsOrganic solvent

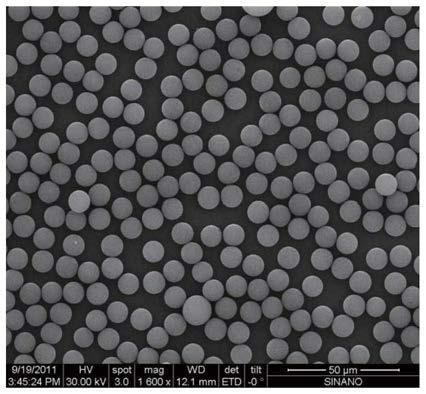

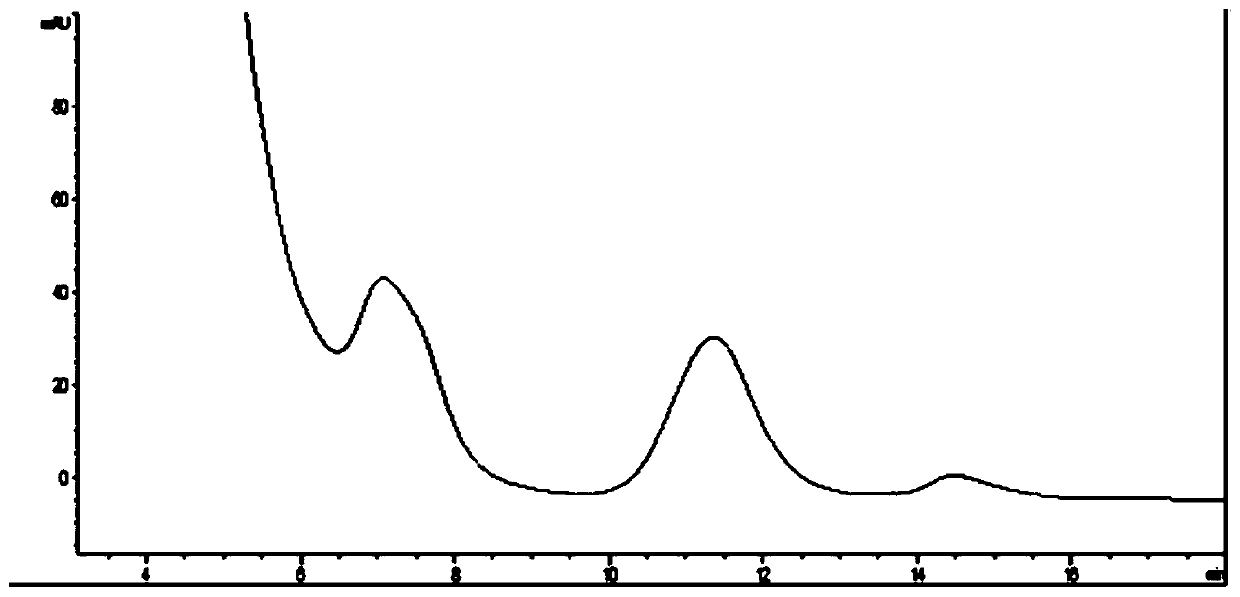

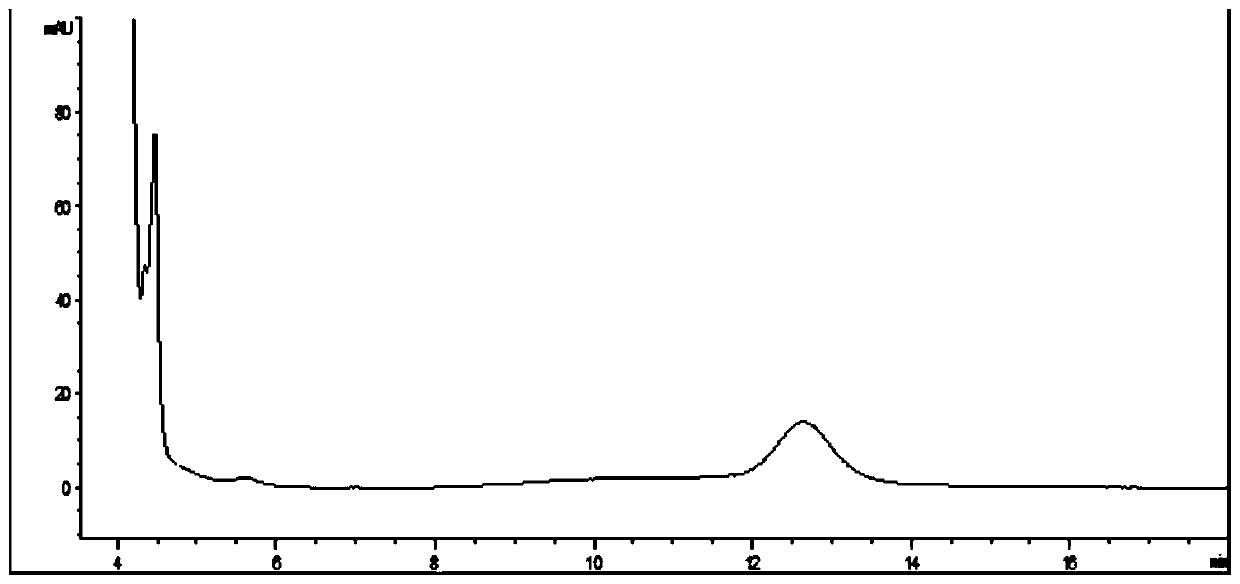

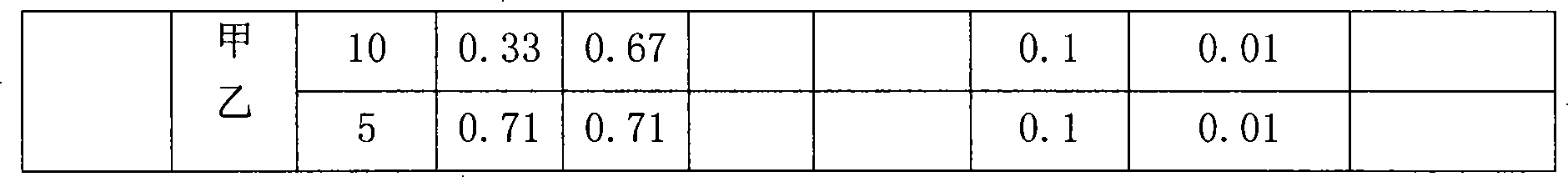

The invention provides a separation and purification method for dalbavancin. The method comprises the following steps: dissolving and filtering a crude dalbavancin extract; loading a sample of a crude solution obtained after filtering into a chromatographic column equipped with polystyrene high-molecular polymer microspheres for chromatography; carrying out gradient elution on a target product with an aqueous phosphoric acid solution and an organic solvent as mobile phases; and collecting solutions with a target peak value in sections and combining constituent solutions meeting requirements. The separation and purification method is simple, can realize large-scale production and has a high and stable recovery rate.

Owner:CHANGSHU NANOMICRO BIOTECHNOLOGY CO LTD

Method for controlling aluminum component in steel

InactiveCN102021276AReduce entryReduce deoxygenation burdenProcess efficiency improvementMolten steelMolten slag

The invention belongs to the technical field of ferrous metallurgy and relates to a method for controlling an aluminum component in steel. In order to solve technical problems, the invention provides the method for precisely and stably controlling the aluminum component in steel, particularly the aluminum component in low-carbon aluminium steel. The control method comprises the following steps of: A, smelting in an electric furnace or a converter, wherein the primarily smelted molten steel is deoxidized by aluminum after the molten steel is discharged; B, low-frequency (LF) refining; and C, continuous casting. The control method is characterized in that: in the LF refining process, the adding amount of slag is 12 to 14Kg per ton of steel during slagging; and based on 100 weight parts, the slag mainly comprises the following components in part by weight: 60 to 68 parts of CaO, 15 to 20 parts of Al203, more than zero part and less than or equal to 5.0 parts of SiO2, more than zero part and less than or equal to 3.0 parts of MgO and 10 to 15 parts of CaF2. When the control method is used, the activity of SiO2 in the slag can be reduced, and the probability of reaction between aluminum in the steel and SiO2 in the slag can be reduced, so that the aluminum component in the molten steel is precisely controlled and the desulfurization rate of the molten slag is also improved at the same time.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Formula and preparation method of aluminum type aluminum alloy additive

The invention discloses a formula and a preparation method of an aluminum type aluminum alloy additive. The additive comprises, by weight, 80-85% of metal powder, 14-18% of aluminum powder, 1-1.5% of aluminum stearate and 0.5-1% of aluminum-magnesium powder. The metal powder is any one of iron, manganese, copper, titanium and chromium. The purity of the metal powder is larger than or equal to 98%, the average grain diameter of the powder ranges from 0.01 mm-0.5 mm, the purity of the aluminum powder is larger than or equal to 96%, and the average grain diameter of the power ranges from 0.01 mm-0.5 mm. The metal powder, the aluminum powder, the aluminum stearate and the aluminum-magnesium powder are evenly mixed and pressed into blocks through an oil press, and the blocks are packaged with aluminum foil to form finished products. The addition method is simple, and the additive rapidly fuses at the normal temperature of aluminum alloy melting, no fusing agent exists, and influences on the environment are small. The casting yield is high and stable, and components of melt are easy to control.

Owner:正邦(福建)冶金材料有限公司

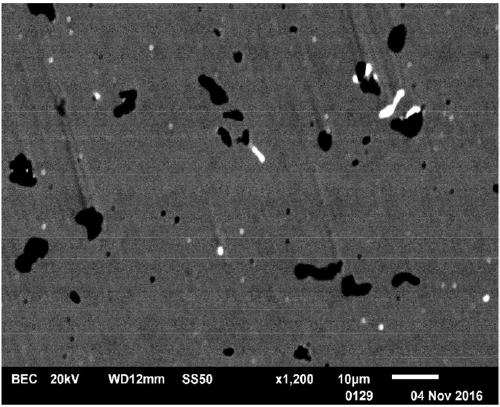

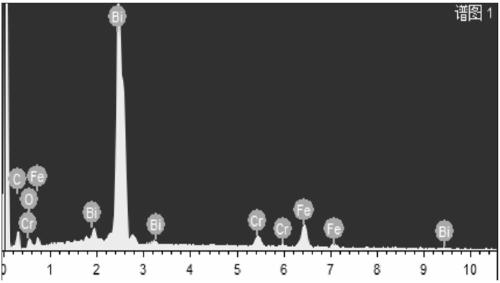

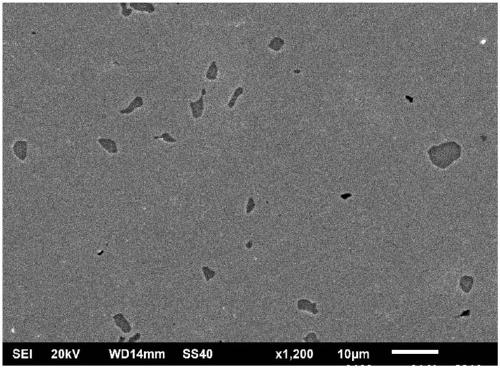

Method used for realizing dispersion uniform distribution of bismuth element in alloy steel containing bismuth

The invention discloses a method used for realizing dispersion uniform distribution of bismuth element in alloy steel containing bismuth. The method comprises following steps: 1) molten iron is subjected to desulfuration; 2) converter smelting is performed, aluminum iron alloy and ferro-silicon alloy are added successively after steel tapping, and then a ladle slag modifier is added for ladle slag modification; 3) ladle slag is refined; 4) an alloy feed pipe made of a fire resistant material is inserted into steel liquid level so as to be 100 to 300mm below of the steel liquid level, and metal bismuth element, which possesses a low melting point, and granularity of 3 to 30nm, and is easy to gasify, is added into the molten iron using the alloy feed pipe, wherein adding amount of bismuth element is 0.5kg / t.s or less; 5) argon is taken as a bottom blowing gas of steel ladle, wherein intensity of argon is controlled at 30 to 100l / min.ts; and 6) a continuous casting platform is used for casting, protective atmosphere pouring is adopted for the whole course, and weak electromagnetic stirring is adopted in a secondary cooling section. The method is high in yielding rate; is capable of diffusing bismuth element in steel, so that uniform distribution is realized, excellent steel comprehensive properties are obtained, and properties of every parts of steel are uniform; and can be widely used in the field of molten steel smelting technology.

Owner:武汉钢铁有限公司

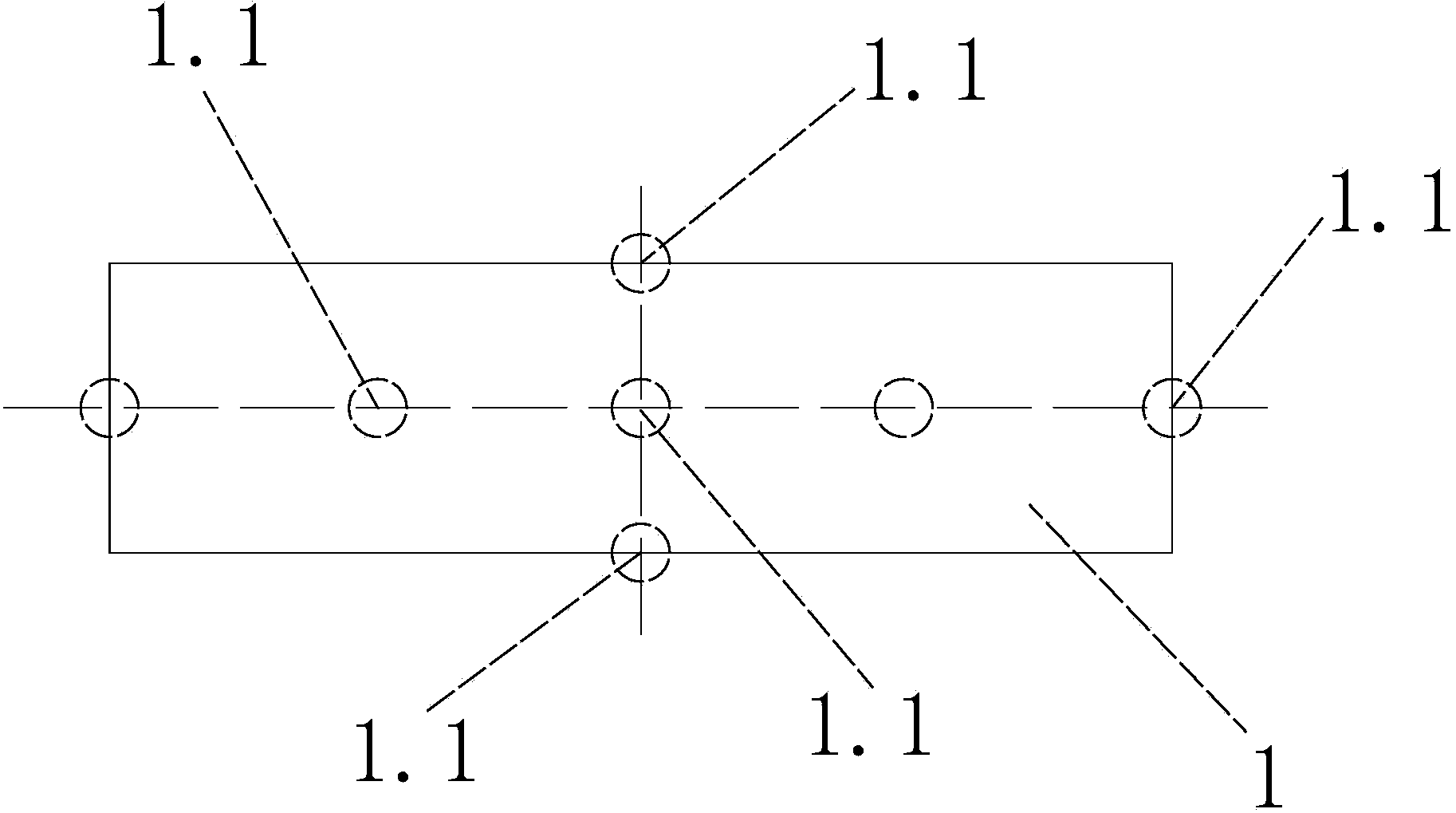

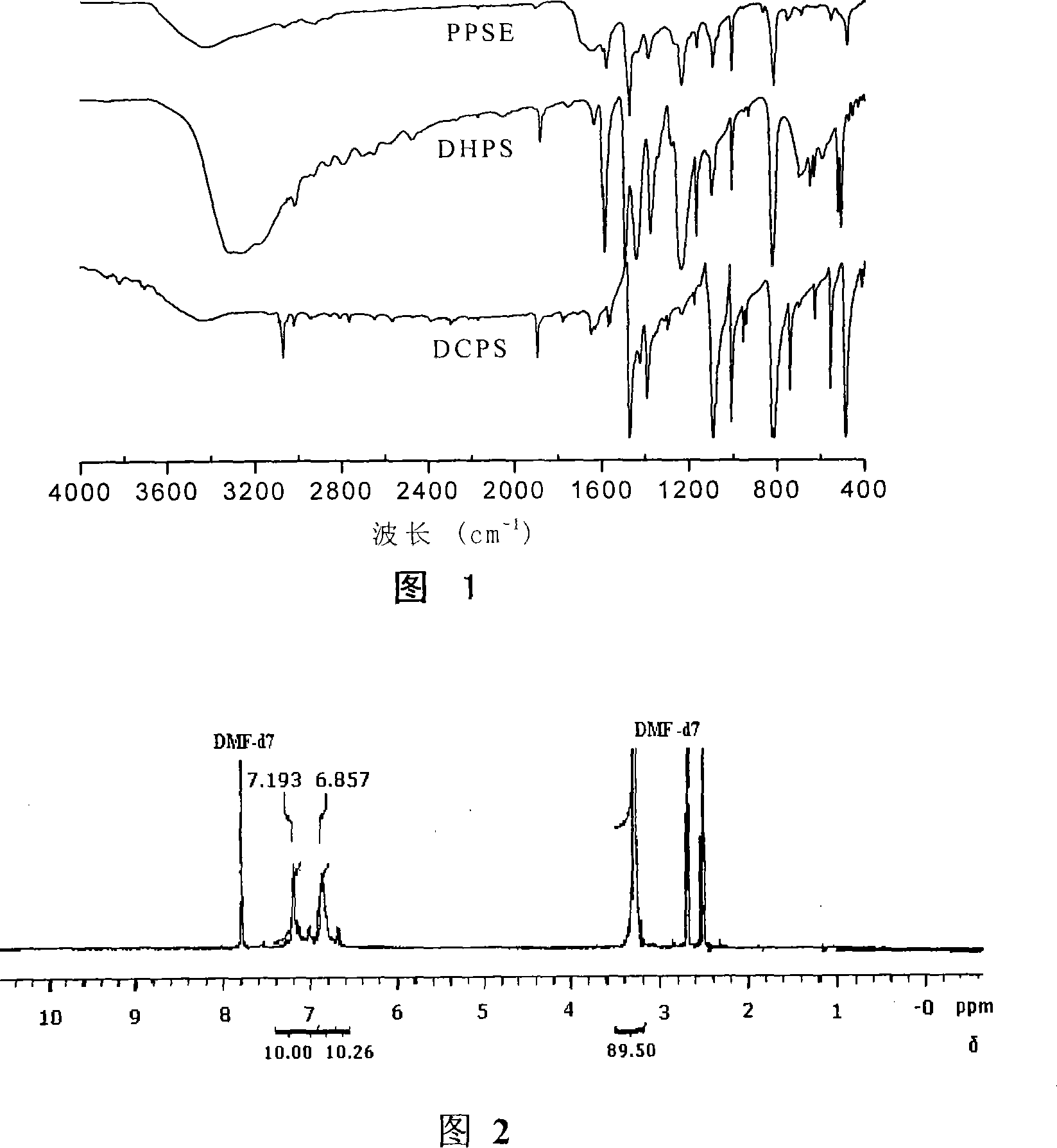

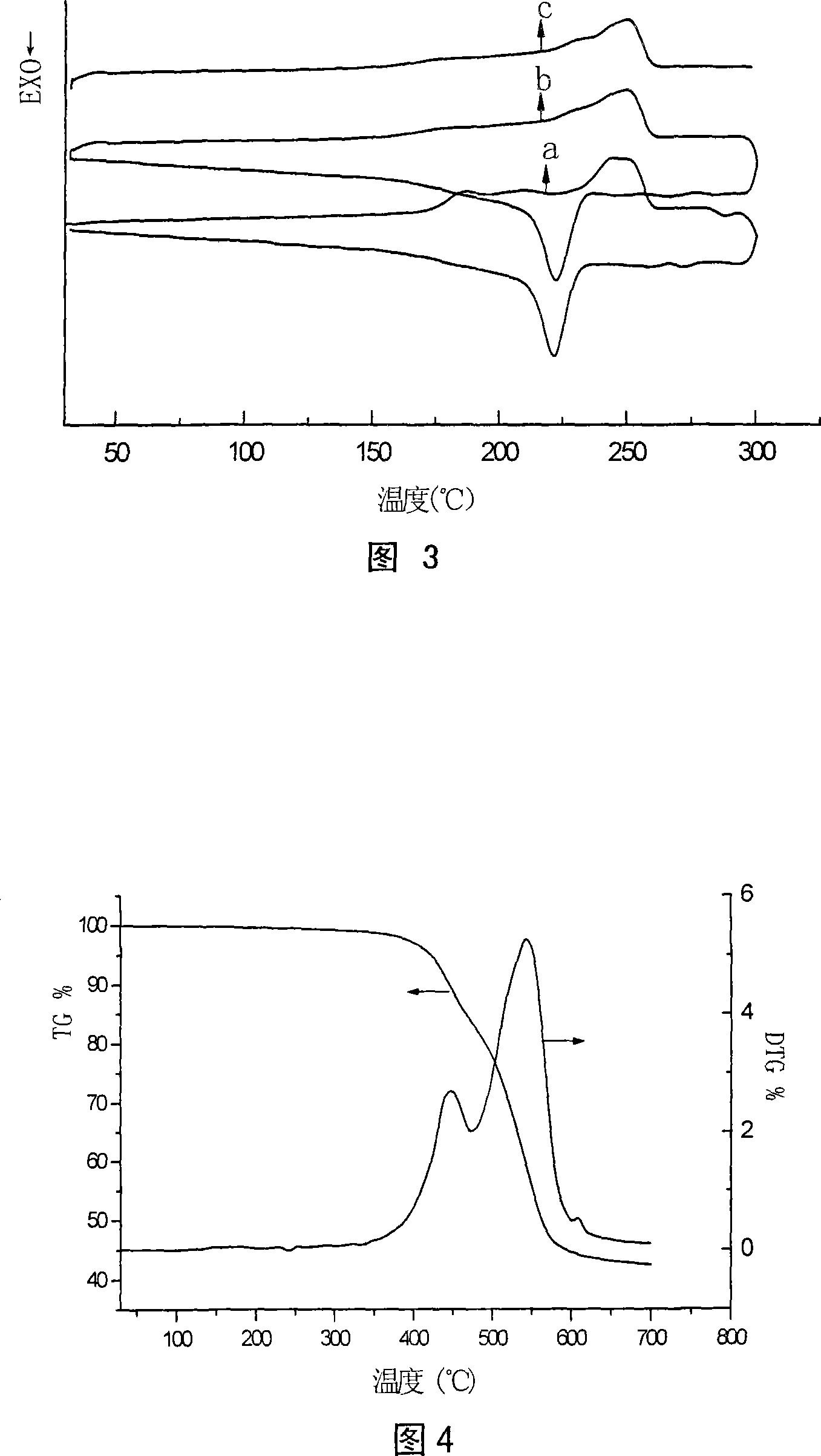

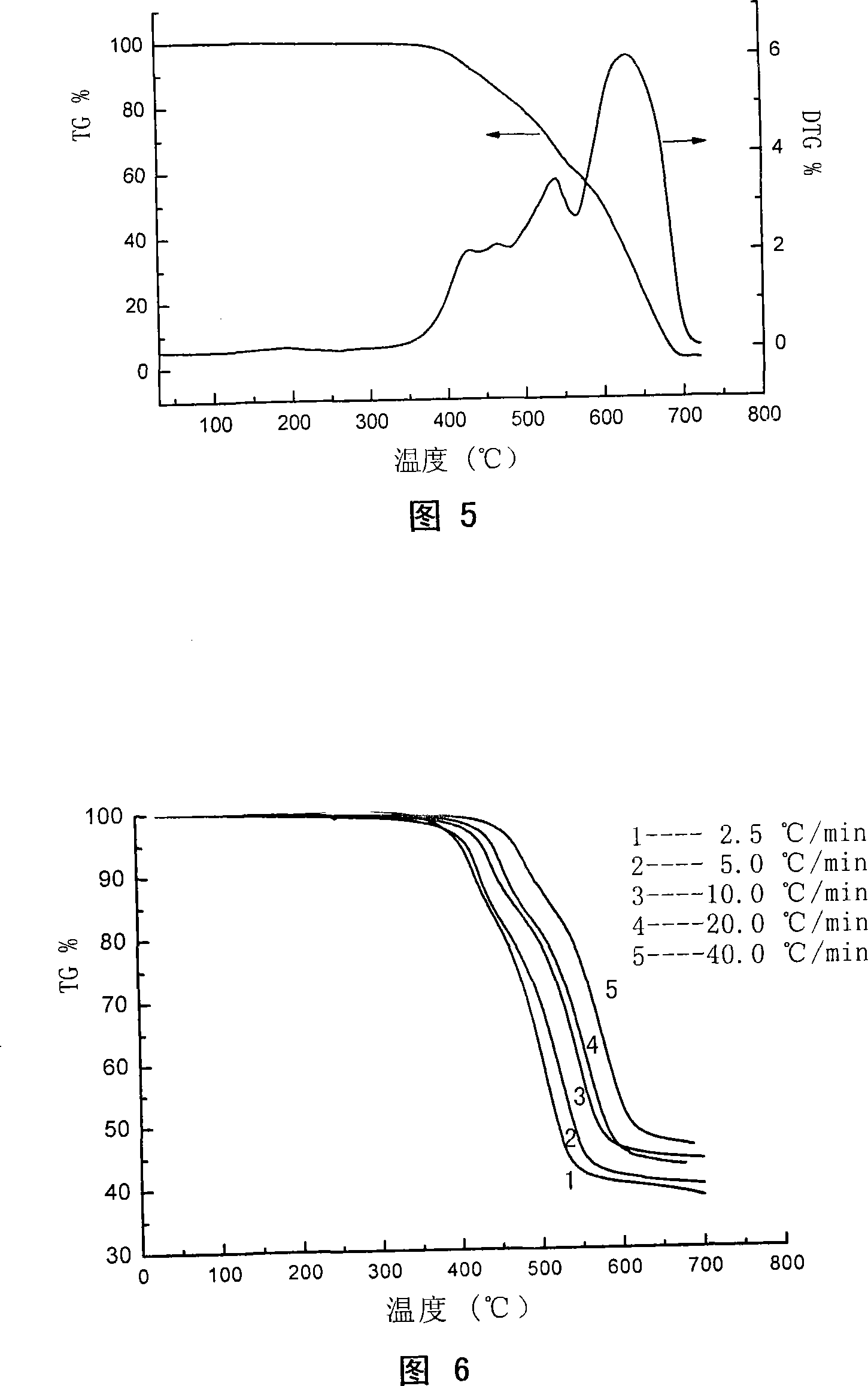

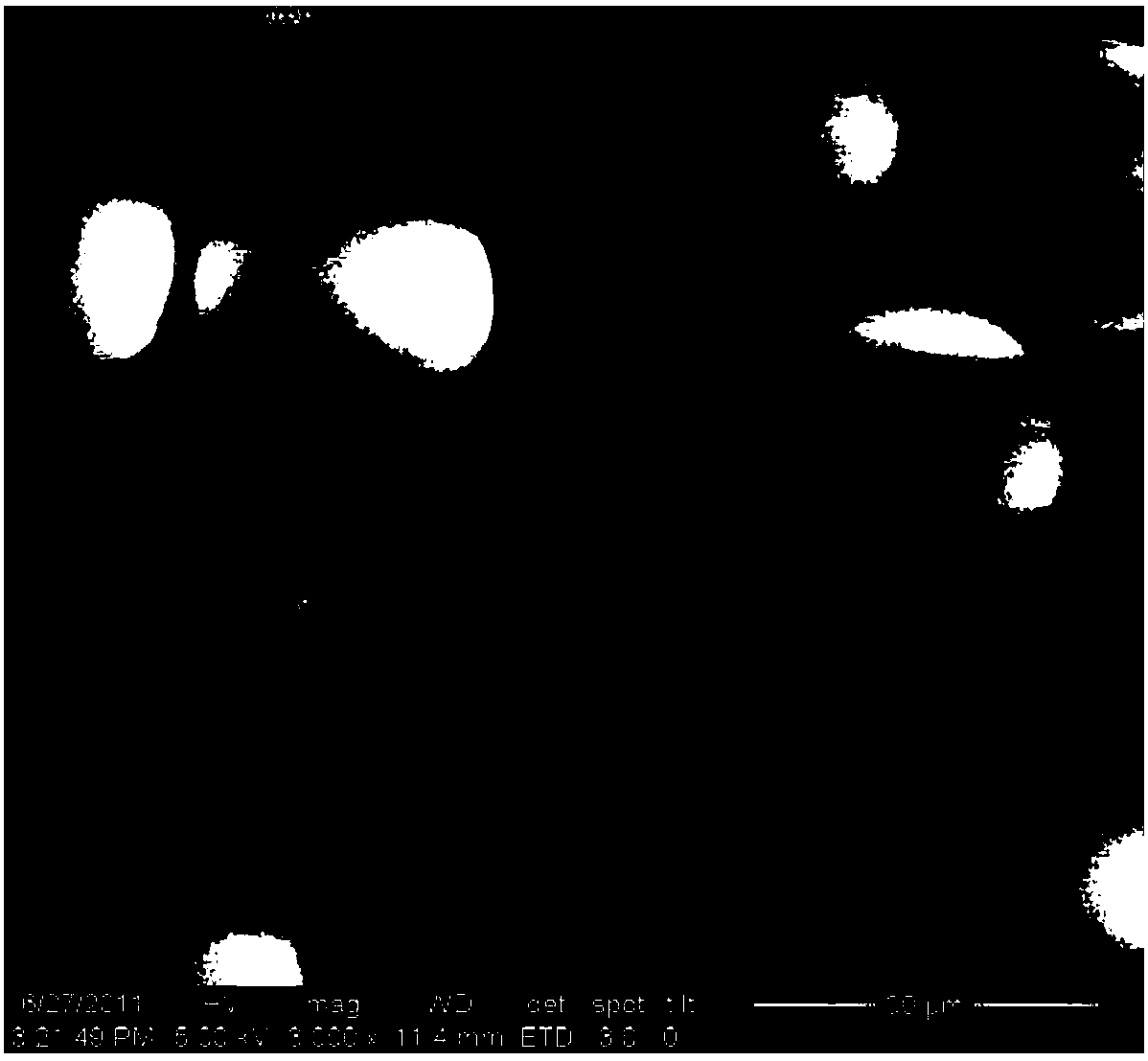

Method for preparing polyphenylene oxide sulfide

This invention discloses a method for preparing poly (phenylene sulfide). The raw materials include: monomers 4, 4'-dihydroxyl diphenyl sulfide (DHPS) and 4, 4'-dihalogen diphenyl sulfide at a mol. ratio of 1:1; additive 1.1-2.6 mol. / mol. DHPS; composite catalyst 0.22-1.08 mol. / mol. DHPS; solvent 400-700 mL / mol. DHPS; azeotropic dehydrating agent 200-400 mL / mol. DHPS. The method comprises: (1) adding the above raw material into a reactor under nitrogen protection, stirring, heating to 140-150 deg.C until azeotropic refluxing, sealing the reactor when water and the azeotropic dehydrating agent are completely distilled out, heating to 180-350 deg.C, and polymerizing for 4-10 h; (2) precipitating the solution, filtering, washing, purifying and vacuum-drying to obtain poly(phenylene sulfide).

Owner:SICHUAN UNIV

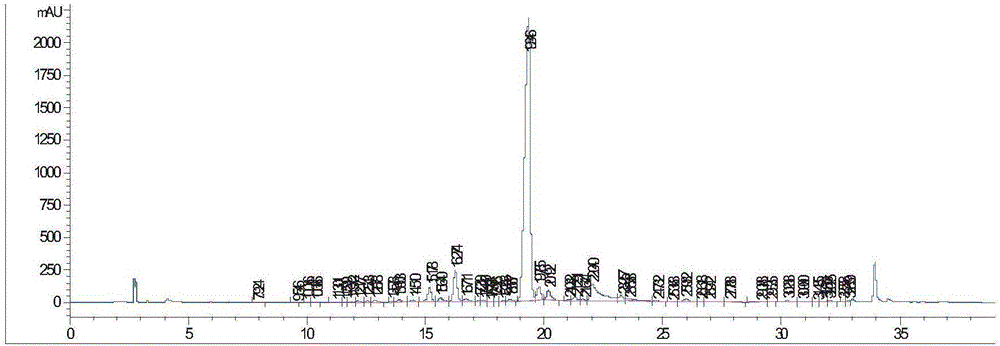

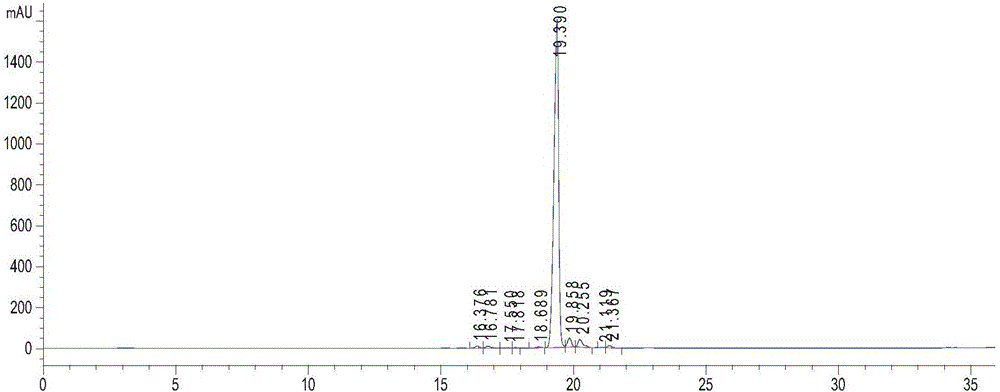

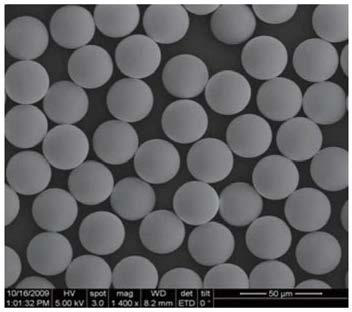

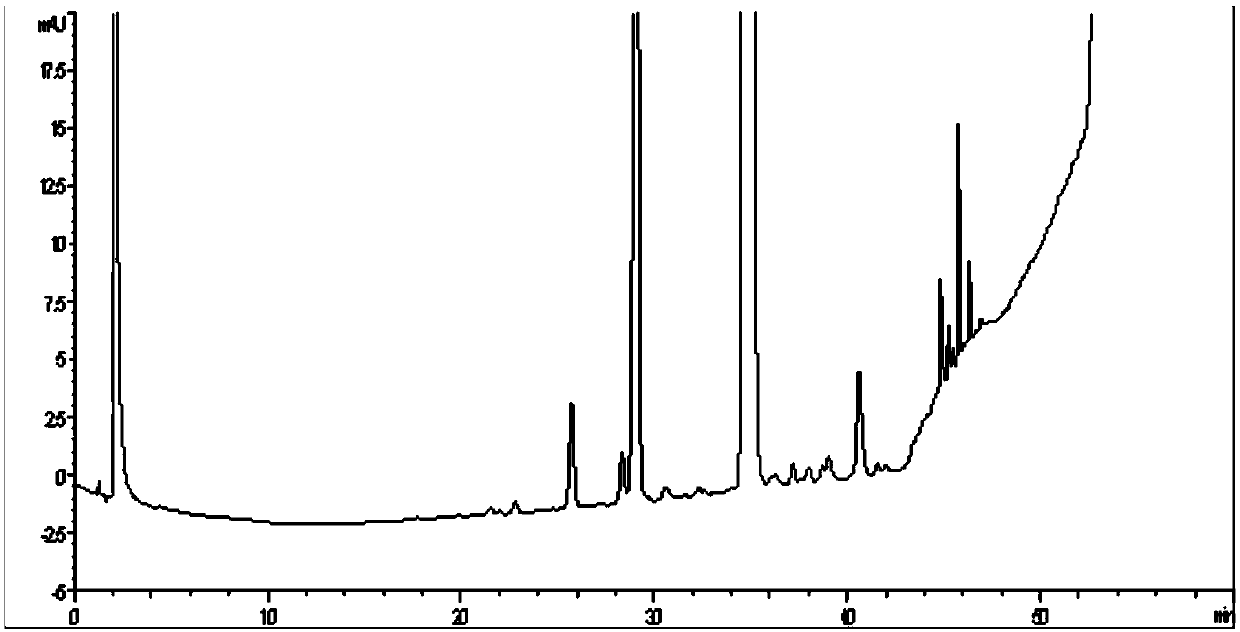

Separation and purification method of cetrorelix

ActiveCN107759667AHigh purityHigh and stable yieldLuteinising hormone-releasing hormonePeptide preparation methodsPurification methodsOrganic solvent

The invention provides a method for efficiently separating and purifying cetrorelix. The method comprises the following steps: dissolving and filtering a crude cetrorelix extract; applying a filteredsolution to a chromatographic column with uniform-particle reverse-phase silica gel, and performing chromatography; eluting a target product by using an aqueous acetic acid solution and an organic solvent as a mobile phase; sectionally collecting solutions with target peaks, and combining component solutions which meet requirements. The method is used for deeply purifying the cetrorelix; by only one chromatographic purification step, a requirement that the any individual impurity content of the cetrorelix is lower than 0.1% can be met; the purification yield is high and stable; moreover, the separation method is simple and convenient and can be applied to large-scale production, and the production cost is greatly reduced.

Owner:SUZHOU NANOMICRO TECH CO LTD

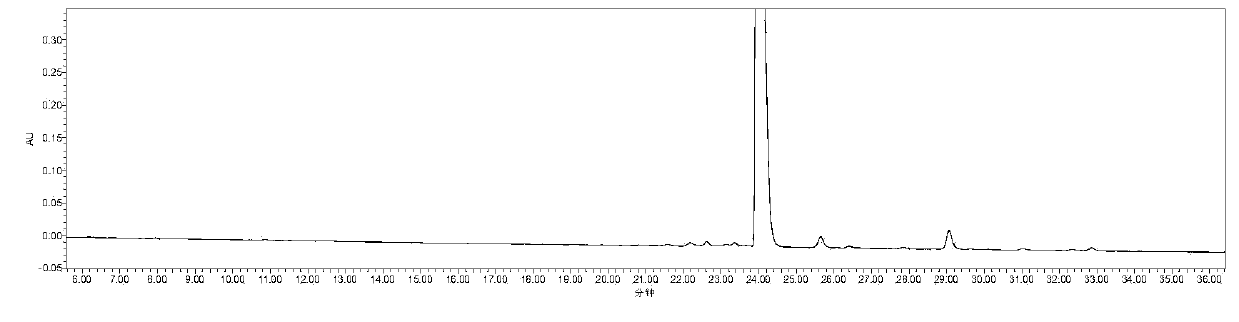

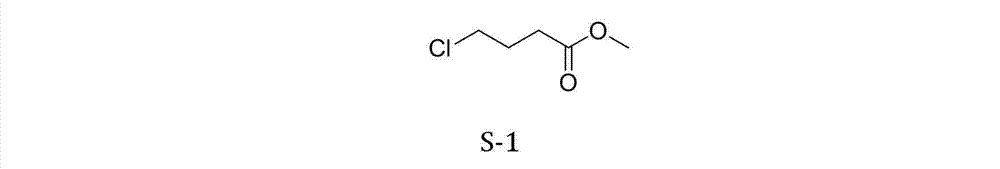

Synthetic method of methyl 4-chlorobutyrate

InactiveCN102898307AMild reaction conditionsSimple processOrganic compound preparationCarboxylic acid esters preparationAtmospheric pressurePhosphorus trichloride

The invention discloses a synthetic method of methyl 4-chlorobutyrate. The method comprises the following steps: adding gamma-butyrolactone, methanol and an acidic catalyst into a reactor, adding phosphorus trichloride in drops under an atmospheric pressure and a temperature of 30 to 60 DEG C, keeping warm and continuously reacting for 0.5 to 2 hours after the adding, and getting the methyl 4-chlorobutyrate through a post-treatment of the reaction solution after the reaction, wherein the acidic catalyst is 1 to 5 % by mole amount of the gamma-butyrolactone, the mole ratio of the gamma-butyrolactone and the methanol is 1 : 2-5, and the mole ratio of the gamma-butyrolactone and the phosphorus trichloride is 1 : 0.35-1. The synthetic method of the methyl 4-chlorobutyrate has characteristics of mild reaction condition, concise technology, environmentally-friendly raw materials, less three waste (waste gas, waste water and industrial residue) and simple post-treatment.

Owner:ZHEJIANG UNIV

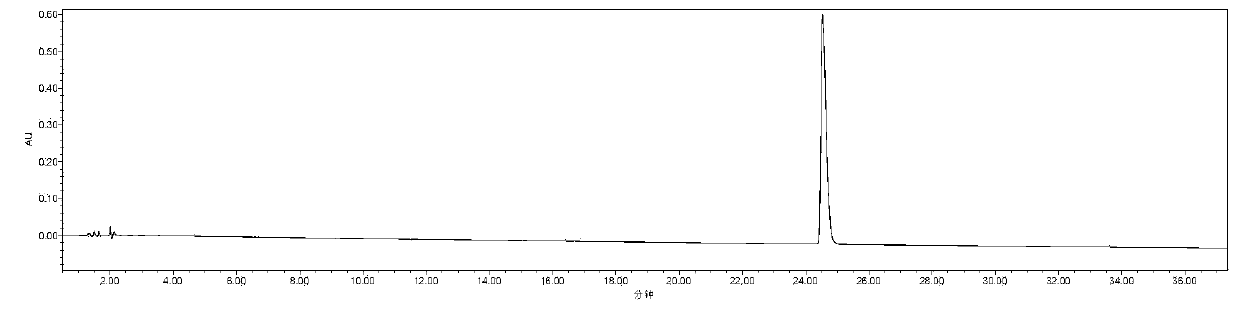

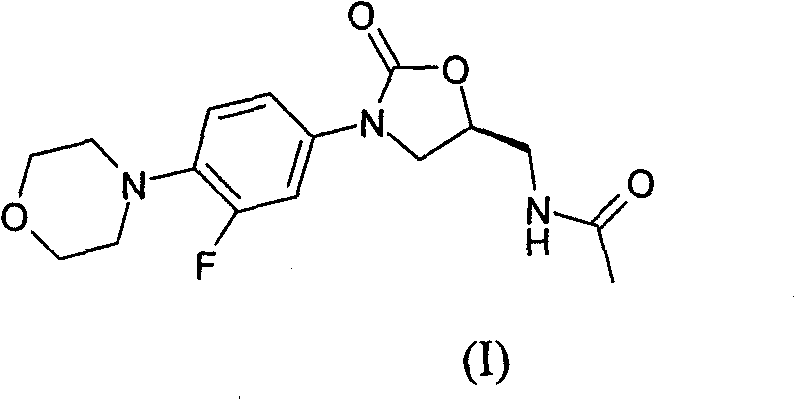

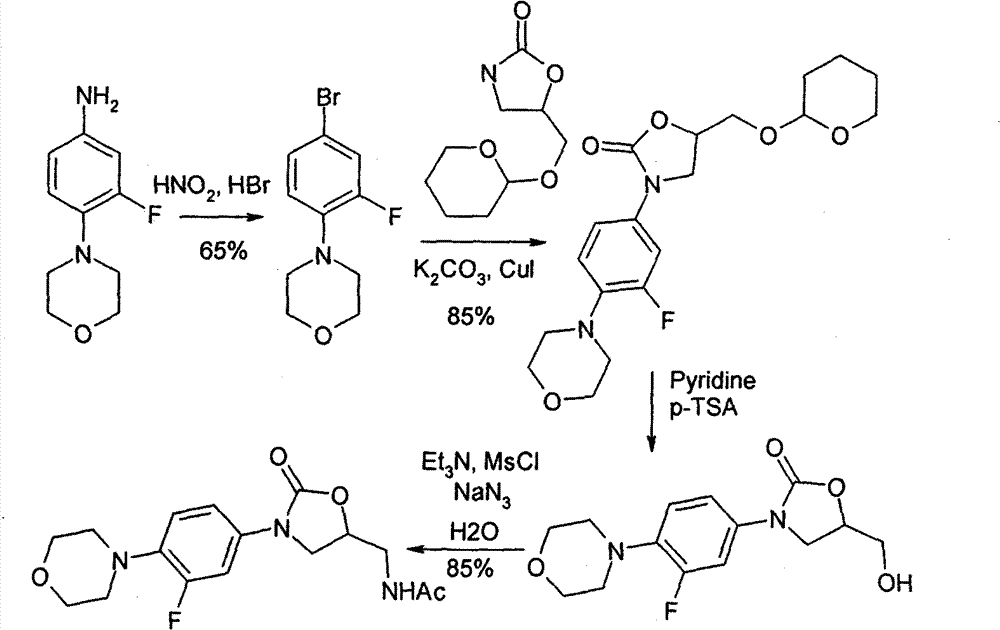

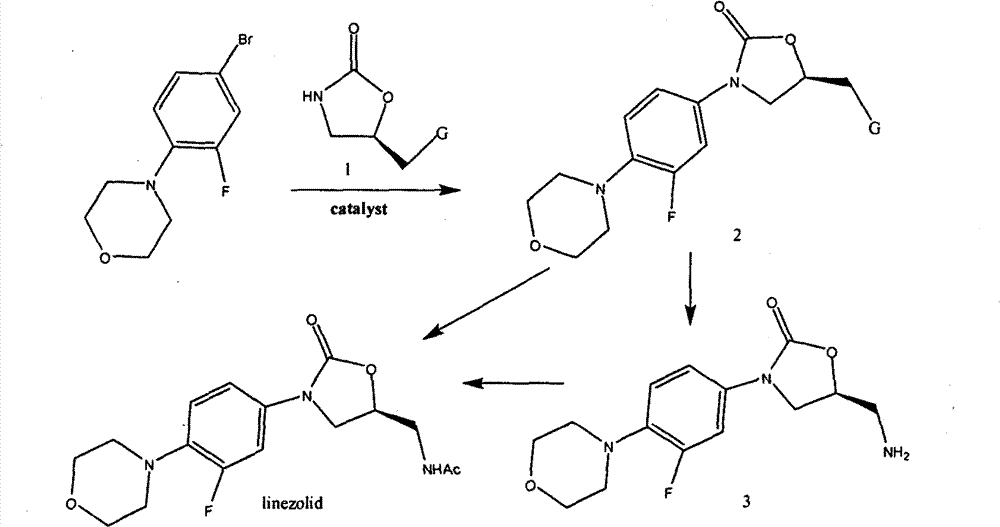

Method for preparing linezolid

The invention relates to a method for preparing linezolid. The method comprises the following steps of: reacting 3-fluorine-4-morpholinyl bromobenzene used as a raw material, with a chiral oxazolidinone compound in the presence of a catalyst, so as to directly obtain the linezolid, or to obtain the linezolid after conversion. Compared with the existing method for synthesizing linezolid, the method disclosed by the invention is simple in route, convenient to operate, slight in pollution and stable in yield.

Owner:CHONGQING MEDICAL UNIVERSITY

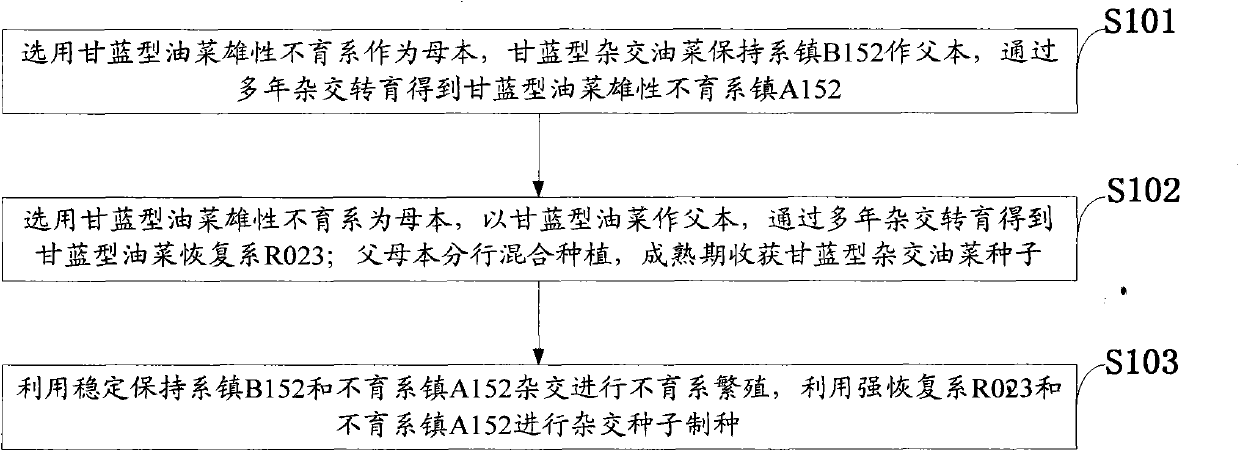

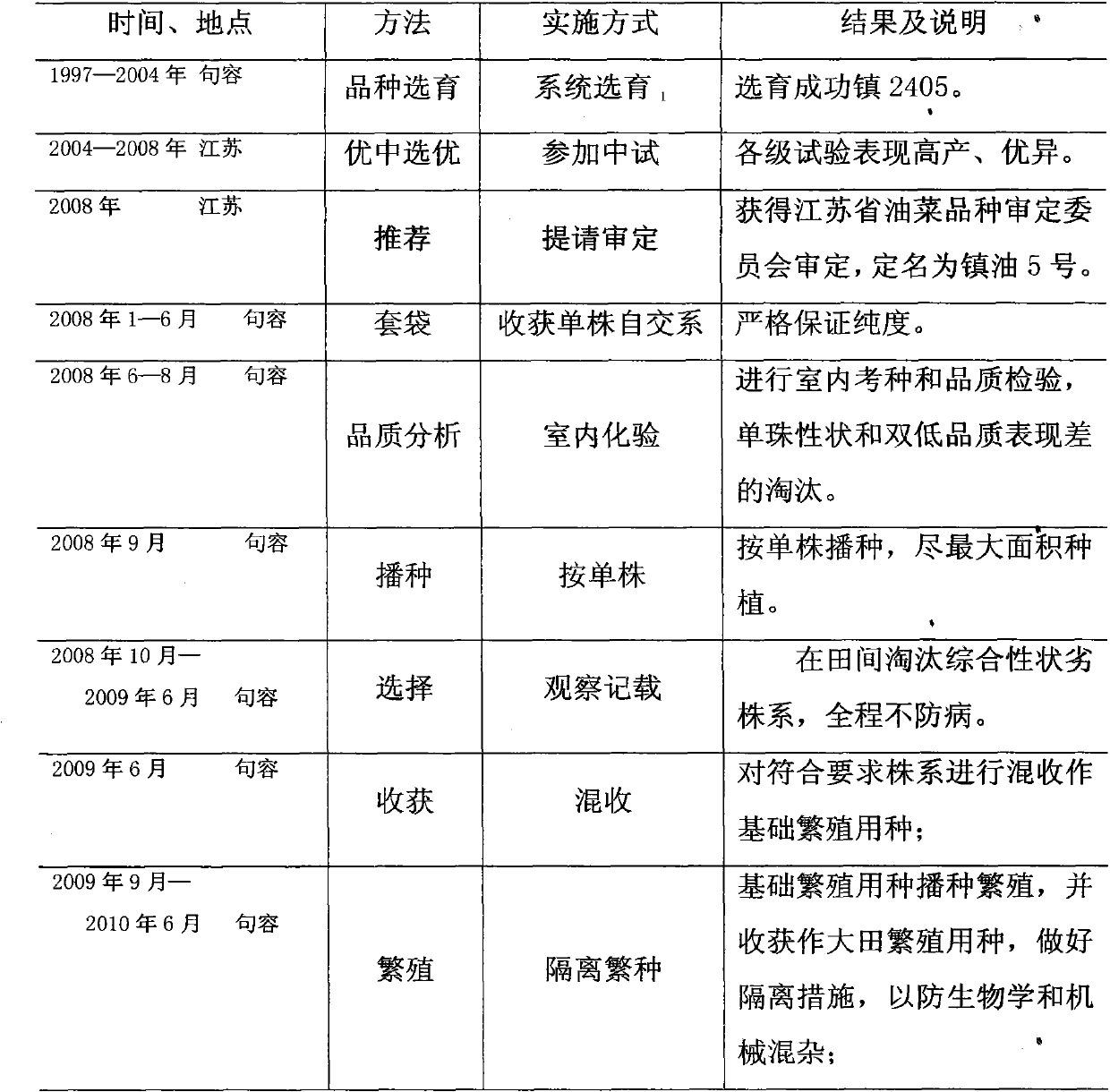

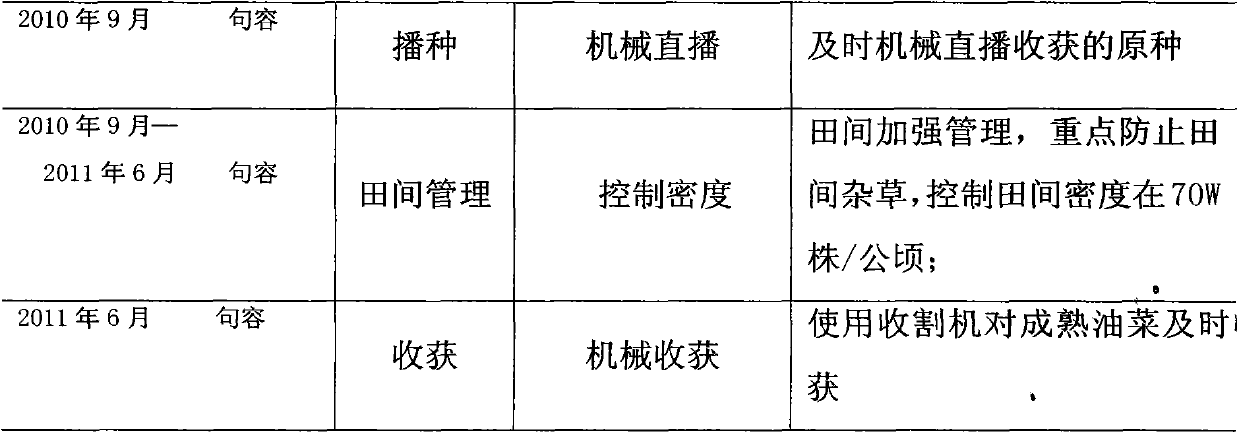

Combined seed production method for three-line hybrid oilseed rape

InactiveCN103461097AGuarantee the purity of seed productionProlong flowering period encounter timePlant genotype modificationFlowering seasonHybrid seed

The invention discloses a combined seed production method for three-line hybrid oilseed rape, which comprises the following steps: selecting a cabbage type rape male sterile line as the female parent, selecting a cabbage type hybrid rape maintainer line ZhenB152 as the male parent, and performing hybrid transformation for multiple years to obtain a cabbage type rape male sterile line ZhenA152; selecting a cabbage type rape male sterile line as the female parent, selecting cabbage type rape as the male parent, and performing hybrid transformation for multiple years to obtain a cabbage type rape restorer line R023; mixed planting the female parent and the male parent in different lines, and harvesting cabbage type hybrid rape seeds in the mature period; hybridizing the stable maintainer line ZhenB152 and the sterile line ZhenA152 to breed a sterile line, and hybridizing the strong restorer line R023 and the sterile line ZhenA152 to produce hybrid seeds. The seeds prepared through the combined seed production method have high self regulation capability and are easy to plant and popularize, the individual is upright during the seedling stage, and grows healthily during the bolting period; the spring sprouting property is strong, the flower season is concentrated, the grains are dense, the yield components are coordinated, and the mature consistency is good. In addition, the seed production process of the seed production method is safe, convenient and simple.

Owner:江苏丰源种业有限公司

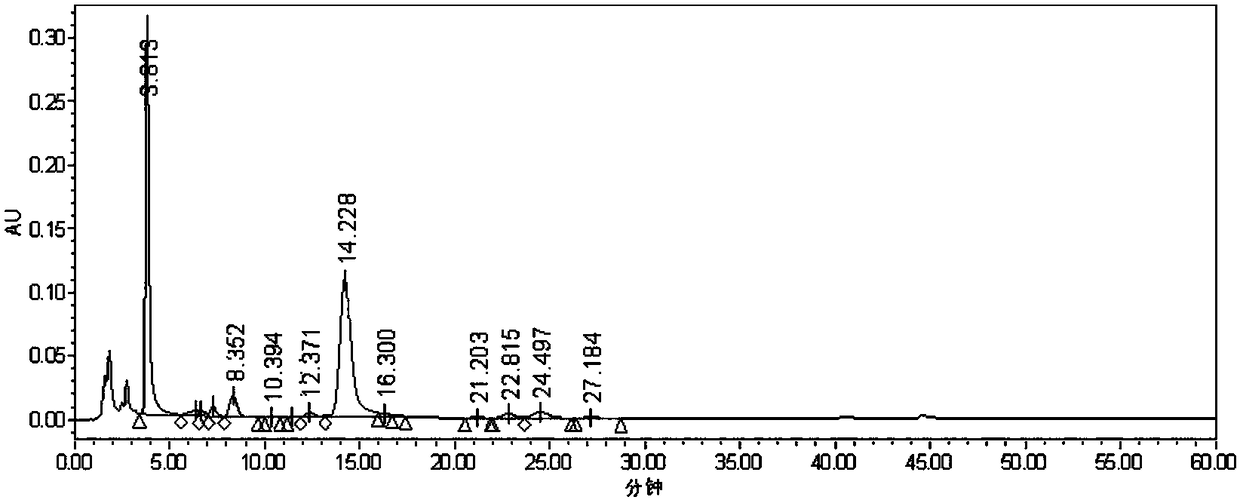

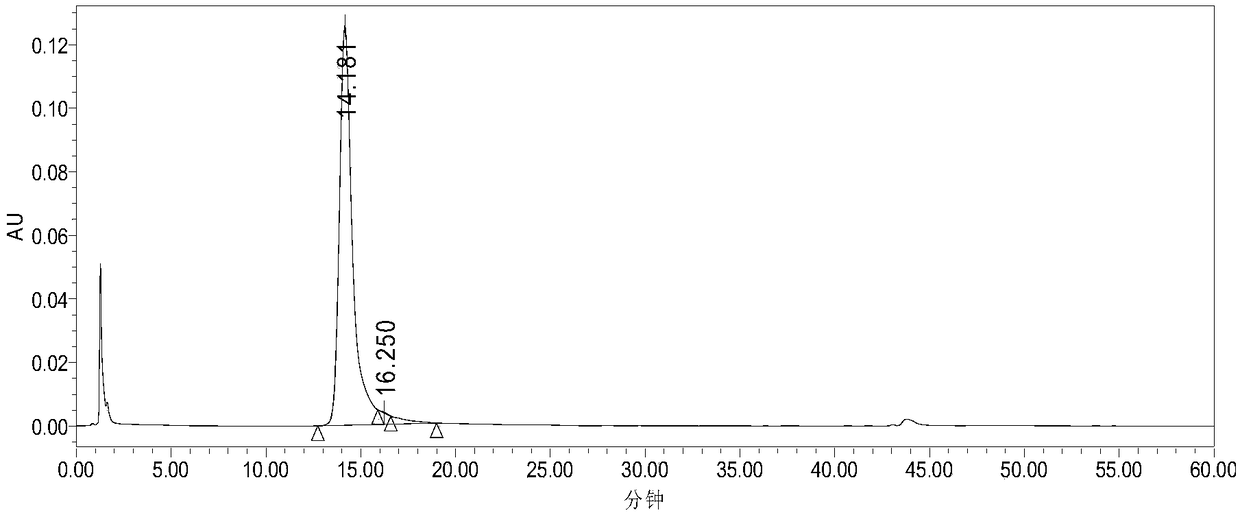

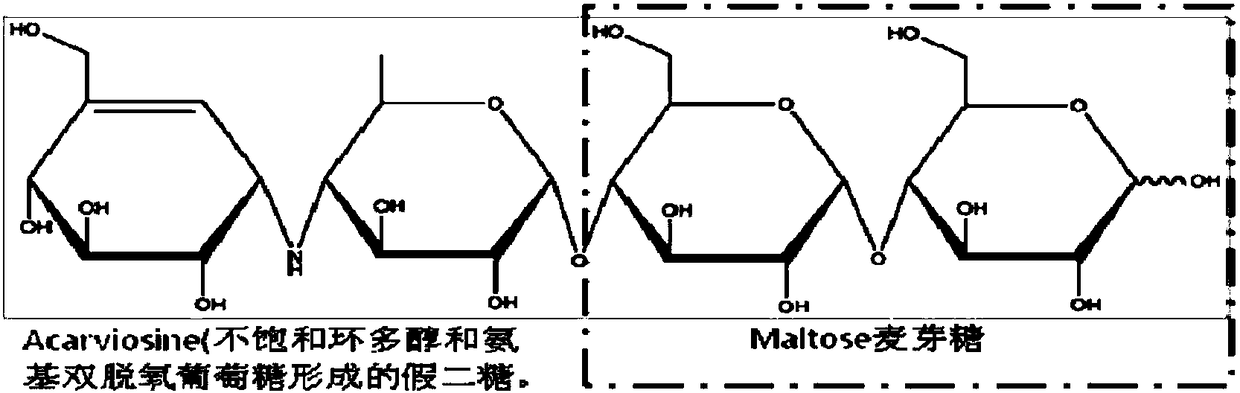

Separating and purifying method of acarbose

InactiveCN108148104AHigh purityHigh and stable yieldSugar derivativesSugar derivatives preparationOrganic solventIon exchange

The invention provides a high-efficient separating and purifying method of acarbose. The method comprises the following steps of filtering an acarbose solution, adjusting a pH value of the solution, loading a treated acarbose solution sample into an ion-exchange chromatography medium full of monodisperse polystyrene / divinyl benzene, carrying out chromatography, adopting a hydrochloric acid solution as a flow phase for eluting a target product, and collecting a target solution to obtain a high-purity acarbose solution. According to the purifying method, only one-step purification is needed, only hydrochloric acid water solution is utilized during an eluting and regenerating process, no other organic solvent is involved, after purifying, the purity can reach to 99 percent or more, the totalyield is 80 percent or more, and the method is suitable for industrial production.

Owner:SUZHOU NANOMICRO TECH CO LTD

Culture method of Armillaria Staude fungus

ActiveCN1923999AIncrease productionHigh and stable yield of active polysaccharideFungiSubmerged fermentationActive ingredient

The invention discloses a culturing method of little halimasch fungi, which comprise the following steps: adopting Armilariella tabescens and halimasch as starting bacteria; culturing seed to obtain solid bacterial suspension in the liquid culture medium; stewing under 24-28 deg.c for 16-22d; extracting active polysaccharide as raw material of drug.

Owner:合肥诚志生物制药有限公司

Method for producing squatting pan by high-pressure molds

InactiveCN103978540AGood surface smoothnessHigh strengthSlip casting mouldsDiaphragm pumpUltimate tensile strength

The invention discloses a method for producing a squatting pan by high-pressure molds. A horizontal high-pressure grouting forming device is used for producing the squatting pan. The high-pressure grouting forming cycle includes the following steps of (1) grout filling, (2) grouting, (3) grout returning and (4) strengthening, wherein in the step of (1) grouting filling, grout is conveyed to the molds through a pneumatic diaphragm pump, in the step of (2) grouting, external pressure acts on the grout in the molds so that the grout can be dehydrated and hardened to be shaped, in the steps of (3) grouting returning, extra grout in a hollow grouting area of a blank is discharged, and in the step of (4) strengthening, compressed air is led to an inner cavity of the blank, so that water in the blank is uniform, and the strength of the blank is improved. The micro-reticular resin mold is adopted, the device is in a horizontal pouring mode, and a reliable guarantee is provided for demolding of the blank, and accordingly the blank is not prone to deforming; the device is of a double-mold structure, multiple high-pressure resin molds can be arranged, and the device can be used for producing wash basins and also can be used for producing squatting pans by replacement of the molds; according to the method, energy conservation and emission reduction can be achieved, clean production can be achieved, the qualified rate of products and production efficiency are greatly improved, and meanwhile, work intensity of workers is greatly reduced.

Owner:HOCHENG CHINA

Method for separating and purifying pig ganglioside

InactiveCN109705176ALow costLess amount of mobile phaseSugar derivativesSugar derivatives preparationOrganic solventElution

The invention provides a method for efficiently separating and purifying porcine ganglioside, which comprises the steps of: dissolving and filtering a crude extract of the pig ganglioside; applying afiltered solution to a chromatography column filled with a homogenous normal-phase silica gel for chromatography; using ultrapure water and an organic solvent as a flow phase for elution of a target product; collecting the solution of the target peak in stages, and collecting the component liquid meeting the requirements. The method is applied to the deep purifying of the pig ganglioside, and onlyneeds one-step chromatography to satisfy the requirement that the pig ganglioside purity is greater than 99% and the yield is greater than 93.0%. The purification yield is high and stable, and the separation method of the invention is simple and convenient, can be used for large-scale production, and the production cost is greatly reduced.

Owner:SUZHOU NANOMICRO TECH CO LTD

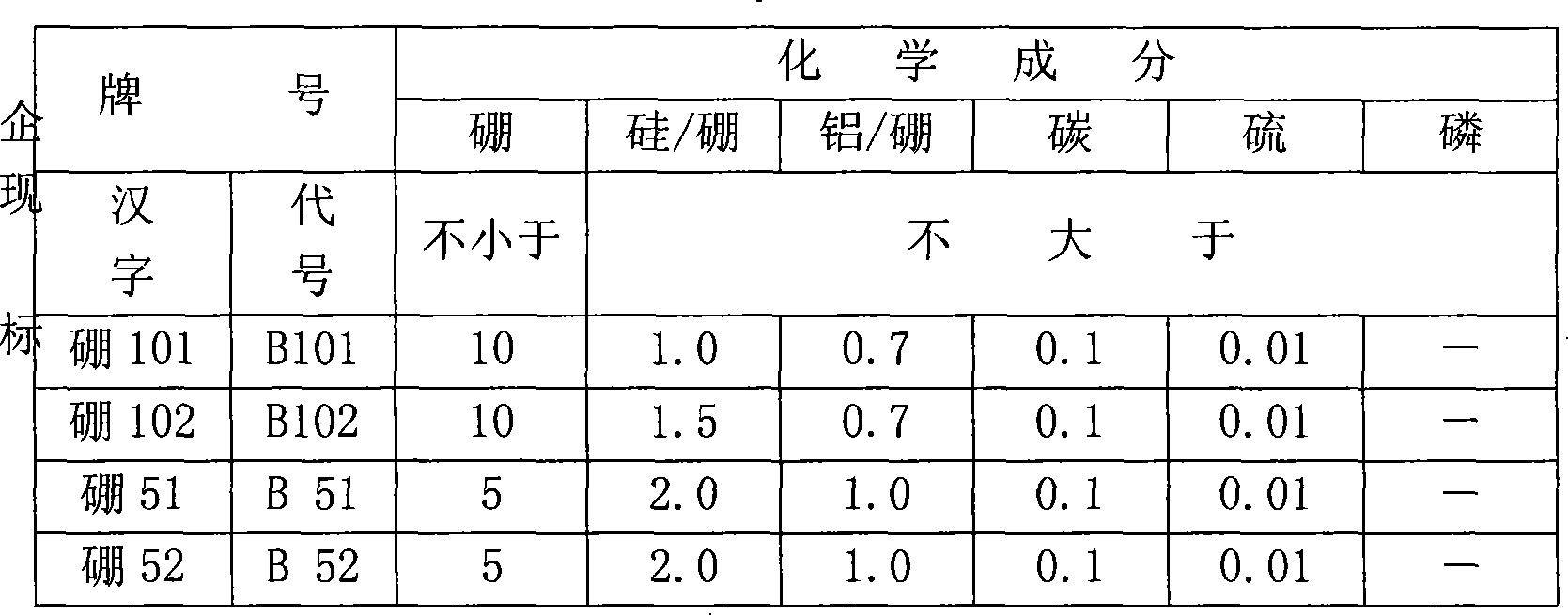

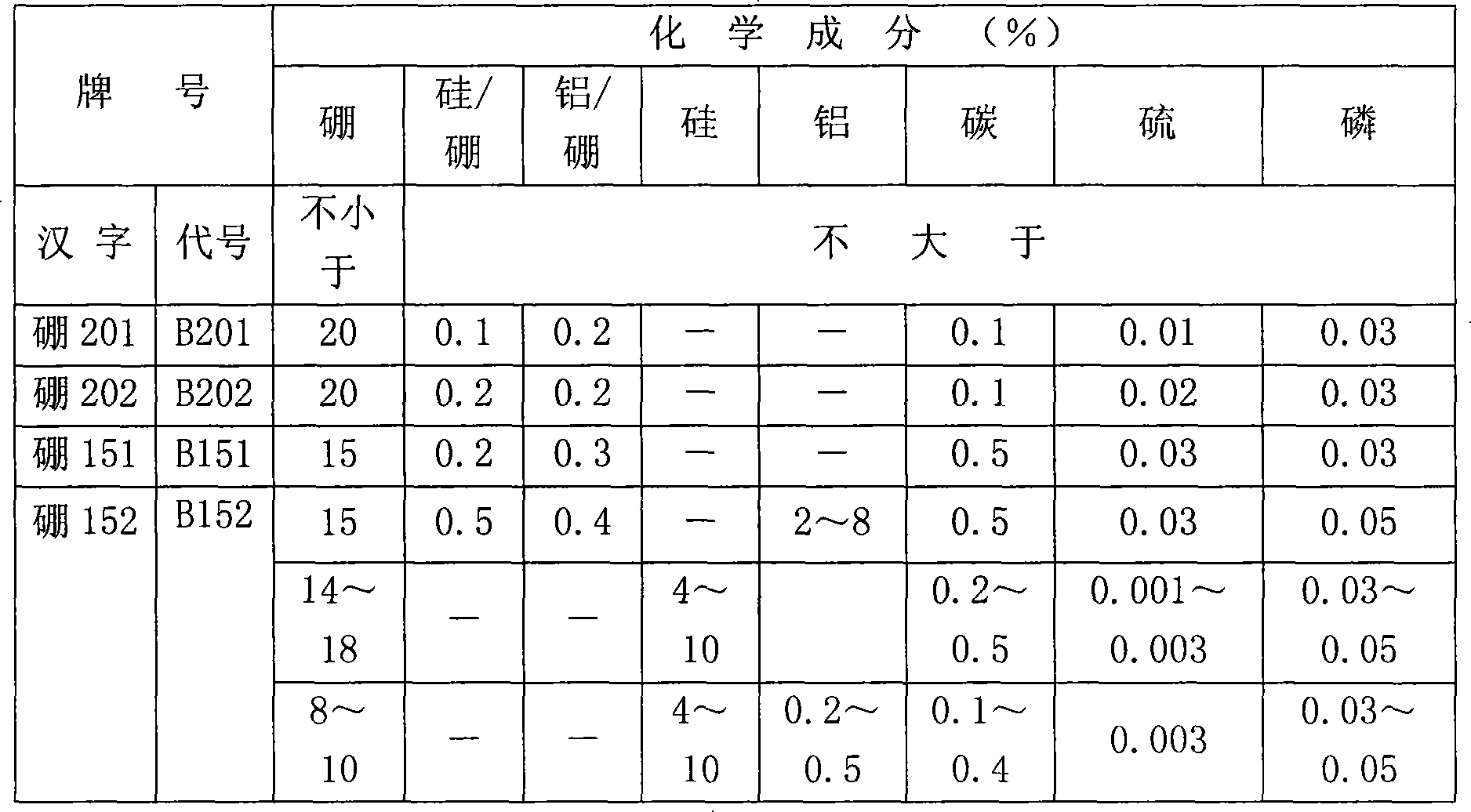

Aluminum ferroboron composite intermediate alloy and method of use thereof

The invention relates to aluminum-boron-ferro compound master alloy and a method thereof, which belongs to the ferrous alloy technical field. The percent by weight of chemical composition is: Al: 10-30%, Mn: <=2.0%, B: 2-10%, P :< =0.1, S: <=0.1% and C :< =1.0%, the allowance is Fe, and a used technique thereof is to add molten steel in the late period. The adding method in the smelting process comprises following steps: deoxidizing the molten steel weakly at the rear of a convertor, refining work stations to finish deoxidation and desulfurization, then, controlling the content of the aluminum to the weight range of 0.01-0.030% according to the requirements of molten steel finished products, here, adding the aluminum-boron-ferro compound master alloy in a mode of lump materials, stirring for 5-20 minutes, when the temperature is 1550-1650DEG C, and taking steel ladles out of a refining station. The method of the invention has the advantages that the stability control of the component of boron in the boron micro-alloying process is prominently increased, the yielding rate of the boron is increased, the method of the invention can be used to smelt trace boron alloyed structural steel and in a thin slab continuous casting and continuous rolling assembly line to produce low-carbon aluminium sedation boron microalloy steel.

Owner:CENT IRON & STEEL RES INST

Preparation methods for copper-chromium intermediate alloy and copper-chromium-zirconium alloy

The invention discloses preparation methods for a copper-chromium intermediate alloy and copper-chromium-zirconium alloy. The preparation method for the copper-chromium intermediate alloy comprises the following steps: (1) selecting chromium with the particle size of 10-50 mm, placing a copper block at the bottom of a graphite crucible, and placing the chromium into branch bins of a charging hopper; (2) vacuumizing the graphite crucible, energizing the graphite crucible for heating, stopping vacuumizing when the copper block starts to melt, and charging argon gas of which the pressure is 0.01-0.02 MPa; (3) continuously energizing the graphite crucible till the copper block fully melts, adding chromium in batches through the charging hopper, controlling the interval between the addition time of the previous batch of chromium and the addition time of the subsequent batch of chromium, and adding the subsequent batch of chromium after the previous batch of chromium metal fully melts; (4) after finishing the adding of the chromium, refining for 15 minutes, adjusting the temperature to 1,200-1,250 DEG C, and casting for forming the copper-chromium intermediate alloy. When the copper-chromium intermediate alloy is used for preparing the copper-chromium-zirconium alloy, the higher and stable chromium yield can be achieved, and the smelting time of the copper-chromium-zirconium alloy can be shortened; moreover, impurities are prevented by using the graphite crucible.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

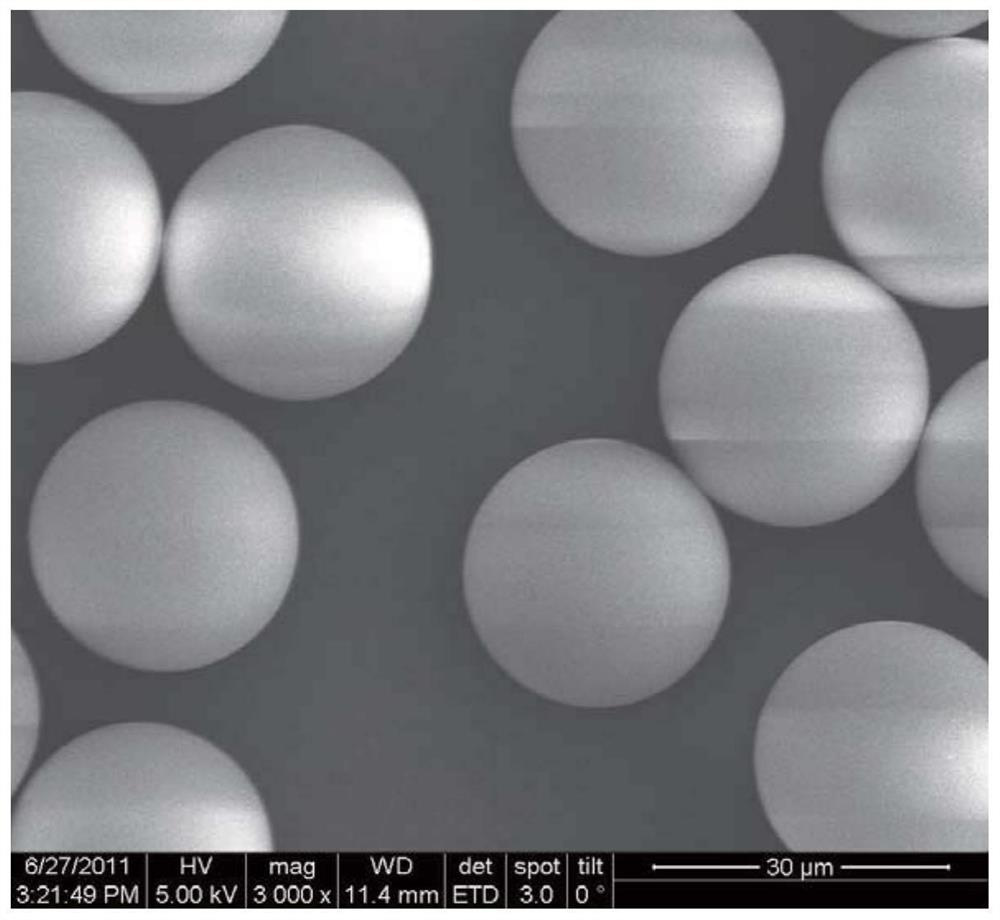

High-yield separation and purification method of prostaglandin E2

ActiveCN112479962ACost pollution-freeShort purification cycleOrganic chemistryChromatographic columnOrganosolv

The invention provides a high-yield separation and purification method of prostaglandin E2. The method comprises the following steps: dissolving and filtering a prostaglandin crude product; loading the filtered solution into a chromatographic column filled with homogeneous reversed-phase silica gel for chromatography; eluting the target product by adopting an acetic acid aqueous solution and an organic solvent as mobile phases; and collecting solutions with target peak values in sections, and summarizing the component solutions meeting the requirements. Monodisperse UniSil C18 or UniSil C8 isadopted as a stationary phase, the separation method is simple, large-scale production can be achieved, and the recovery rate is high and stable.

Owner:SUZHOU NANOMICRO TECH CO LTD

V and Cr containing microalloy building steel wire rod and production method thereof

The invention belongs to the field of ferrous metallurgy, and particularly relates to a V and Cr containing microalloy building steel wire rod and a production method thereof. The V and Cr containingmicroalloy building steel wire rod and the production method thereof are provided according to the problems that vanadium nitride alloys selected for preparing nitrogen containing alloy steel in the prior art are low in nitrogen content, few in kind and the like. The steel wire rod comprises, by weight percent, 0.15%-0.30% of C, 0.30%-1.00% of Si, 0.60%-1.30% of Mn, 0.0060%-0.0180% of N, not larger than 0.040% of P, not larger than 0.040% of S, 0.010%-0.160% of V, 0.10%-0.60% of Cr and the balance Fe and inevitable impurities. The preparation method of the steel wire rod is characterized in that an N containing cored wire is fed into a furnace rear small platform, and N is adjusted to the proper level. The method is simple in operation, the nitrogen yield is high and stable, the productioncost can be effectively reduced, and the method is worthy of use and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

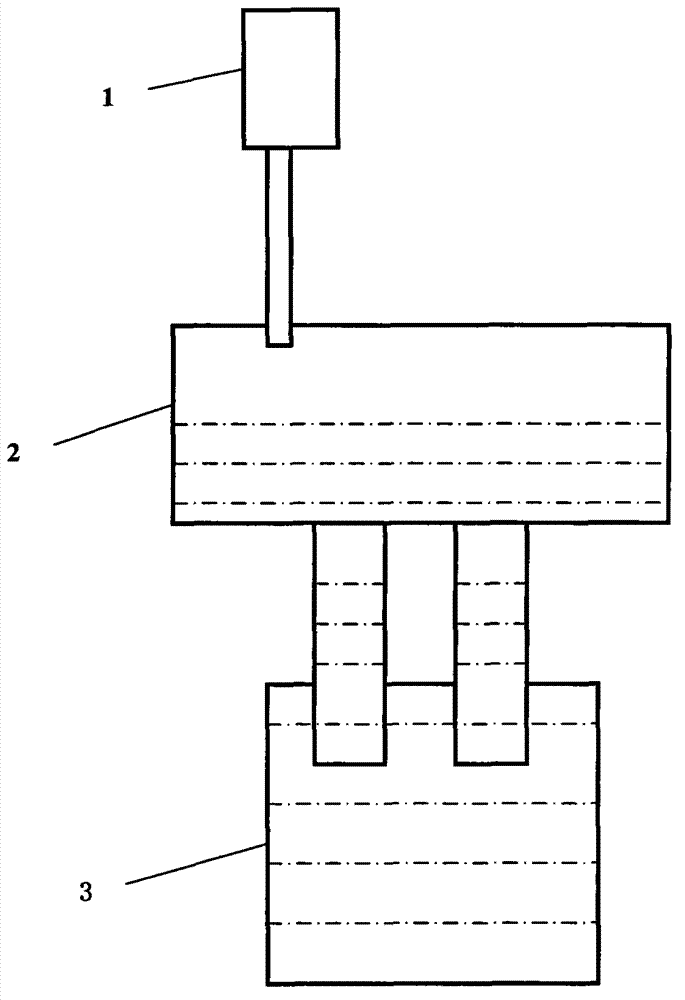

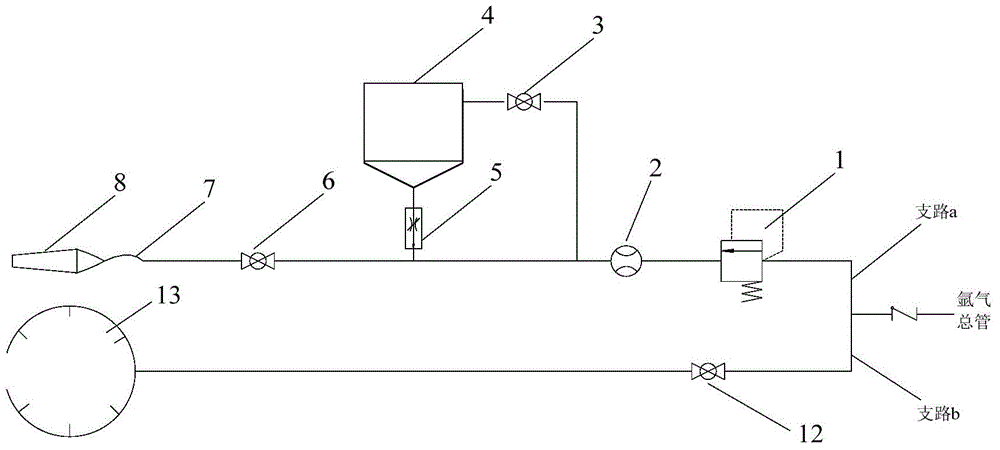

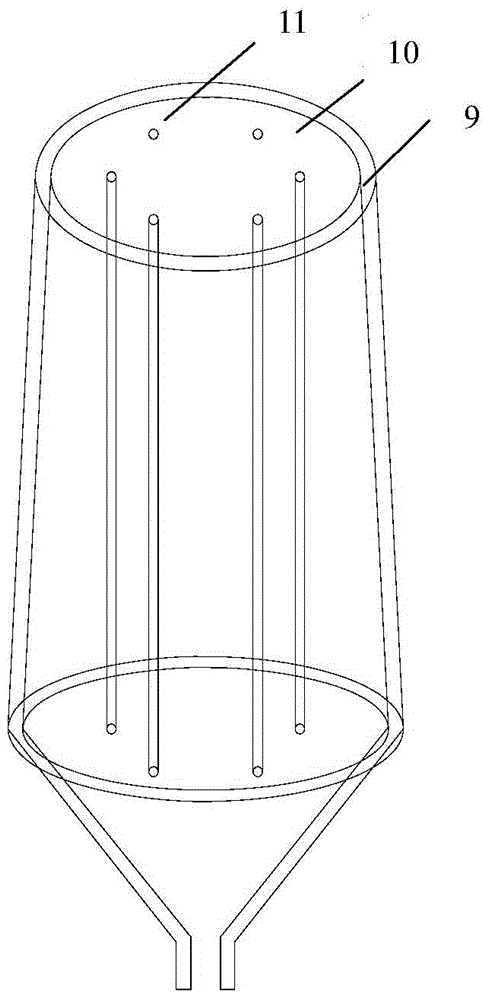

Low-boiling rare-precious metal tundish alloying device and method

ActiveCN104874779ARealize long-term storagePrevent oxidationMelt-holding vesselsBoiling pointSmall footprint

The invention relates to a low-boiling rare-precious metal tundish alloying device and a method, belongs to the technical field of steel. The alloying device comprises an alloyed powder transferring gas pipeline and a control device branch a, a tundish impact zone liquid level gas protecting device branch b and an integrated control software. The alloyed powder transferring gas pipeline and the control device branch a are connected to an argon main pipe of a steel works, an electronic pressure maintaining valve is mounted at the control device branch a to regulate argon pressure, an electronic flowmeter is mounted at the rear of the electronic pressure maintaining valve to monitor argon flow, and a powder storing and transferring device is mounted at the rear of the electronic flowmeter. The powder storing and transferring device is composed of a ball valve, a powder storing device and a high-precision regulating valve. The ball valve is used for cutting off argon when the control device branch a is out of service. The tail end of the control device branch a is connected with a side blow gun, embedded in the impact zone, through a metal hose, and spraying powder alloying is realized via the side blow gun under steel liquid level. The device is small in occupied area, convenient to install and maintain, and small in investment.

Owner:CENT IRON & STEEL RES INST

Method for separating and purifying sugammadex

The invention provides a method for efficiently separating and purifying sugammadex. The method comprises the steps that a crude extract of sugammadex is dissolved and filtered; the filtered solutionis subjected to sample loading to exchange resin loaded with a weak anion for chromatography; a salt solution is used as a flow relative target product for elution; and a solution of a target peak iscollected in stages, and a component solution meeting the requirements is summarized. The method is used for deep and pure purification of the sugammadex, only one-step chromatographic purification isneeded to meet the requirement that the purity of the sugammadex is more than 99.0% and the single impurity is less than 0.1%, and the purification yield is high and stable. The method adopts an aqueous solution of sodium acetate and an aqueous solution of sodium chloride as a mobile phase, and does not use an organic solvent, and the adopted mobile phase is safe, non-pollution and low in cost. Meanwhile, the separation method is simple and convenient and can be used for large-scale production, and the production cost is greatly reduced.

Owner:SUZHOU NANOMICRO TECH CO LTD

Environment-friendly lead-free easy-cutting stainless steel used for ball-point pen point and smelting method thereof

The invention aims at providing environment-friendly lead-free easy-cutting stainless steel used for a ball-point pen point and a smelting method thereof. The stainless steel is characterized in thatthe stainless steel is ooCr22Mo2BiS stainless steel and comprises the components including, by mass, smaller than or equal to 0.03% of C, smaller than or equal to 2.0% of Mn, smaller than or equal to1.0% of Si, 21.0-23.0% of Cr, 1.0-3.0% of Mo,, smaller than or equal to 0.30% of Ni, 0.15-0.35% of Bi, 0.2-0.4% of S, smaller than or equal to 0.015% of P, smaller than or equal to 0.10% of Pb and thebalance Fe. According to the environment-friendly lead-free easy-cutting stainless steel used for the ball-point pen point, the Bi replaces Pb, an intermediate alloy is adopted for increasing the Bisteady yield, and accordingly, the environment-friendly lead-free easy-cutting stainless steel used for the ball-point pen point is prepared; and the smelting method of the stainless steel is easy, the preparation cost is low, and the smelting method is applicable to large-scale application and production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Stainless steel material and manufacturing methods thereof

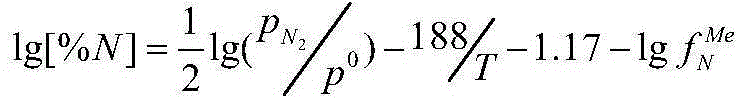

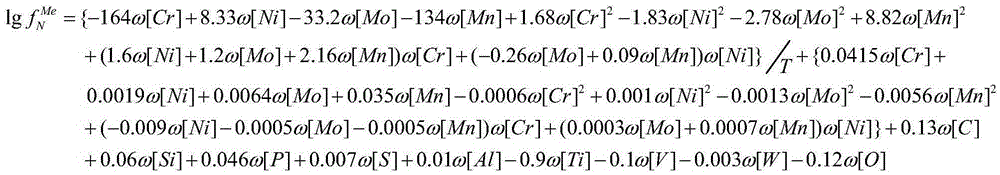

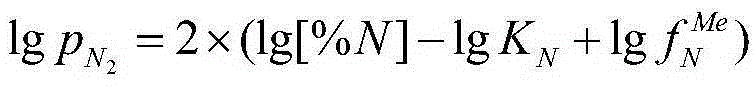

ActiveCN105296869ANo allergiesHigh strengthOther manufacturing equipments/toolsPunchingCold hardening

The invention discloses a stainless steel material and manufacturing methods thereof. The stainless steel material is Cr-Mn-N austenitic stainless steel with nickel replaced with nitrogen. The manufacturing methods comprise a smelting method, a blank punching method and a machining method. The smelting method mainly comprises the step of smelting high-nitrogen steel through two alloying nitrogen-increasing methods, namely using nitrogen-containing materials and gaseous nitrogen. The blank punching method mainly comprises the steps of conducting circulative blank punching, conducting heat treatment, conducting solid solution treatment, and controlling the heat retention temperature and heat retention time, wherein hardness values and impact toughness values serve as the main reference for die selection. The machining method mainly comprises the steps of controlling appropriate machining parameters of milling and turning. The stainless steel material and the manufacturing methods thereof have the advantages that the stainless steel material is the novel austenitic stainless steel; the smelting method is applicable to batch smelting of the high-nitrogen steel with the nitrogen content ranging from 0.4 wt% to 0.75 wt%; the blank punching method inhibits cold hardening phenomena in the high-nitrogen steel machining process, and blank punching is facilitated; through the machining method, the problem that machining difficulty is large due to high hardness of the high-nitrogen steel is solved.

Owner:CENT IRON & STEEL RES INST +1

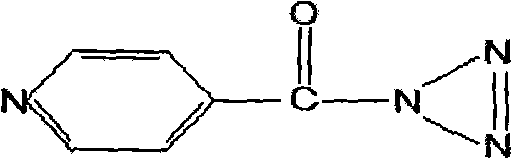

Synthesizing method of isonicotinyl hydrazine azide

ActiveCN101735144AThe process route is simple and clearThe operation process is simpleOrganic chemistryAzideChemical synthesis

The invention relates to the technical field of chemical synthesis, in particular to a synthesizing method of isonicotinyl hydrazine azide. The method overcomes the problems of complicated operation, using a large amount of organic solvent, long cycle length, high cost and being not suitable for mass production of the prior art. The adopted technical scheme is as follows: the synthesizing method of isonicotinyl hydrazine azide comprises the following steps: (1) in a reaction kettle, adding water solution of isoniazide and hydrochloric acid and stirring to dissolve; (2) dropwise adding water solution of sodium nitrite under stirring and keeping the reaction temperature at 0 DEG C to 5.0 DEG C; and (3) adding water solution slowly in the reaction system under stirring, precipitating crystal from the reaction solution, filtering, drying and obtaining high-purity isonicotinyl hydrazine azide. Compared with the prior art, the method has the advantages of 1.high yield and stability; 2.simple preparing steps, 3.environment protection; and 4.being suitable for industrial production.

Owner:NORTHWEST A & F UNIV

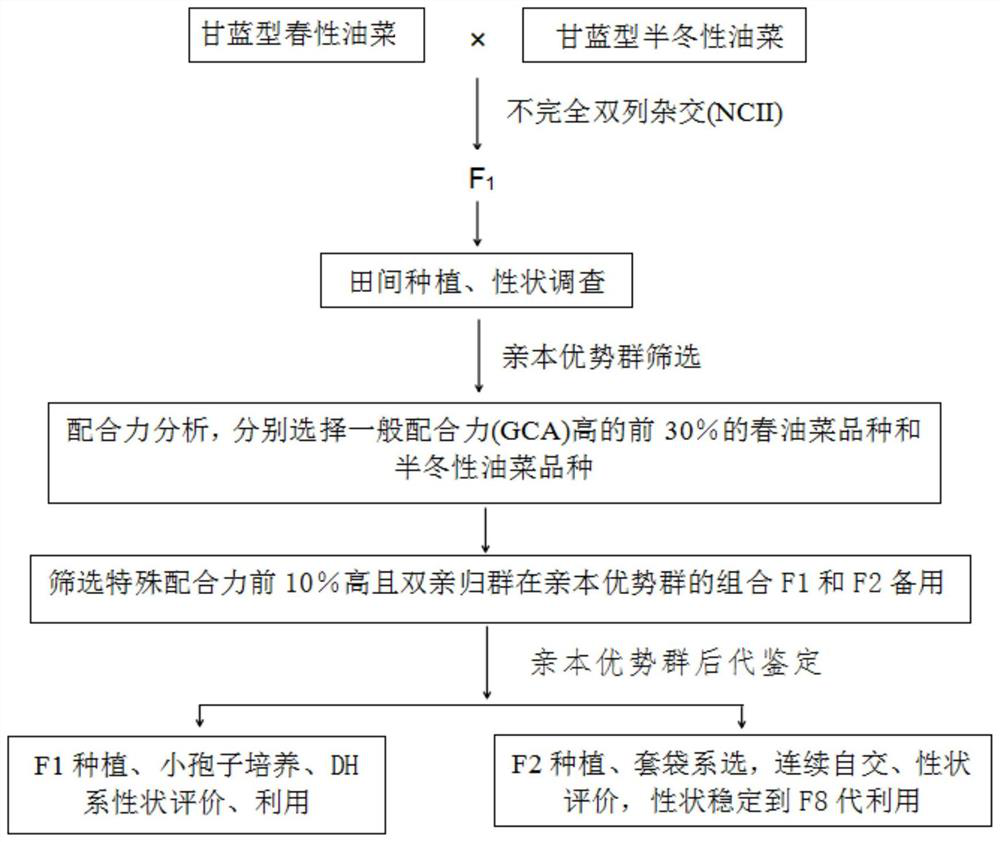

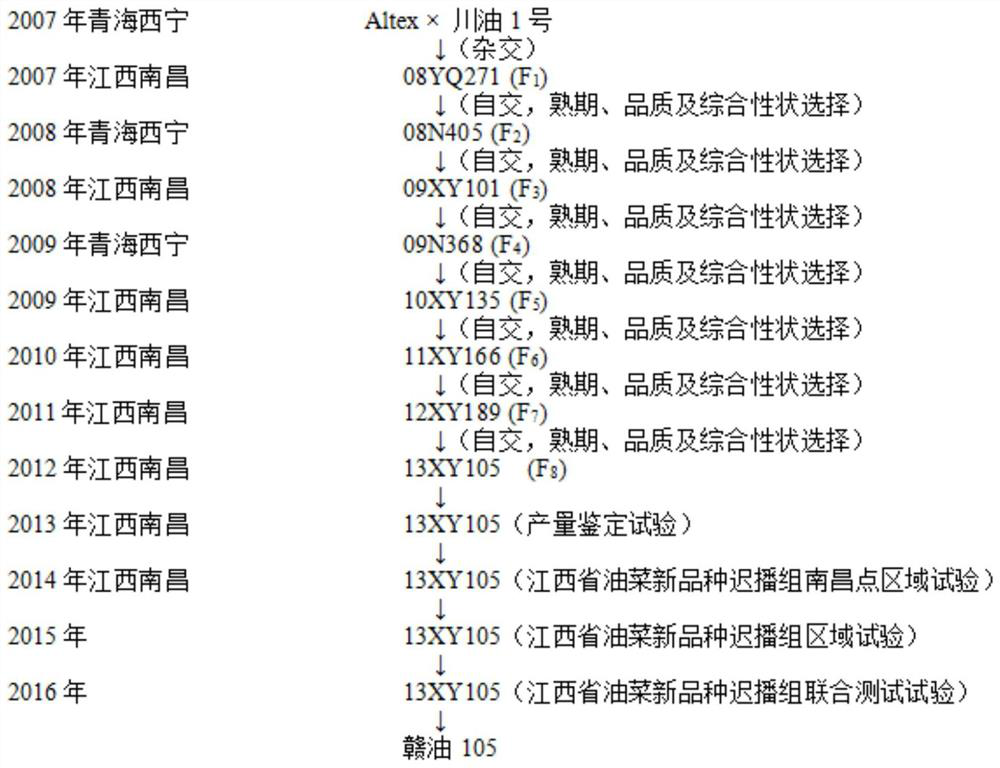

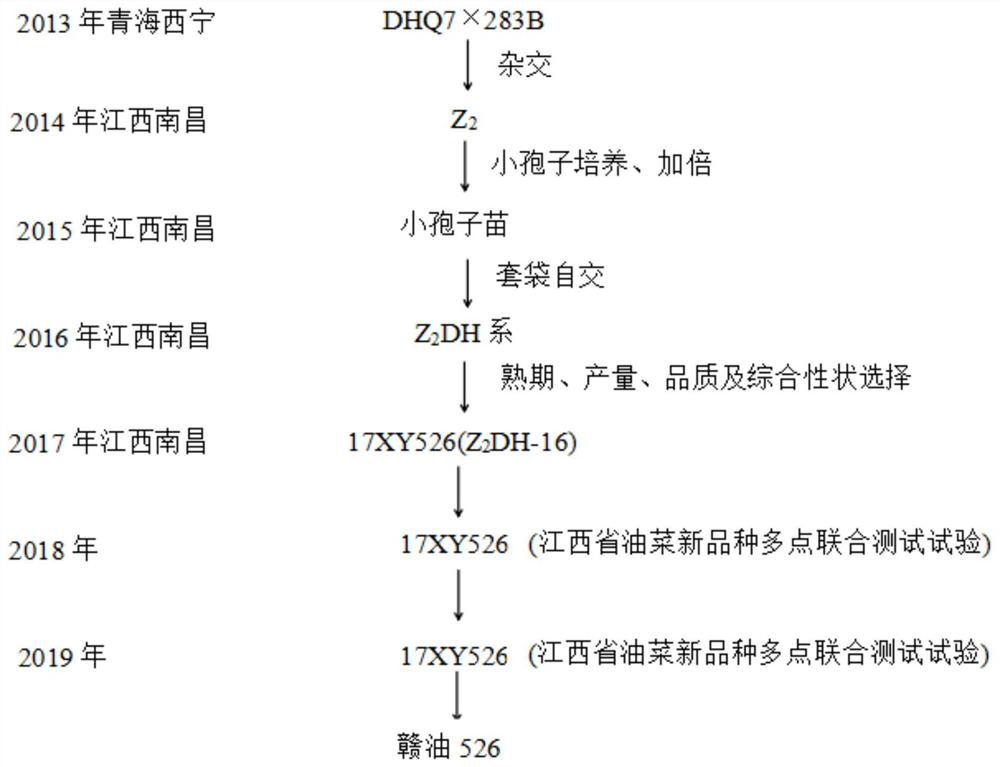

Breeding method for early-maturing brassica napus variety

PendingCN111758554AShorten the breeding cycleImprove breeding efficiencyPlant genotype modificationBiotechnologyBrassica

The invention belongs to the technical field of crop breeding, and specifically relates to a breeding method for an early-maturing brassica napus variety. The breeding method comprises three steps ofcombination configuration and field test, parent dominant group screening and parent dominant group offspring identification. The breeding method for the early-maturing brassica napus variety on the basis of the parent dominant group is provided for the first time; excellent comprehensive characters of a semi-winter brassica napus dominant group variety are introduced into a spring brassica napusdominant group variety with early maturity by combining analysis of the general combining ability of parents and the special combining ability of hybridized combinations; thus, excellent comprehensivecharacters and early maturity can be better combined; the early-maturing brassica napus variety can be screened and identified more easily; the breeding efficiency is improved; the uncertainty of variety screening in the prior art is avoided; meanwhile, the method provided by the invention is easy to implement and low in cost.

Owner:江西省农业科学院作物研究所

Product and method for direct vanadium alloying of molten steel

The invention discloses a product and method for direct vanadium alloying of molten steel, and belongs to the technical field of metallurgy. By means of the product and the method, a vanadate vanadium compound, a reduction and carbonization agent and a nitrogen increasing agent during synchronous vanadium-nitrogen alloying are crushed and mixed uniformly, the mixture is packaged into a closed reactor serving as a carbon steel shell to be prepared into a sealed monomer product, the sealed monomer product is added into a transfer hot steel ladle or baking hot steel ladle waiting for tapping before and after steel ladle hot repair, steel ladle heat storage is directly used for carbothermal pre-reduction and carbonization of vanadium in the vanadate compound, reduction of vanadium and subsequent molten steel vanadium or vanadium-nitrogen alloying are further completed in the subsequent tapping process so as to replace a finished ferrovanadium alloy or vanadium-nitrogen alloy, vanadium increase of the vanadium compound on the molten steel or synchronous vanadium increase and nitrogen increase of the molten steel are completed, and therefore direct vanadium or vanadium-nitrogen alloying is carried out on the molten steel through carbothermal reduction by adopting a two-step method of vanadate and other compounds.

Owner:MAANSHAN XINGDA METALLURGICAL NEW MATERIAL +1

Cerium iron alloy and preparation and usage methods thereof

A cerium iron alloy and preparation and usage methods thereof belong to the technology field of rare earth iron alloy. The component ranges of the alloy are: 0.1 to 15 wt% of cerium, and the rest is Fe and inevitable impurities, whose total amount is smaller than 1.0 wt%. The preparation technology adopts vacuum induction furnace for melting, takes cerium with purity larger than 99.0% and pure iron with purity larger than 99.0% as the raw materials, and then the raw materials are blended according to a formula that 0.1 to 15 wt% of cerium, and the rest is Fe. Then the mixture is melted in the vacuum induction furnace, the pressure of the vacuum room is controlled under 100 Pa, and the melting temperature is controlled in a range of 1550 to 1600. After the alloy is all melted, vacuum state is maintained for 4 to 6 minutes, then the vacuum is released. Finally ingot castings with qualified size are casted at the atmosphere of protection argon gas. The preparation method has the advantages that the alloy has a high density, and is not easy to be oxidized, pulverized, or damped; the yield of rare earth cerium is high during the steel-making process and the content of the rare earth cerium is stable.

Owner:包头市北科创业高新材料有限责任公司

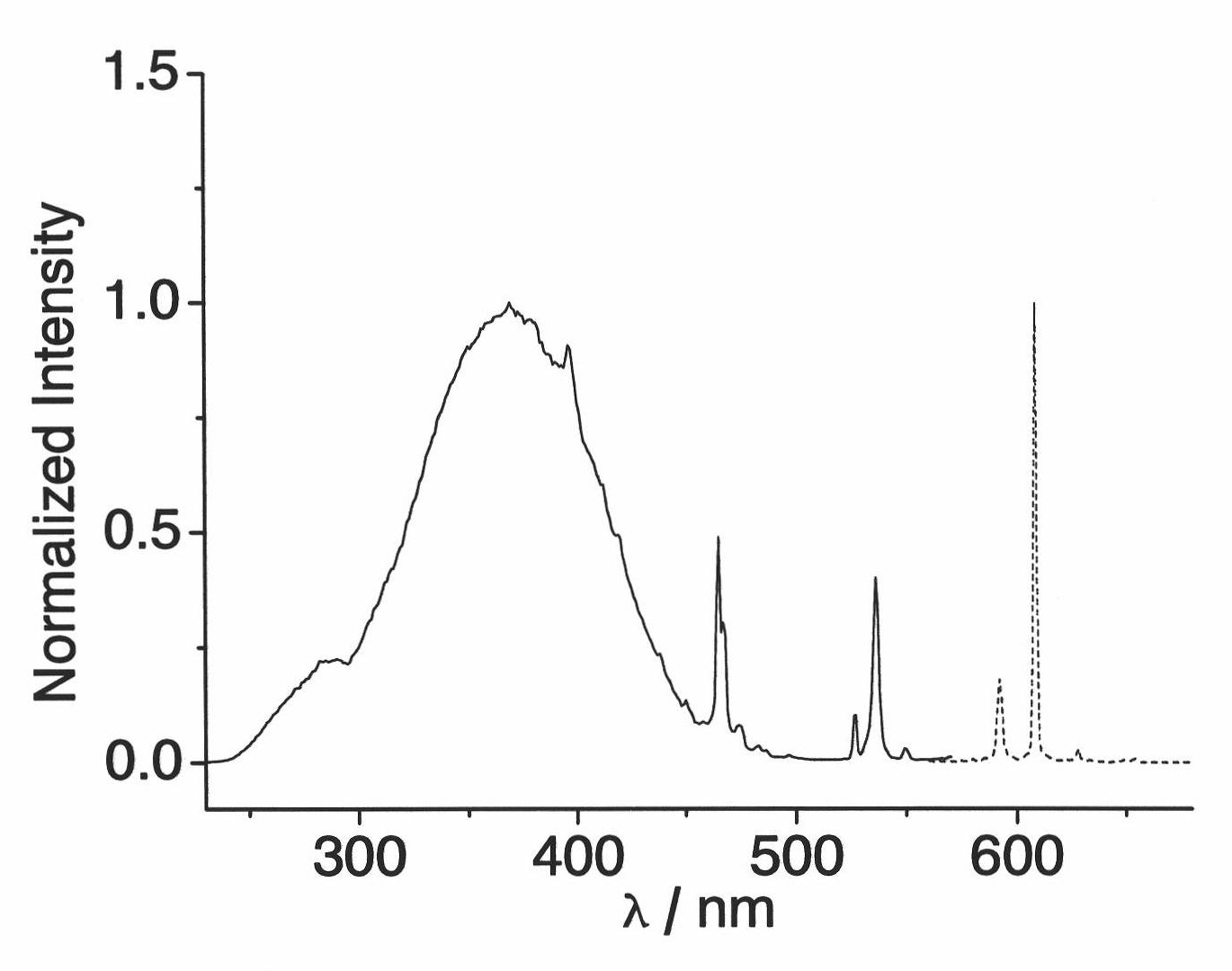

Gasochromic rare earth complex and preparation method and application thereof

InactiveCN101798320AOvercome stabilityHigh purity of luminous colorGroup 3/13 element organic compoundsLogic circuits using opto-electronic devicesRare earthLogic gate

The invention discloses a gasochromic rare earth complex. The structure of the gasochromic rare earth complex is obtained by the coordination of rare earth metal Eu (III) and a tripod type ligand MeNTB. The invention also discloses a preparation method of the above complex, comprising: carrying out coordination on rare earth salt and MeNTB ligand at the molar ratio of 1:2 to obtain the gasochromic rare earth complex. The gasochromic phenomenon obtained by the complex of the invention has high signal strength, speed, stability and repeatability; moreover, the response strength, response range and response time can be further improved by decorating the ligand and selecting metal; in addition, the complex can be used for designing gasochromic switches and logic gate devices and has wide application prospect.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com