Stainless steel material and manufacturing methods thereof

A stainless steel and high-nitrogen steel technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems that the ratio of nitrogen addition in stainless steel cannot meet the design requirements, and the difficulty of smelting nitrogen-containing stainless steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

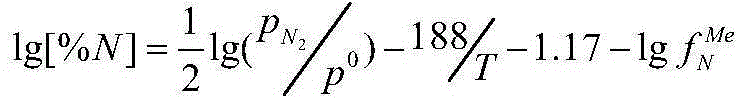

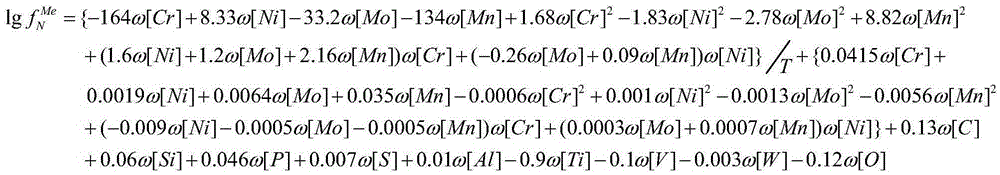

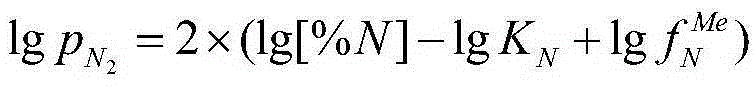

Method used

Image

Examples

Embodiment 1

[0135]The stainless steel material is a Cr-Mn-N austenitic stainless steel with nitrogen substituted for nickel, and the stainless steel material contains the following components by weight:

[0136] Cr: 18%; Mn: 14%; N: 0.4%; C: 0.1%.

Embodiment 2

[0138] The stainless steel material is a Cr-Mn-N austenitic stainless steel with nitrogen substituted for nickel, and the stainless steel material contains the following components by weight:

[0139] Cr: 22%; Mn: 17%; N: 0.75%; C: 0.12%.

Embodiment 3

[0141] The stainless steel material is a Cr-Mn-N austenitic stainless steel with nitrogen substituted for nickel, and the stainless steel material contains the following components by weight:

[0142] Cr: 18%; Mn: 14%; N: 0.4%; C: 0.1%; S: 0.02%; P: 0.025%; Si: 0.8%; Cu: 0.2%; Al: 0.01%; and Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com