A method for low-concentration hydrochloric acid leaching of calcium and strontium chemical separation of Weishan Lake rare earth concentrate

A rare earth concentrate, low concentration technology, applied in the direction of improving process efficiency, can solve the problems of serious three waste pollution, long process flow, low rare earth yield, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

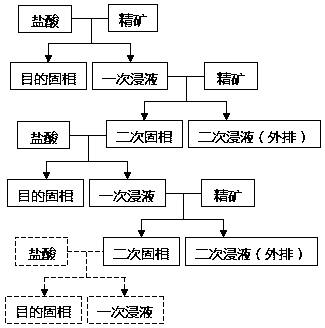

Method used

Image

Examples

Embodiment 1

[0029] Example 1 A method for leaching calcium and strontium chemical separation of Weishan Lake rare earth concentrate with low-concentration hydrochloric acid

[0030] The grade of Weishan Lake rare earth concentrate used as raw material is lower than 40%.

[0031] 1. Measure 11.8m³ of hydrochloric acid, inject it into the reaction tank, the concentration of hydrochloric acid (equivalent concentration) is 2.6N, put in 3.73t Weishan Lake rare earth concentrate, raise the temperature to 90°C and stir for 2 hours. At this time, the concentration of rare earth will not change. to terminate the reaction.

[0032] Filtrate to obtain the filtrate, which is injected into another tank as a primary acid bubble liquid, with a total of 14.2m³;

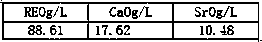

[0033] Filter to obtain 2.2t of filter residue, said filter residue: the moisture content is 15.90%, the rare earth oxide content is 50.81%; it is the target solid phase.

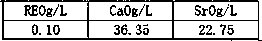

[0034] The content of ingredients in the primary acid bubble solution:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com