Separating and purifying method of acarbose

An acarbose, separation and purification technology, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problem of low yield, and achieve simple and convenient separation methods, high yields, and high yields. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

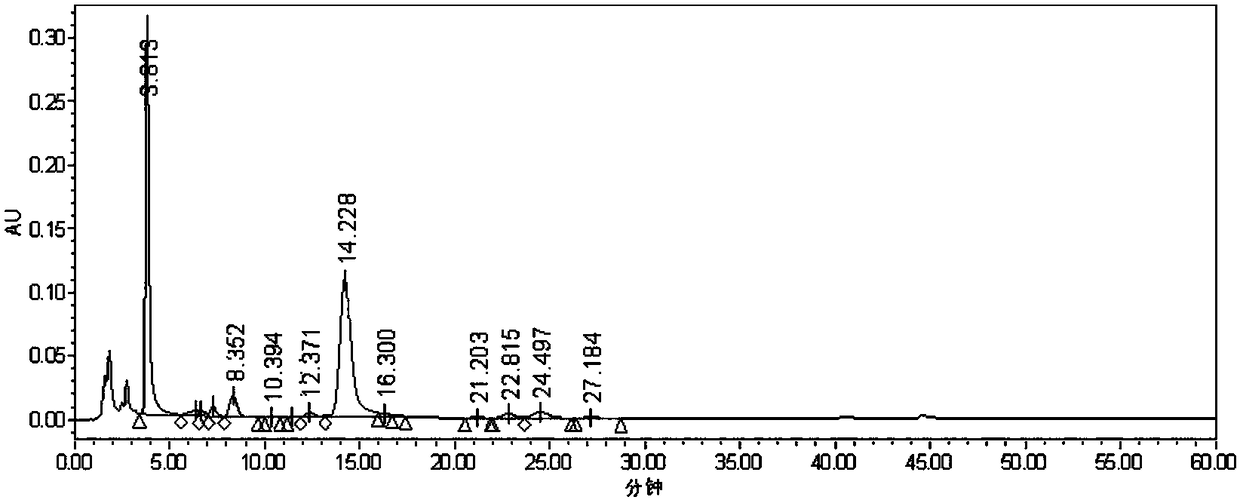

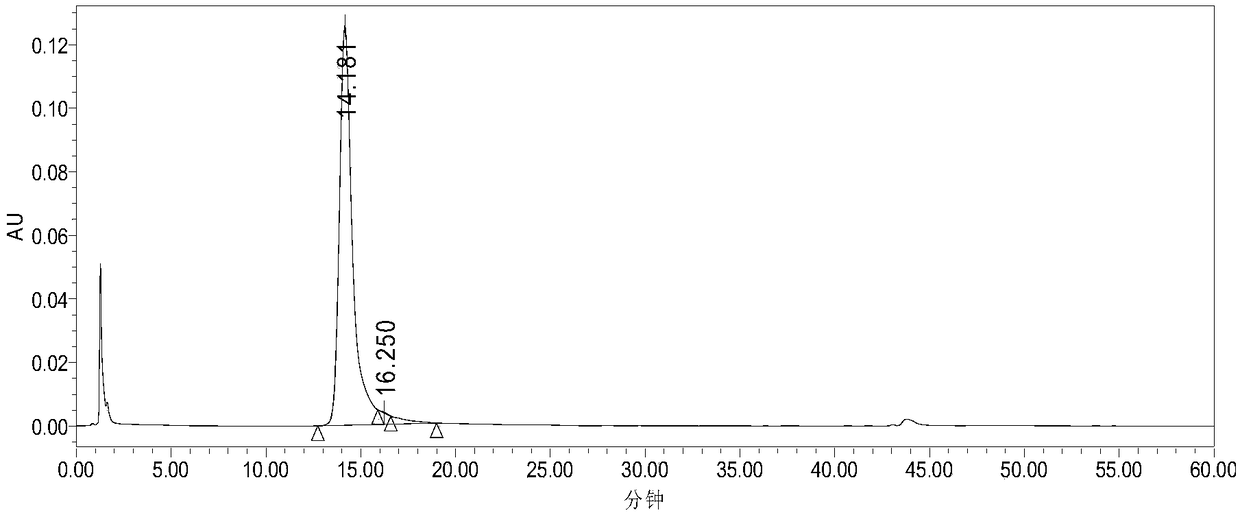

[0041] 567ml crude acarbose (45.25% purity), filtered with a filter membrane with a pore size of 8μm, collected the filtrate, and adjusted its pH to 5.05 with 0.5N hydrochloric acid. A 16×405mm chromatographic column, UniAcarbose GIII microspheres (manufactured by Suzhou Nanomicro Technology Co., Ltd.) was used as the chromatographic column packing, and the packed column volume was 81ml. Before loading the sample, equilibrate the column with ultrapure water, and then load the acarbose solution after the above treatment into the column containing UniAcarboseGIII microspheres at a flow rate of 3-7 times the column volume per hour. Chromatography was performed, and then 0.5N hydrochloric acid solution was used for elution. The solution of the target peak is collected in sections, and the components that meet the requirements are summarized. After high performance liquid chromatography analysis, the purity of acarbose in the eluent is above 99.7%, and the yield is 86%.

[0042] figu...

Embodiment 2

[0050] 156ml crude acarbose (40.958% purity), filtered with a filter membrane with a pore size of 8μm, collected the filtrate, and adjusted its pH to 5.01 with 0.5N hydrochloric acid. A 16x260mm chromatographic column, UniAcarbose GIII microspheres (manufactured by Suzhou Nanomicro Technology Co., Ltd.) as the chromatographic column packing, with a packing volume of 52ml. Before loading the sample, equilibrate the chromatography column with deionized water, and then load the sample at a flow rate of 3-7 times the column volume per hour, and then use 0.5N hydrochloric acid solution for elution. The solution of the target peak is collected in sections, and the components that meet the requirements are summarized. After high performance liquid chromatography analysis, the purity of acarbose in the eluent is over 99.3%, and the yield is 85%.

Embodiment 3

[0052] 567ml crude acarbose (43.504% purity), filtered with a filter membrane with a pore size of 8μm, collected the filtrate, and adjusted its pH to 5.08 with 0.5N hydrochloric acid. A 16×405mm chromatographic column, UniAcarbose GIII microspheres (manufactured by Suzhou Nanomicro Technology Co., Ltd.) was used as the chromatographic column packing, and the packed column volume was 81ml. Before loading the sample, equilibrate the chromatography column with deionized water, and then load the sample at a flow rate of 3-7 times the column volume per hour, and then use 0.5N hydrochloric acid solution for elution. The solution of the target peak is collected in sections, and the components that meet the requirements are summarized. After high performance liquid chromatography analysis, the purity of acarbose in the eluent is over 99.1%, and the yield is 82%.

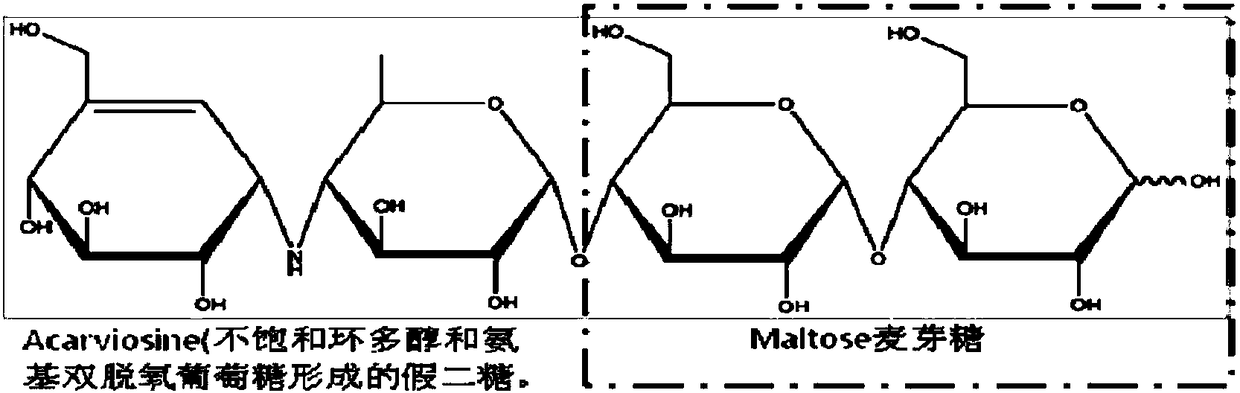

[0053] The present invention uses monodisperse polystyrene / divinylbenzene ion chromatography medium as the exchange filler, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com