Plug-in sampling device of mixed gas burning type heat value instrument and application thereof

A technology of mixed gas and sampling device, which is applied in the direction of sampling, measuring devices, instruments, etc., can solve the problems of uneven gas composition and inaccurate measurement of the calorific value of mixed gas, and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

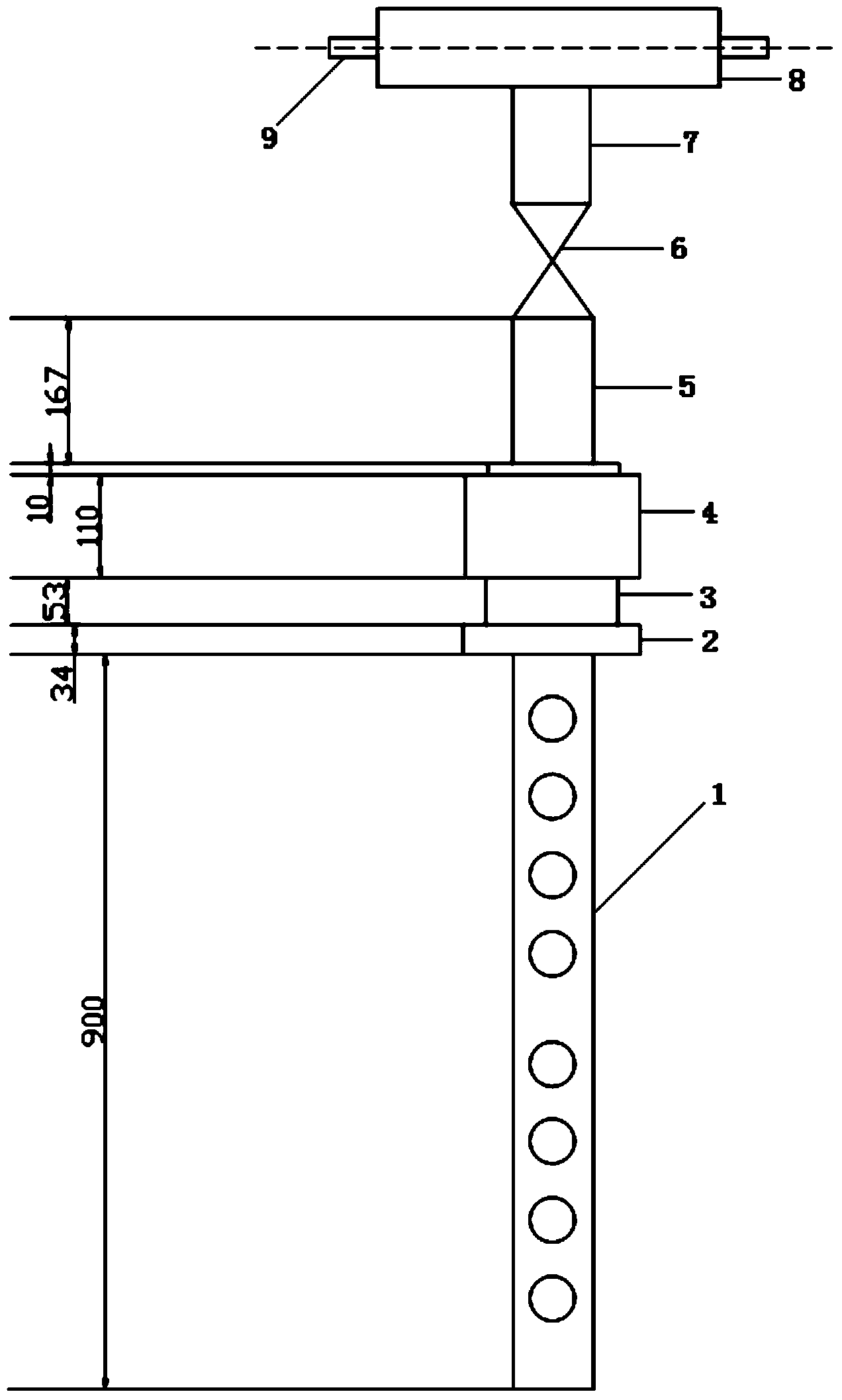

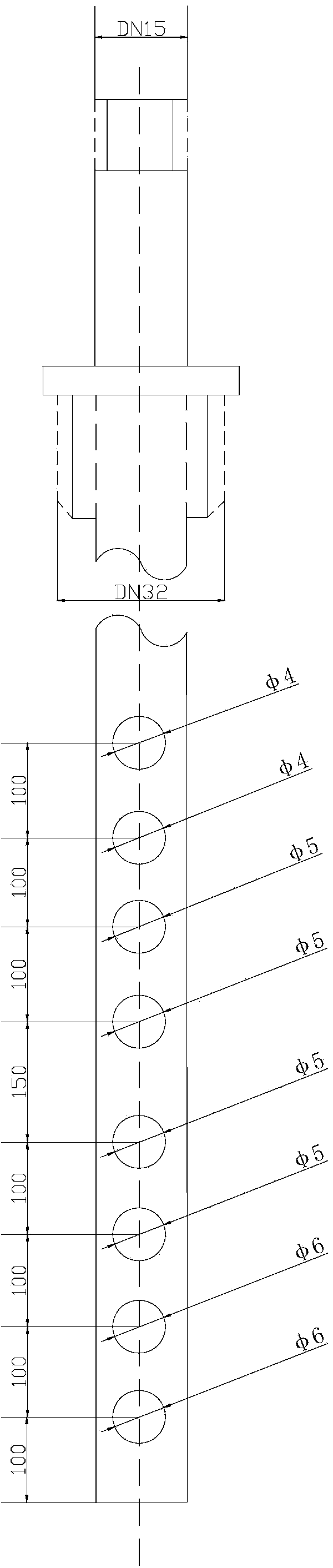

[0025] Such as figure 1 As shown, this embodiment provides a plug-in sampling device for a mixed gas combustion calorimeter, including a three-way valve 8, a straight ball valve 6, a ball valve 4 and a sampling pipe 1 arranged in sequence from top to bottom in the vertical direction. The three-way valve 8 is a left and right communication structure, and a calorific value meter connecting pipe 9 is horizontally arranged on its left and right ports respectively, and its lower port is connected with the upper port of the straight-through ball valve 6 through the first thread connecting pipe 7, and the first thread The upper and lower ports of the connecting pipe 7 are respectively welded and fixed to the lower port of the three-way valve 8 and the upper port of the straight-through ball valve 6;

[0026] Sampling tube 1 is arranged vertically, its lower port is closed and its upper port passes through ball valve welding base 2 and ball valve 4 successively from bottom to top and ...

Embodiment 2

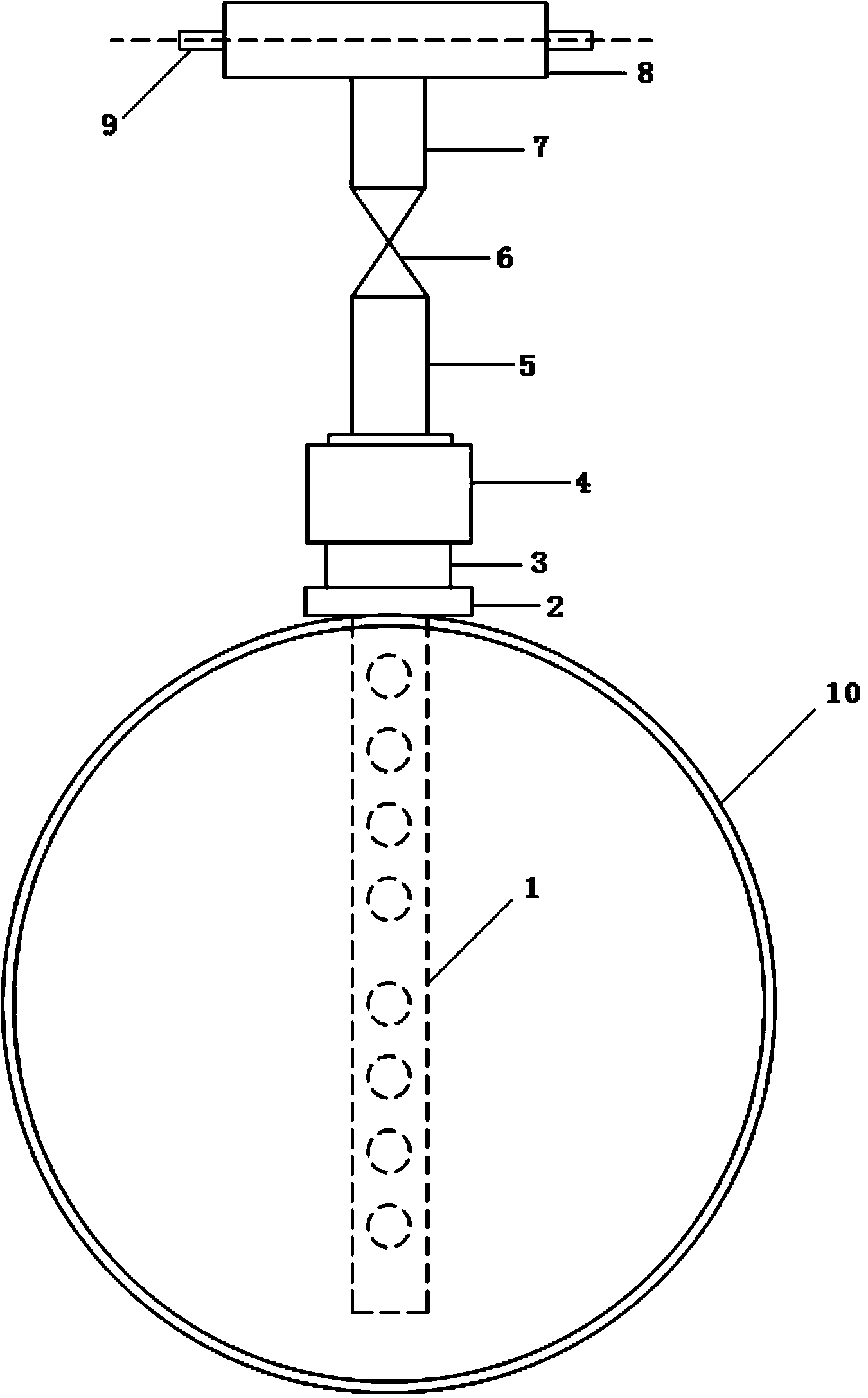

[0033] Such as image 3 As shown, the present embodiment provides an application of a plug-in sampling device for a mixed gas combustion type calorific value meter. A sampling hole is punched at the top of the mixed gas pipeline 10, and the sample of the plug-in sampling device for a mixed gas combustion type calorific value meter is The pipe 1 extends into the sampling hole in the vertical direction, and the lower surface of the ball valve welding base 2 is welded and fixed to the mixed gas pipeline 10. Since the size of the mixed gas pipeline 10 is DN1000, the length of the sampling pipe 1 located at the lower end of the ball valve welding base 2 Therefore, the distance between the lower end of the sampling pipe 1 and the bottom end of the mixed gas pipeline 10 is one-tenth of the diameter of the mixed gas pipeline. connect;

[0034] Taking the calorific value meter of mixed gas for internal use in Nansteel as an example, the 200,000 gas tanks of Nansteel Energy Center, cok...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com