Method for adding rare earth into RH refining furnace

A refining furnace and rare earth technology, which is applied in the field of iron and steel metallurgy, can solve the problems of no suitable rare earth adding method, low rare earth yield, poor metallurgical effect, etc., and achieves stable rare earth yield, high rare earth yield, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

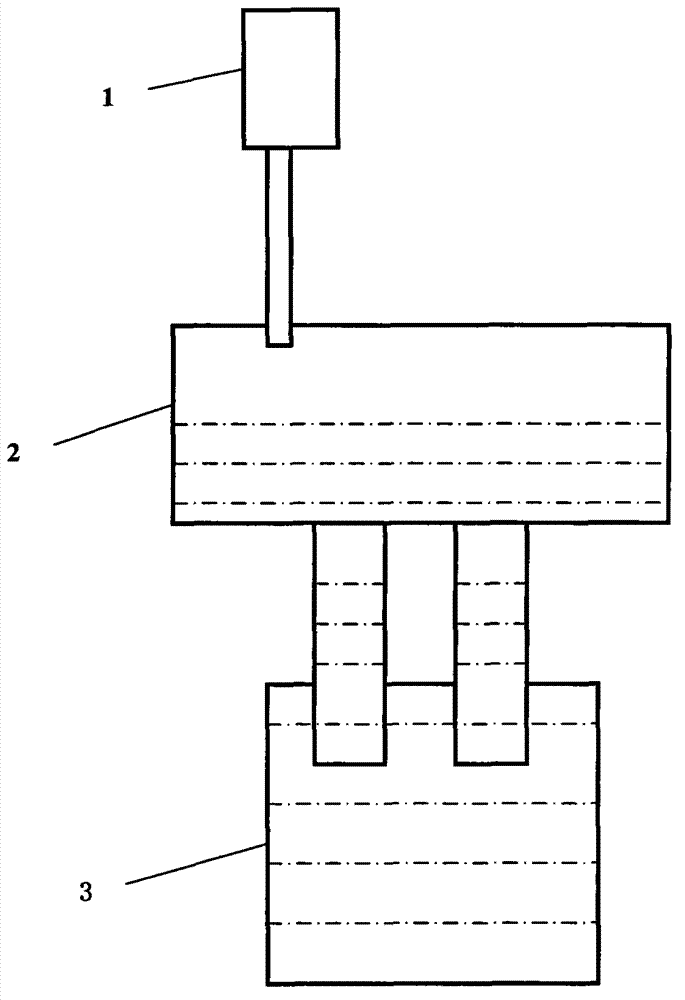

Image

Examples

Embodiment 1

[0036] According to the addition of 0.01wt% rare earth, lanthanum content of 20wt% rare earth lanthanum iron alloy, and 210 tons of molten steel, 105 kg of lanthanum iron alloy needs to be added. Add the prepared lanthanum-iron alloy in the vacuum feeding bin in advance;

[0037] The 210-ton converter clean steel production technology is used in steelmaking, and the steel produced is Q345E, including hot metal desulfurization, converter end point control, deoxidation with aluminum, LF refining for high-efficiency desulfurization, temperature measurement and oxygen determination, and total oxygen T.O in steel = 0.0018% , active oxygen a[O]=0.0002%, [S]=0.003% (mass percentage);

[0038] When the RH vacuum treatment reaches 17 minutes, the rare earth lanthanum iron alloy is added into the vacuum chamber from the vacuum feeding bin. After the molten steel is vacuum treated for 2 minutes, it is blown with argon gas and stirred for 10 minutes. , the pouring process went smoothly. ...

Embodiment 2

[0041] According to the addition of 0.012wt% rare earth, lanthanum content of 25wt% rare earth lanthanum ferroalloy, and 210 tons of molten steel, 100 kg of lanthanum ferroalloy needs to be added. Add the prepared lanthanum-iron alloy in the vacuum feeding bin in advance;

[0042] The 210-ton converter clean steel production technology is used in steelmaking, and the steel produced is Q345E, including hot metal desulfurization, converter end point control, deoxidation with aluminum, LF refining for high-efficiency desulfurization, temperature measurement and oxygen determination, and total oxygen T.O in steel = 0.0016% , active oxygen a[O]=0.0002%, [S]=0.002% (mass percentage);

[0043] When the RH vacuum treatment reaches 17 minutes, the rare earth lanthanum iron alloy is added into the vacuum chamber from the vacuum feeding bin. After the molten steel is vacuum treated for 2 minutes, it is blown with argon gas and stirred for 10 minutes. , the pouring process went smoothly....

Embodiment 3

[0046] According to the addition of 0.008wt% rare earth, lanthanum content of 20wt% rare earth lanthanum ferroalloy, and 210 tons of molten steel, 84 kg of lanthanum ferroalloy needs to be added. Add the prepared lanthanum-iron alloy in the vacuum feeding bin in advance;

[0047]The 210-ton converter clean steel production technology is used in steelmaking, and the steel produced is Q345E, including hot metal desulfurization, converter end point control, deoxidation with aluminum, LF refining for high-efficiency desulfurization, temperature measurement and oxygen determination, and total oxygen T.O in steel = 0.0018% , active oxygen a[O]=0.0002%, [S]=0.003% (mass percentage);

[0048] When the RH vacuum treatment reaches 17 minutes, the rare earth lanthanum iron alloy is added into the vacuum chamber from the vacuum feeding bin. After the molten steel is vacuum treated for 2 minutes, it is blown with argon gas and stirred for 10 minutes. , the pouring process went smoothly. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com