Environment-friendly lead-free easy-cutting stainless steel used for ball-point pen point and smelting method thereof

A technology of lead-free ballpoint pen and smelting method, which is applied in the field of alloys, can solve problems such as instability, seldom seen, difficult yield of easy-cutting elements, etc., and achieve simple smelting method, low preparation cost, and stable yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

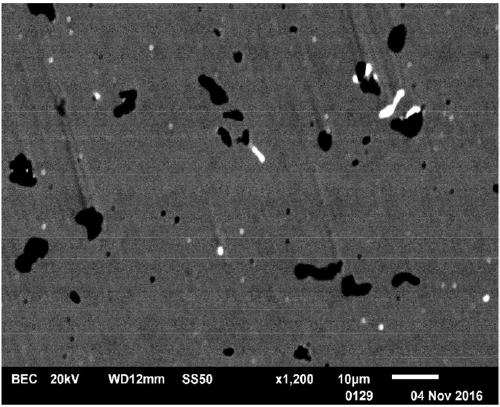

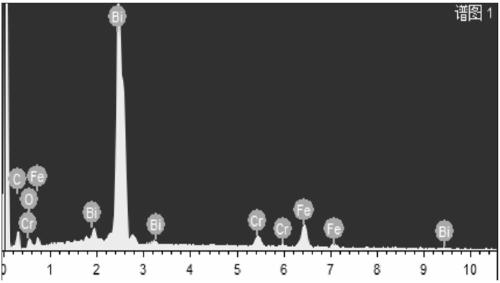

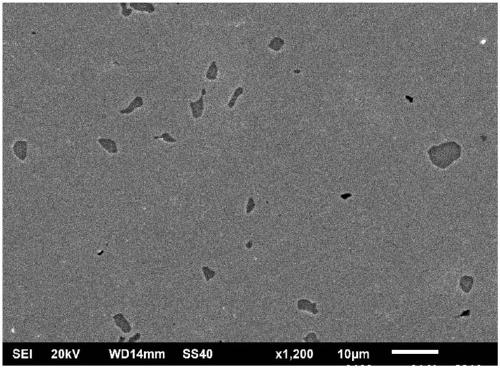

Image

Examples

Embodiment 1

[0024] Making AlBi master alloy:

[0025] Al and Bi fragments are added to the corundum crucible at a mass ratio of 9:1 and mixed evenly (the amount of Bi is added at 0.30% of the total amount, and the amount of AlBi master alloy added is 3%). Melt in the medium and stir evenly, and quickly pour it on the rotating red copper drum cooled by circulating water (200-300r / min) after being out of the furnace, so as to obtain a uniform, flake-shaped AlBi master alloy with a thickness of 1mm.

[0026] Vacuum induction and positive pressure melting:

[0027] Put the calculated and weighed metal chromium, silicon, manganese, molybdenum, nickel, iron sulfide, AlBi master alloy and pure iron into a 50Kg vacuum and positive pressure induction furnace for melting, in which the AlBi master alloy needs to be melted and refined before joining.

[0028] When refining, the power transmission power is 80-100KW, the vacuum degree is ≤1Pa, and the refining time is 15 minutes. After refining, clo...

Embodiment 2

[0032] The difference with Example 1 is:

[0033] The amount of Bi in stainless steel is added at 0.40%, and that of AlBi alloy is 4%. When the AlBi alloy is added after refining, the 50Kg vacuum and positive pressure induction furnace is filled with argon with a pressure of 0.8MPa. Sampling after casting the ingot for chemical analysis, its chemical composition is shown in Table 1, wherein the content of Bi is 0.292%, and the content of Pb is 0.002%, which is far less than the maximum lead content of 0.2% of the internationally recognized environmental protection pen tip material. After calculation, the yield of Bi was 73%.

Embodiment 3

[0035] The difference with Example 1 is:

[0036]The amount of Bi in stainless steel is added at 0.40%, and that of AlBi alloy is 4%. When AlBi alloy is added after refining, the pressure of argon gas in the 50Kg vacuum and positive pressure induction furnace is 1.0MPa. Sampling after casting the ingot for chemical analysis, its chemical composition is shown in Table 1, wherein the content of Bi is 0.324%, and the content of Pb is 0.003%, which is far less than the maximum lead content of 0.2% in internationally recognized environmentally friendly pen tip materials. After calculation, the yield of Bi was 81%.

[0037] Table 1 embodiment stainless steel chemical composition

[0038] C

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com