Hot dip galvanizing Al rare earth alloy for steel and iron member hot dip galvanizing and its ingot type and method

A technology of hot-dip galvanizing and steel components, applied in hot-dip galvanizing process, metal material coating process, coating and other directions, can solve the problem of not providing simple and easy to use, and achieve convenient forklift forklift and stacking, wetting performance Good, good galvanized quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The hot-dip galvanized aluminum rare earth alloy used for hot-dip galvanizing of steel components has a composition of 0.008% (wt) Al; 0.006% (wt) RE; the rest is zinc and unavoidable impurities.

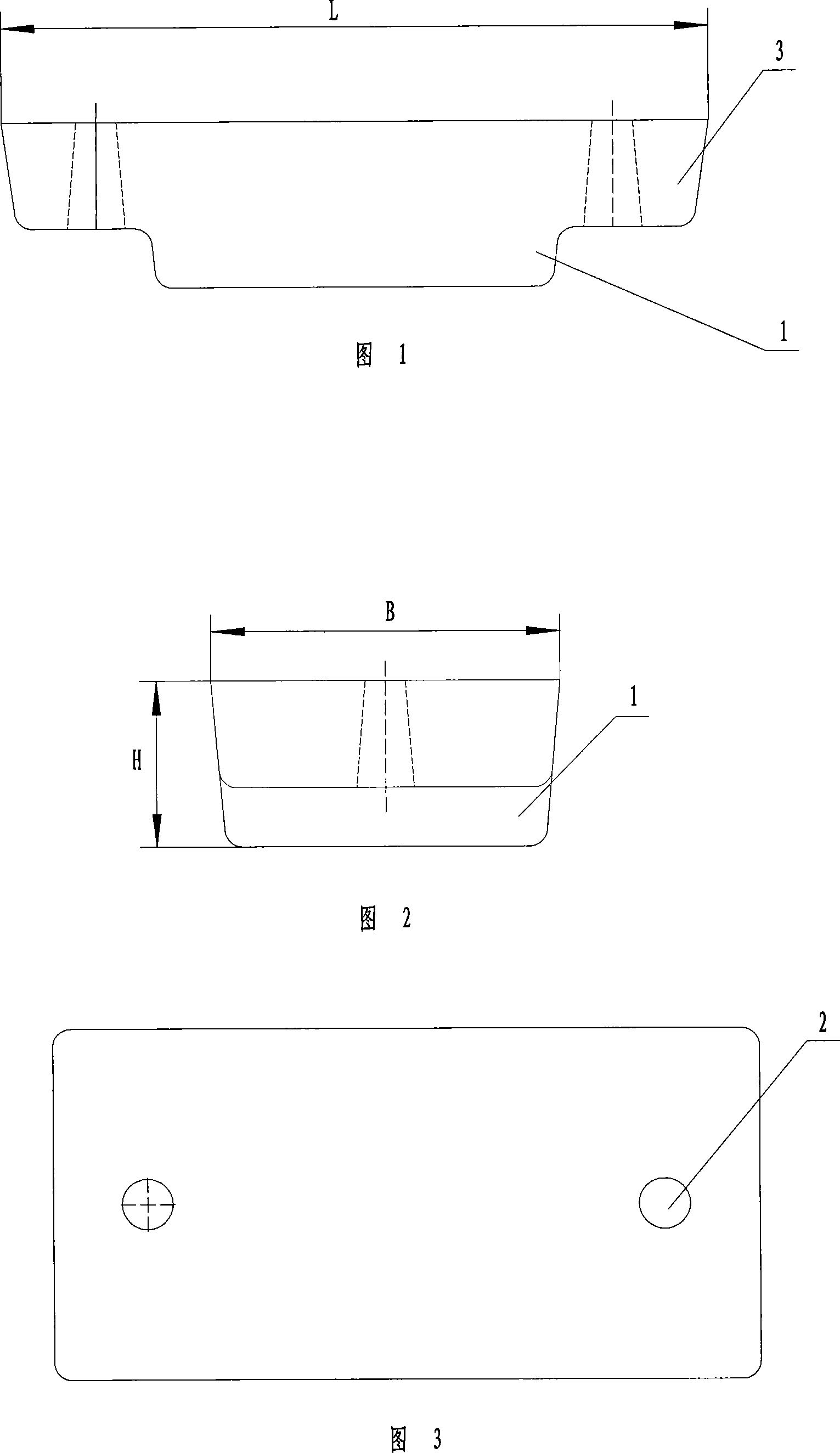

[0025] The ingot type of hot-dip galvanized aluminum rare earth alloy is a rectangular zinc ingot body 1 with two symmetrical ear warps 3 "T", and the upper plane and the bottom of the zinc ingot body 1 are planes. One of the ear hooks 3 is provided with a hanging hole 2 . The four sides of the zinc ingot body 1 are inclined planes, the upper cross section of the zinc ingot body 1 is larger than the lower cross section, the ingot weight is 900kg, the length L of the ingot shape is 1160mm, the width B is 580mm, and the height H is 260mm.

[0026] The above-mentioned hot-dip galvanized aluminum rare earth alloy ingot is used to hot-dip galvanize steel components, and the zinc alloy ingot is melted into a zinc bath. The obtained zinc bath has stable and uniform alloy element con...

Embodiment 2

[0028] The hot-dip galvanized aluminum rare earth alloy used for hot-dip galvanizing of steel components has a composition of 0.012% (wt) Al; 0.006% (wt) RE; the rest is zinc and unavoidable impurities.

[0029] The hot-dip galvanized aluminum rare earth alloy ingot is a "T" shaped rectangular zinc ingot body 1 with two symmetrical ears 3, and the upper plane and the bottom of the zinc ingot body 1 are planes. Both ear hooks 3 are provided with hanging holes 2 . The four sides of the zinc ingot body 1 are inclined surfaces, the upper cross section of the zinc ingot body 1 is larger than the lower cross section, the ingot weight is 1100kg, the length L of the ingot shape is 1200mm, the width B is 600mm, and the height H is 300mm.

[0030] The above-mentioned hot-dip galvanized aluminum rare earth alloy ingot is used to hot-dip galvanize steel components, and the zinc alloy ingot is melted into a zinc bath. The obtained zinc bath has stable and uniform alloy element content, goo...

Embodiment 3

[0032] The hot-dip galvanized aluminum rare earth alloy used for hot-dip galvanizing of iron and steel components consists of 0.008% (wt) Al; 0.01% (wt) RE; the rest is zinc and unavoidable impurities, and the ingot shape is the same as in Example 1.

[0033] The above-mentioned hot-dip galvanized aluminum rare earth alloy ingot is used to hot-dip galvanize steel components, and the zinc alloy ingot is melted into a zinc bath. The obtained zinc bath has stable and uniform alloy element content, good fluidity, good wettability, and excellent corrosion resistance of the coating. and good mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com