MBT garbage permeameter with compaction hammer and convenient-to-move permeation column and adjustable water head

A technology of permeation column and permeameter, which is applied in the field of geotechnical testing, can solve the problems that sample preparation affects the accuracy of test results, MBT garbage penetration test is complicated, and there is no compaction instrument, so as to facilitate loading and dismantling of samples and improve sample preparation. Effect, the effect of sample uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

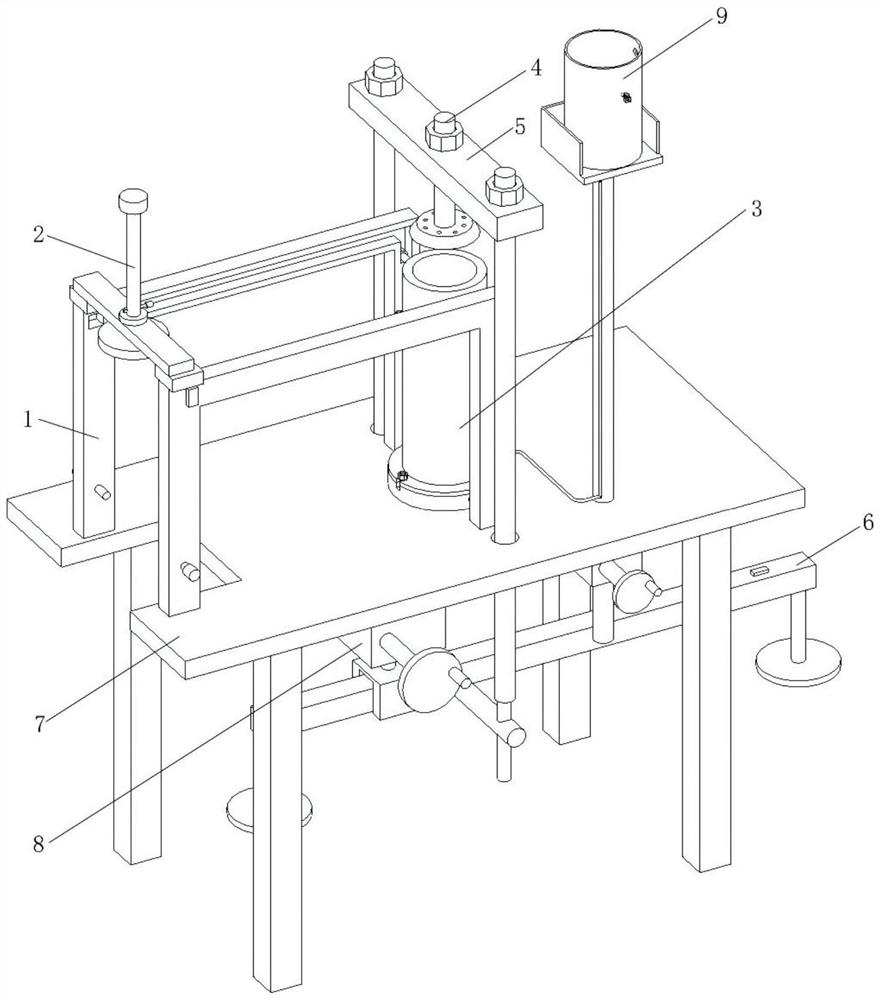

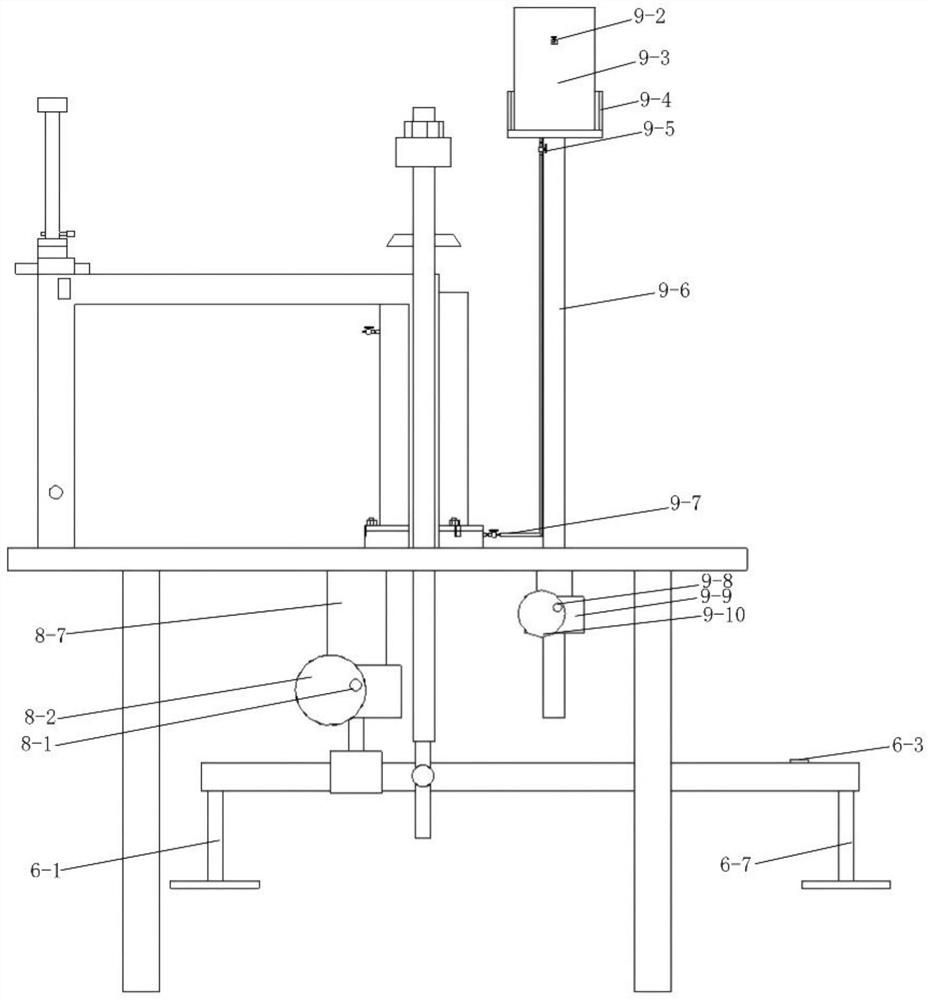

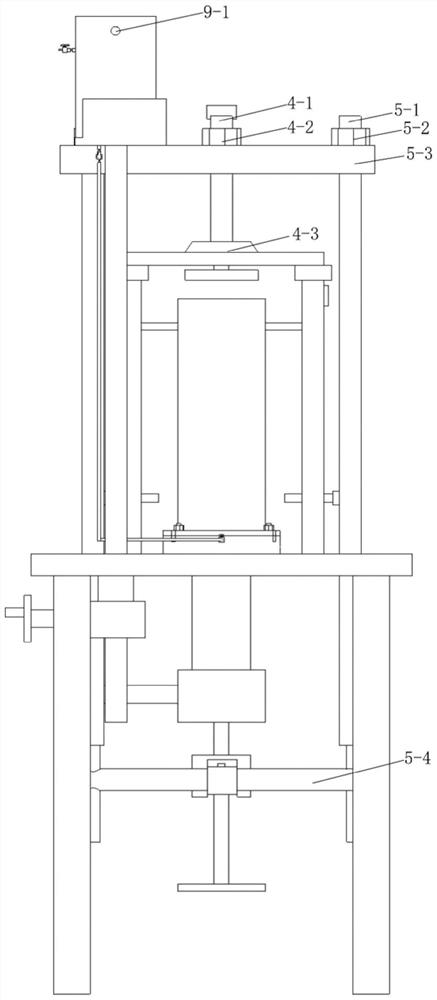

[0031] Such as figure 1 , 2 As shown in and 3, the MBT garbage infiltrator with a compaction hammer that is easy to move and has an adjustable water head includes a sliding track component 1, a compaction device 2, a permeation column 3, a gland component 4, a support component 5, and a lever labor-saving device , Infiltration table 7, lifting device 8 and water storage device 9. Such as Figure 5 As shown, the bottom of the infiltration column 3 is fixed to the water inlet tray 3-7, and a sealing ring is provided between the infiltration column 3 and the water inlet tray 3-7; the water inlet 3-8 of the water inlet tray 3-7 is connected to the water storage device The water outlet 9-5 of 9 is connected by a water pipe 9-7, and the top of the permeation column 3 is provided with a drain port 3-3; 3 outflow; the top of the permeation column 3 is fixed with two permeation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com