Aluminum ferroboron composite intermediate alloy and method of use thereof

A master alloy, aluminum boron technology, applied in the field of aluminum boron iron composite master alloy, can solve the problem of high yield strength of hot-rolled strip, achieve the effect of improving performance, convenient operation and reducing burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with embodiment.

[0027] In a 120t converter-LF-thin slab continuous casting and rolling production line in a domestic factory, Al-Mn-B-Fe composite master alloy is applied. The alloy composition is shown in Table 3. 1.5kg / t-steel-aluminum was added for pre-deoxidation when the converter was tapping, and the LF refining feed aluminum wire was deeply deoxidized and desulfurized. At this time, the top slag turned white, and the Al content in the steel was 0.015%. Add 1.0kg / t-steel-aluminum-boron-iron composite master alloy, stir weakly for 10 minutes and leave the station. The composition is shown in Table 4, and the performance comparison of hot-rolled steel products of typical steel grades and comparative steel grades is shown in Table 5.

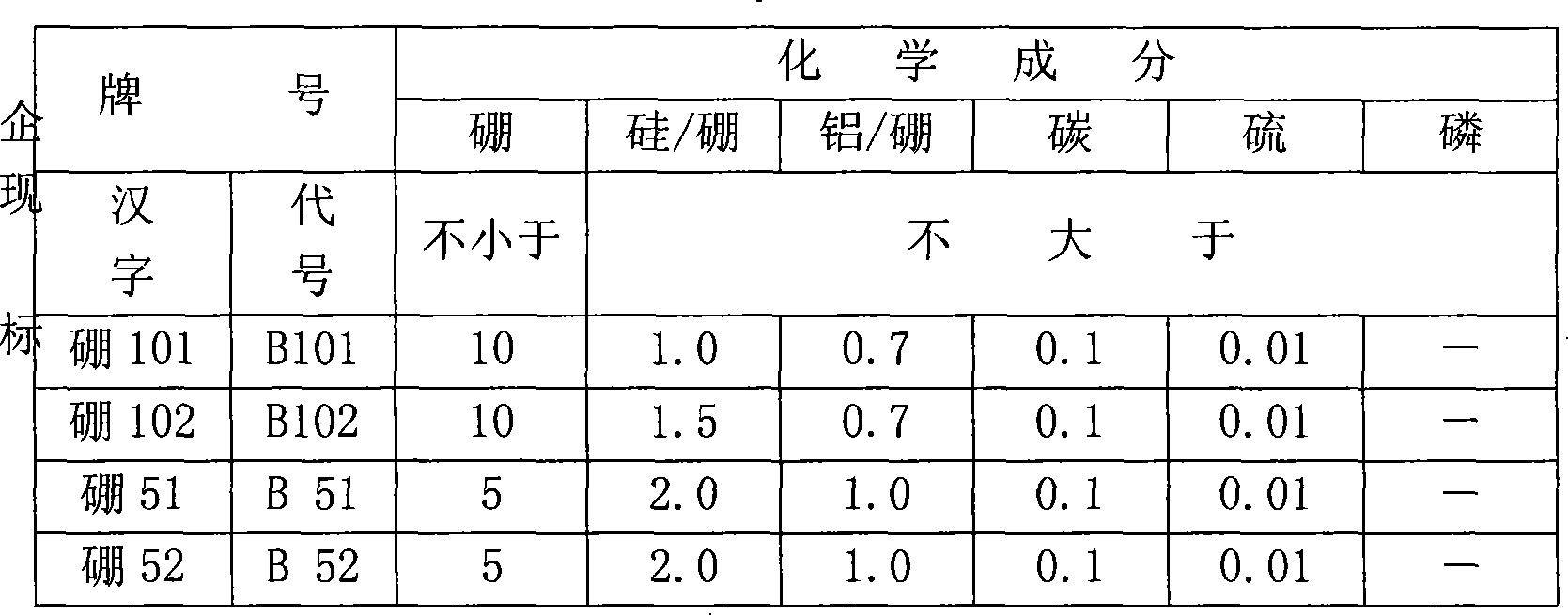

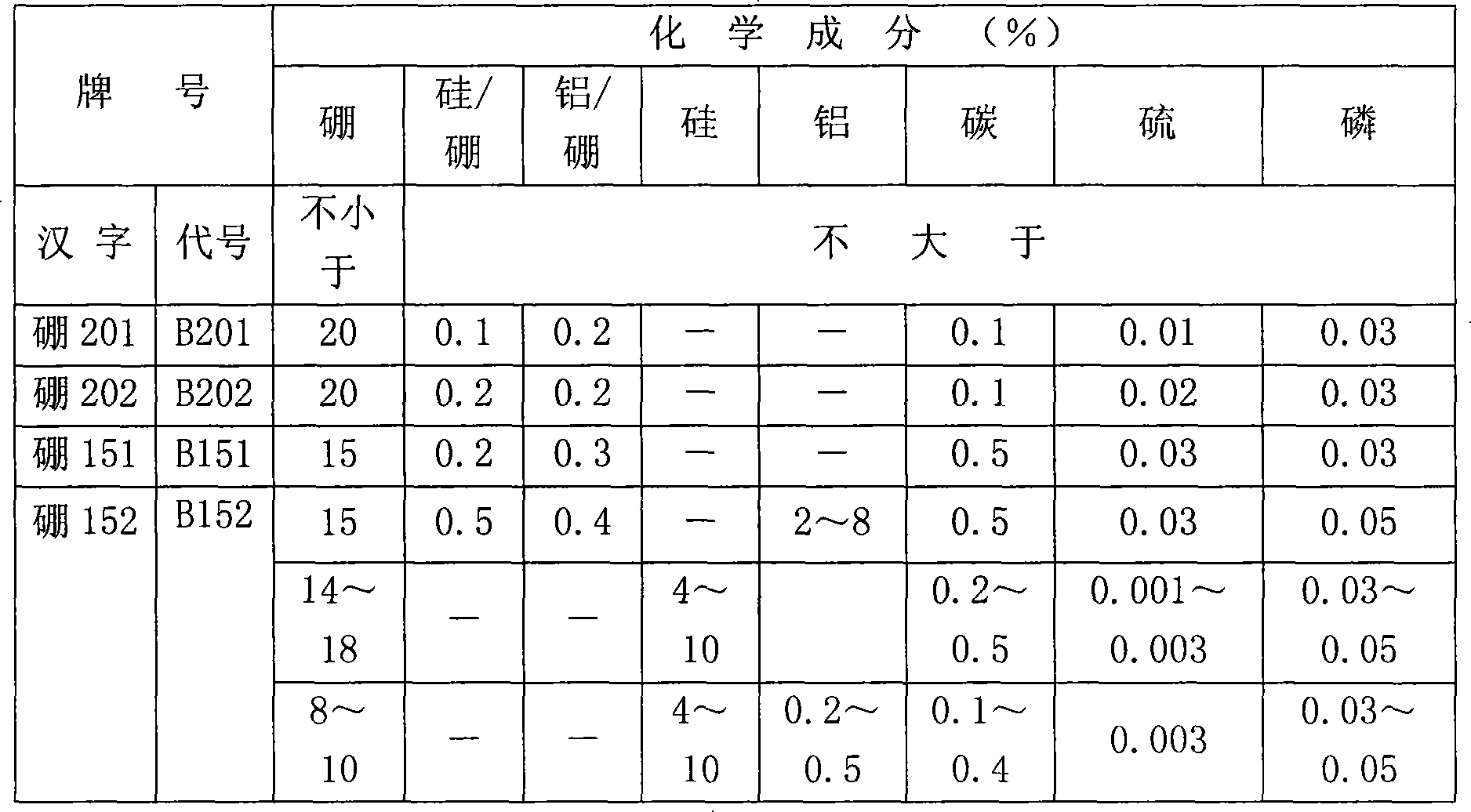

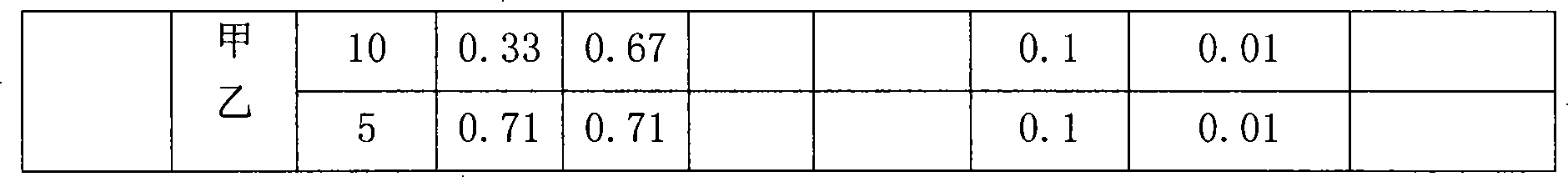

[0028] Table 3: Chemical composition of typical Al-B-Fe composite master alloys

[0029] the element

Al

mn

P

S

Si

B

Fe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com