Production method for rare earth alloying of wide steel strip iron-chromium-aluminum continuous casting slab

A production method and rare earth alloy technology, which is applied in the production field of rare earth alloying of wide steel strip iron-chromium-aluminum continuous casting slabs, can solve the problems of continuous casting water blocking slab transverse cracking and low rare earth yield, and achieve distribution Uniformity and the effect of improving the yield of rare earth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

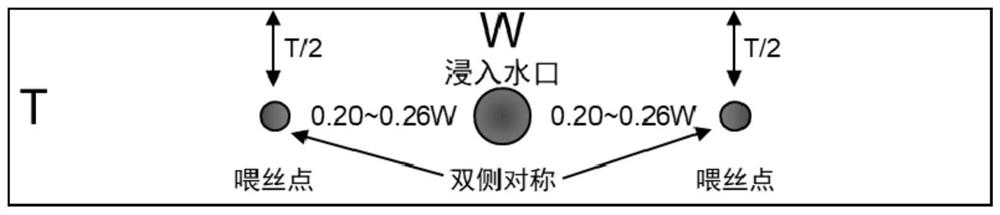

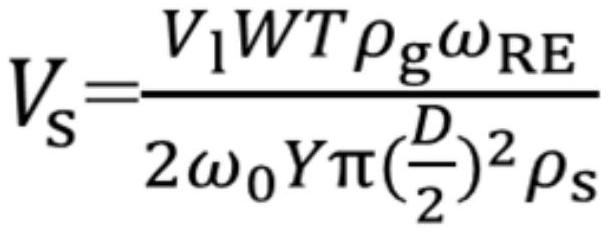

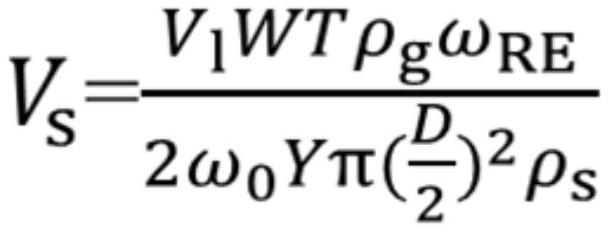

[0060] Taking the brand 1Cr13Al4 as an example, its chemical composition by mass percentage is: C: 0.015%, Si: 0.22%, Mn: 0.10%, P: 0.015%, S: 0.0015%, Cr: 13.9%, Al: 4.6%, Ti : 0.23%, N: 0.003%, and the rest are Fe and other unavoidable impurities. The specifications of the iron-chromium-aluminum alloy continuous casting slab are: thickness 200mm, width 1220mm, weight 16.5 tons, and the slab density is 7.4g / cm 3 .

[0061] The production method of the iron-chromium-aluminum continuous casting slab crystallizer feeding wire rare earth alloying of embodiment 1 comprises the following steps:

[0062] (1) Prepare a rare earth wire with a diameter of 2.5mm, the total proportion of lanthanum and cerium elements is 97.5Wt.%, and the density of the rare earth wire is 6.3g / cm 3 , the rare earth wire diameter is uniform.

[0063] (2) The iron-chromium-aluminum molten steel is processed by K-OBM-S→VOD→LF, and the slag above 86% is cleaned after the converter furnace, and the oxygen c...

Embodiment 2

[0069] Taking the brand 0Cr18Al4 as an example, its chemical composition by mass percentage is: C: 0.018%, Si: 0.21%, Mn: 0.48%, P: 0.014%, S: 0.0015%, Cr: 17.2%, Al: 4.0%, Ti : 0.12%, N: 0.004%, and the rest are Fe and other unavoidable impurities. The specifications of the iron-chromium-aluminum alloy continuous casting slab are: thickness 200mm, width 1160mm, weight 15.7 tons, and slab density 7.3g / cm 3 .

[0070] The production method of the iron-chromium-aluminum continuous casting slab crystallizer feeding wire rare earth alloying of embodiment 2 comprises the following steps:

[0071] (1) Prepare a rare earth wire with a diameter of 2.8mm, the total proportion of lanthanum and cerium elements is 98.0Wt.%, and the density of the rare earth wire is 6.3g / cm 3 , the rare earth wire is straight and does not bend.

[0072] (2) The iron-chromium-aluminum molten steel is processed by K-OBM-S→VOD→LF, and the slag above 88% is cleaned after the converter furnace, and the oxyge...

Embodiment 3

[0078] Taking the brand 0Cr21Al6 as an example, its chemical composition by mass percentage is: C: 0.017%, Si: 0.22%, Mn: 0.09%, P: 0.013%, S: 0.001%, Cr: 20.2%, Al: 5.5%, Nb : 0.08%, Ti: 0.13%, N: 0.003%, and the rest are Fe and other inevitable impurities. The specifications of the iron-chromium-aluminum alloy continuous casting slab are: thickness 200mm, width 1080mm, weight 13.1 tons, and slab density 7.2g / cm 3 .

[0079]The production method of the iron-chromium-aluminum continuous casting slab crystallizer feeding wire rare earth alloying of embodiment 3 comprises the following steps:

[0080] (1) Prepare a rare earth wire with a diameter of 3.0mm, the proportion of lanthanum is 97.0Wt.%, and the density of the rare earth wire is 6.2g / cm 3 , The rare earth wire joint is welded firmly.

[0081] (2) The iron-chromium-aluminum molten steel is processed by K-OBM-S→VOD→LF, and more than 90% of the slag is cleaned after the converter furnace, and the oxygen content and sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com